It is winter, my fun car is garaged. I have a month or so off betweeen semesters at engineering school and thought I'd finally put some effort into a 4A-G of my own. I've been sharing it on some 4A-G communities looking for some feedback and encouragement. Please, let me know what you think!

The build started the day I got home from a semester away. I pulled some parts out of storage and let them sit and equalize in temp before continuing.

4A-Gs came with one of two crankshafts. Earlier engines used a crank with 40mm crankpins. Later ones had 42mm crankpins. While the 40mm cranks are lighter, they were put in weaker blocks with low compression pistons.

The crankshaft I'm using is one of three 40mm crankshafts I have at my disposal. Right now it looks to be the best candidate for this build.

My measuring is rather ritualistic. I measure each feature a minimum of 9 times, three each in three directions. All of my instruments read to 1 micron ( 0.001mm ). All three measurements in one direction must come out within a micron of eachother. If they do not I keep measuring until they do.

This goes into a spreadsheet. If Toyota specifies a tolerance this autopopulates. If there's a corresponding size designation this autopopulates. When I have mating features done it will pick bearing sizes and give me clearances. I can shuffle bearings around to get more precise clearances. Once I know my sizes I order them up from Toyota, then measure the actual bearings that come in, shuffle them around, and do a final install and plastigauge.

Here is Jeff's wicked-awesome engine blueprinting spreadsheet

These are Molnar Technologies 40/20 rods I'd put together a while ago. These will allow me to pair that 40mm crank with OEM 81.5mm blacktop 20v pistons. This is a combination which cannot be done with OEM parts, as the early and late 4A-Gs had different wrist pin sizes. According to this box these weigh in at 419.4 grams. I'll be throwing them up on the balance soon, hopefully. Right now my 0.1g scale is AWOL. I must've left it in the FSAE shop at school. The connecting rods had been sitting in the office for a few months, they shoul be the right temp, so I started to work on them first. I measure each big end a minimum of 9 times: 3 in each of 3 directions. This all goes into that spreadsheet which calculates the average and runout. These rods were all fairly good. I have them labeled by letters, as I haven't yet weighed them to decide what cylinder they're going in.

These are Molnar Technologies 40/20 rods I'd put together a while ago. These will allow me to pair that 40mm crank with OEM 81.5mm blacktop 20v pistons. This is a combination which cannot be done with OEM parts, as the early and late 4A-Gs had different wrist pin sizes. According to this box these weigh in at 419.4 grams. I'll be throwing them up on the balance soon, hopefully. Right now my 0.1g scale is AWOL. I must've left it in the FSAE shop at school. The connecting rods had been sitting in the office for a few months, they shoul be the right temp, so I started to work on them first. I measure each big end a minimum of 9 times: 3 in each of 3 directions. This all goes into that spreadsheet which calculates the average and runout. These rods were all fairly good. I have them labeled by letters, as I haven't yet weighed them to decide what cylinder they're going in.

The next day I started into the crankshaft. I measure each crankpin and main a minimum of 9 times.

I'd had it polished locally, and they took off a little more material than I'd have liked. Everything is just bearly under minimum spec. Luckily my rods are on the bottom end of Toyota's specs, so my rod bearing clearances are fine. Will have to wait on the mains.

I'd had it polished locally, and they took off a little more material than I'd have liked. Everything is just bearly under minimum spec. Luckily my rods are on the bottom end of Toyota's specs, so my rod bearing clearances are fine. Will have to wait on the mains.

After I was done with the office work I took the AE111 block out to the driveway to give it ithe TechnoSquare treatment.

This is one of the later, so called "7 rib" 4A-G blocks. These were fitted with 42mm crankshafts from the factory. They are considered stronger than the early blocks. This block is also equipped with oil squirters, something early blocks were not given.

All of the casting flash and all of the rough parts of the casting in the crankcase was ground down. I then took it to the machine shop to sit in the sonic tank over the weekend. I ordered my rod bearings from Toyota; two sets of #1s and 2 sets of #2s. I have a set of each in the bearing bank in case I need to switch them around. I did take a quick detour through the sales department and test drove an FR-S. I liked it. A lot.

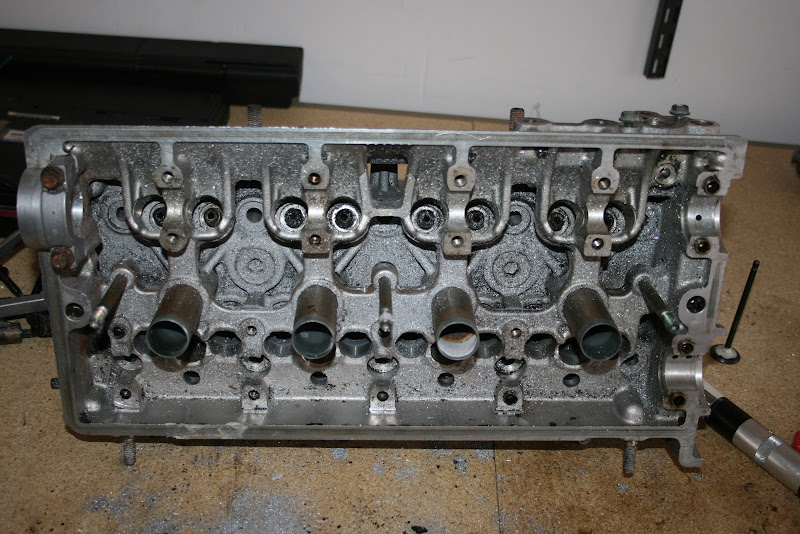

A similar deburring process is done on the head. Unfortunately, while doing bowl work one of my carbides came loose, I think because of a worn bearing in my flex shaft on my die grinder, and ate one of my seats rather deep. New seats on these heads are expensive and many shops are apprehensive about doing them, so I'm looking at a few options. I can probably cut this seat deep and compensate, but I don't think I want to. Equal breathing is important! That woulb mean cutting ALL of my seats deep.

I can also start into the AE111 head that's on the car right now, but I'd like to keep it in running condition. That'd mean switching heads, which would mean putting my AE101 head on it. Not fun.

I also have an AE101 head, but I'm not sure I want to play with it. I have been thinking of epoxying the intake ports and redoing them to be more like AE111 ports, but that's rather involved. Not expensive, though...And the AE101 head I have has good guides and seats.

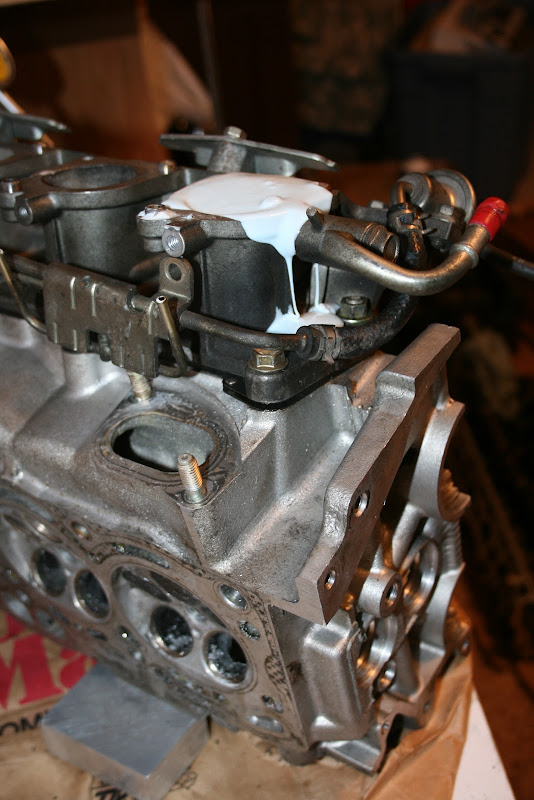

Next I assembled the mains with ARP studs and Tomei ladder bars.

Block didn't come out to shabby. Before I got these all torqued down I realized I missed the washer on the right on main #5. This block is measuring tight and slightly distorted on the mains. I'm picking up a better torque wrench, as I no longer have a Snap-On, and getting my ARP lube from my shop and trying again. If it still isn't right, I've another block at my disposal, but it means more deburring and another weekend in the tank.

Block didn't come out to shabby. Before I got these all torqued down I realized I missed the washer on the right on main #5. This block is measuring tight and slightly distorted on the mains. I'm picking up a better torque wrench, as I no longer have a Snap-On, and getting my ARP lube from my shop and trying again. If it still isn't right, I've another block at my disposal, but it means more deburring and another weekend in the tank.

Then I cleaned up some bearings, measured, and labeled them.

rod bearings came in and got measured out. Not bad.

rod bearings came in and got measured out. Not bad.

Bearing on the left is a main. Bearing on the right is a rod.

All of the OEM 4A-G main bearings I have are made by TAIHO. 42mm rod bearings are also made by Taiho.

Bearing on the left is a main. Bearing on the right is a rod.

All of the OEM 4A-G main bearings I have are made by TAIHO. 42mm rod bearings are also made by Taiho.

Those 40mm rod bearings, and all 40mm 4A rod bearings I've seen, are marked with that logo. Power Enterprise F1 Black bearings are made by the same company, as are all of the Clevites I've seen for the 4A. I believe it's for DAIDO bearings.

I was not happy with the roundness of the main bores on the block I'd deburred, so I went out to the garage and got another one! This one measured out much better and looked to be a substantially better casting. So much better, in fact, that I'm not going to bother deburring it. Anyway, I measured the main bores, went through my main bearing bank, and put together a set of main bearings.

By my calculations, my main bearing clearances are as follows:

1 - 0.029

2 - 0.029

3 - 0.028

4 - 0.029

5 - 0.029

and my rod bearing clearances are 0.041 across the board.

I assembled the bottom end with some Plastigauge.

Here you can see this block is a very clean casting.

Here you can see this block is a very clean casting.

40mm crankshaft. I'm running on the big end of OEM recommended clearances as I plan on revving this thing rather high.

40mm crankshaft. I'm running on the big end of OEM recommended clearances as I plan on revving this thing rather high.

Tomei ladder bars and ARP main studs should help keep this thing together when revving it up there. I'm also going to be using a 7A oil pan, which is a nice aluminum casting and ties into the transmission bellhousing.

Tomei ladder bars and ARP main studs should help keep this thing together when revving it up there. I'm also going to be using a 7A oil pan, which is a nice aluminum casting and ties into the transmission bellhousing.

And here's the plastigauge! On the right is my knee. Yes, I'm in my PJs. Again, I'm recovering from something nasty. My wife is an elementary teacher. I call her class 'plague rats'.

Below my knee is my new Brownline torque wrench. It's MASSIVE, which would make it cumbersome in other work, but is fantastic here. The extra length makes it nearly effortless.

And here's the plastigauge! On the right is my knee. Yes, I'm in my PJs. Again, I'm recovering from something nasty. My wife is an elementary teacher. I call her class 'plague rats'.

Below my knee is my new Brownline torque wrench. It's MASSIVE, which would make it cumbersome in other work, but is fantastic here. The extra length makes it nearly effortless.

I use a vernier caliper to measure the width of the plastigauge and interpolate between the widths on their card.

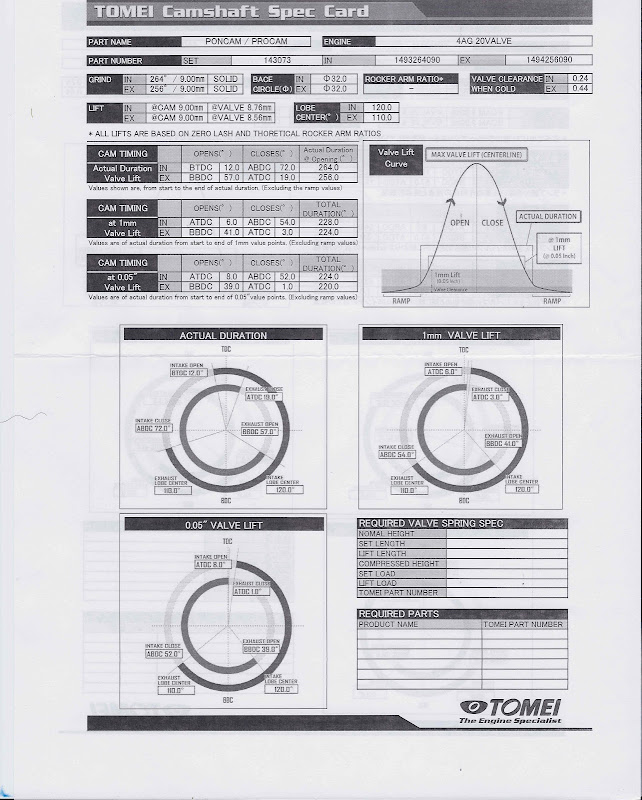

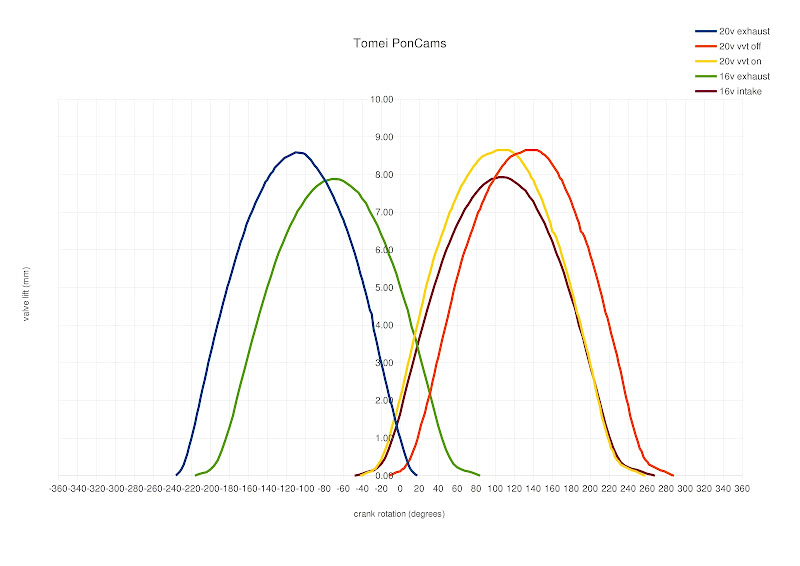

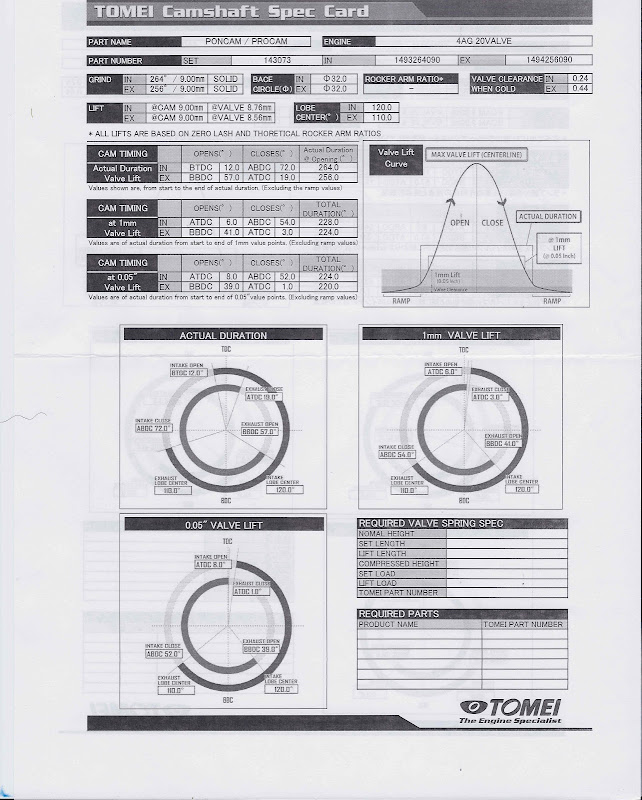

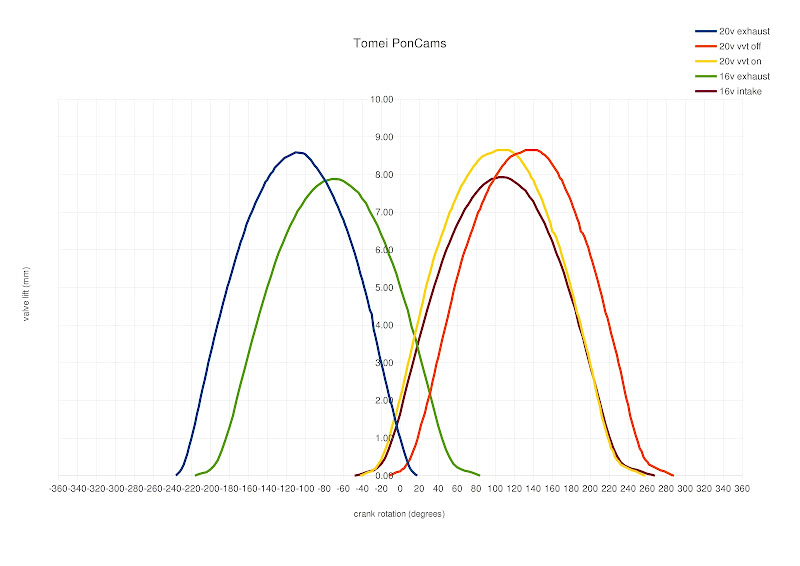

I finally openned up my cams. I got a set of their 20v PonCams for this engine. Tomei has the best timing cards I've ever seen.

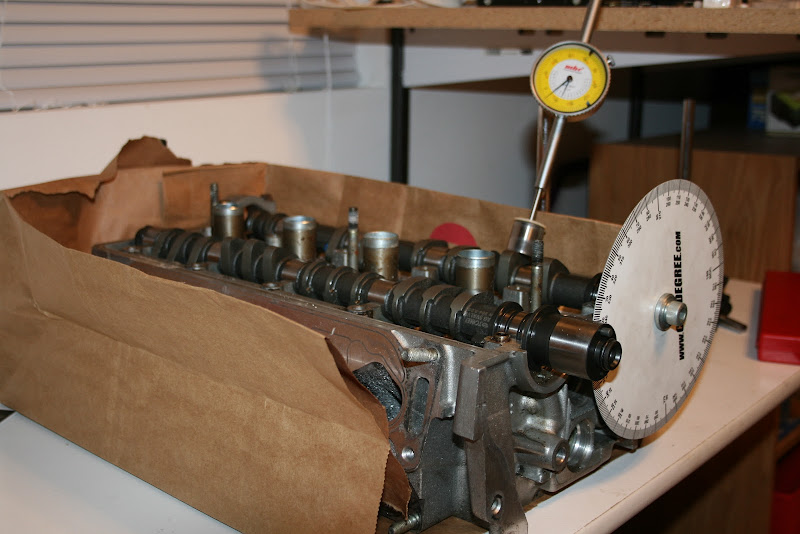

Cams then went into the head to map their profile. I usually have a nice set of V-blocks for this, but these also got left in the FSAE shop at school.

The 16v numbers were from a while ago. I'm not sure if my 16v exhaust timing is right. I'll have to look for a timing card.

That's with VVT changing timing 30 degrees. I'm also not sure if that is right, but I'm thinking it may be considering the advanced timing closely matches the 16v intake timing.

Timing cams is going to be relatively easy for me. I have access to both an AE101 and AE111 intake gear. There's a 5 degree difference in timing between the two. I can also install a Toda offset pin, which provides a further 5 degrees. So I get a choice of four discrete positions for my intake timing, and of course their respective "VVT on" positions. I will likely not screw with the Toda pin unless it would be necessary to get closer to the Tomei centerline.

I have an adjustable exhaust pulley, which may get some fiddling, but I doubt much. The major effect here will be the drastic difference in intake and exhaust manifolds compared to stock, which could produce different ideal timing, but I don't think by much.

As I said earlier, I will probably go to the dyno with an adjustable intake pulley to allow quick intake timing changes. This will allow me to find out which of the two VVT pullies would work better. The order of operations will be:

install AE111 pulley. Find and record centerline.

install AE101 pulley. Find and record centerline.

Extrapolate 2 other centerlines if offset pin is used.

install Toda pulley. Set to whichever timing is furthest from Tomei specs. Record position on pulley.

Set to whichever timing was closest to Tomei specs. Record position on pulley. Calculate VVT positions. Make sure I can actually achieve them within Toda adjustment range. If not, move a tooth on the belt, modify the pulley, etc.

Take it to the dyno! Having the positions known will mean a minimum of fiddling around on the dyno proper. I can quickly adjust between my discrete positions.

It's hard to tell, but this is an AE111 head. So we will have molds of both 20v heads!

I found the valves I'd used for doing valve testing. The numbers I came up with as being most ideal are VERY similar to the valves Ferrea later developed, which is why a set is sitting here ready to go on whatever head I end up using.

I've installed the Ferrea valves in the AE101 head and got it ready for the flowbench. Unfortunately my shop laptop and USB > RS232 adapter is, you guessed it, at the FSAE shop. I'll have to either wait or order another if I'm going to get this head flowed!

Woody

MegaDork

1/1/13 11:35 p.m.

I admire your patience and attention to detail. I suspect that you will be a very good engineer.

Thank you!

Aaaaand here's the difference between AE101 and AE111 intake ports!

There is enough of a difference between the side walls of the ports that I wonder if duplicating an AE111 port on the AE101 head will be possible without running into other cavities in the head.

Nashco

UltraDork

1/2/13 8:08 p.m.

I haven't seen the silcone mold trick before...neat! I'm guessing the casting thing is typical for people doing porting and I'm just behind the curve...you have any links of a "how to" on using that stuff? Seems like it'd be a bear to remove without damaging the silicone.

Bryce

I'd be interested in doing that as well. Sure helps give the port volume a nice visualization to plan out your modifications!

sobe_death wrote:

I'd be interested in doing that as well. Sure helps give the port volume a nice visualization to plan out your modifications!

It's really easy, and VERY strong. I use Tap Plastics anaerobic RTV Silicone. Cast it with something sticking out of the port so you have something to pull on. Be VERY careful with your ratios. Let it cure for a long time, then PULL and it'll come out just like that!

burdickjp wrote:

By my calculations, my main bearing clearances are as follows:

1 - 0.029

2 - 0.029

3 - 0.028

4 - 0.029

5 - 0.029

and my rod bearing clearances are 0.041 across the board.

Should be:

1-0.0029

2-0.0029

3-0.0028

4-0.0029

with a rod bearing clearance of 0.0041. Yes?

It looks like there are 5 main bearings.

burdickjp wrote:

Jerry From LA wrote:

Should be:

1-0.0029

2-0.0029

3-0.0028

4-0.0029

with a rod bearing clearance of 0.0041. Yes?

Nope. I work in metric.

Then:

1-.00114 2-.00114 3-.00110 4-.00114 in,

With a rod bearing clearance of .00161 in.

I know these motors run tight but those numbers are at the hairy edge of what most machinists are able to produce with any kind of repeatability.

OEM specs are:

con rod: 0.030-0.061mm 0.0012-0.0024in

mains: 0.015-0.045mm 0.0006-0.0018in

I've got more conrod bearings on the way to open them up a little bit.

Whoops. I thought you were consenting on the number of numbers, not the numbers.

wvumtnbkr wrote:

Whoops. I thought you were consenting on the number of numbers, not the numbers.

This block has 5 mains and 4 rods. I'm sorry, and I'll blame the internet for being an imperfect form of communication, but I really don't know what you are asking...

That you can measure to the thousandth of a millimeter (?!) with home tools? The sig figs seem to say that you can.

Teh E36 M3 wrote: That you can measure to the thousandth of a millimeter (?!) with home tools? The sig figs seem to say that you can.

Yessir. Starrett and Mitutoyo both make good vernier mics which read to a micron. I prefer Mitotoyos, but went with Starrett for uniformity.

I love mitutoyo. the absolute best I've ever seen and used, definitely blows my blue point mac set out of the water lol

Jerry From LA wrote:

burdickjp wrote:

By my calculations, my main bearing clearances are as follows:

1 - 0.029

2 - 0.029

3 - 0.028

4 - 0.029

5 - 0.029

and my rod bearing clearances are 0.041 across the board.

Should be:

1-0.0029

2-0.0029

3-0.0028

4-0.0029

with a rod bearing clearance of 0.0041. Yes?

To clarify my statement(s): I thought that Jerry was commenting on the "count" of numbers (i.e. in his post he has 4 numbers whereas you have "5"). I was pointing out that there are in fact 5 main bearings, not 4.

I later realized that Jerry was commenting on the tolerances and (in a round about way) the units.

And, I concur that Mitutoyo kisk ass.

end threadjack

Wow. So I think I'm now understanding better your OCD mic'ing process: you're going at 120, 240, and 360 degrees rotationally, and from one end of the bearing surface to the other longitudinally to check for taper, correct? That's berkeleying thorough. Nicely done.

I spent time yesterday with plasticine, shaping tools, and an untouched silvertop head. I'm starting with an untouched port. Next I'll open up a different port on the head and make changes such as the desperately needed short-side-radius, bowl, and valve-guide boss work. I'll then build up that port with plasticine and see what I can do.

Here's where we are at now:

Not done yet, but getting there. Today will be more shaping and then flowbench time!

These are Molnar Technologies 40/20 rods I'd put together a while ago. These will allow me to pair that 40mm crank with OEM 81.5mm blacktop 20v pistons. This is a combination which cannot be done with OEM parts, as the early and late 4A-Gs had different wrist pin sizes. According to this box these weigh in at 419.4 grams. I'll be throwing them up on the balance soon, hopefully. Right now my 0.1g scale is AWOL. I must've left it in the FSAE shop at school. The connecting rods had been sitting in the office for a few months, they shoul be the right temp, so I started to work on them first. I measure each big end a minimum of 9 times: 3 in each of 3 directions. This all goes into that spreadsheet which calculates the average and runout. These rods were all fairly good. I have them labeled by letters, as I haven't yet weighed them to decide what cylinder they're going in.

I'd had it polished locally, and they took off a little more material than I'd have liked. Everything is just bearly under minimum spec. Luckily my rods are on the bottom end of Toyota's specs, so my rod bearing clearances are fine. Will have to wait on the mains.