Hey guys. Welcome to my blog... I figured this blog would fit in quite nicely with the grassroots theme over here..

With out further delay here is my baby the day I brought her home....

The back story.. I bought her with only 79,000km on the clock. Don't let the low millage fool you, this car was rode hard and put away wet for a good portion of her life. The friend I bought it from happen to know most of the back story on the car. She was bought off the show room floor in 88 and put to use in TSD rally's. It shows, at some point the front bumper was ripped off, the under carriage was pretty beat up. In that time it was also stolen and recovered twice.. By the time the car had 39,000kms on it the first owner passed away and the car sat in a garage for a number of years. Sometime around 2001 the car was sold to a young college student who wasn't able to drive it much. Shortly after that my friend bought it and was using it for his daily driver. Unable to upkeep with the maintenance it needed he decided to sell it.

The car needed a fair bit of work before making its return to daily driver status. Lets start at the first stage.

September long weekend 2014 I got time to bring the car into work and put a major amount of time on it.

Stock suspension out. hummm can you spot whats wrong?? both rear springs broken, both rear shocks blown and the right front shock was blown.

The stock exhaust system had the cat converter deleted.

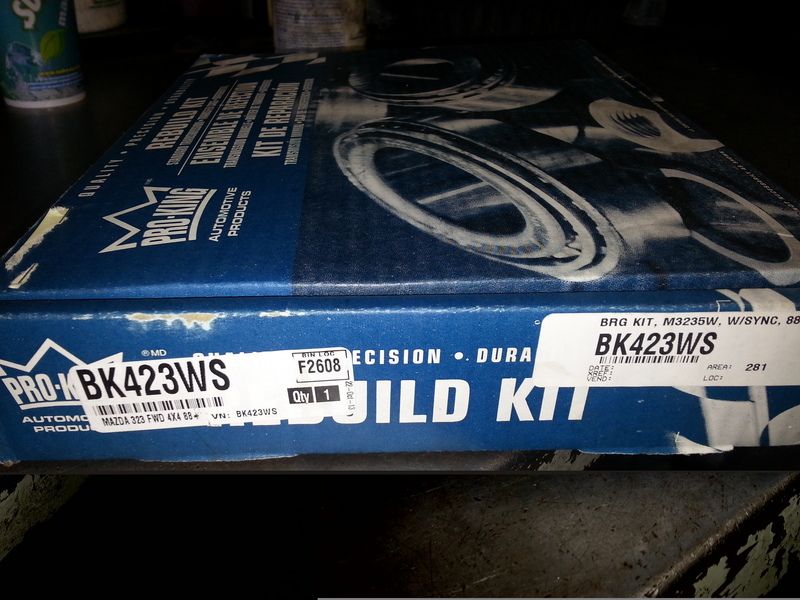

First thing I addressed was the front brakes. New pads had been supplied with the car when I bought it. Sourcing new rotors was cheap and easy. I replaced the grease seals and repacked the bearings.

I also pressure washed the knuckles and cleaned them up.

Putting things back together went really slick with this hub tool..

more to come..

An interesting note. A miata valve cover gasket can be used if you can't find one for a b6t. The bolt holes are slightly different shape but it all goes in place and seals up.

An interesting note. A miata valve cover gasket can be used if you can't find one for a b6t. The bolt holes are slightly different shape but it all goes in place and seals up.

Now you undo the 3 mounting bolts and the actuator will slide off. YA!

Now you undo the 3 mounting bolts and the actuator will slide off. YA!

OEM Mazda seals.

OEM Mazda seals.