Your progress only motivates me more towards this power plant vs olds215/roverv8 for the 'B' thanks for taking the HIT ![]()

Your progress only motivates me more towards this power plant vs olds215/roverv8 for the 'B' thanks for taking the HIT ![]()

In reply to 759NRNG: if you need an Olds/Pontiac V8, let me know because I happen to have one and a bunch of spare parts

In reply to loosecannon: I'll see you and raise you ....thanks but no I'd rather pursue the LNF/LHU path that you've so valiantly forged bro! the mere fact that a bell freekin' housing can be had for these FWD's blew me away ...thank you

In reply to 759NRNG: ok, try to get an LNF with the E78 ECM, it's much easier to get info and programming for it. My E39A ECM is still mostly unknown

Can the E78 ECM talk to the LHU....I mean are sensors these days created 'looking' for specific impulses from dedicated ECM's? Man that made my head hurt. Hey also on Wikipedia it states that the LHU has a max engine speed of 6350rpm. Apologies, your a busy/business man so tell me to go post this for others (brainiacs) to respond to... no hurt feelin's ![]()

In reply to 759NRNG:

No, I believe the LHU is different enough that it can't use the E78 ECM. If that makes your head hurt,you should see all the tables that can be adjusted for the LHU-it's mind blowing. The LHU max rpm is 6350 but changing that is just a simple tune away. They are reliable to 7000 rpm, above that they need a better harmonic damper and maybe valve springs.

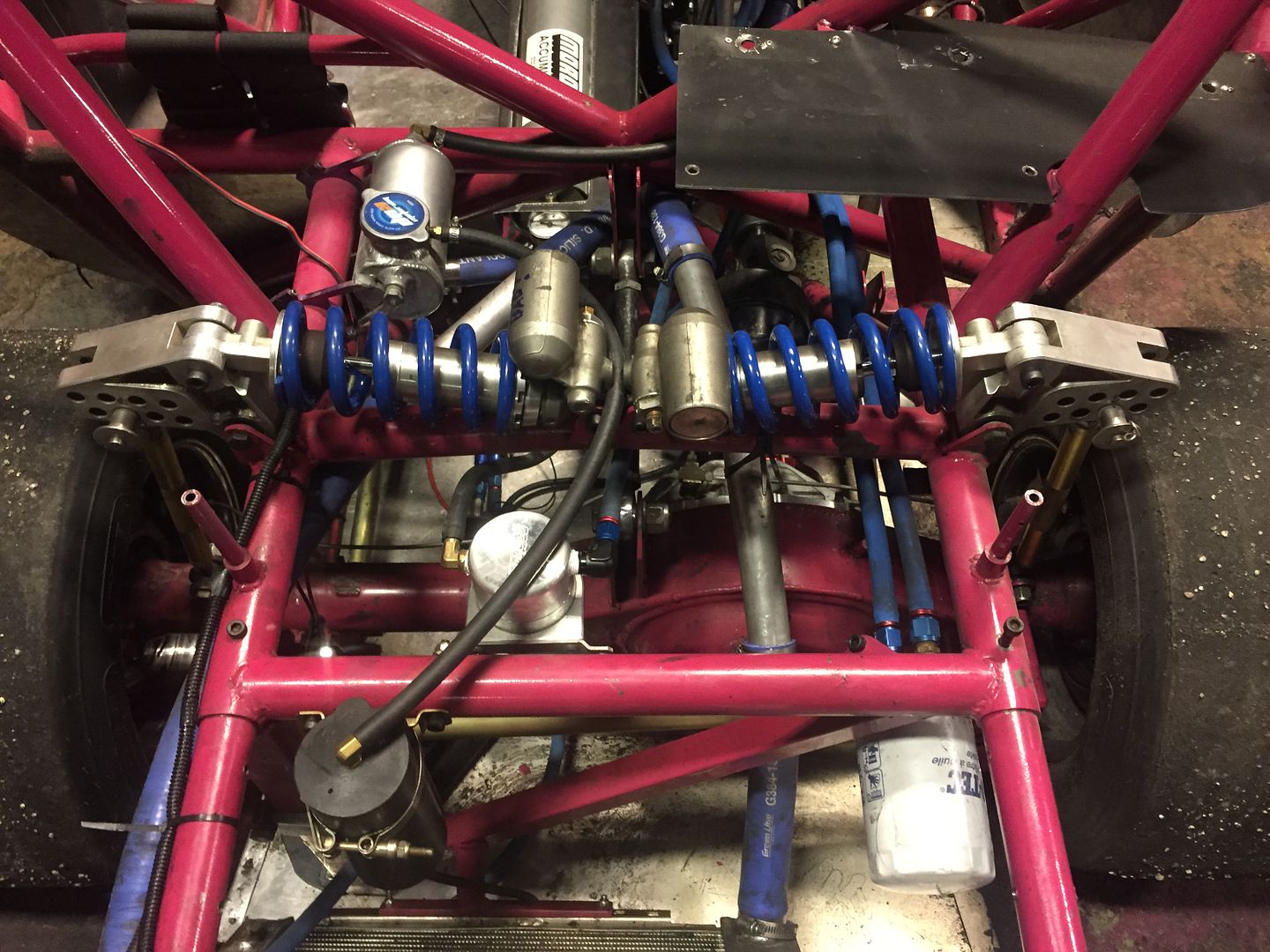

Now that I have had to swap motors a few times, I am pretty tired of unplugging all the sensors while it is in the car. I changed the ECM location to the top of the engine and added a few quick disconnect plugs and not the process should go a lot easier. I also changed the 1/8" copper oil pressure line to a 3/16" braided line for quicker reacting pressure gauge. And I installed an adjustable wastegate and set it to open at 11 psi. The rebuilt Regal motor is all ready to be dropped in.

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_9659_zpsnzmrewzd.jpg.html] [/URL]

[/URL]

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_9658_zpsis3dse5j.jpg.html] [/URL]

[/URL]

All the hoses hooked up, fluids filled (OMG it takes 11 liters to fill the oil system!) and million wires connected-nothing left but to fire it up. It made one revolution and fired up. It made no funny noises, has 60 psi oil pressure at idle and has no blowby. It does vibrate more at idle and that is expected because I installed neutral balance shafts, but smooths right out at higher rpm.

I ordered a new electric fuel pump that is rated for up to 450 boosted horsepower and installed it today. I was disappointed to see that the pump I had been running in the car was identical, or was it? Side by side, you can't tell the difference except that the one in the car was rated for only 330 boosted hp. The old one is a Walbro model 393 and the new one is a model 392. This might explain some strange behavior from the engine.

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_9751_zpsqcdxqwlx.jpg.html] [/URL]

[/URL]

I'm back, caught the startup video, sounds GREAT! What is your idle rpm? Is there a scheduled dyno visit in the near future? and.....back to the top of the list ![]()

In reply to 759NRNG:

1100 rpm. I have to schedule a dyno visit but before I do that, I want to replace the cam gear bolts and get some more run time on the engine. I have burned through 3 gallons of gas so far.

In reply to 759NRNG:

I have been doing the boring work of running in the rebuilt engine and bleeding the air out of the cooling system. Both involve starting it up,warming to temperature, revving up and down the rpms, letting engine cool and doing it all over again. I burned through 5 gallons of gas doing this and today I changed the oil and it came out looking so perfect, I could use it again (but I won't).

I also pulled the TrueTrac diff out and replaced it with a clutch style diff, hopefully that cures the wheelspin problem.

Today I did something more interesting, I changed the coilover springs. I have watched video of the car at Nationals and it seemed to move around far too much compared to my competitors. I started digging into it and measured my motion ratio so I could calculate wheel rate and frequency. I have always used 575 lb/in for my spring rate but while checking into aftermarket springs on the Racetech site, I discovered that the 07-08 yamaha R1 shocks were softer than I previously thought. I got stiffer springs and according to my calculations, they should give me the exact wheel rate that I want. I made my own spring compressor so I could change them at the track.

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_9888_zps2q9z8ixh.jpg.html] [/URL]

[/URL]

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_9896_zps2jvsbsha.jpg.html] [/URL]

[/URL]

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_9892_zpsnejqt5x5.jpg.html] [/URL]

[/URL]

In reply to 759NRNG:

What do you mean? I have a picture of the spring compressor with the shock in its clutches and the air impact on the nut that tightens it up

In reply to 759NRNG:

[URL=http://smg.photobucket.com/user/loosecannon/media/MGB-GT/IMG_9924_zpsclduk8pe.jpg.html] [/URL]

[/URL]

In reply to 759NRNG:

No, I made the cups flat then put a twist in them to match up to the twist in the coils, then welded those to the bars with the pivot. Now that I've used it a few times, I know how to improve the design but I won't use it enough to make that worthwhile.

In reply to SkinnyG:

I think if I used square tubing, with the one cup welded at 90 degrees at one end, then welded the other cup to another short piece of slightly larger square tubing that slid up and down on the first piece, then used a similar threaded rod to move the cups together and apart, it would make for a better spring compressor. I hope you can picture that.

I needed this style of compressor monday night on a frigging geo tracker.

Im watching closely so i can make one.

loosecannon wrote: In reply to SkinnyG: I think if I used square tubing, with the one cup welded at 90 degrees at one end, then welded the other cup to another short piece of slightly larger square tubing that slid up and down on the first piece, then used a similar threaded rod to move the cups together and apart, it would make for a better spring compressor. I hope you can picture that.

I like the adjustability aspect, still with the 'cup' plate angled somewhat to the coil, correct? How would you 'hold' the sliding end in place.....slip pin with an 'R' clip?

In reply to 759NRNG:

Yeh, cup is angled to match coil. I had a dyno session today and, of course, it didn't go as smooth as planned. The new clutch held in 4th gear and the new wastegate also seemed to work, that was good. Oil pressure was great, engine temp was awesome but the new NGK IX plugs I put in seemed to be crap. These are the same model plugs I run in my race kart and they are good, but the Ecotec didn't like them. I had to solve some low boost, limp mode, overly rich and overly lean problems and changed the tune probably a dozen times and by the time I got things in the range they should be, the plugs seemed to be fouled and would break up at high rpm. Nothing I could do about it so I took my 340 hp/370 ft/lbs home and ordered some new plugs. It wasn't what I was hoping for but there were some positives, like no fuel pressure issues and this engine is very smooth at high rpm now that I ditched the balance shafts. Here is the video https://www.youtube.com/embed/Ef3AQBIeO5E

You'll need to log in to post.