DrBoost

UltimaDork

4/10/17 7:38 p.m.

One of the, no, THE coolest thing about 3D printing is being able to take an idea you have in your brain, create it on a computer, then actually make it a real thing! It makes me giddy every time.

We had a perpetual mess of charging cords and devices/phones laying on an end table. It was driving NurseBoost and I crazy. So I got the calipers out, took some measurements, and created it in google sketchup.

Then I put it through the printer program to slice it and....BAM! The crazy idea that was in my brain was now in my hand.

I don't see how anyone can doubt that 3D printing will change the consumer market.

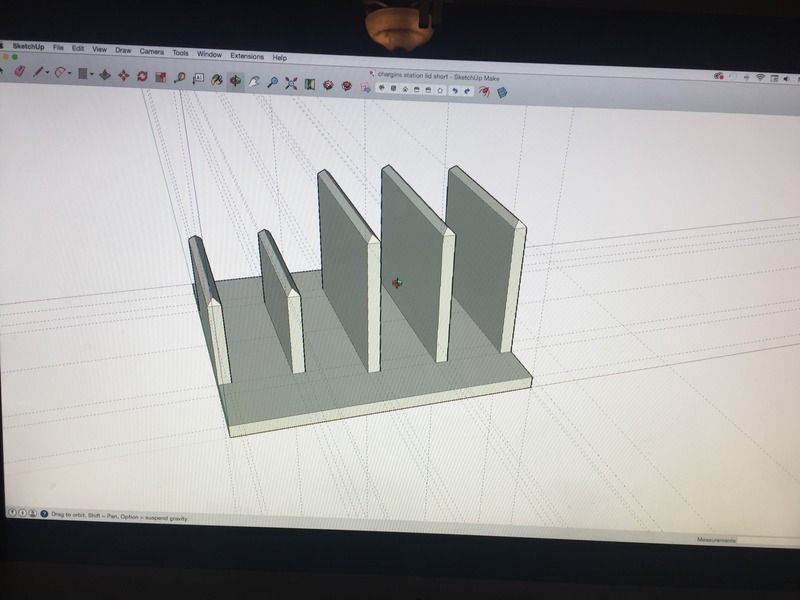

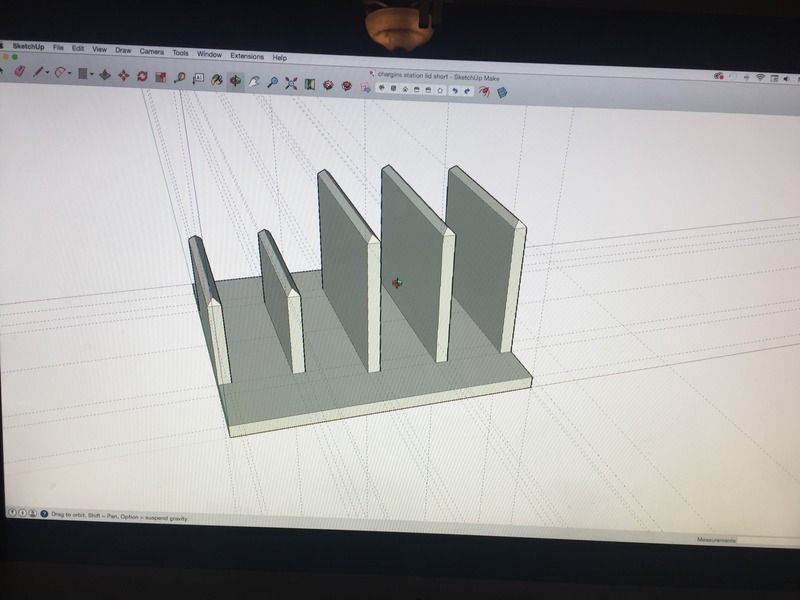

Here's the lid in sketchup

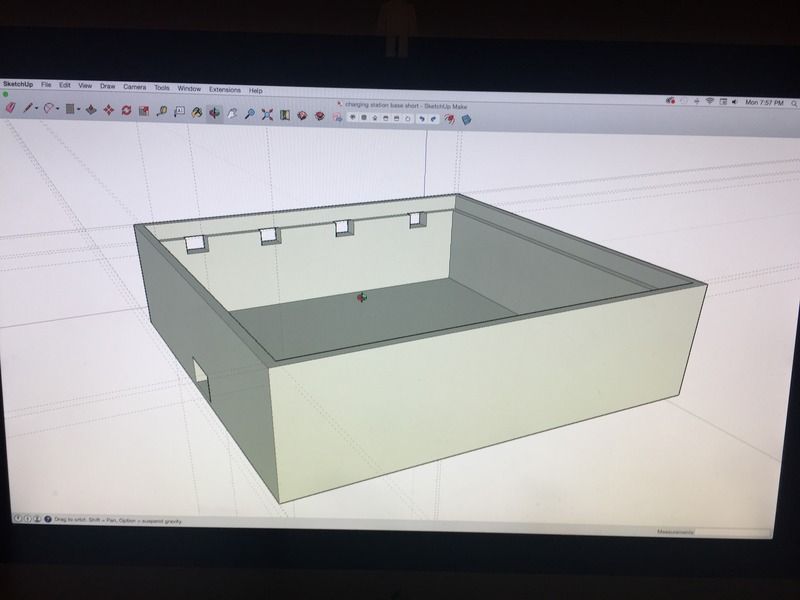

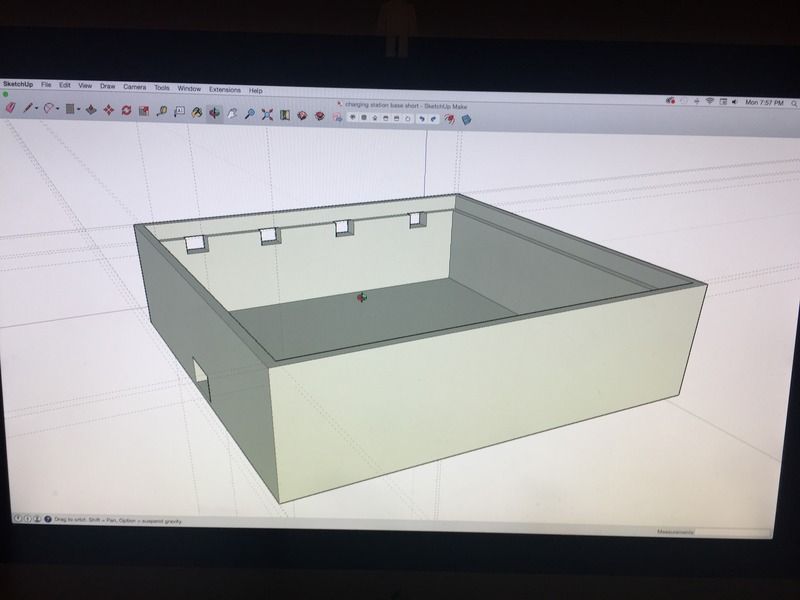

Here's the base in sketchup

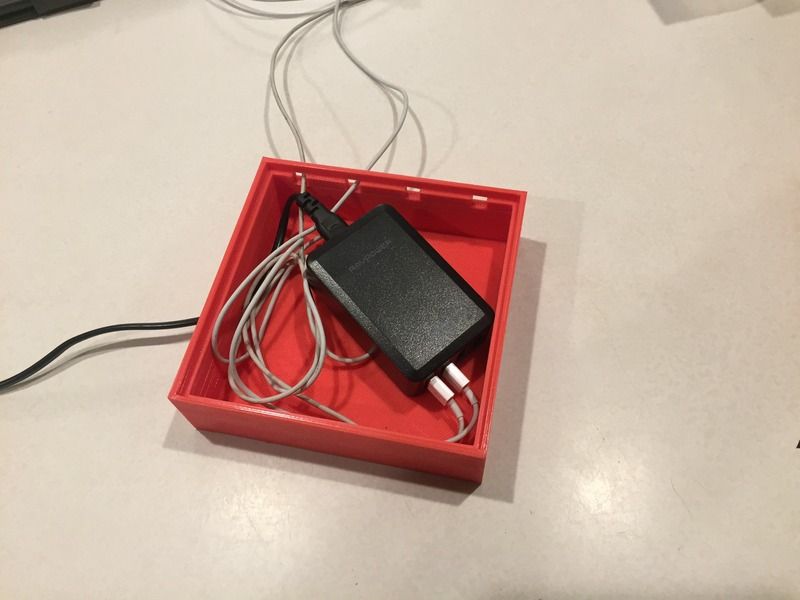

Here's both pieces

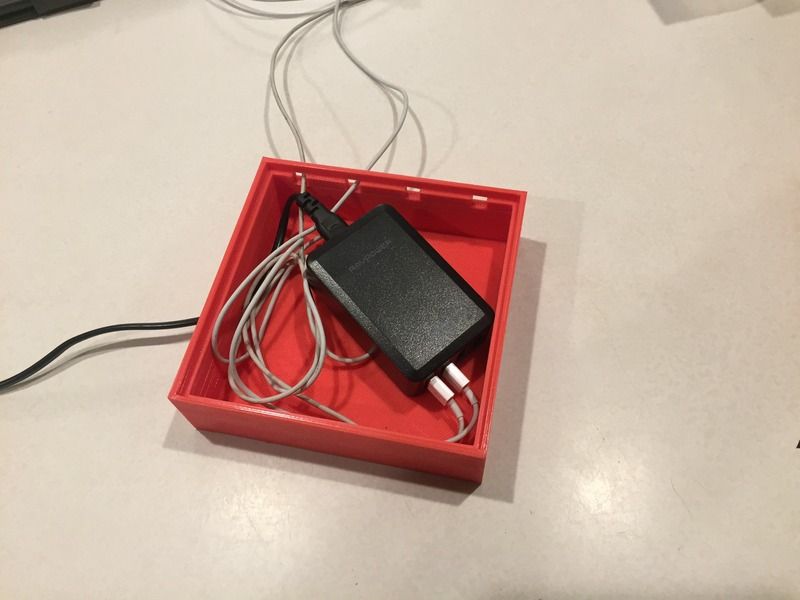

Here's the inside with the USB hub and 2 of the 4 cables

And the finished product. I couldn't find the other 2 lightening cables

If I were to print another one, I already see some design improvements, but all-in-all, not only am I happy with the finished product, I really am blown away that I can have an idea in my head then using a free CAD-type program made it a digital idea, then using an inexpensive printer and very inexpensive filament, make it a thing that I am using.

so, er, you wanna sell one?

EvanR

SuperDork

4/10/17 8:18 p.m.

I like it, but I'd like to suggest some airflow holes on the side opposite the cords. That power brick wants some cool air.

I have an insert I'd like made if you want to take it on?

What printer do you have?

Looks like a fun tool to make interior accessories for. Things like cupholders that can actually hold a bottle on an E36

DrBoost

UltimaDork

4/11/17 5:39 a.m.

Kendall_Jones wrote:

so, er, you wanna sell one?

I wasn't thinking about that, but I've actually got a decent amount of interest on facebook. What would you expext to pay at something like Target?

Remember, it's plastic and doesn't look perfect like a molded part. Some people really like the look of a printed part? But some may not.

DrBoost

UltimaDork

4/11/17 5:40 a.m.

EvanR wrote:

I like it, but I'd like to suggest some airflow holes on the side opposite the cords. That power brick wants some cool air.

I hadn't thought of that. Thanks for the input.

DrBoost

UltimaDork

4/11/17 5:42 a.m.

MINIzguy wrote:

What printer do you have?

Looks like a fun tool to make interior accessories for. Things like cupholders that can actually hold a bottle on an E36

I have a Prusa (style) iV3 from Makerfarm.

It's cool, you can make plastif doo-dads, or use the prints to make molds for a DIY foundry

Jerry

UltraDork

4/11/17 6:59 a.m.

I was just thinking if I had a 3D printer, I could make my own risers for the WRX spoiler I just bought. Nothing crazy, just an inch or two extra height. (I saw one for the first time a few weeks ago out of town, and searching for them they are fairly expensive and much taller than I really want)

I saw on the news that Nike is now 3D printing some of their new shoe bottoms.

RossD

UltimaDork

4/11/17 7:33 a.m.

DrBoost wrote:

Kendall_Jones wrote:

so, er, you wanna sell one?

I wasn't thinking about that, but I've actually got a decent amount of interest on facebook. What would you expext to pay at something like Target?

Remember, it's plastic and doesn't look perfect like a molded part. Some people really like the look of a printed part? But some may not.

Do people ever do a skim coat of fiberglass or filler then paint parts to try to make it silky smooth?

DrBoost

UltimaDork

4/11/17 7:40 a.m.

RossD wrote:

DrBoost wrote:

Kendall_Jones wrote:

so, er, you wanna sell one?

I wasn't thinking about that, but I've actually got a decent amount of interest on facebook. What would you expext to pay at something like Target?

Remember, it's plastic and doesn't look perfect like a molded part. Some people really like the look of a printed part? But some may not.

Do people ever do a skim coat of fiberglass or filler then paint parts to try to make it silky smooth?

I have a 2-part resin that you paint on a print, it smooths it out. If you print in ABS plastic, you can use acetone vapor to smooth the print. In both cases you lose a bit of detail to gain a molded appearance

RedGT

HalfDork

4/11/17 9:43 a.m.

You can be pretty careful with the acetone bath or brush and with some practice retain details but still improve the strength. I've made about 8 or 10 Miata cold air intakes now and some Brio train track parts and broken-toy parts for my daughter but I lack the design time to play around with other stuff.

DrBoost

UltimaDork

4/11/17 4:48 p.m.

Hey JG, are you still printing? You got yours before I got mine, curious to see if you still use it and what you think of it after a few years.

T.J.

UltimaDork

4/11/17 7:22 p.m.

I just ordered a prusa clone kit fof my birthday present. I started playing around with Fusion360 today and it seems easy enough to create 3d models. Looking forward to building the thing and printing something.

DrBoost wrote:

Hey JG, are you still printing? You got yours before I got mine, curious to see if you still use it and what you think of it after a few years.

Mine's cranking away as we speak on some camera dolly parts. For low-volume manufacturing and the ability to make on-the-fly changes to parts it really can't be beat. I have two Makerbot clones that i got off of eBay. They were cheap enough that I actually bought the second one because it was cheaper than buying a bunch of maintenance parts. So they basically keep each other running (although I tend to use one way more than the other because it holds calibration better).

I'm really wanting to buy one of those CNC router dealies. Like this one:

https://www.inventables.com/technologies/x-carve

Looks like a great way to make a huge mess, and have some fun at the same time.

DrBoost

UltimaDork

4/11/17 8:54 p.m.

T.J. wrote:

I just ordered a prusa clone kit fof my birthday present. I started playing around with Fusion360 today and it seems easy enough to create 3d models. Looking forward to building the thing and printing something.

Sweet! Where'd you get it from?

DrBoost

UltimaDork

4/11/17 8:55 p.m.

JG Pasterjak wrote:

DrBoost wrote:

Hey JG, are you still printing? You got yours before I got mine, curious to see if you still use it and what you think of it after a few years.

Mine's cranking away as we speak on some camera dolly parts. For low-volume manufacturing and the ability to make on-the-fly changes to parts it really can't be beat. I have two Makerbot clones that i got off of eBay. They were cheap enough that I actually bought the second one because it was cheaper than buying a bunch of maintenance parts. So they basically keep each other running (although I tend to use one way more than the other because it holds calibration better).

I'm really wanting to buy one of those CNC router dealies. Like this one:

https://www.inventables.com/technologies/x-carve

Looks like a great way to make a huge mess, and have some fun at the same time.

That x carve looks cool. What would you use it for?

DrBoost

UltimaDork

4/12/17 7:40 a.m.

T.J. wrote:

In reply to DrBoost:

Reprap guru

Cool! Keep us updated over the first few months or year. I'm very curious to see how the cheaper printers perform and hold up.

The i3 design is tried and true, and pretty simple. You just don't have to spend a ton of money on a decent printer anymore.

What are your plans for it? Just tinkering, or do you have an intended use?

Welcome to another addictive hobby.

RossD

UltimaDork

4/12/17 8:07 a.m.

I figured I share something that happened last night.

I was at a large industrial fan manufacturer last night for a professional society meeting and R&D lab tour. (Their sound lab was awesome, but that's a different topic.)

They had a couple 3d printers. The small one was up in the engineering office for them to play with and the other was in the R&D lab. The big one was $100k, 6' tall, about 3' wide and deep. They were printing centrifugal fan wheels with it and would run them through tests; run them as in move air. He said they had to pay an extra $30k to have a 'program switch' flipped so they could utilize the entire printer table size. He said they use ABS and it has a second head that deposits the water soluble support medium. The wheel of ABS was more like an ink jet cartridge with a chip built into it. He said they pay per the foot and even if they physically have more filament, if they didn't pay for it, it wouldn't come out of the cartridge. He also said it cost about 12x what the ABS filament cost for the small one up by the engineers.

The next question asked by just about everyone listening to the conversation was: Will all the fans be made, no, printed out of plastic in the future? Yes. Yes they will be. He said it will be the future of manufacturing.

It was reassuring since most of us assume this would be the future but to hear it from an actual manufacturer was kind of fun and exciting.

T.J.

UltimaDork

4/12/17 8:18 a.m.

In reply to DrBoost:

I mostly just wanted to learn about it. I do have a couple small projects I plan on printing solutions for. I need a new insert for my band saw (somehow I lost the original one) and I need a collar for the depth stop on my drill press (I broke the original one and it seems impervious to glues).

Here is model for the collar so far.

Here is the broken original:

I made the ear connection a little differently since that seemed like the weak point. For the past couple years I have been using an inelegant chuck of wood as my depth stop collar. It works, but is ugly and it should be fun to create a new one out of plastic.

I made the ear connection a little differently since that seemed like the weak point. For the past couple years I have been using an inelegant chuck of wood as my depth stop collar. It works, but is ugly and it should be fun to create a new one out of plastic.

RedGT wrote:

You can be pretty careful with the acetone bath or brush and with some practice retain details but still improve the strength. I've made about 8 or 10 Miata cold air intakes now and some Brio train track parts and broken-toy parts for my daughter but I lack the design time to play around with other stuff.

Wait, 3D printed miata intakes?

Do you sell them?

RedGT

HalfDork

4/12/17 12:53 p.m.

In reply to Cooper_Tired:

I have to listen to the (company-owned) printer on my desk run for a solid day to make one...not trying to make a business of it but I've made a bunch for friends and acquaintances. 1.6 only so far. I'm short on time to design any others. The 1.8 CAI over-the-radiator model that is available for free would be a significant amount of effort for me to piece together from three separate prints. You're better off getting it done by someone printing as a business, would probably run you $100-$150ish.

I made the ear connection a little differently since that seemed like the weak point. For the past couple years I have been using an inelegant chuck of wood as my depth stop collar. It works, but is ugly and it should be fun to create a new one out of plastic.

I made the ear connection a little differently since that seemed like the weak point. For the past couple years I have been using an inelegant chuck of wood as my depth stop collar. It works, but is ugly and it should be fun to create a new one out of plastic.