As you toil and toil to clean up all these parts, just remember how many of us are following anxiously, insanely jealous, wishing we had the time and space for such an ill advised project. I look at those blast cabinets every time I’m in hf, and daydream about the projects I could start to justify them. Keep up the good work!

In reply to douglawrence42 :

Thanks, I really do love my life.

Stopped at HF yesterday and got their powder coating kit and a tub of red. Why red? Becasue Deucekid#4 though it was the coolest color to test with. Even he knows red stuff is faster. Also stopped by WalMart and bought a $40 toaster oven. Almost had it stolen when I showed it to Mrs. Deuce. Apparently it's 'nicer' than the one in the kitchen. All I know is that it's bigger and doesn't fit in the same spot, so I get it in the garage. Let this be a cautionary tale.

I looked around and decided to powercoat this paint can opener. Ran it over the wire wheel on the grinder for a second and decided it was prepped.

Without reading ANY of the instructions I hooked up the power source and the gun and gave it a go. The trigger on this sucker is sensitive. You can release a HUGE cloud of powder.

I sprayed the opener with powder, brought it inside and......dropped it. Crap. Back outside and coated it again. At least I took a picture this time. Too bad my camera didn't quite want to focus.

And into the oven. 400 F. I should get a thermometer to check the temperature, but within 4-5 minutes the power was shiny and flowing, so it must be close. I love the clear front for this sort of thing. I set the timer for 2o minutes and cleaned everything up. Powder is messy, at least how handle it.

Cooled off and here we are. The coating is too thin. This is why we test. I'm pretty happy with how simple it is. A nice hard coating in less than an hour.

Now that I've done it once it's time to step back and read the instructions. Most of the rest of the day is booked so that'll have to be later. Fun morning.

efahl

New Reader

11/10/17 12:05 p.m.

mazdeuce - Seth said:

... read the instructions.

WHAT?!? That would be the easy way, but it wouldn't be The Cowboy Way.

In reply to mazdeuce - Seth :

I see you recycle/collect 5 gal paint buckets, too. Do you nest them and have a heck of a time prying them apart? My solution - hot melt glue wooden scraps to give them wiggle room.

bucket ears

In reply to ronniejay :

5-gallon buckets are like ketchup bottles. You just have to find the sweet spot and slap them on the side so they jump apart.

Or stick the tip of an air blower down in between them and give them a little puff of compressed air.

I just cram them together and then swear at them when I need to get them apart. Hasn't failed me yet.

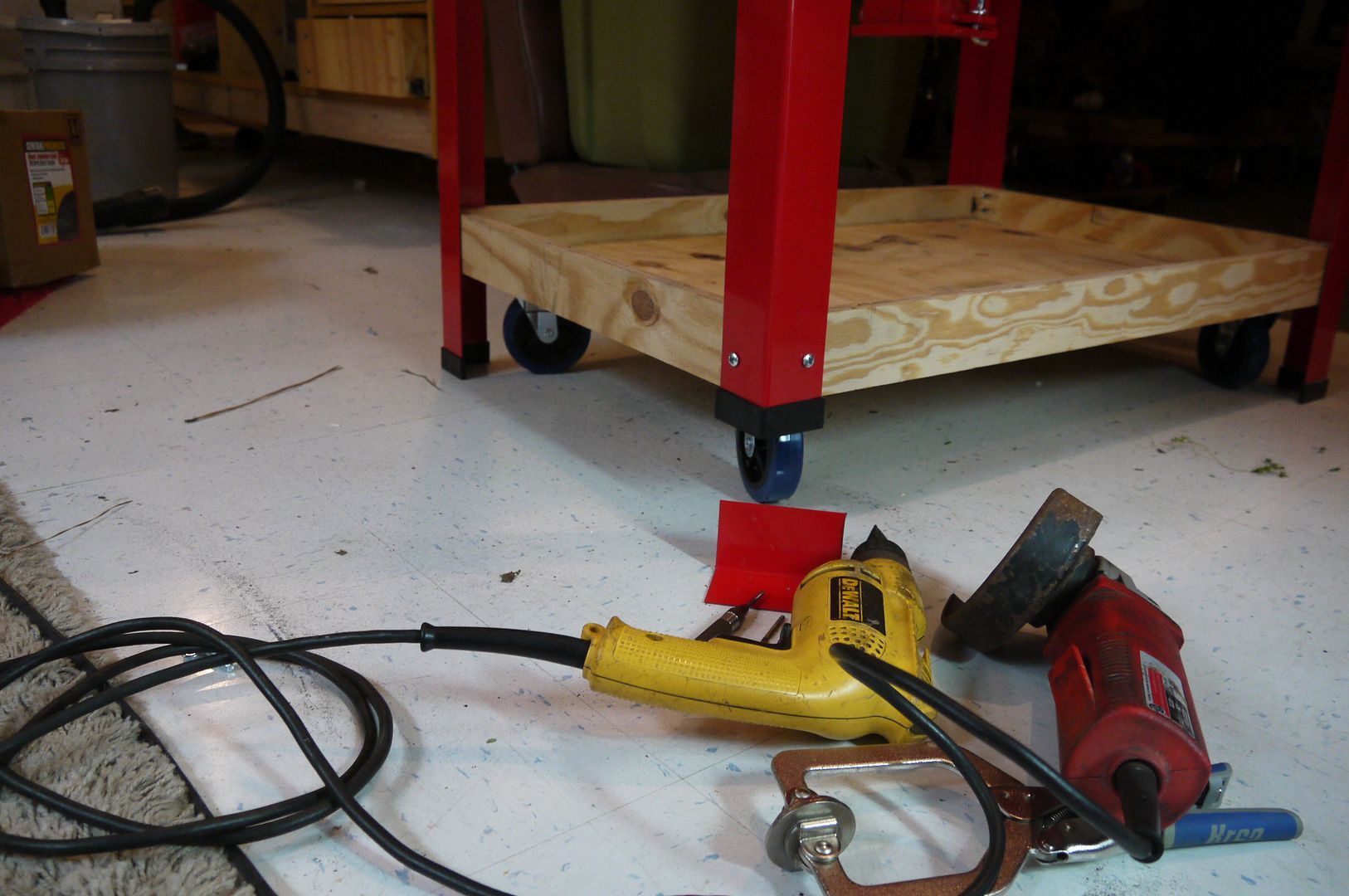

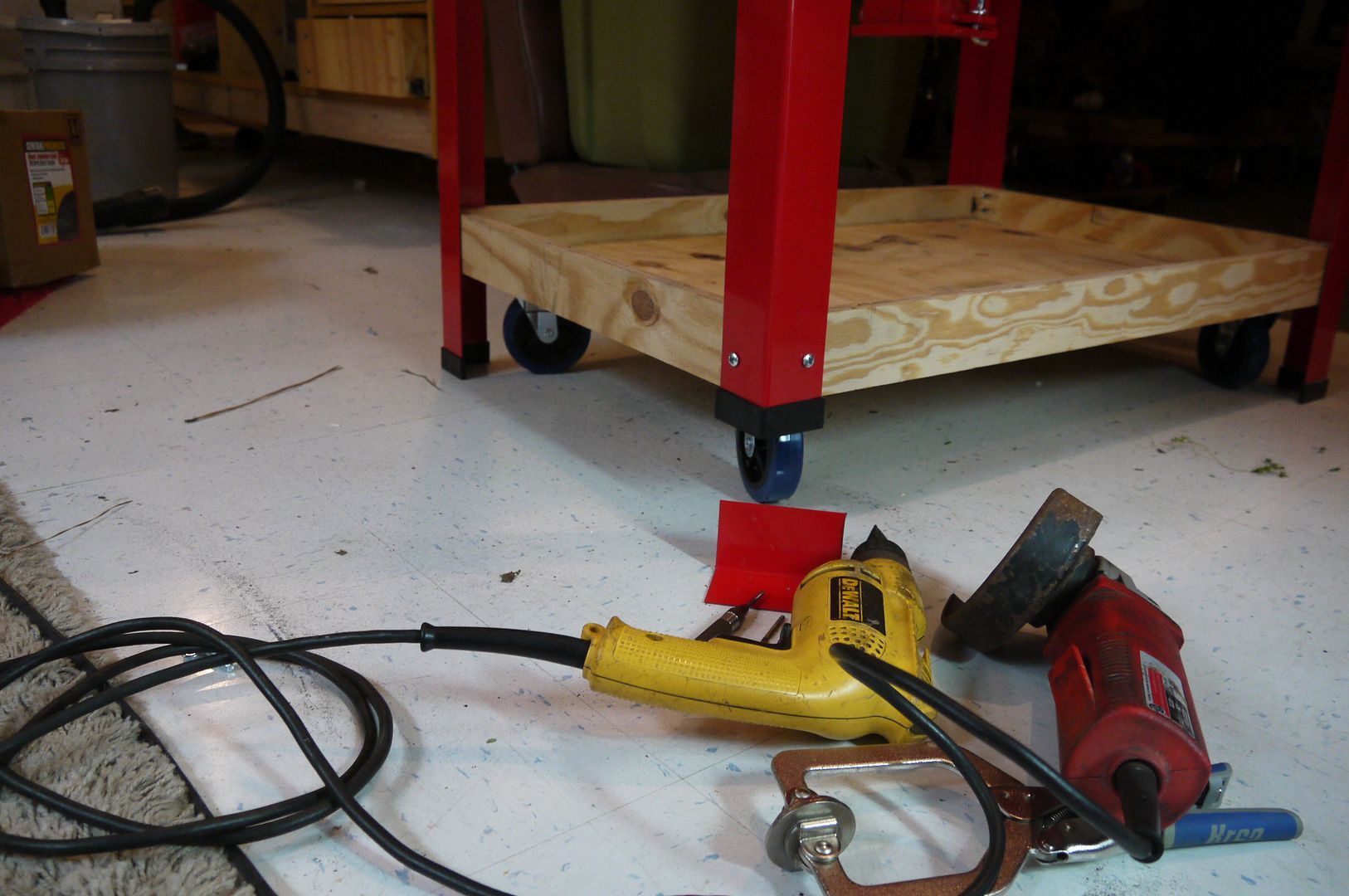

For some reason I put the photo of my whole days work yesterday on the cabover thread. Maybe because it took me all to day to bolt four wheels to a board and I was tired and confused?

Anyway, today I finished the rolling tray thingy and screwed the legs to it. I liked the height of the cabinet so I just set the cabinet over the tray, screwed the legs to it, cut them off and put the caps back on. If I ever want to set it on the floor again I'll just lose a couple inches. Also, I didn't have to figure out a way to hold the cabinet in the air and get it all lined up, which was my main motivator to be honest.

All set up, the buckets for the filtration system fit. I actually knew they would. In addition, I can shove a two gallon bucket under the trap door and catch the media when do I a media change. I swapped from glass beads to aluminum oxide today and it worked well.

The biggest reason to put things in wheels is so I can roll it outside quickly. Even with the filters I want to keep dust out of the building. The cabinet has a home here, next to the 911.

I just open the door, pull out the air hose and extension cord, close the door again and I'm in business. Less than a minute and I'm blasting.

I did have a little trouble with glare on the glass today. I figured out that if I mashed my face right against the window the glare was gone. Mrs. Deuce thought it looked funny, so of course she snapped a picture. It looks uncomfortable, but with with my head resting against the glass it's about like taking a nap on your desk during grade school.

I can run the compressor for 10-15 minutes out of an hour before the tank gets hot and I get moisture issues. 10 minutes is about as long as sandblasting if fun anyway, so it works out.

Try some satin clear screen protector vinyl. Should eliminate glsre anx help save the plexi.

coexist said:

mazdeuce - Seth said:

Nice catch, Coexist.... a case of life imitating art.

RossD

MegaDork

11/13/17 7:21 a.m.

Try to find some polarized safety glasses for the reflections.

Add some coffee mug handle stickers to the arm holes on the blast cabinet, and replace the warning sticker with a wrench.

You could expand that operating time by getting a second large tank to plumb in, your compressor will run longer to fill both, but once filled it'll last longer before you run out. (it's not a 2:1 ratio unfortunately)

In reply to Mad_Ratel : I just hook my compressors together. I have a cheap 1/2 hp Chinese made one I bought three decades ago that absolutely refuses to die. That I plug into my 5 hp one with the 65 gallon tank that's died more times than I care to count. The 1/2 hp one gives me about 30% longer run time before the pressure drops too low. Or when the big Campbell Hausfeld dies again I can still work. Just have to adjust for the longer time required to fill the tank

When I've ran multiple compressors together, I've adjusted the pressure switches in a way that the main compressor runs first, and if/when it can't keep up, the second one then fires up to help.

Small update on a small project.

I'm technically not done with the first workbench I built way back when. I still need to screw the cabinets together, install the kickplate, and make doors. While I was waiting for all of that to happen the bench started to sag. Turns out that wheels on the corners isn't enough when you start adding a bunch of weight to the cabinets.

Luckily Home Depot still carries the same casters so I was able to completely disassemble the bench, flip over the base, add the middle wheels and reassemble all of it. Much better.

This is all a very long way of saying that more wheels is better on a workbench.

RossD

MegaDork

11/14/17 2:40 p.m.

Nice work on the bench. As for the buckets, a 1 foot section of thick rope in the bottom of the lower bucket keeps the upper one from falling into it too far.

Everyone says that once you get a lift you also get about 40 new friends. I'm not sure how true that is as yesterday was the first time since putting in the lift that someone actually asked me to use it, and he was a friend before I even put it in. One of the guys we autocross with needs to put a clutch in his CRX and the consensus is that a lift, though not necessary, will probably make it easier.

I moved things around and bolted the second post back down. Only takes 3-4 minutes. I raised it up and hit the shelf. I knew I would.

You know this was just an excuse to use the jig saw. I love me some jig saw time.

With both shelves clearanced the lift is back in business.

And then (of course) the CRX guy does an inventory check and realizes that he doesn't quite have all the parts he needs. Ah well, at least the lift is back together.

Because this little detour is going to be classified as "cleaning up" I'm going to throw it in the Grosh thread instead of making a new one. I have too many open threads anyway.

Motorcycle #1 is a 1983ish Honda XR200R. Disassembled. The motor it together and in a box. The kick start gear is stripped. The plan was to split the case to fix that, refresh all the chassis bushings/bearings, and reassemble. I got it to this point and learned that the gear was expensive and the case gaskets were NLA. If someone offered to give me a disassembled XR200R today I'd refuse. It has zero value to me. Anyone want it?

Next is my 2004ish Genuine Stella. It's a Vespa clone made on license in a factory in India and imported during the final wild west days of two strokes in the US.

I bought it new and rode it a bit over 900 miles before I lit myself on fire and couldn't wear a helmet or gloves for six months.

In the end it was decided that me giving up riding on the road was the right thing to do while kids lived at home. It's been sitting. It's worth putting a bit of effort into this one to make it run and pass it on. Still has compression when it kicks over. I always though the shop part of the Grosh would be a nice well lit area to work on bikes. I'm going to give it a chance.

You're notice the gas tank missing in the last picture. It was pretty decent smelling 10 year old gas all things considered, but it's draining on the brush pile right now. We're going to burn this week.

After man handling international parts for a while, cleaning up a scooter indoors next to a couch should feel like a nice break

It would make great Grosh wall art!

Happy Thanksgiving everyone! Thought I would invade this space for a moment with the greatest holiday discovery I have made since building my grosh in 2014. Due to moving in and cold and rain or similar, I decided to try running the gas smoker in the shop several years ago. And it has been a revelation! I have 12’ ceilings, about 900 square feet, and a 10 foot roll up door. For that volume at least, I don’t get smoked out. But I do get weather proof bbq and smoking, I cook next to my tools, and the best part is my shop smells like a bbq pit for the next few weeks! So tomorrow I’ll be smoking a 14 lb bird while doing valve cover gaskets on a e39 540i. Hope everyone following mazduece has a great thanksgiving also.

Mazdeuce...I just finished reading the 'grosh' thread from the beginning to today. It has been an inspiration for me to tackle several projects, including a complete makeover of my garage which I am in the middle of now. Thank you for helping a 67 YO get motivated.

What are the deets on the compressor you have running the cabinet? I searched and didn't find them.

If I lived closer I'd love to help you whip up some 220V for the grosh.

Oh, and that scooter!!!