Well over the last month I have been working on something to get more involved into motor sports, and being able to go on a track and mimic what I have been doing in video games for many years.

Earlier this year, I won a contest at work and was able to attended the Ron Fellows Performance Driving School in Nevada. It was held at Spring Mountain Raceway, a track that Michelin and GM use for testing and they also host club races throughout the year. The backdrop was stunning, and being my first time in Nevada I was overwhelmed by it all, and did not get nearly as many photos as I should have gotten.

Earlier this year, I won a contest at work and was able to attended the Ron Fellows Performance Driving School in Nevada. It was held at Spring Mountain Raceway, a track that Michelin and GM use for testing and they also host club races throughout the year. The backdrop was stunning, and being my first time in Nevada I was overwhelmed by it all, and did not get nearly as many photos as I should have gotten.

The venue was set up like a resort, they had garages for club members, and a huge hotel on site for guests. If you look in the back ground you can see the owners house's.

The venue was set up like a resort, they had garages for club members, and a huge hotel on site for guests. If you look in the back ground you can see the owners house's.  I learned so much at the event it was unreal. Simple things like looking where your going and not in front of you, and holding the steering was key. And once we were able to put the skills to the test it all made sense. We drove stock C7 stingrays on track for one full day and I ended up winning 3rd place overall in the Auto X contest between all the attendees. Going back home and driving was so different after being able to thrash around a corvette all weekend. Back in September I attended a track day for the first time in my own vehicle at Little Talladega in my Jetta. It was a last minute thing, and the track day was hosted by my good friend George (@nemesis5.0). It was a Mustang track day, but he had a few spots open for me to bring my Jetta out for the day.

I learned so much at the event it was unreal. Simple things like looking where your going and not in front of you, and holding the steering was key. And once we were able to put the skills to the test it all made sense. We drove stock C7 stingrays on track for one full day and I ended up winning 3rd place overall in the Auto X contest between all the attendees. Going back home and driving was so different after being able to thrash around a corvette all weekend. Back in September I attended a track day for the first time in my own vehicle at Little Talladega in my Jetta. It was a last minute thing, and the track day was hosted by my good friend George (@nemesis5.0). It was a Mustang track day, but he had a few spots open for me to bring my Jetta out for the day.  My Jetta is no track car by any means. It has a stage 2 APR tune, and has most of the supporting mods for the engine but other then that it has stock brakes, regular street tires and H&R springs. To me the car handled great, and did what i needed it to do. My biggest fear was my brakes at the event, with the tune and mods, the car has good power. But I knew if i pushed it to hard on the straights I would over due the stock brakes and put myself in the dirt. Before that day the Jetta was a daily driver, but driving it on a track and with no regard was the most fun I had ever had in a vehicle. I was eager to get back out and do another track day in the Jetta, with some upgrades to the brakes and a second set of tires strictly for the track. But on my way home, I noticed the brakes felt a little mushy, the tires didnt feel as smooth, and I realized... damn I have to drive this car to work on Monday. NO part of this ends good for me and the Jetta.

My Jetta is no track car by any means. It has a stage 2 APR tune, and has most of the supporting mods for the engine but other then that it has stock brakes, regular street tires and H&R springs. To me the car handled great, and did what i needed it to do. My biggest fear was my brakes at the event, with the tune and mods, the car has good power. But I knew if i pushed it to hard on the straights I would over due the stock brakes and put myself in the dirt. Before that day the Jetta was a daily driver, but driving it on a track and with no regard was the most fun I had ever had in a vehicle. I was eager to get back out and do another track day in the Jetta, with some upgrades to the brakes and a second set of tires strictly for the track. But on my way home, I noticed the brakes felt a little mushy, the tires didnt feel as smooth, and I realized... damn I have to drive this car to work on Monday. NO part of this ends good for me and the Jetta.

I still wanted to take the Jetta back out again on a track, so I had planned to get it ready for the next event in March 2019. After being realistic with myself, it just did not make sense to put that much wear and tear on the Jetta, and then expect it to be a proper daily during the week. I started to search and look for something cheap, and with a decent aftermarket that I could have to take out and enjoy at track days and not have to worry about it as much.

But did not have space or the funds to purchase another vehicle, so something had to go. So i decided to part ways with my Mercedes and help fund this journey. I had not owned it for very long, and it was as nice as it was gonna get in my hands, I had a few sets of wheels for it, and lowered it. The car was damn near perfect for its age, but it wasnt the right tool for the job. After selling the Benz, I had a bigger budget, and went looking for something Japanese, reliable, cheap, fun , and some sort of aftermarket support. I narrowed it down to a RSX, EP3 Si, Integra, Prelude, Mazda Protege, SRT4. I noticed that all the cars were from a certain era. To me the 99 to the 2000s was the golden era for the import automotive scene. The cars were what they were meant to be and nothing more, but they can be transformed into whatever you want it to be. They were not trying to be luxury sedans, they were efficient , nimble, economical and sporty .

But did not have space or the funds to purchase another vehicle, so something had to go. So i decided to part ways with my Mercedes and help fund this journey. I had not owned it for very long, and it was as nice as it was gonna get in my hands, I had a few sets of wheels for it, and lowered it. The car was damn near perfect for its age, but it wasnt the right tool for the job. After selling the Benz, I had a bigger budget, and went looking for something Japanese, reliable, cheap, fun , and some sort of aftermarket support. I narrowed it down to a RSX, EP3 Si, Integra, Prelude, Mazda Protege, SRT4. I noticed that all the cars were from a certain era. To me the 99 to the 2000s was the golden era for the import automotive scene. The cars were what they were meant to be and nothing more, but they can be transformed into whatever you want it to be. They were not trying to be luxury sedans, they were efficient , nimble, economical and sporty .

Finding these cars in decent shape for a good price is really tough these days. My biggest thing was having a decent body, and be in good running condition, if it needed repairs it was fine, I just wanted to be able to drive it home under its own power. I did not wanna have to pull a motor, transmission or do major body work from the start. Most RSXs were beaten to death, or to expensive. Majority of the EP3s suffered from the same problem. Integras and Preludes were all over the place, but either it was swapped and just needed a "tune" or it to expensive. I only really saw one SRT4 for sale but it was a little too cheap and jsut did not seem right.

I have owned 13 Mazdas and deep down I wanted another Mazda. I owned a Mazdaspeed Protege back in 2013 and it was a great car. One of the best handling FWD cars at the time, but the cars are plagued with drive train issues and were under powered. Like the SRT4, the MSP was not as easy to find in good running condition for a reasonable price. I had thought of maybe finding a MP3 or a Protege 5, which shared the same handling dynamics minus the turbocharged engine.

I had my eye on a really clean EP3, the car was a little more then I wanted to spend. But I wanted to at least throw him a lowball offer and see if he would bite. Before I could offer him , he told me the car had been in a fender bender and he was selling it for cheaper then what I was going to offer. I was mentally prepared to be driving home a EP3 Si that afternoon, the only thing I needed to see was photos of the damage. And that is where the communication stopped..... I never heard from the guy again after that.

I had been seeing this Protege 5 popup on CL for almost a month. The car was a little too cheap, so I was suspicious of it. Thinking that it had to have major issues that they did not mention in the ad. But never took the time to read the ad, and see how honest it was. You can almost visualize what type of person you are dealing with when you read their Craiglist ads. The car was owned by a couple that had been driving it to work for the last few years. It seemed perfect, the last thing I wanted was a modified car. I got a response from the owner at around 5pm as I got ready to leave work. She had mentioned that someone else was coming to buy it later that night, but I had called here first so she would hold it for me if I could come by that night. At that time it was around 6pm, and I was sitting in traffic on 285. I did not get to their house until around 7:30, drove it around the neighborhood and was sold on it instantly. The car was clean and well taken care of by regular people, ready to be ruined by me. I drove home, got a ride back that night, and bought the car for $1200! The most notable issue was the left front hub bearing, which is a common issue. The only thing that troubled me was the 288,000 miles. But the motor and transmission felt solid on the ride home. But I could not get a true idea what I am dealing with until the wheel bearing is replaced.

I had been seeing this Protege 5 popup on CL for almost a month. The car was a little too cheap, so I was suspicious of it. Thinking that it had to have major issues that they did not mention in the ad. But never took the time to read the ad, and see how honest it was. You can almost visualize what type of person you are dealing with when you read their Craiglist ads. The car was owned by a couple that had been driving it to work for the last few years. It seemed perfect, the last thing I wanted was a modified car. I got a response from the owner at around 5pm as I got ready to leave work. She had mentioned that someone else was coming to buy it later that night, but I had called here first so she would hold it for me if I could come by that night. At that time it was around 6pm, and I was sitting in traffic on 285. I did not get to their house until around 7:30, drove it around the neighborhood and was sold on it instantly. The car was clean and well taken care of by regular people, ready to be ruined by me. I drove home, got a ride back that night, and bought the car for $1200! The most notable issue was the left front hub bearing, which is a common issue. The only thing that troubled me was the 288,000 miles. But the motor and transmission felt solid on the ride home. But I could not get a true idea what I am dealing with until the wheel bearing is replaced.

My goal with the P5 is to get involved in doing track days, auto x, time attack and just being behind the wheel on a track. I wanted to be able to drive the car at its full potential with basic upgrades and learn. I also wanted to stick to a tight budget, and try my hardest to save any way I can on some things, but spend the extra dollar when necessary. The P5 at one point had a huge aftermarket and was a very popular car when ti was released. The car was pushed to the side once the Mazdaspeed 3 was released. A lot of the big names do not really support the car as much anymore. The weakest part of the P5 is the drive train, but nothing that can not be prevented. Without turbocharging the 2.0 liter FSDE motor will last as long as it needs to. But if not careful it will easily spin a bearing, mainly due to the oem oil pan baffle. If you ever heard the phrase "zoom zoom boom" it literally came from the 2.0 FS motor. Its sounds bad, but its not as bad as it seems, especially if you know what to do to prevent it from happening.

The first goal of this build is to make it to the March Track day being held by JZilla Track days with my friends at Atlanta Speed Company, who will be helping me on and off the track with the build. So I will be sharing the process with everyone here, and soon move on to adding videos alongside these posts in the near future.

A week after purchasing the car I got the Wheel bearing replaced on the front driver side. And upon further inspection the passenger side was brand new, so I lucked out with that. The cost of the part was only $25 on Rock Auto .

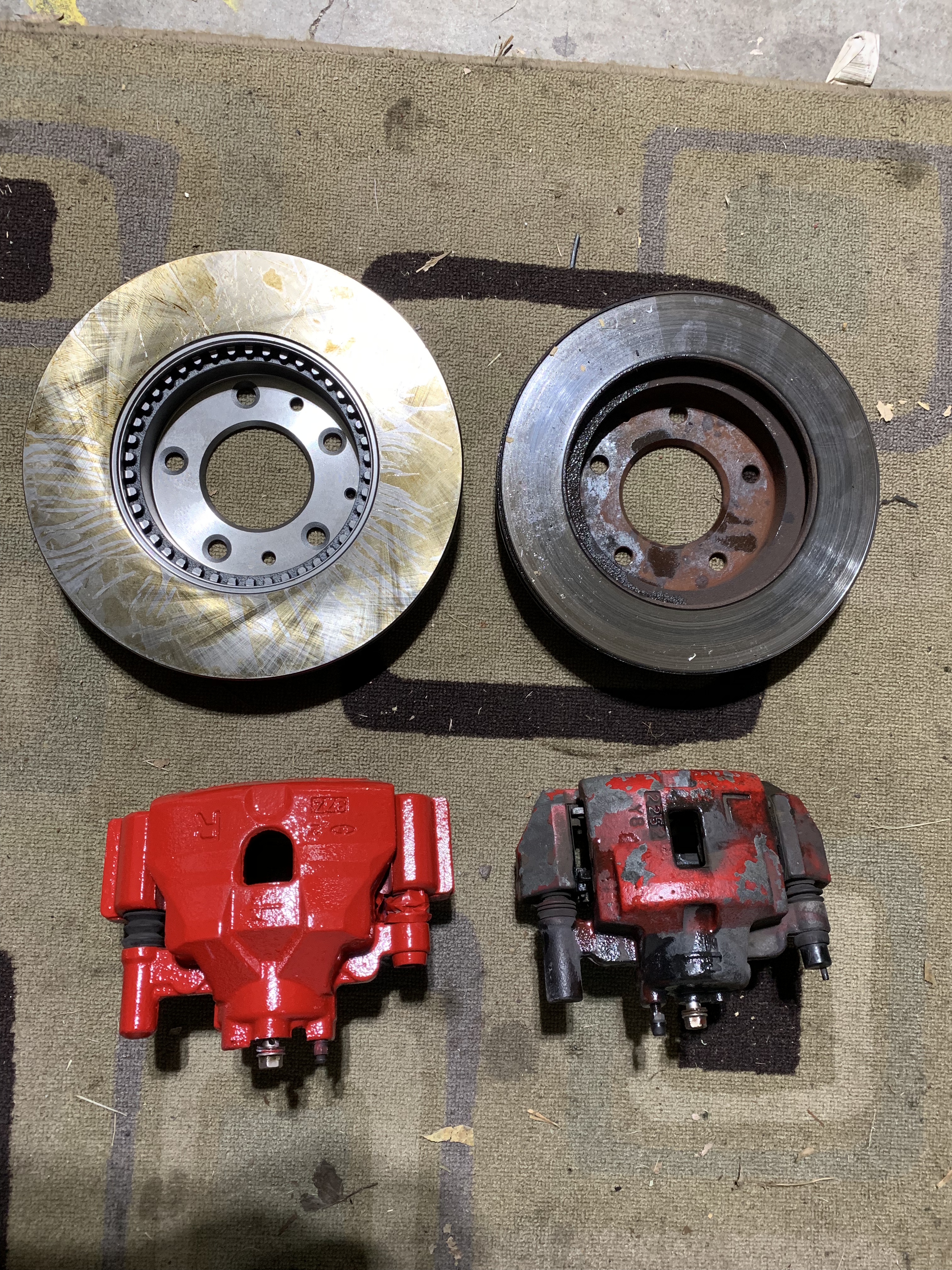

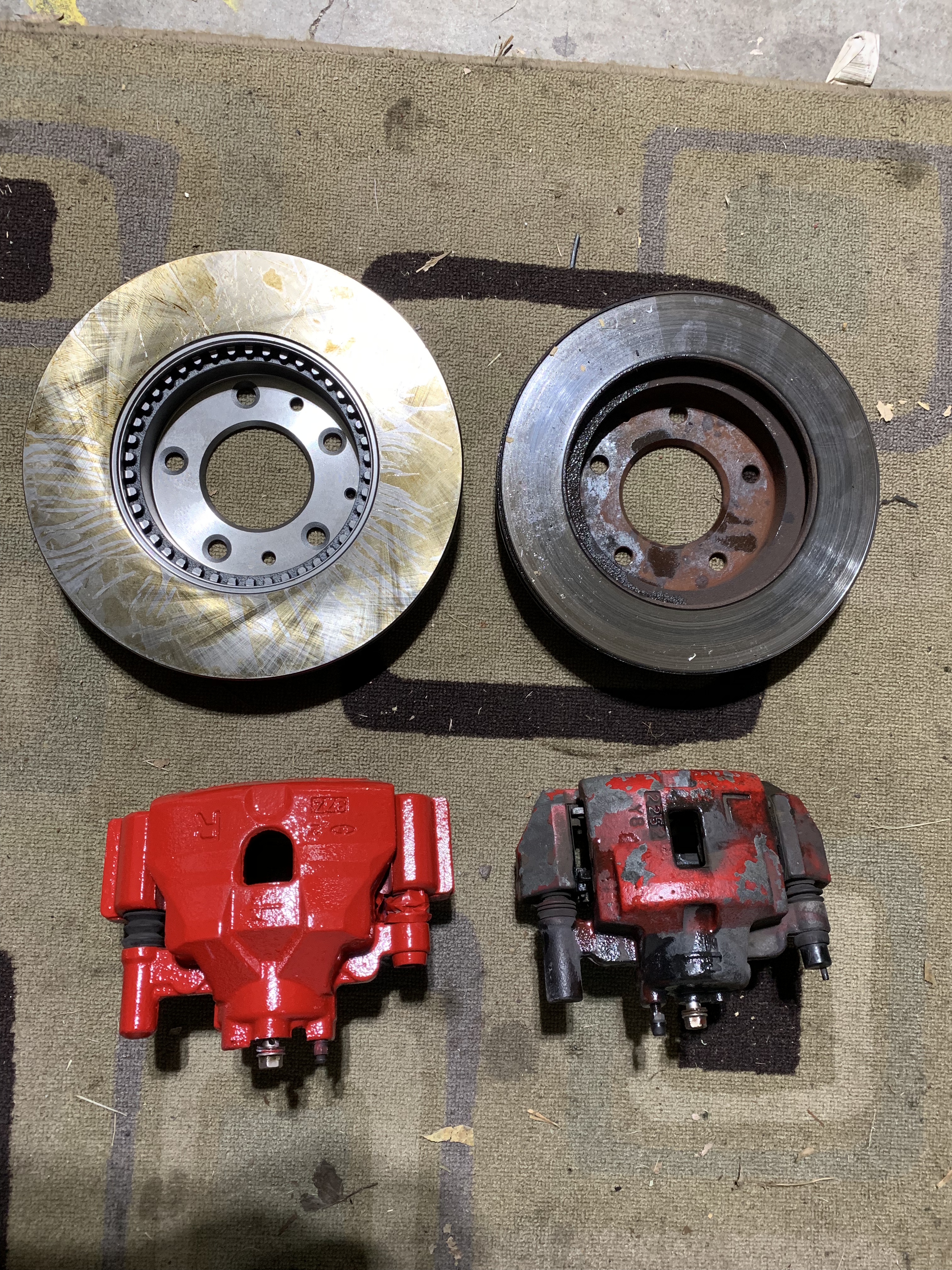

While getting the bearing done, I figured it was a good time to try and get some better brakes on the car. So we went with a easy and cheap oem upgrade.

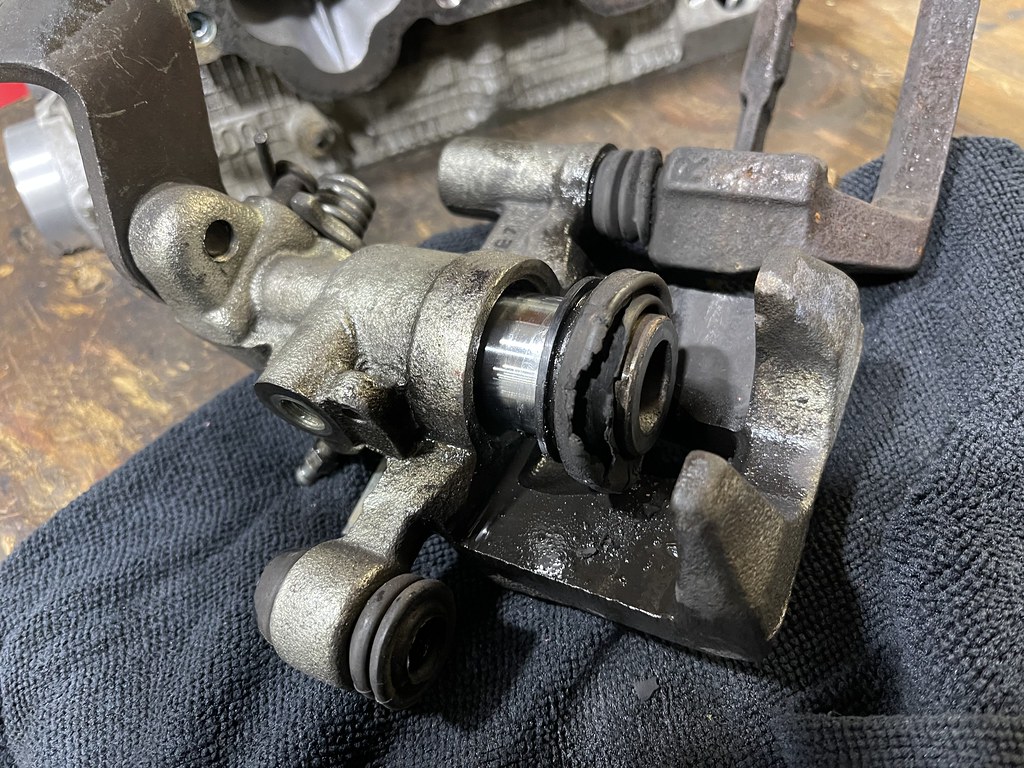

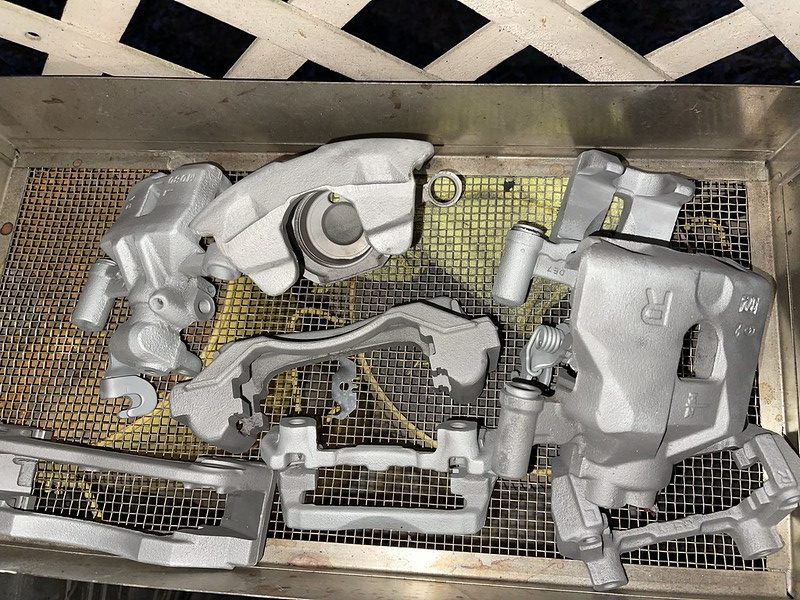

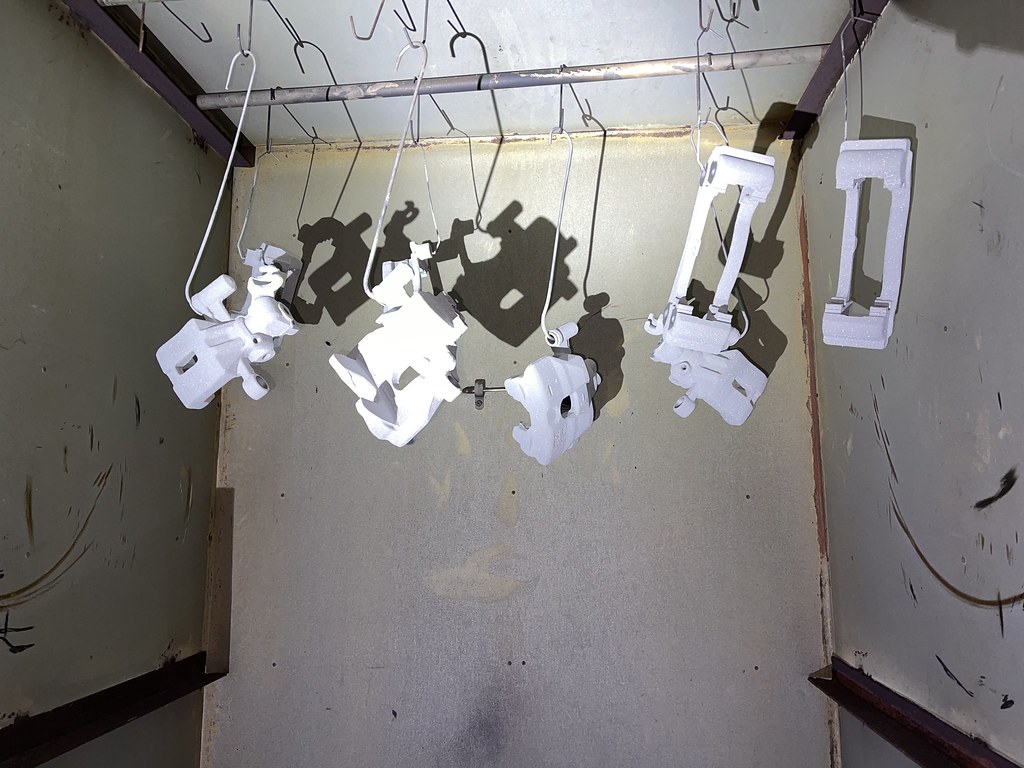

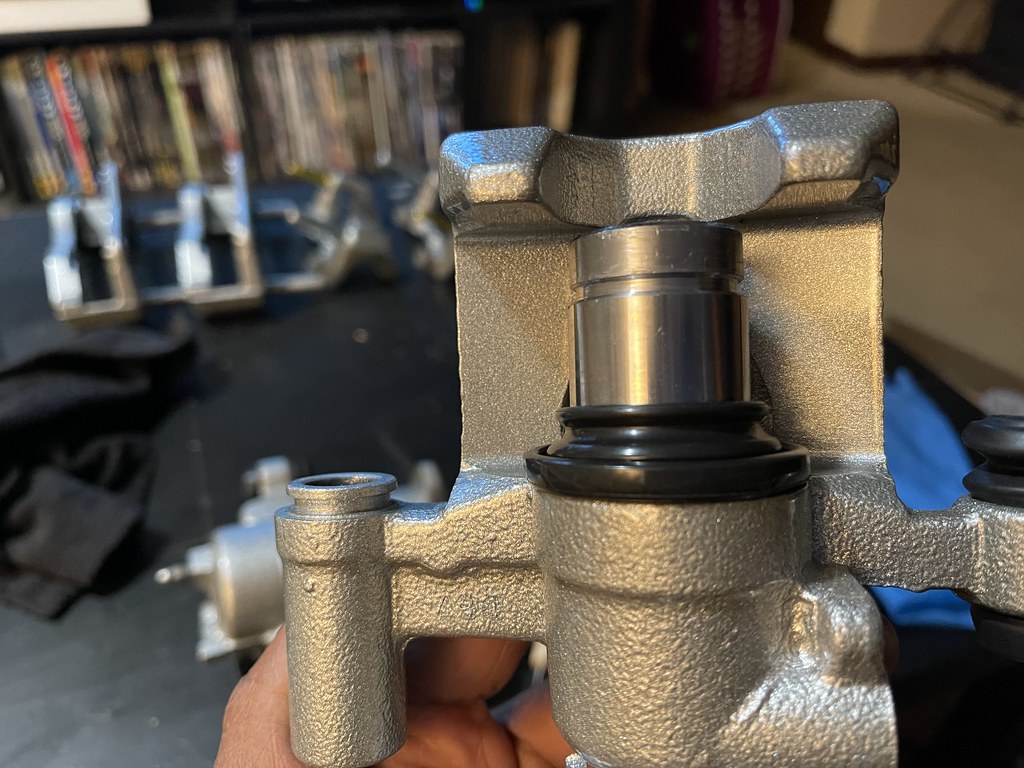

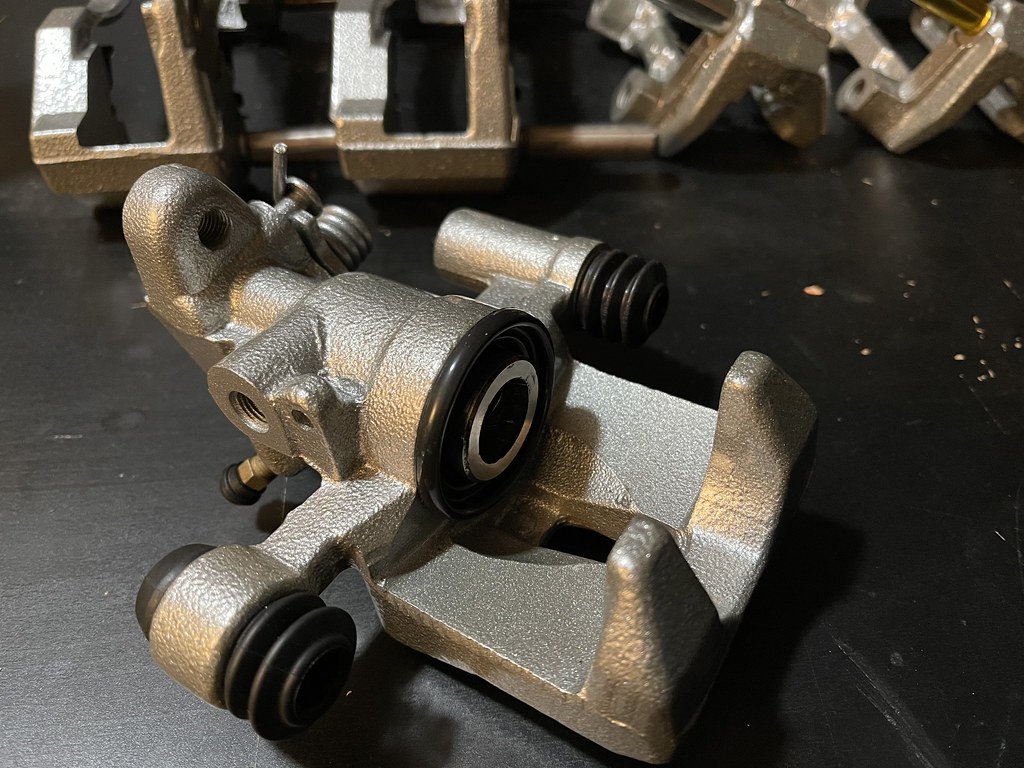

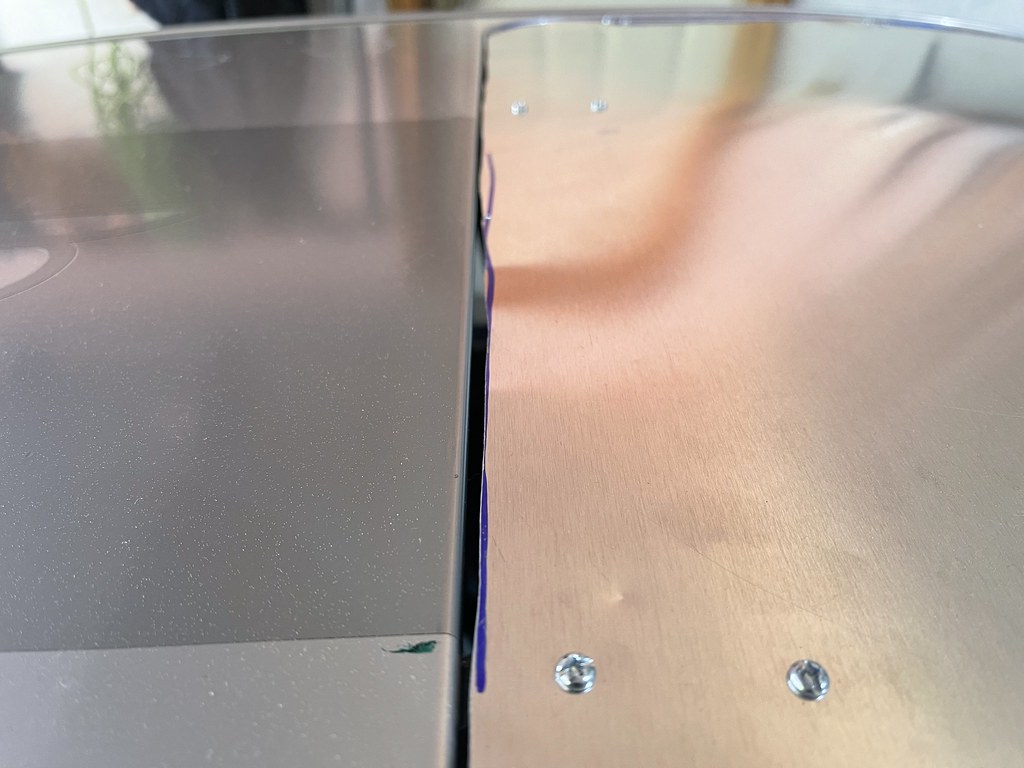

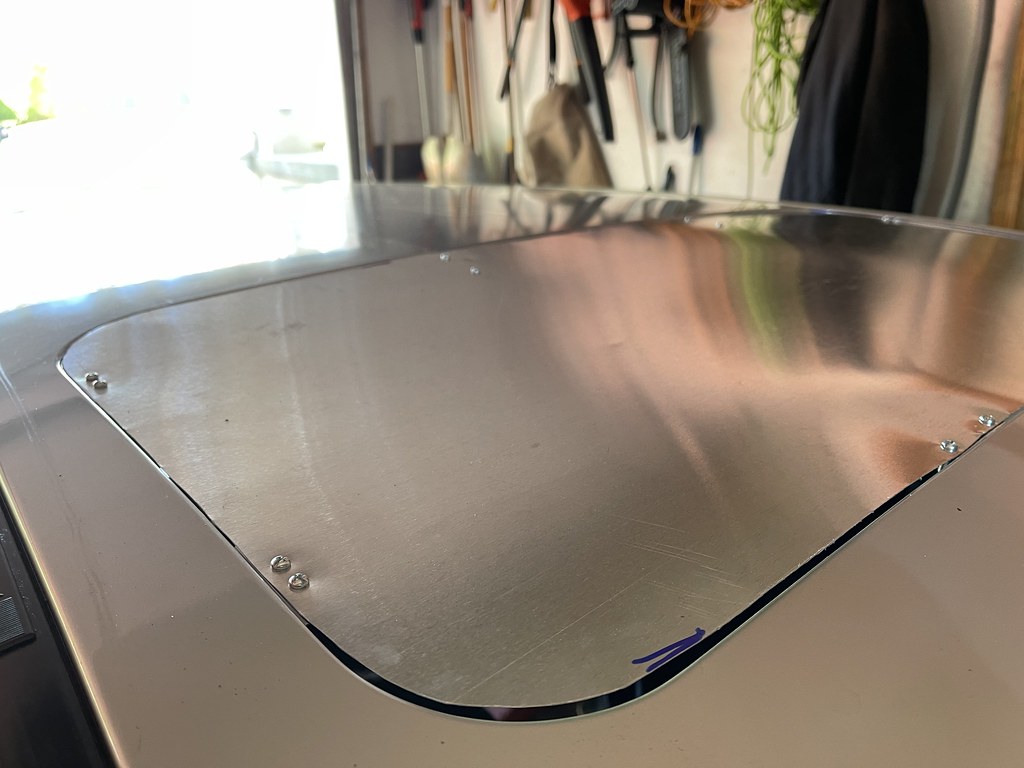

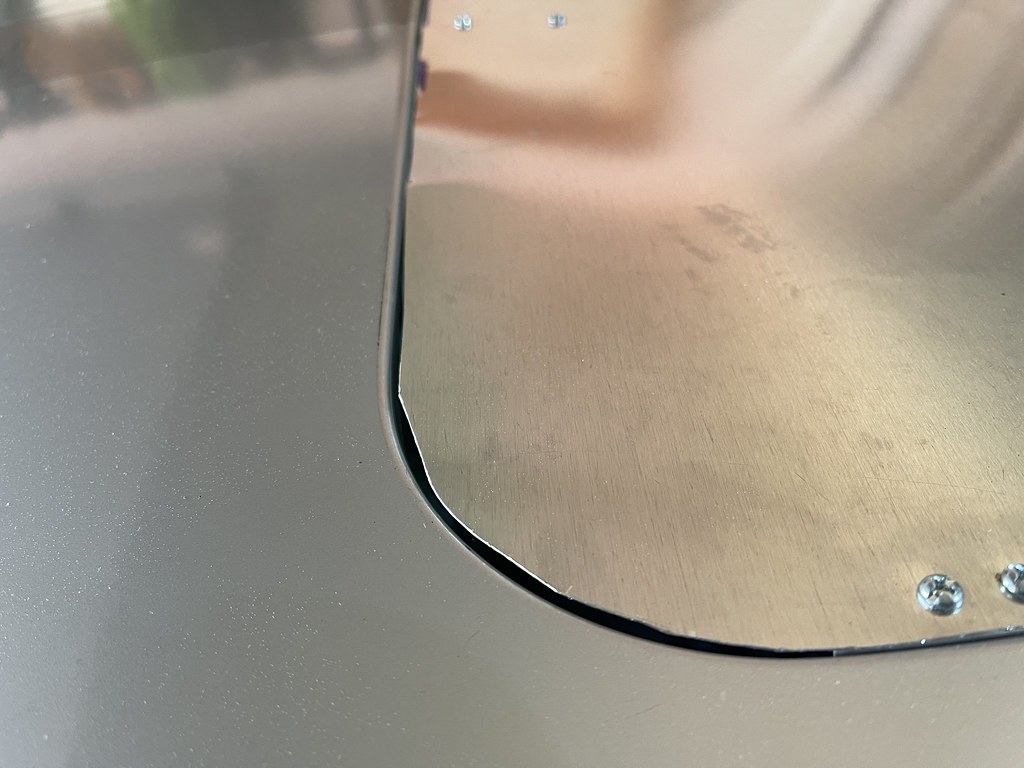

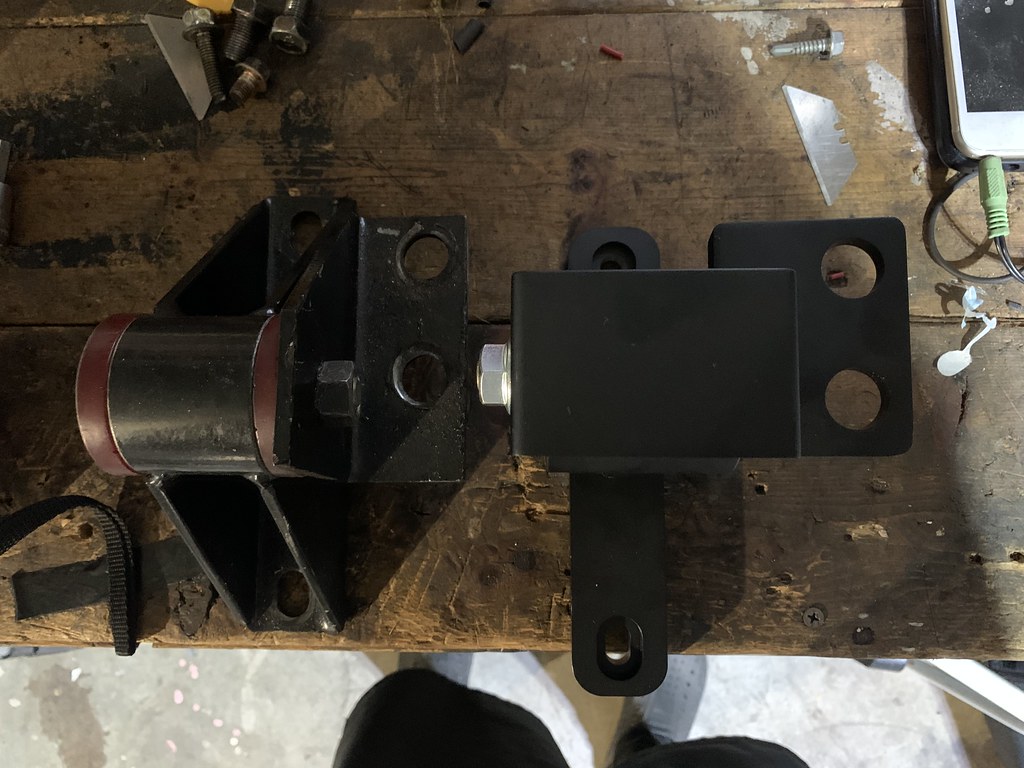

The left Caliper is from a 2004 Mazda 6, and the Right is the OEM Protege 5 caliper. The swap is a direct swap and requires no additional modifications. The Mazda 6 rear also works on the P5, I am just gonna go with a better pad and rotor for the rear.

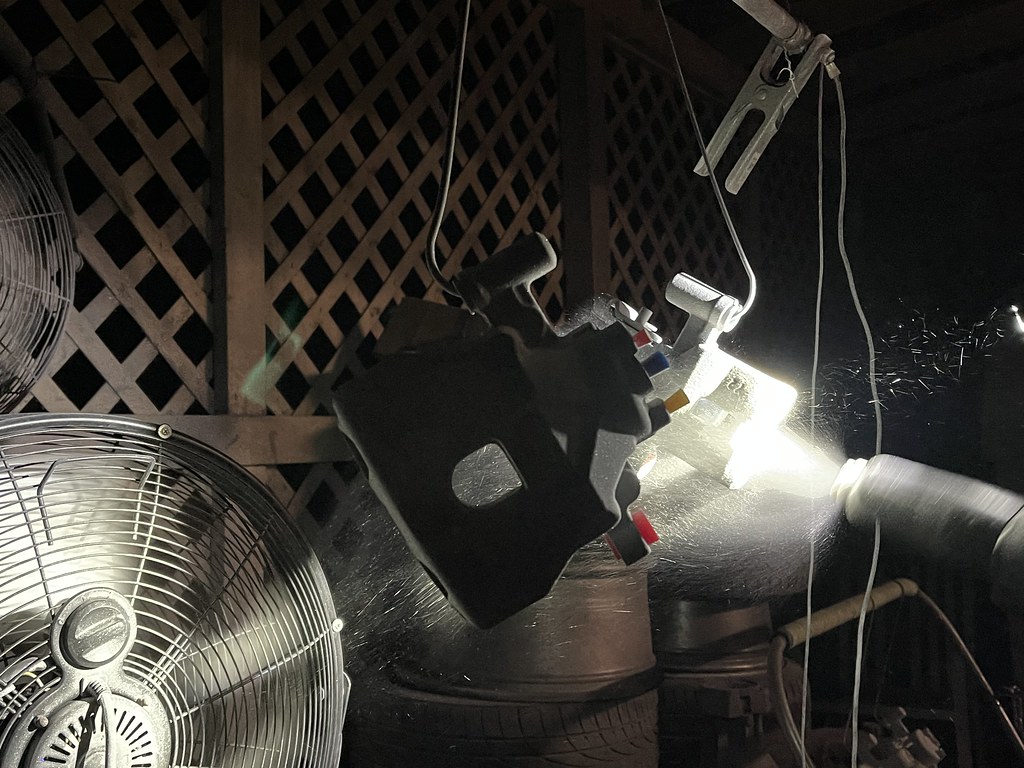

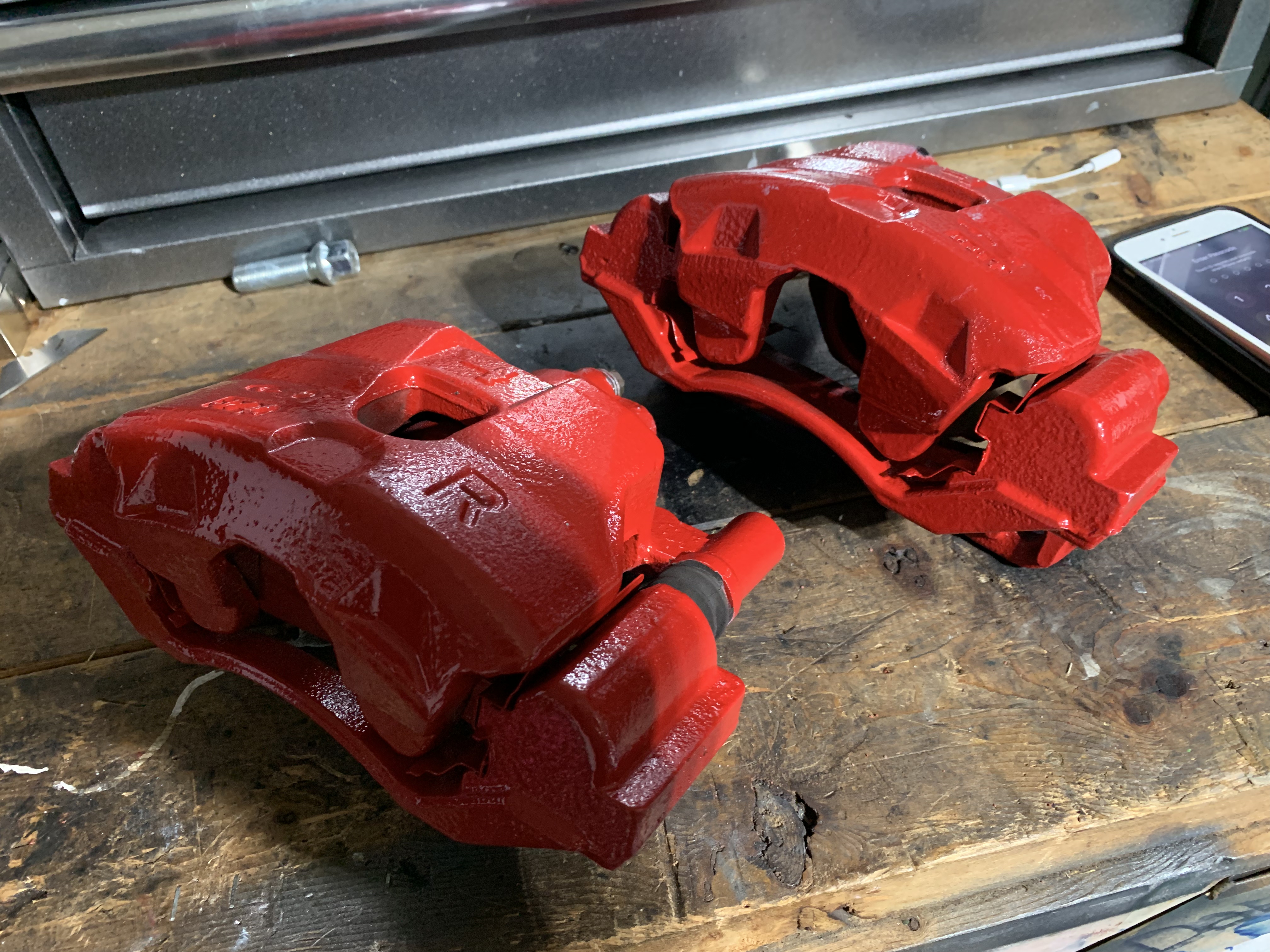

A race car red paint for the calipers...

You can really see the difference in the two above. The difference was night and day with this upgrade, being so much lighter then the 6 the P5 stops on a dime. You can also use the Mazdaspeed 6 brakes, but it requires the use of a 17" wheel, and it would make finding replacement pad/rotors a little more difficult if I had to go with specific MS6 pad and rotors. And the regular 6 brakes get the job done. This cost me a total of $90 including new blank pads and rotors.

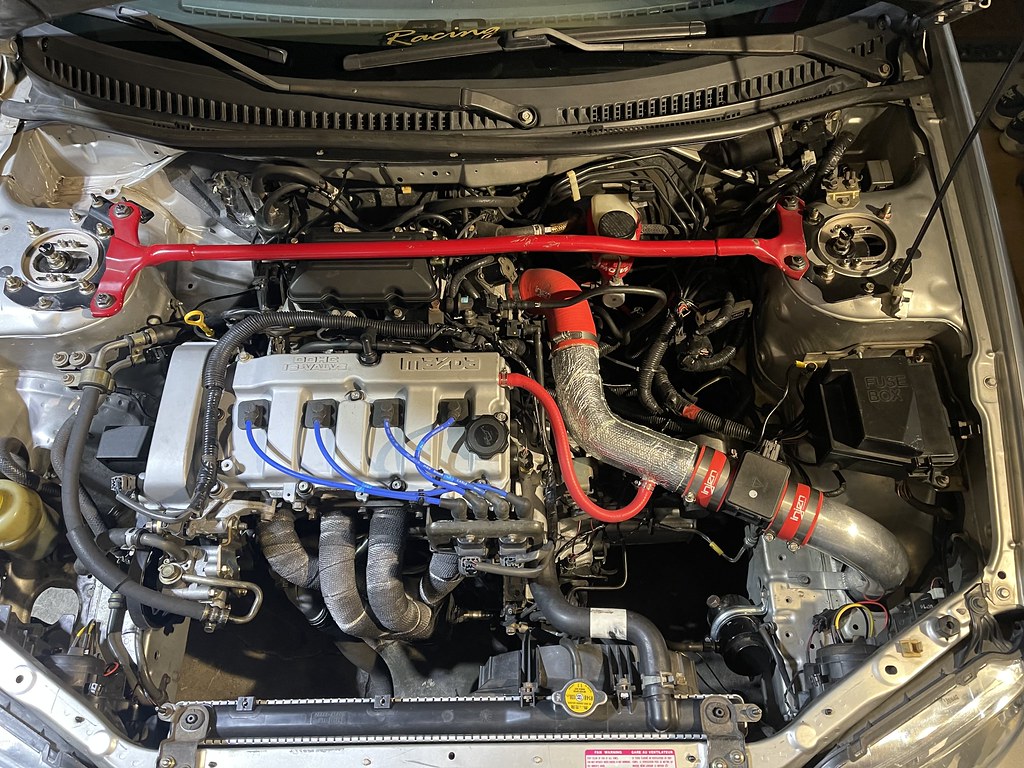

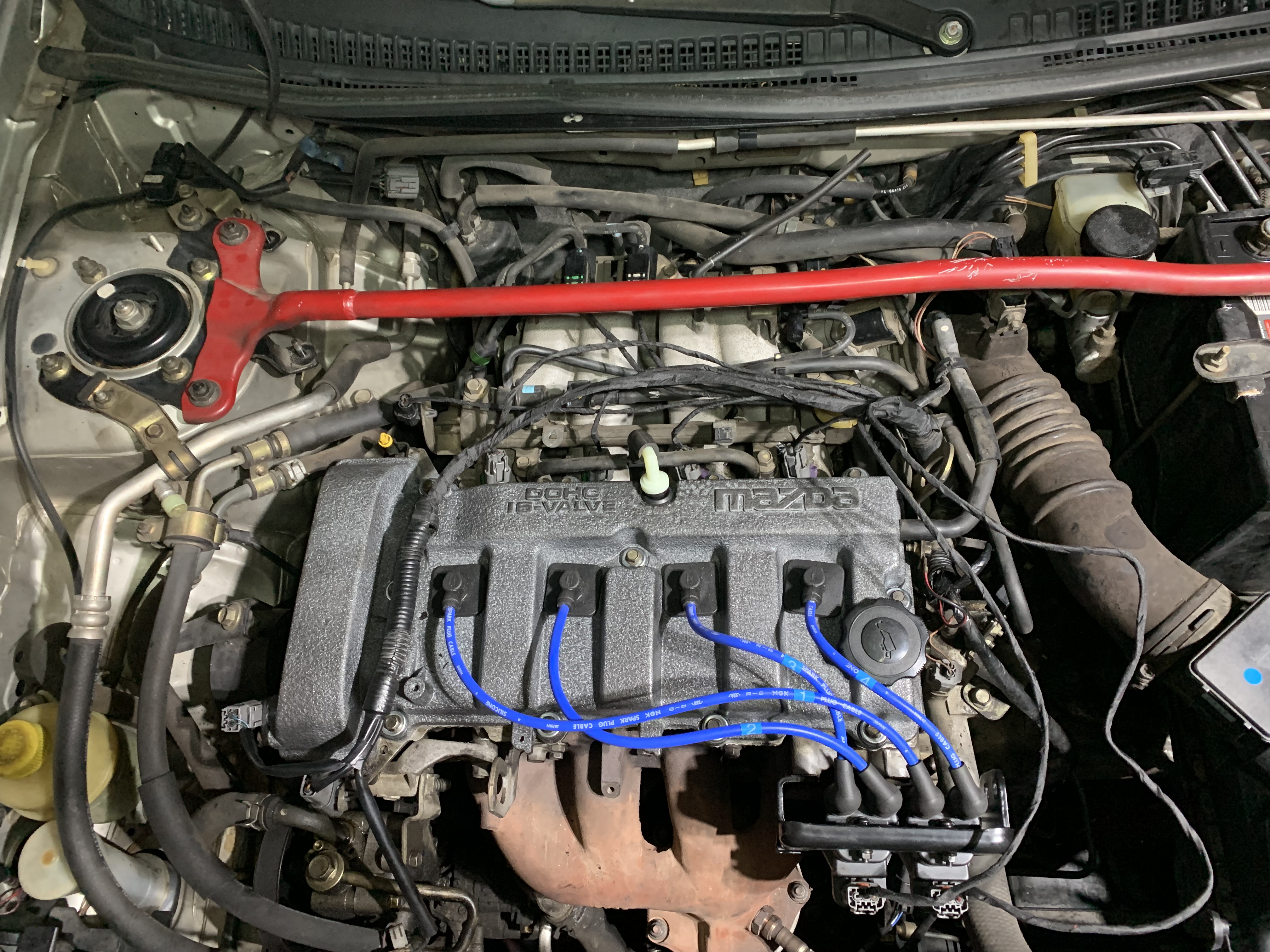

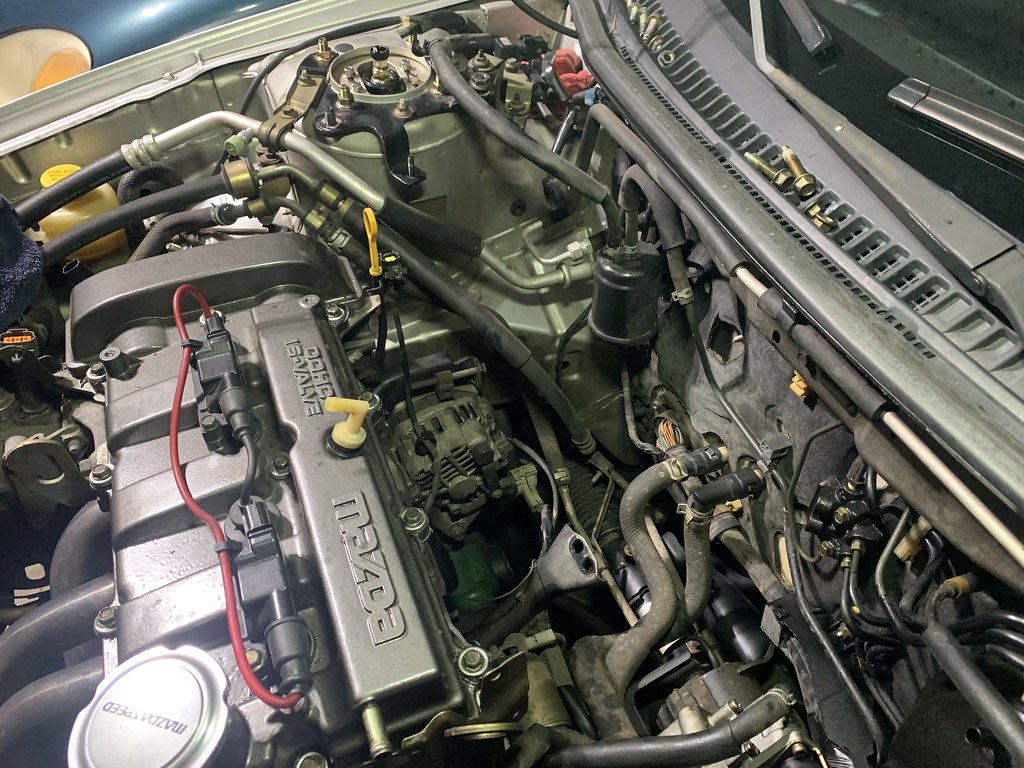

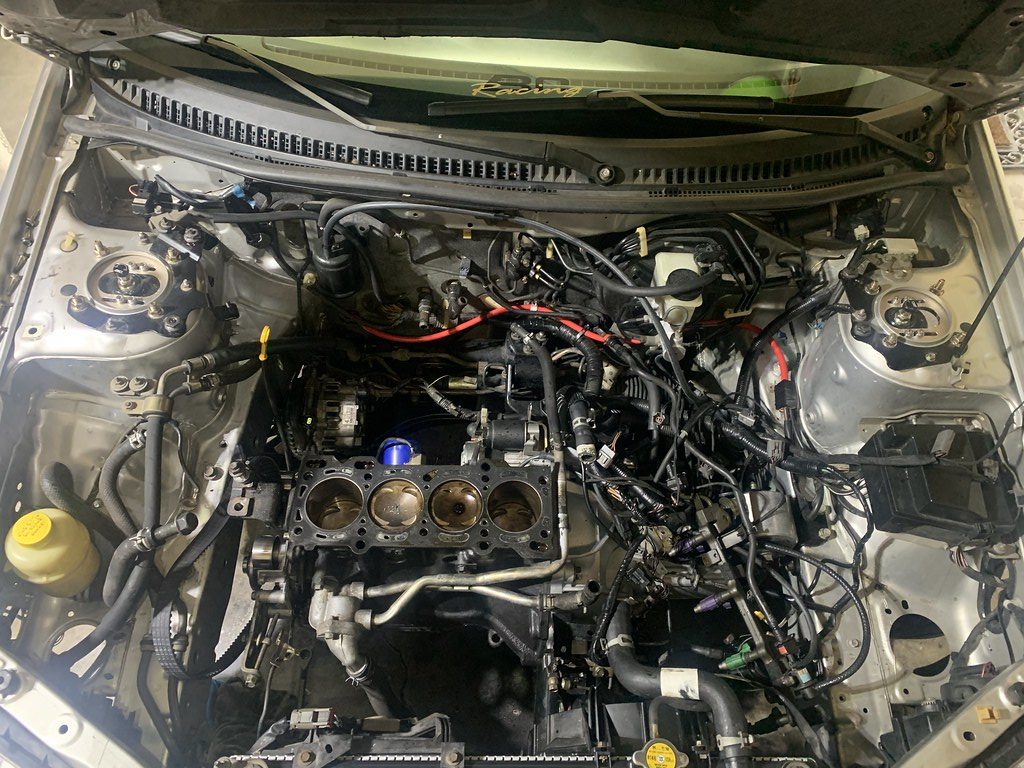

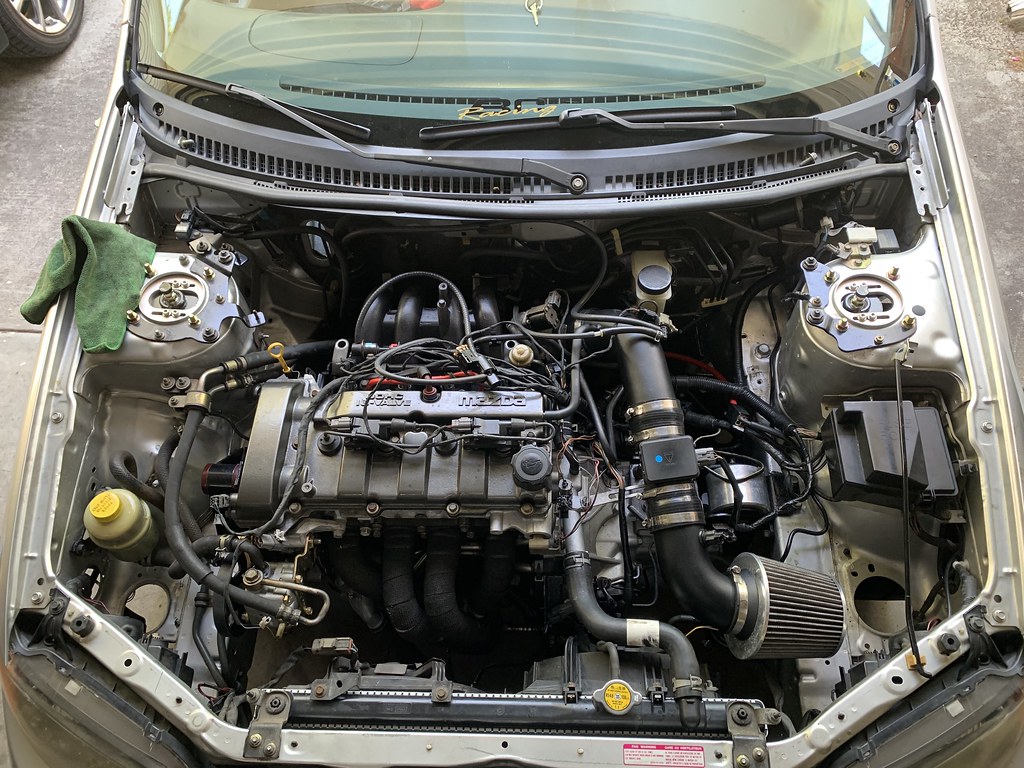

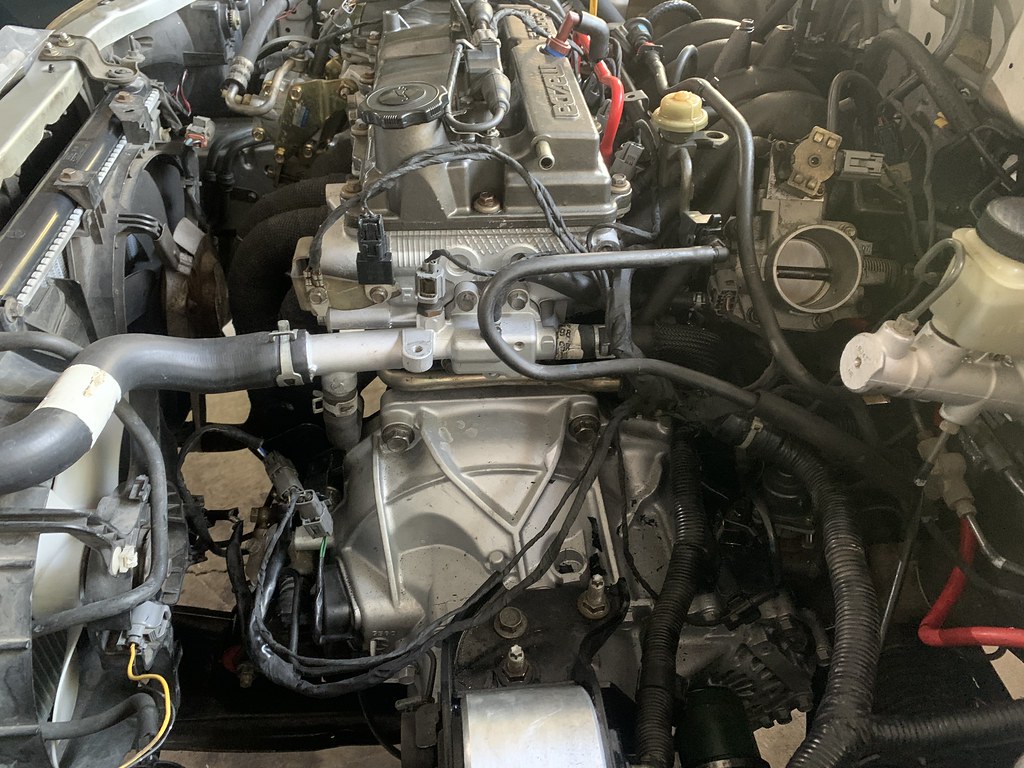

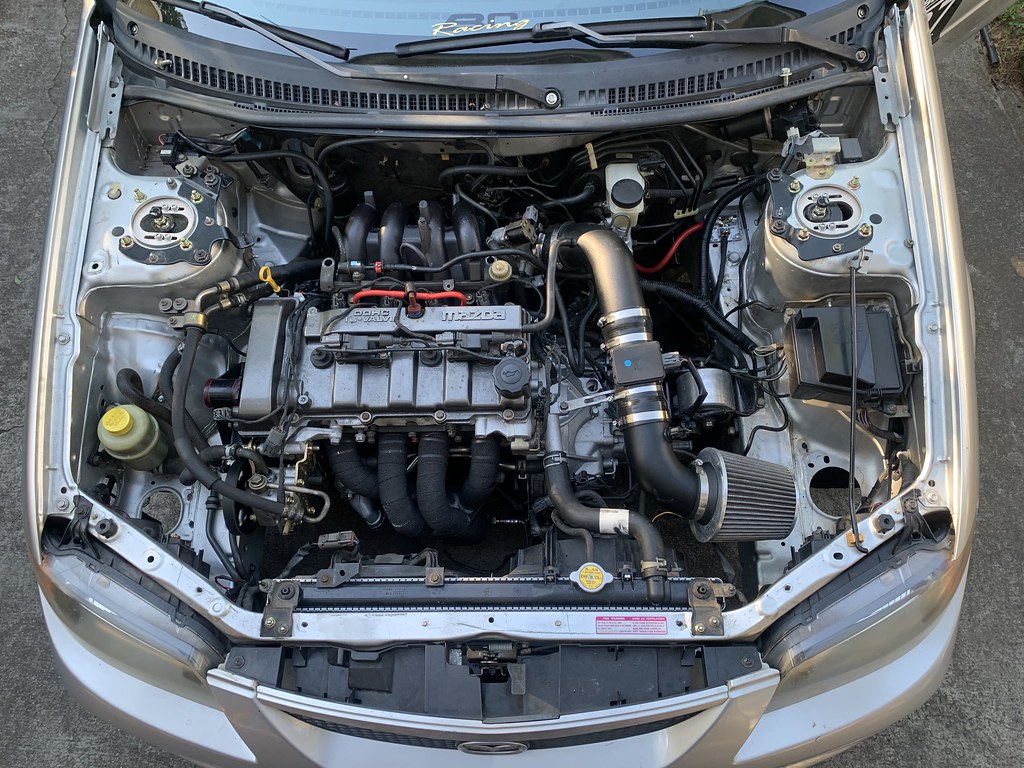

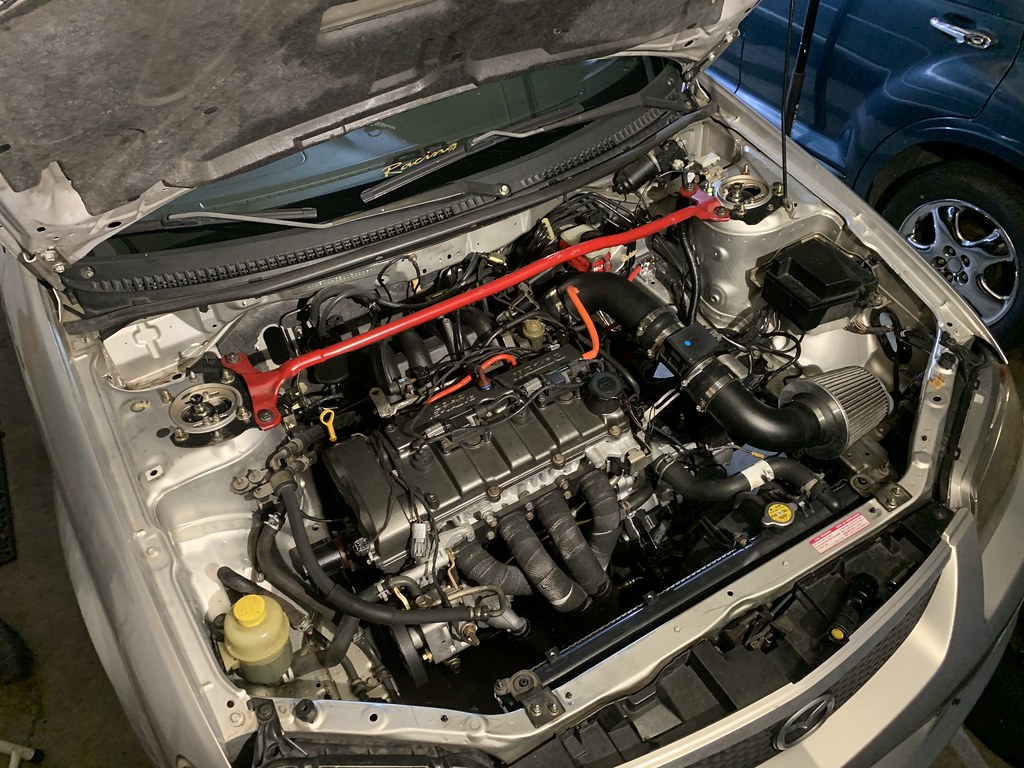

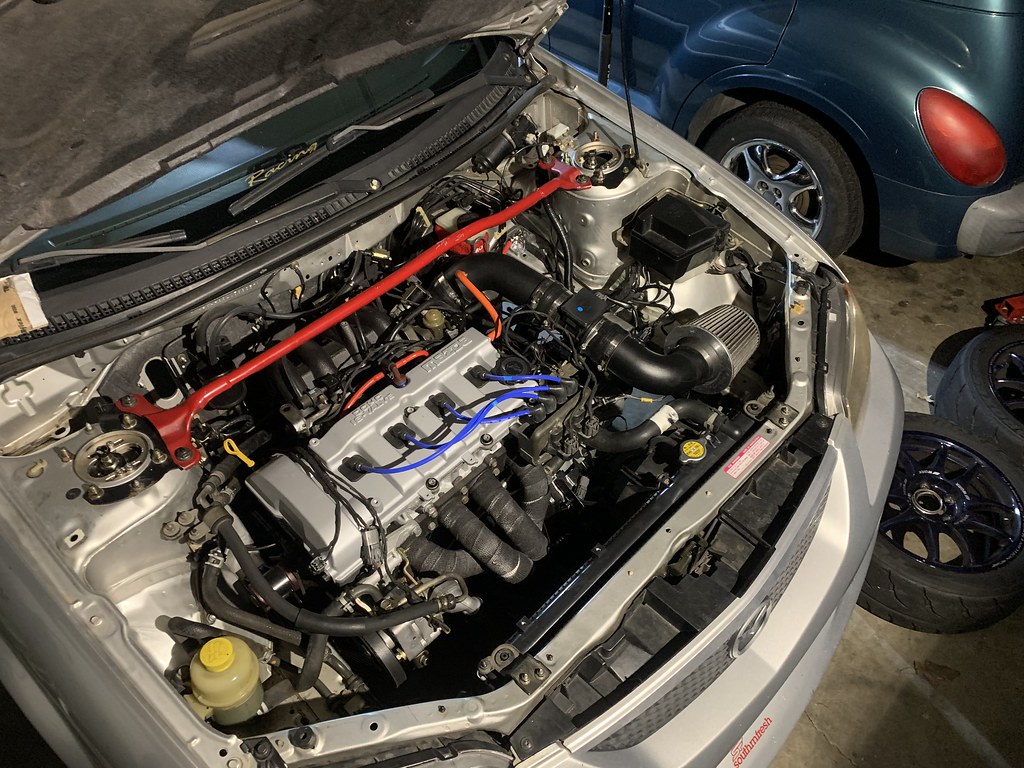

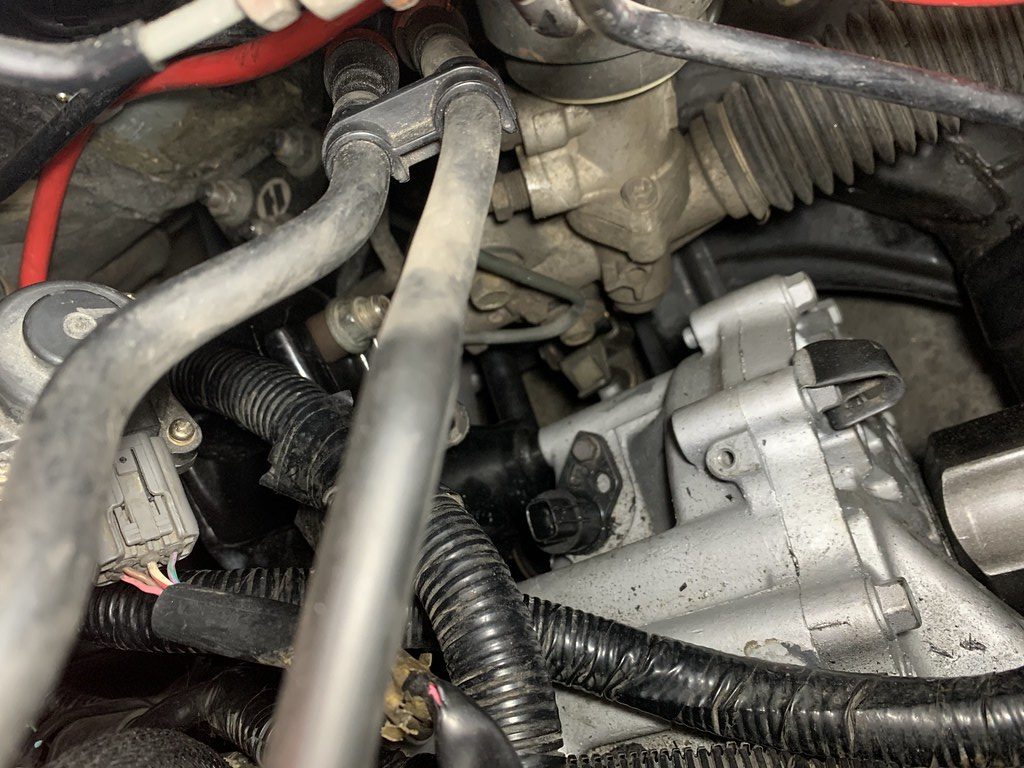

Mazda has always had some of the most cluttered engine bays. So I wanted to clean it up some and make things more accessible. And the car had a real bad valve cover gasket leak that needed to be fixed.

The previous owner said he just replaced the plugs and wires, but I always feel the need to replace them on any new car just because.

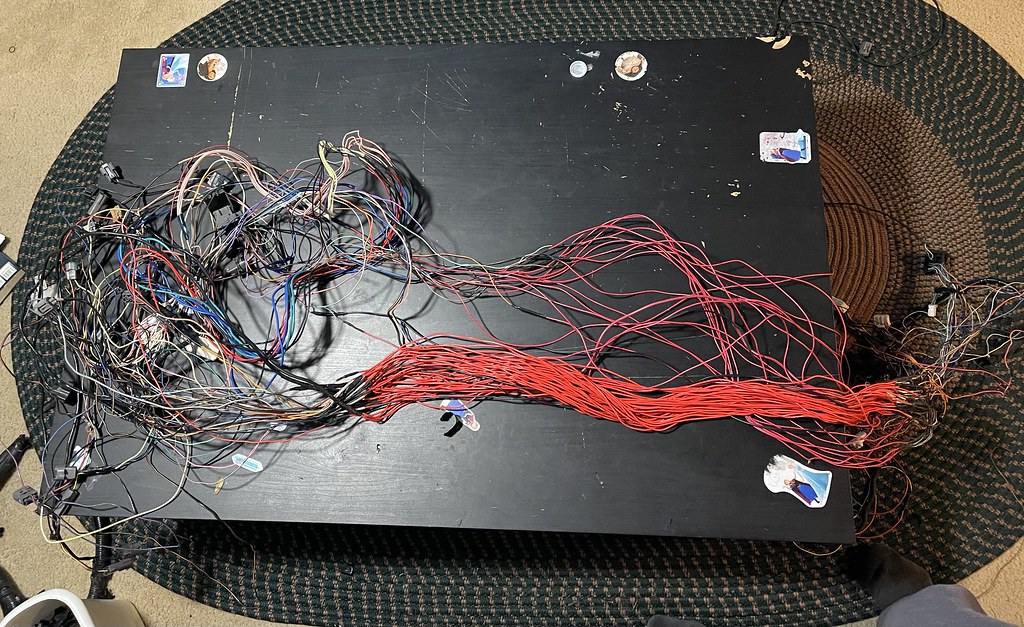

To get rid of some of the clutter, you can convert the ignition system from a shared 2 coil setup to a individual coil setup. But it requires a 626 valve cover, and a coil and wire from a earlier model 1.8 Protege. You simply unwrap the coil pack harness, and it gives you more space for you to use the setup.

Pretty simple modification, which has no proven performance gain, but it simplifies things and removes all the clutter on the valve cover.

Pretty simple modification, which has no proven performance gain, but it simplifies things and removes all the clutter on the valve cover.  Once its all done, I wrapped up the wire in harness fabric tape.

Once its all done, I wrapped up the wire in harness fabric tape.

The only thing is the extra long coil wire on the right, but that will be handled later. Total this cost $94 and Valve cover Gasket with parts from Rockauto.

The only thing is the extra long coil wire on the right, but that will be handled later. Total this cost $94 and Valve cover Gasket with parts from Rockauto.

-

- 2002 Mazda Protege 5: $1200.00

- Mazda 6 brake upgrade: $90

- Coil pack conversion and valve cover gasket: $94

- Total: $1384

After getting those things taken care of, I felt better about driving the car on the street and really see how the car drove on the road. Next we get on to the wheels / tires and suspension..

Thanks for reading! Comments, suggestions, recommendations are welcome in the comment section or via email.

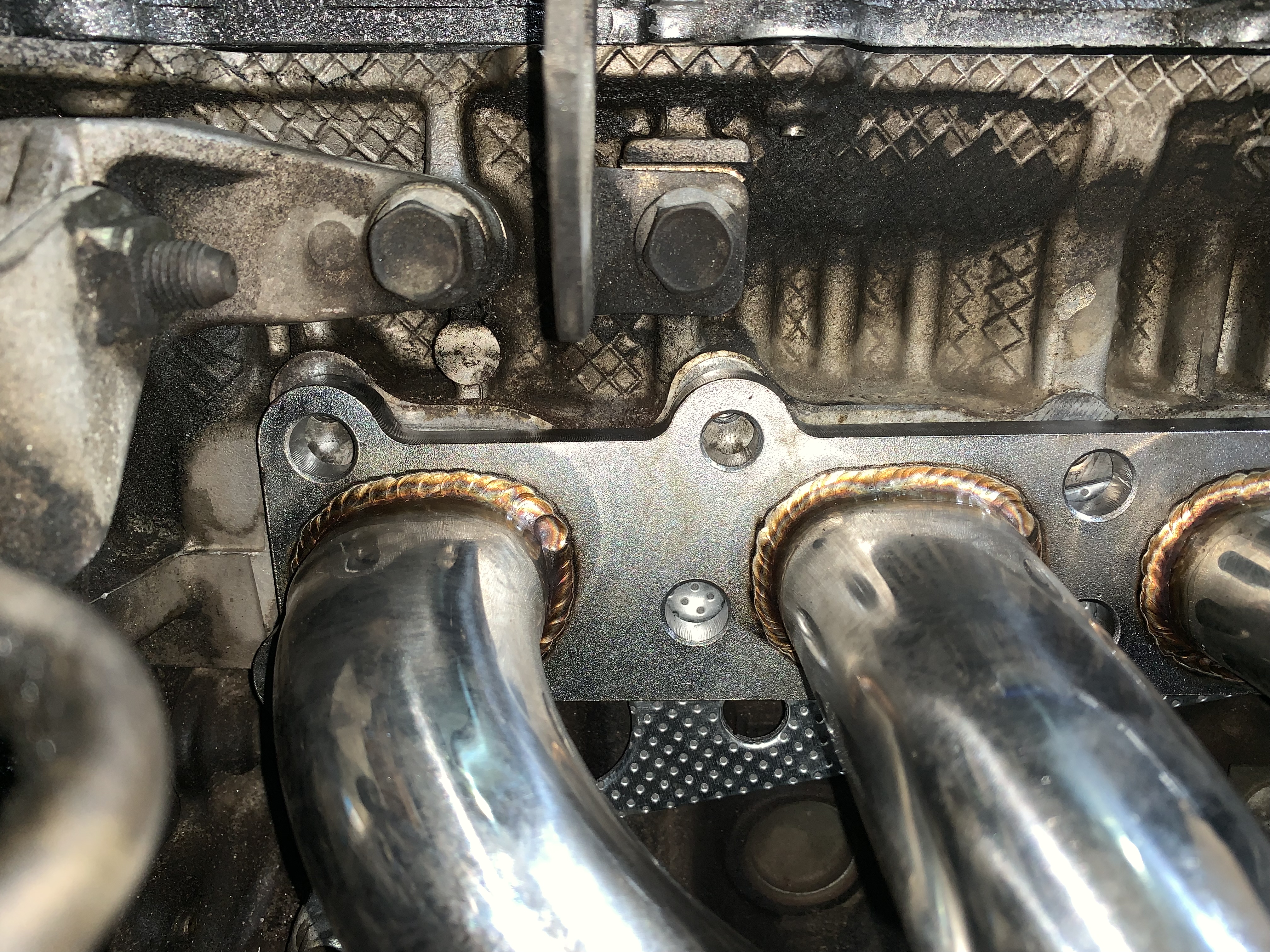

One of the issues that previous owner told me about was the catalytic converter code the car had, so the best solution was a header. There are not many companies making bolt-ons for these cars, so budget in mind and saving money when possible. I decided to go with the cheapest header I could find on ebay. I found one for $56 free shipping, it arrived a few weeks later, and this is the result. A decent piece of metal in the shape of what should be a header. I at the minimum expected E36 M3ty welds, and eventually having to have it repaired several times.

One of the issues that previous owner told me about was the catalytic converter code the car had, so the best solution was a header. There are not many companies making bolt-ons for these cars, so budget in mind and saving money when possible. I decided to go with the cheapest header I could find on ebay. I found one for $56 free shipping, it arrived a few weeks later, and this is the result. A decent piece of metal in the shape of what should be a header. I at the minimum expected E36 M3ty welds, and eventually having to have it repaired several times. The second problem is that the header either fits the head, or the exhaust. In this photo the header is bolted to the exhaust, and it does not line up to the head.

The second problem is that the header either fits the head, or the exhaust. In this photo the header is bolted to the exhaust, and it does not line up to the head.  This photo shows the header installed on the head, and it does not line up with the exhaust at all. I thought it may work with a aftermarket exhaust, but you can also see it forcefully resting on the oil pan. After about 45 mins of thinking of ways to make this thing work. I went on Ebay, and setup the header for a return, and as of today it has been returned and I have been refunded. I was forced to re install the OE manifold and Catalytic converter back on... so to be continued on the header situation.

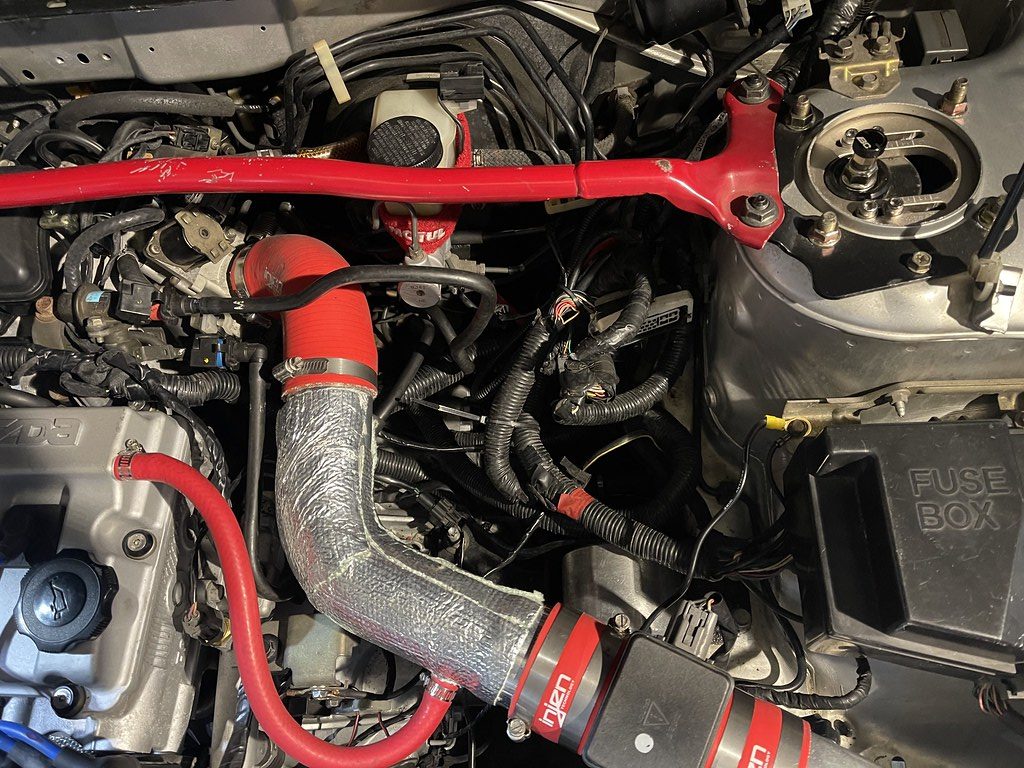

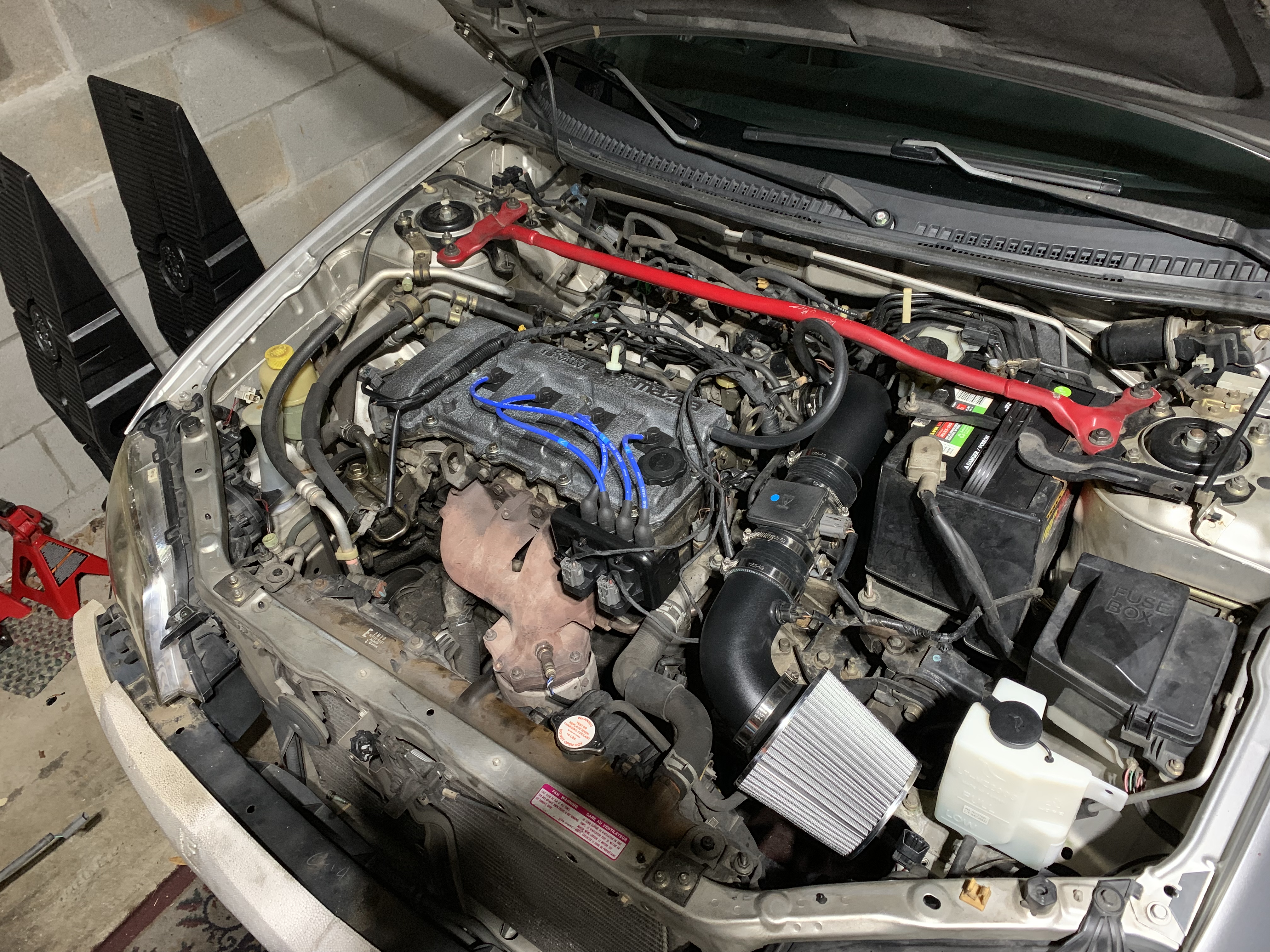

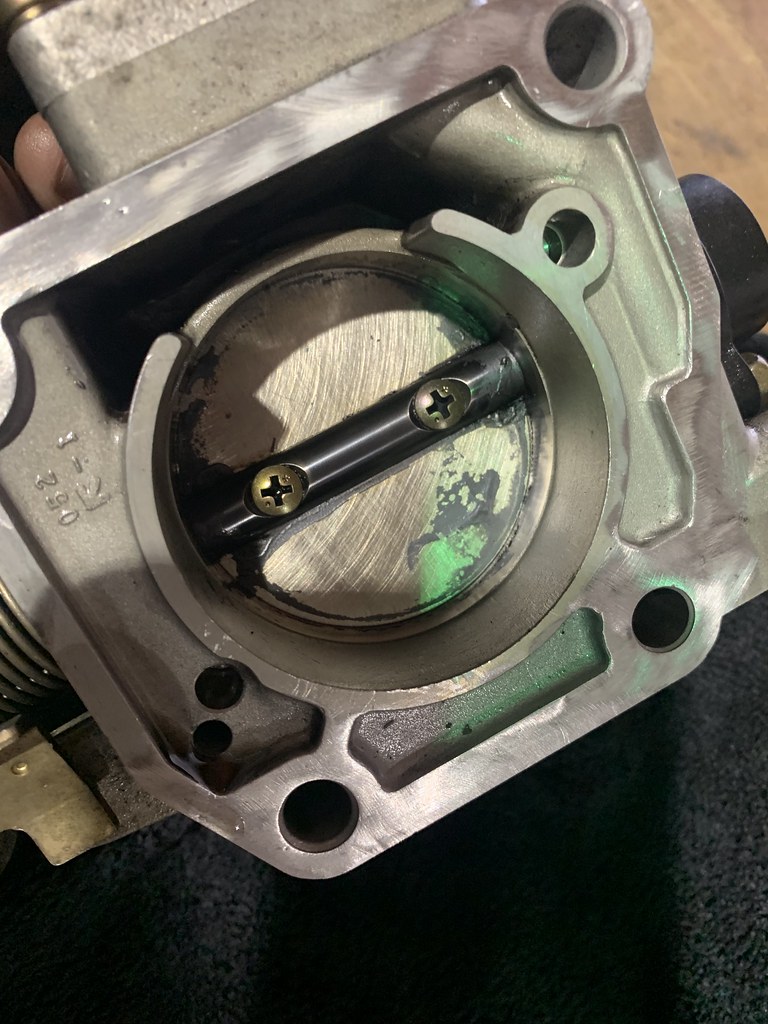

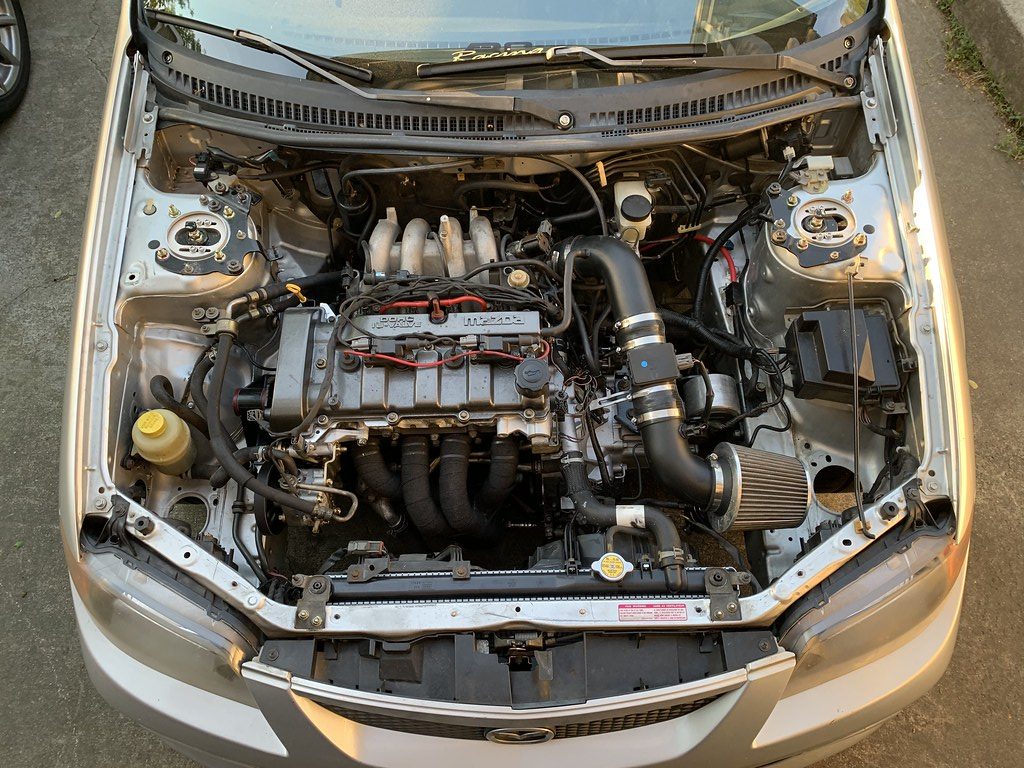

This photo shows the header installed on the head, and it does not line up with the exhaust at all. I thought it may work with a aftermarket exhaust, but you can also see it forcefully resting on the oil pan. After about 45 mins of thinking of ways to make this thing work. I went on Ebay, and setup the header for a return, and as of today it has been returned and I have been refunded. I was forced to re install the OE manifold and Catalytic converter back on... so to be continued on the header situation. I tried my luck again with eBay with the intake. Injen and AEM make intakes for these cars, that are known to fit, but they are more then what I wanted to spend. So I found a cheap ebay intake for $31 shipped. It came with a crazy heat shield that I did not install. But the intake very well and was straight forward and it fit pretty well for the price, I will more then likely swap out the filter later on.

I tried my luck again with eBay with the intake. Injen and AEM make intakes for these cars, that are known to fit, but they are more then what I wanted to spend. So I found a cheap ebay intake for $31 shipped. It came with a crazy heat shield that I did not install. But the intake very well and was straight forward and it fit pretty well for the price, I will more then likely swap out the filter later on.  Foggy headlights have always been a pet peeve of mine, and the plastic headlights on the Protege are known for yellowing. My first thought was to get a cheap set online, but I could not find a new set for a reasonable price. The regular protege single beam headlights are under $100 , but the dual beam P5 ones are still a little pricey.

Foggy headlights have always been a pet peeve of mine, and the plastic headlights on the Protege are known for yellowing. My first thought was to get a cheap set online, but I could not find a new set for a reasonable price. The regular protege single beam headlights are under $100 , but the dual beam P5 ones are still a little pricey.  I got lucky and found a set of used headlights from a guy on Facebook for $100. He said they were the Japanese version headlights, but I really did not care. I just wanted something in better condition. They ended up being different from what we offer in the US, and possibly Japanese market. I am very familiar with these cars, but the Protege 5 was a really popular car and sold all over the world with pretty much the same parts, so its hard to truly tell what region these headlights are from. The bulb for the high beam was totally different, and it has a city light in the high beam also. The low beam and turn signals work fine, but I will have to wire the high beams and city light in later to get them to work.

I got lucky and found a set of used headlights from a guy on Facebook for $100. He said they were the Japanese version headlights, but I really did not care. I just wanted something in better condition. They ended up being different from what we offer in the US, and possibly Japanese market. I am very familiar with these cars, but the Protege 5 was a really popular car and sold all over the world with pretty much the same parts, so its hard to truly tell what region these headlights are from. The bulb for the high beam was totally different, and it has a city light in the high beam also. The low beam and turn signals work fine, but I will have to wire the high beams and city light in later to get them to work.  I also found a deal on the Falken Azenis RT615k for track duty. Found a set of new old 2017 stock for $360.

I also found a deal on the Falken Azenis RT615k for track duty. Found a set of new old 2017 stock for $360.  I had been debating on if I should stick with a 16" wheel and save as much weight as possible. But I did some research on wheels that are affordable and lightweight that can hold up to track use. And did not want to take a chance of old ancient JDM relics that would need work to look decent and be safe for track duty.

I had been debating on if I should stick with a 16" wheel and save as much weight as possible. But I did some research on wheels that are affordable and lightweight that can hold up to track use. And did not want to take a chance of old ancient JDM relics that would need work to look decent and be safe for track duty.  The overall look of the gloss graphite ultraforms looked great on the car, but were a little too aggressive for the P5.

The overall look of the gloss graphite ultraforms looked great on the car, but were a little too aggressive for the P5.  Another thing with the P5 is how the rear of the car is more narrow then the front. So you can really see how much they poked.

Another thing with the P5 is how the rear of the car is more narrow then the front. So you can really see how much they poked.  I decided to change up from the gloss graphite Konig Ultragram to the red opal Hypergram in 17x8 +35 for $720

I decided to change up from the gloss graphite Konig Ultragram to the red opal Hypergram in 17x8 +35 for $720

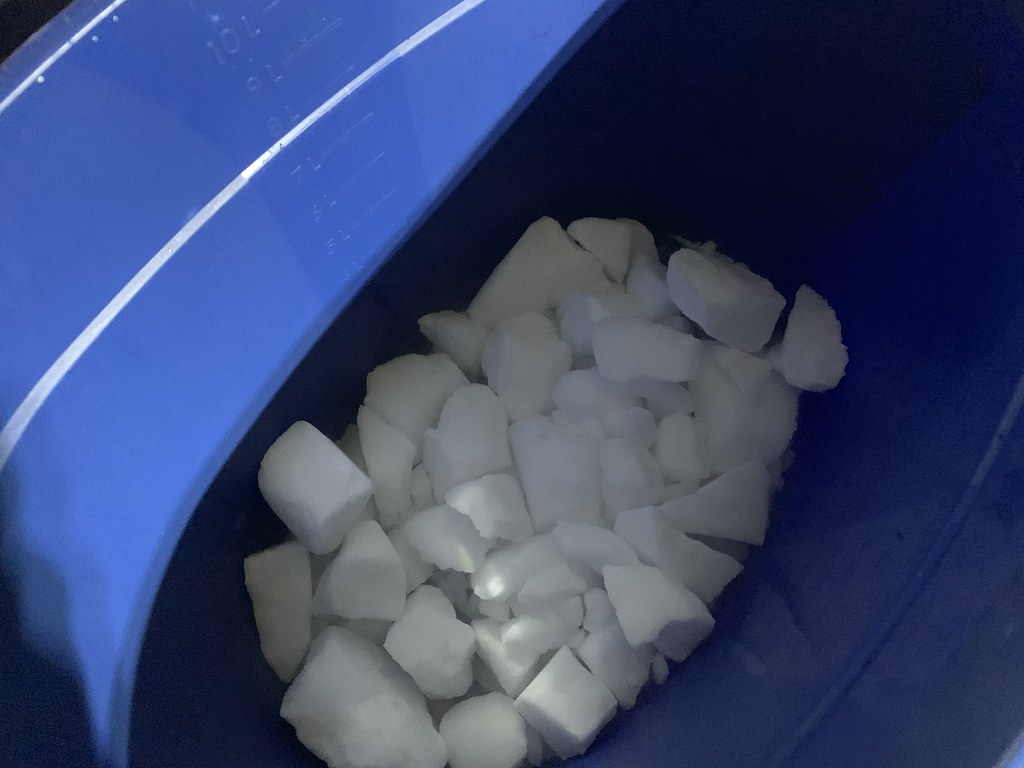

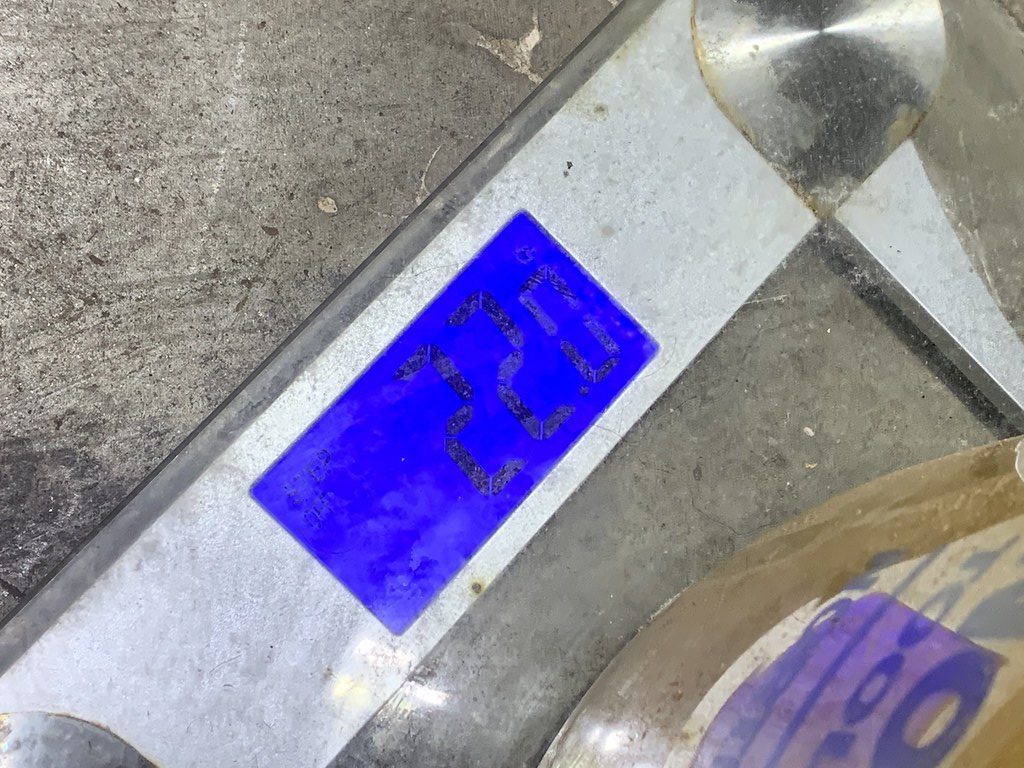

The 17x8 Hypergrams are also lighter then the 17x9 ultragrams by 2 lbs at 16.3lbs. With the tire mounted and aired up to 36psi, it came up to 37lbs even. I would highly suggest the

The 17x8 Hypergrams are also lighter then the 17x9 ultragrams by 2 lbs at 16.3lbs. With the tire mounted and aired up to 36psi, it came up to 37lbs even. I would highly suggest the

The rear section ended up being a little too close to the frame, so I had it modified a little so it would not touch, until I replace it. I am driving the car as much as possible now, and plan to try and take it on a trip up to the dragon before the track day. So hopefully next up date we can finish up the suspension and replace some of the worn bushings and get some fresh fluids.

The rear section ended up being a little too close to the frame, so I had it modified a little so it would not touch, until I replace it. I am driving the car as much as possible now, and plan to try and take it on a trip up to the dragon before the track day. So hopefully next up date we can finish up the suspension and replace some of the worn bushings and get some fresh fluids. Corksport is one of the few vendors still making parts for the P5 Chassis. Most FWD Mazdas have long throw shifters, and one of the weak spots is the rubber bushings in the shift linkage, so its a must to replace them.

Corksport is one of the few vendors still making parts for the P5 Chassis. Most FWD Mazdas have long throw shifters, and one of the weak spots is the rubber bushings in the shift linkage, so its a must to replace them. Old bushings in transmission side of the linkage.

Old bushings in transmission side of the linkage. Rubber and Corksport bronze oil bushings .

Rubber and Corksport bronze oil bushings . Bushings installed on trans side.

Bushings installed on trans side. The second part of the kit has comes with the bushings and bolt for the shifter linkage side. But they are riveted into the shifter. You are supposed to drill it out from the inside. But I did it the wrong way, and tried to shave the top and knock it out. It did not work, and I ended up cutting off the head of the bolt from the inside and knocking it out that way.

The second part of the kit has comes with the bushings and bolt for the shifter linkage side. But they are riveted into the shifter. You are supposed to drill it out from the inside. But I did it the wrong way, and tried to shave the top and knock it out. It did not work, and I ended up cutting off the head of the bolt from the inside and knocking it out that way. Shifter linkage bolt and bushing out of the linkage.

Shifter linkage bolt and bushing out of the linkage. New Corksport bronze oil shifter bushing kit

New Corksport bronze oil shifter bushing kit New bushings and bolt installed.

New bushings and bolt installed. Next was the short shifter .

Next was the short shifter . I searched for weeks to find a old TWM short shifter. But no luck, so I found a Razo short shift kit on eBay for a decent price.

I searched for weeks to find a old TWM short shifter. But no luck, so I found a Razo short shift kit on eBay for a decent price. The kit fit good, and made a huge difference in shift throw.

The kit fit good, and made a huge difference in shift throw. Kit even came with a spacer for the exhaust heat shield.

Kit even came with a spacer for the exhaust heat shield. Next was the gear oil, It did not look or smell as bad as I thought it would. But I had no idea when the last time it had been serviced.

Next was the gear oil, It did not look or smell as bad as I thought it would. But I had no idea when the last time it had been serviced. Most people swear by the Redline MT-90 Gear oil, so I gave it a shot. And it seems to have made my slight 3rd gear grind a little smoother, but doing the shift linkage bushings, short shifter may have had something to do with it as well.

Most people swear by the Redline MT-90 Gear oil, so I gave it a shot. And it seems to have made my slight 3rd gear grind a little smoother, but doing the shift linkage bushings, short shifter may have had something to do with it as well. The next thing was correcting the oil starvation issue these motors are plagued with. The oil baffle system on the Mazda FS , is not built for any sort of spirited driving. The best way to resolve the problem is to either replace the pan with one of the few aftermarket oil pans that comes with an improved baffle setup to help.

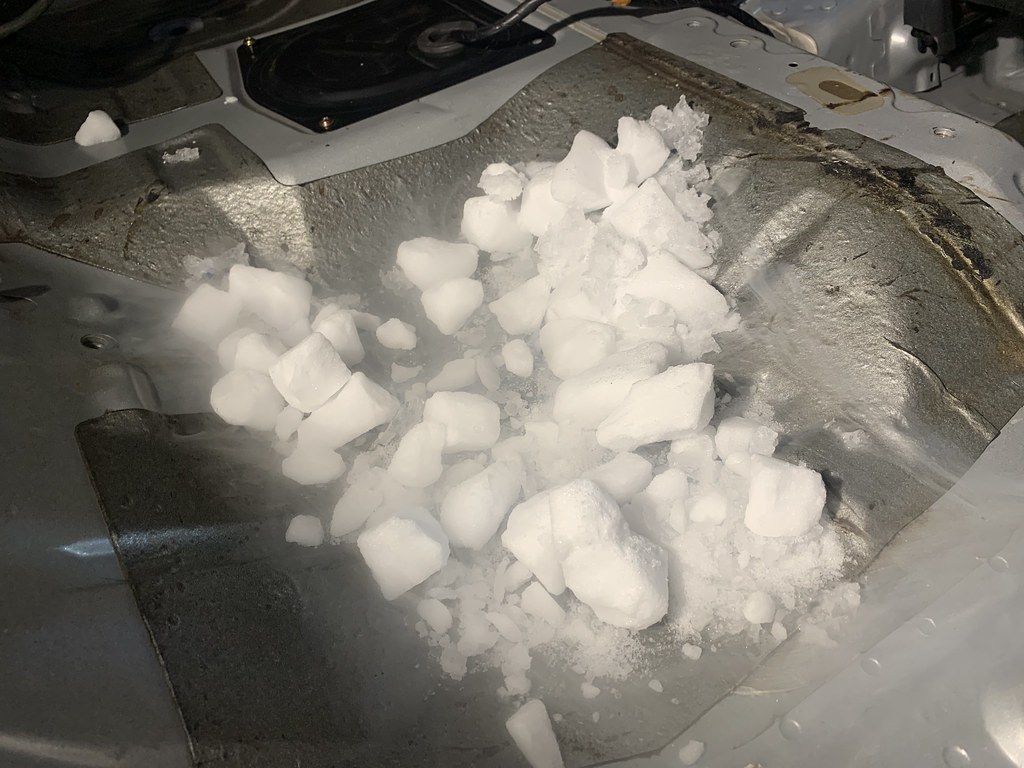

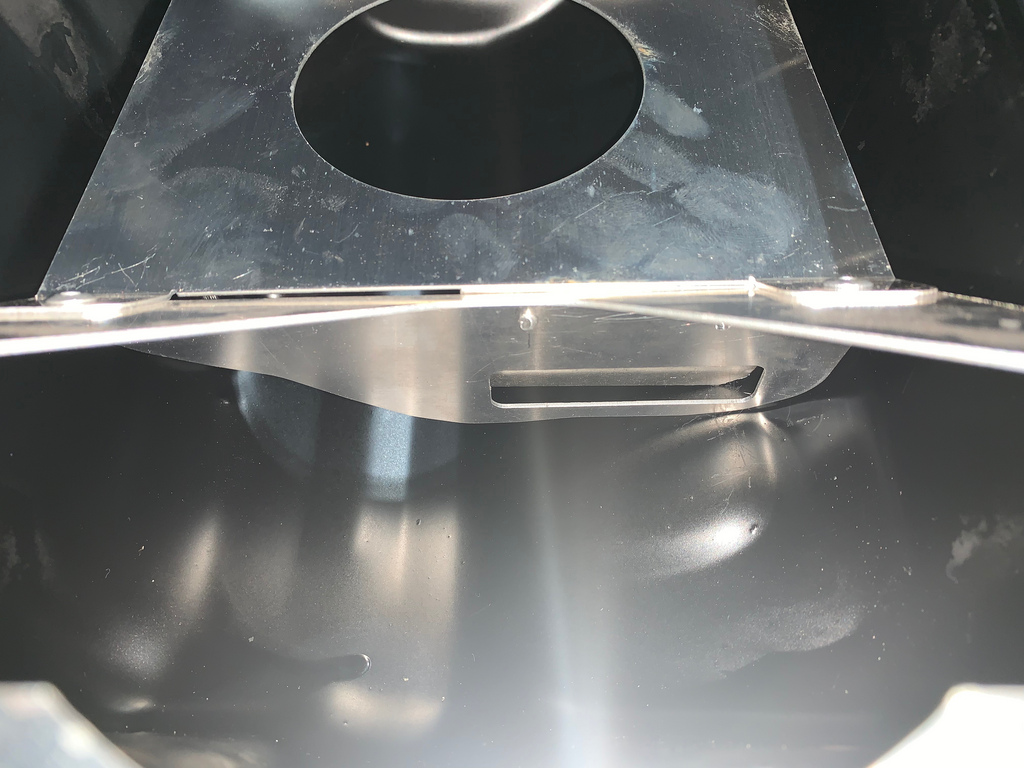

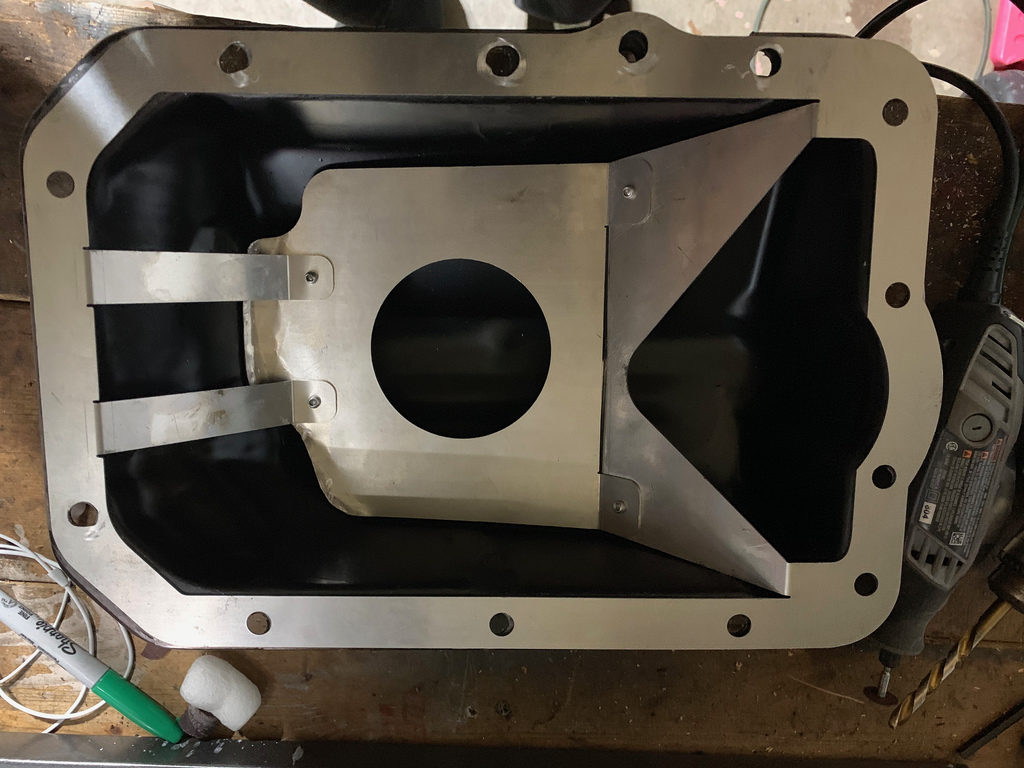

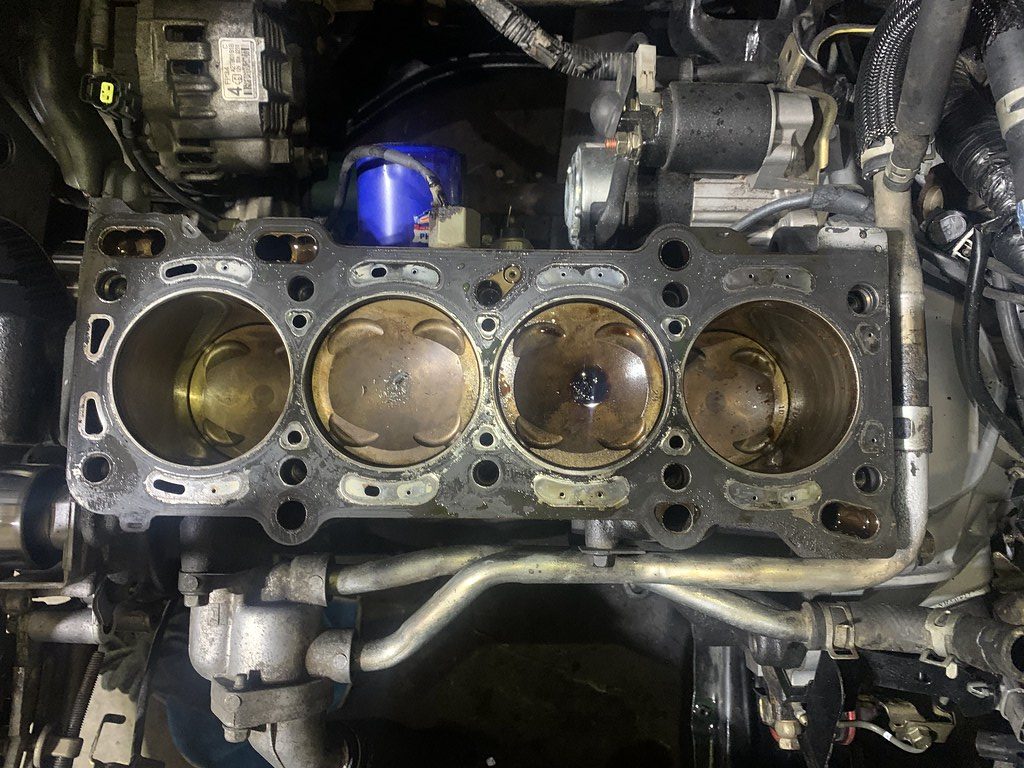

The next thing was correcting the oil starvation issue these motors are plagued with. The oil baffle system on the Mazda FS , is not built for any sort of spirited driving. The best way to resolve the problem is to either replace the pan with one of the few aftermarket oil pans that comes with an improved baffle setup to help. I wanted to keep a budget so I opted to go with a oil baffle insert that just lays inside of the oil pan. You can see the trap door that keeps oil from going back away from the oil pickup.

I wanted to keep a budget so I opted to go with a oil baffle insert that just lays inside of the oil pan. You can see the trap door that keeps oil from going back away from the oil pickup. You can see in the oil pan that there is not any sort of baffle in the lower pan to keep the oil centered by the oil pickup. In order to install the oil [an baffle , the factory baffle has to be removed.

You can see in the oil pan that there is not any sort of baffle in the lower pan to keep the oil centered by the oil pickup. In order to install the oil [an baffle , the factory baffle has to be removed. Again my friends at Atlanta Speed Company took care of me and I got the oe oil pan baffle removed.

Again my friends at Atlanta Speed Company took care of me and I got the oe oil pan baffle removed. As you can see in the photo , the baffle appeared to be made incorrectly. Its almost like it was made backwards. I should of known that this would happen, because no one had ever installed one, and there were no instructions or information about them online. Years ago people would just replace it with the upgraded oil pan, which also had fitment problems. So I did not wanna take the chance and spend the extra cash for something that may not fit right. I spoke with the vendor and they took it back, and said they would get it redone and built right.

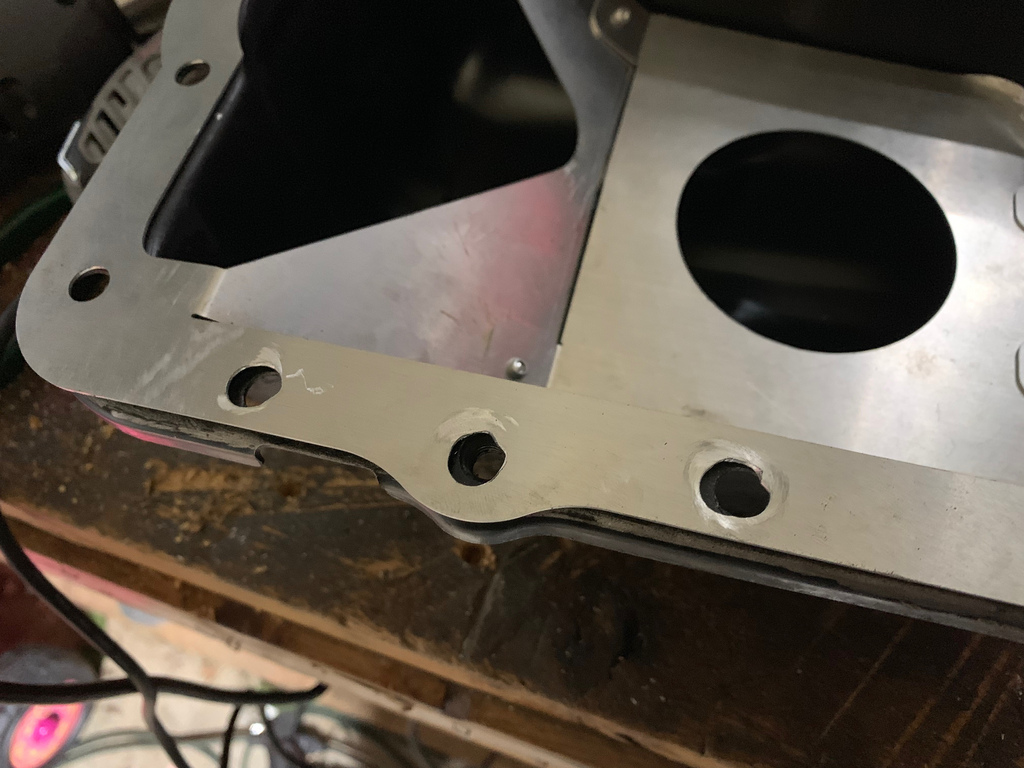

As you can see in the photo , the baffle appeared to be made incorrectly. Its almost like it was made backwards. I should of known that this would happen, because no one had ever installed one, and there were no instructions or information about them online. Years ago people would just replace it with the upgraded oil pan, which also had fitment problems. So I did not wanna take the chance and spend the extra cash for something that may not fit right. I spoke with the vendor and they took it back, and said they would get it redone and built right. After a week, I got it back. And it still had some weird fitment issues. In this photos you can see that the holes were off.

After a week, I got it back. And it still had some weird fitment issues. In this photos you can see that the holes were off. The edges that laid in the pan were much better, but still off as you can see. So the insert could not sit flush on the edges.

The edges that laid in the pan were much better, but still off as you can see. So the insert could not sit flush on the edges. The shelf portion of the baffle was also shaped wrong.

The shelf portion of the baffle was also shaped wrong. At that point I did not have time to have it fixed again for a 2nd time. So I got out some tools to fix the problem and make it fit.

At that point I did not have time to have it fixed again for a 2nd time. So I got out some tools to fix the problem and make it fit. After about a hour and half of bending, trimming , and drilling I managed to get it to fit properly.

After about a hour and half of bending, trimming , and drilling I managed to get it to fit properly. Finally sitting flush. If I had more time, I would have liked to send it back and get it made to fit exact. There is another company that is working on a upgraded oil pan that I am waiting to be released, so when that releases I will change to the whole pan.

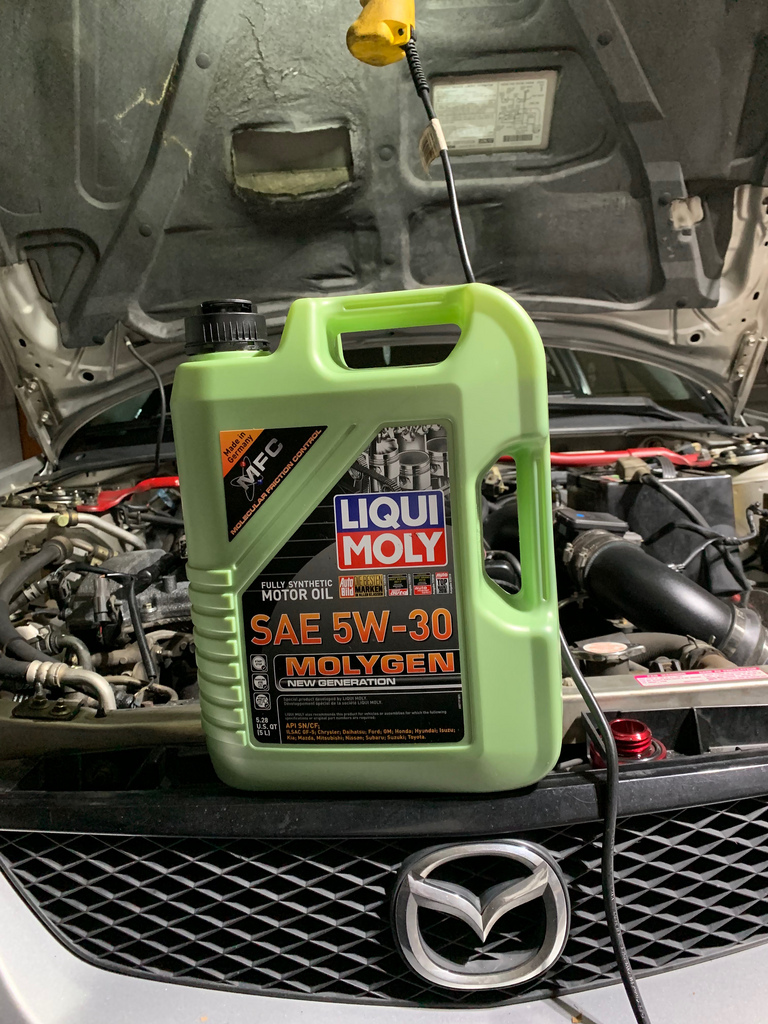

Finally sitting flush. If I had more time, I would have liked to send it back and get it made to fit exact. There is another company that is working on a upgraded oil pan that I am waiting to be released, so when that releases I will change to the whole pan. I also decided to change up to the Liqui Moly - Molygen a try. Since I have heard so much about their new green bottle oil.

I also decided to change up to the Liqui Moly - Molygen a try. Since I have heard so much about their new green bottle oil. And its green.. But I wanted to be sure that the bearings were protected as best possible, and I had absolutely no chances of oil starvation. My only regret was not going with a heavier weight.

And its green.. But I wanted to be sure that the bearings were protected as best possible, and I had absolutely no chances of oil starvation. My only regret was not going with a heavier weight. The cheap exhaust system from eBay fit well, and got the job done as far as being an exhaust. But the car was too loud for me, and sounded terrible. The muffler it came with was pretty much an empty canister.

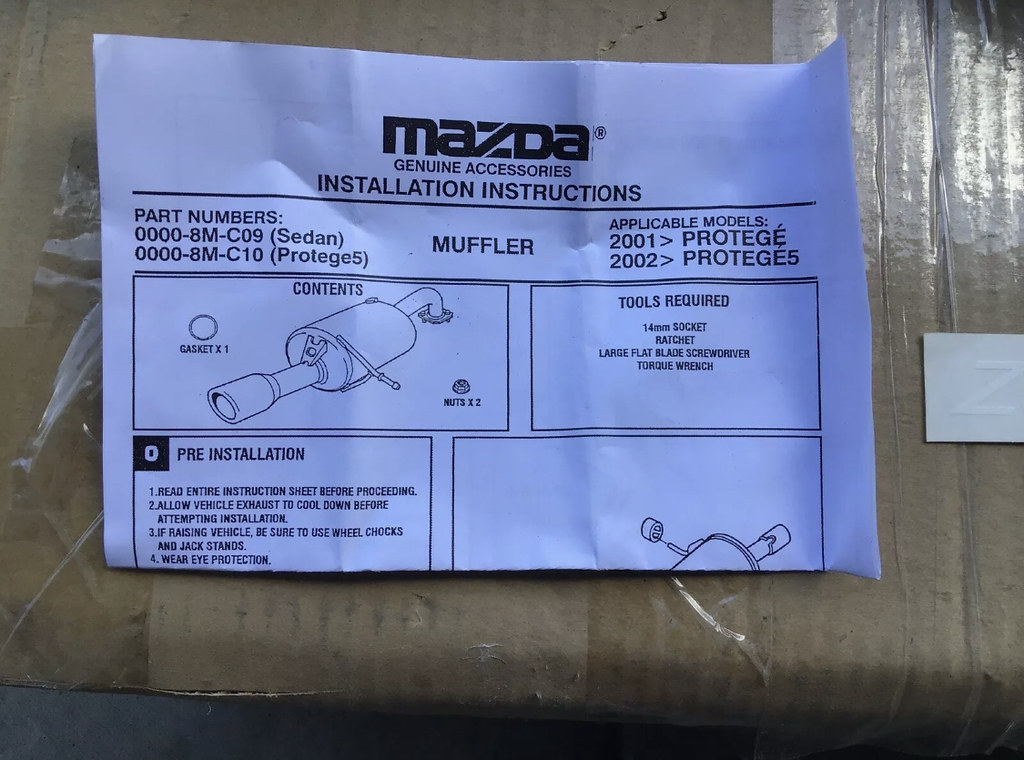

The cheap exhaust system from eBay fit well, and got the job done as far as being an exhaust. But the car was too loud for me, and sounded terrible. The muffler it came with was pretty much an empty canister. I decided to go with a Racing Beat muffler from a Mazdaspeed Protege, to hopefully quiet the car down.

I decided to go with a Racing Beat muffler from a Mazdaspeed Protege, to hopefully quiet the car down.

James at EBtec installing the Muffler. The Protege 5 is not as long as the Protege sedan. So it had to be modified to fit under the bumper

James at EBtec installing the Muffler. The Protege 5 is not as long as the Protege sedan. So it had to be modified to fit under the bumper I also had them remove the catalytic converter.

I also had them remove the catalytic converter. Mid to rear section.

Mid to rear section. The muffler was much quieter, but still a little louder then I would like it. So in the future ill need to add a resonator and flex pipe to it, and possibly replace the muffler in the future.

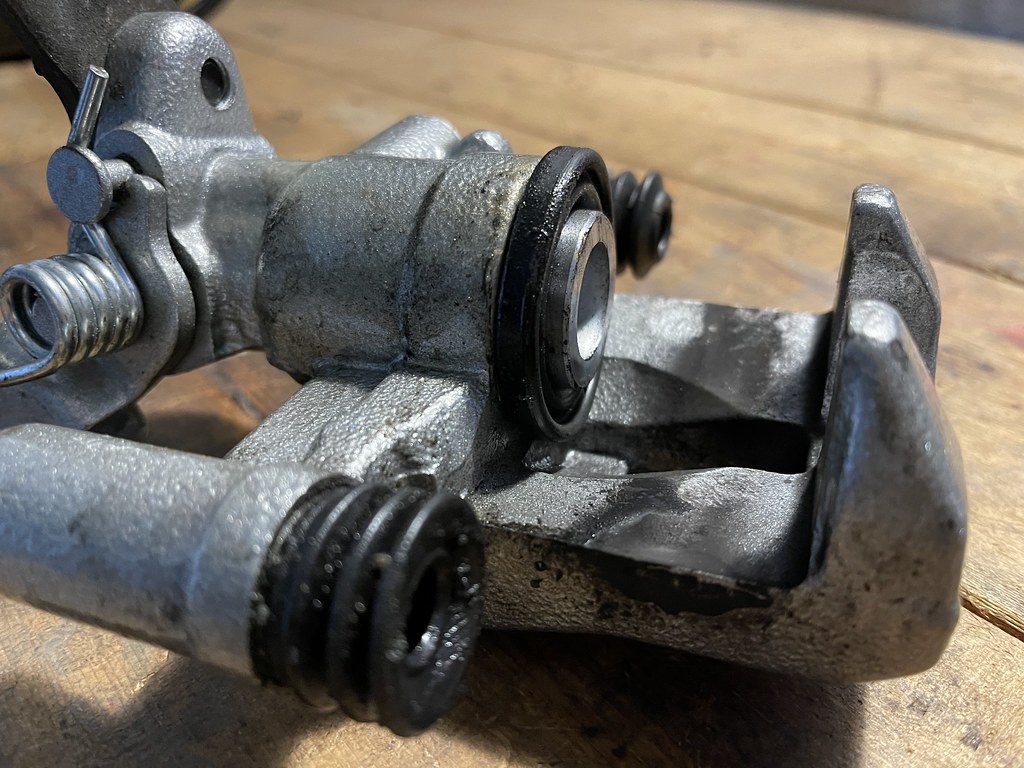

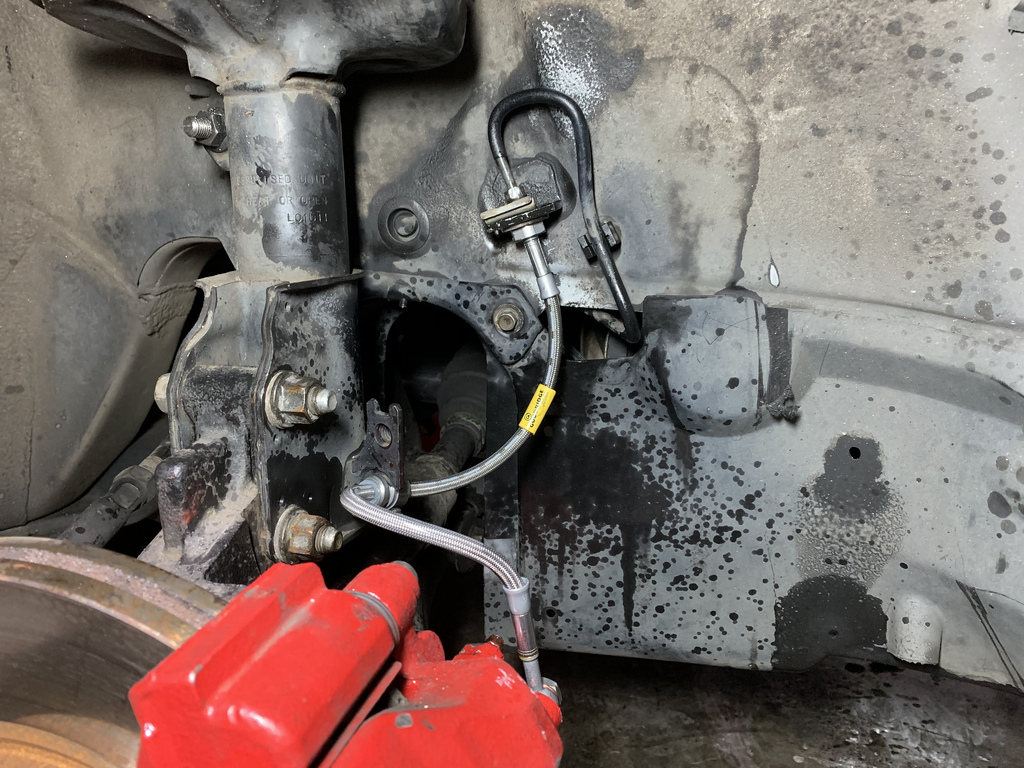

The muffler was much quieter, but still a little louder then I would like it. So in the future ill need to add a resonator and flex pipe to it, and possibly replace the muffler in the future. The next project was changing the brake and clutch lines to stainless steel lines. As mentioned before the car was taken care of by the 2 previous owners, and it looked like one of the rear calipers had been replaced at one point. But if I am going to be putting all confidence into my brakes then I needed to upgrade the brake lines.

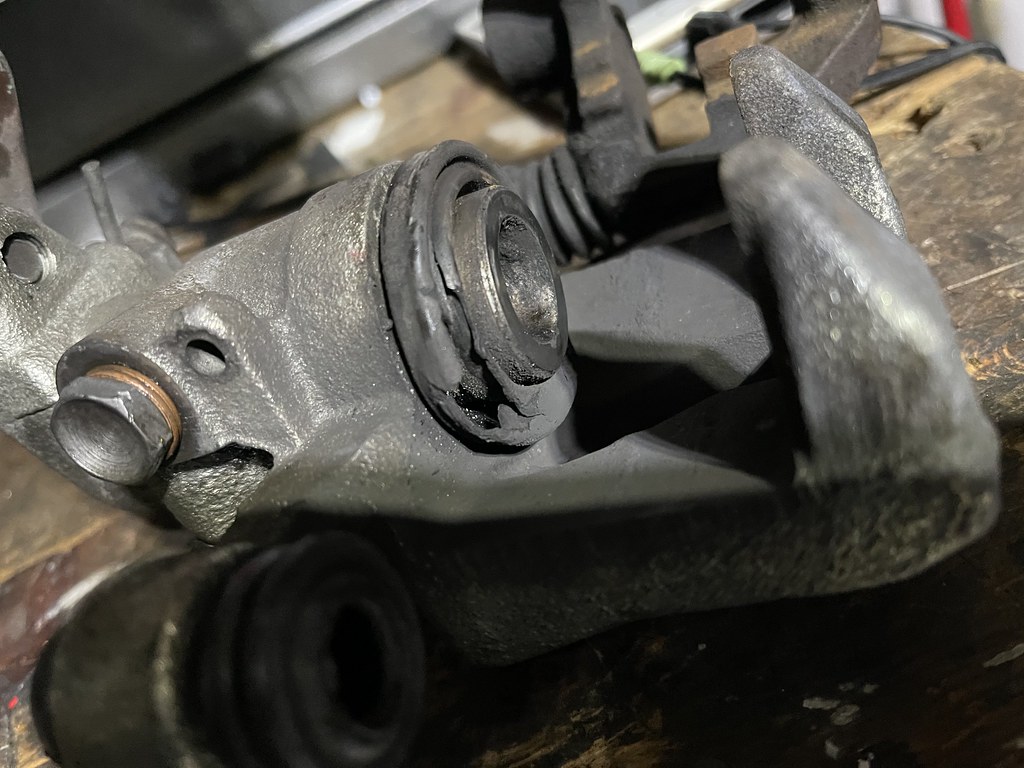

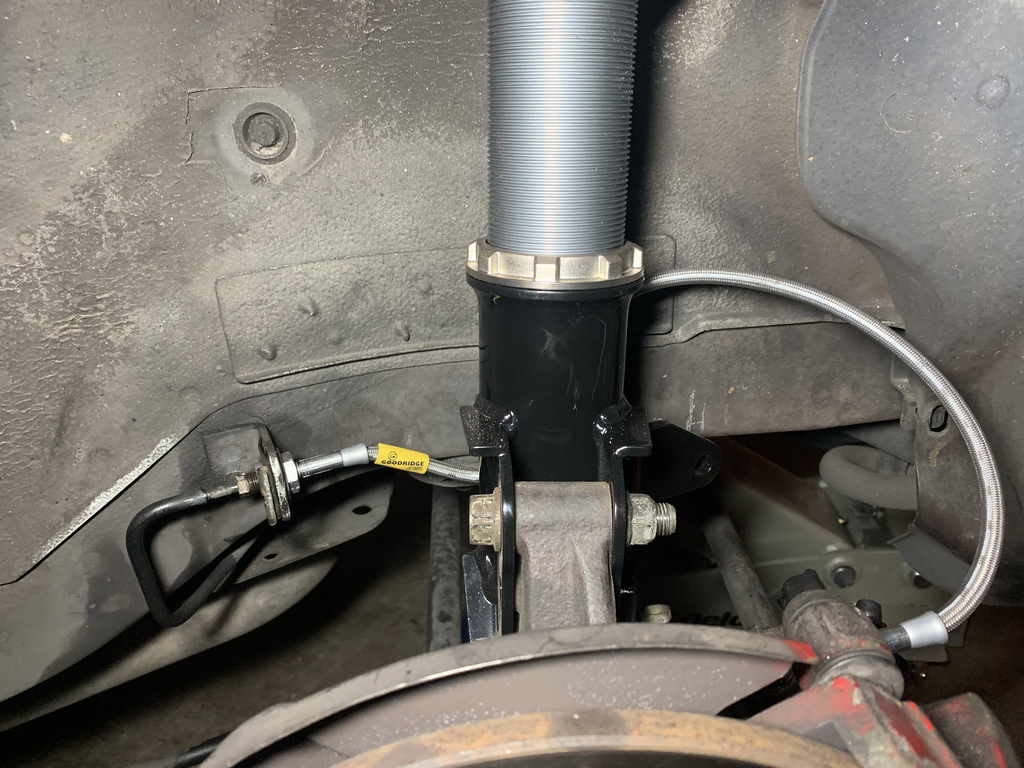

The next project was changing the brake and clutch lines to stainless steel lines. As mentioned before the car was taken care of by the 2 previous owners, and it looked like one of the rear calipers had been replaced at one point. But if I am going to be putting all confidence into my brakes then I needed to upgrade the brake lines. Most of the clutch lines are metal, but a part of it is rubber, and looking at one of the ends, you can see that it could be a potential issue if abused or put under any additional pressure over regular driving.

Most of the clutch lines are metal, but a part of it is rubber, and looking at one of the ends, you can see that it could be a potential issue if abused or put under any additional pressure over regular driving. Went with the Goodridge Stainless Steel lines from

Went with the Goodridge Stainless Steel lines from  I was able to find a matching stainless steel line for the clutch on eBay to match the brake lines.

I was able to find a matching stainless steel line for the clutch on eBay to match the brake lines. Clutch line in

Clutch line in Everything fit well, and went on without a hitch. I had a little trouble with getting the caliper bolt off, and unbolting the bleeder line, so excuse the mess from PB blaster.

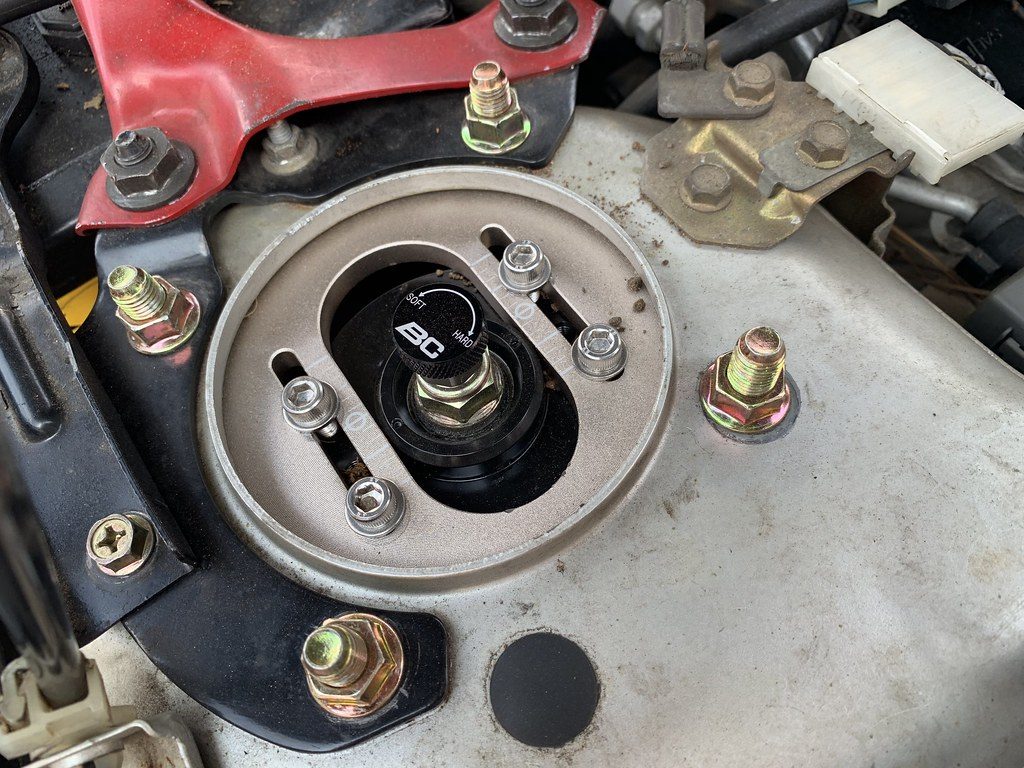

Everything fit well, and went on without a hitch. I had a little trouble with getting the caliper bolt off, and unbolting the bleeder line, so excuse the mess from PB blaster. It was crunch time, and down to the wire, and we still had not gotten coilovers for the car. But Friday afternoon we received our goodies from

It was crunch time, and down to the wire, and we still had not gotten coilovers for the car. But Friday afternoon we received our goodies from  Having worked with BC Racing with my Mazda 6, we decided to run them on the Protege 5. The Mazda 6 was put together to look good, and be low so we used their

Having worked with BC Racing with my Mazda 6, we decided to run them on the Protege 5. The Mazda 6 was put together to look good, and be low so we used their

BC Racing has introduced a new

BC Racing has introduced a new  The Digressive piston shocks provide a slower rebound at higher speeds , and hard cornering, which is perfect for track use. The down side is the alternative to having a slightly harsher ride with daily driving and small bumps at slower speeds. From what I read up about the two styles, it seemed like the perfect setup for the Protege.

The Digressive piston shocks provide a slower rebound at higher speeds , and hard cornering, which is perfect for track use. The down side is the alternative to having a slightly harsher ride with daily driving and small bumps at slower speeds. From what I read up about the two styles, it seemed like the perfect setup for the Protege. The kit also includes a pair of reinforced, shorter sway bar end links, that is a must.

The kit also includes a pair of reinforced, shorter sway bar end links, that is a must.

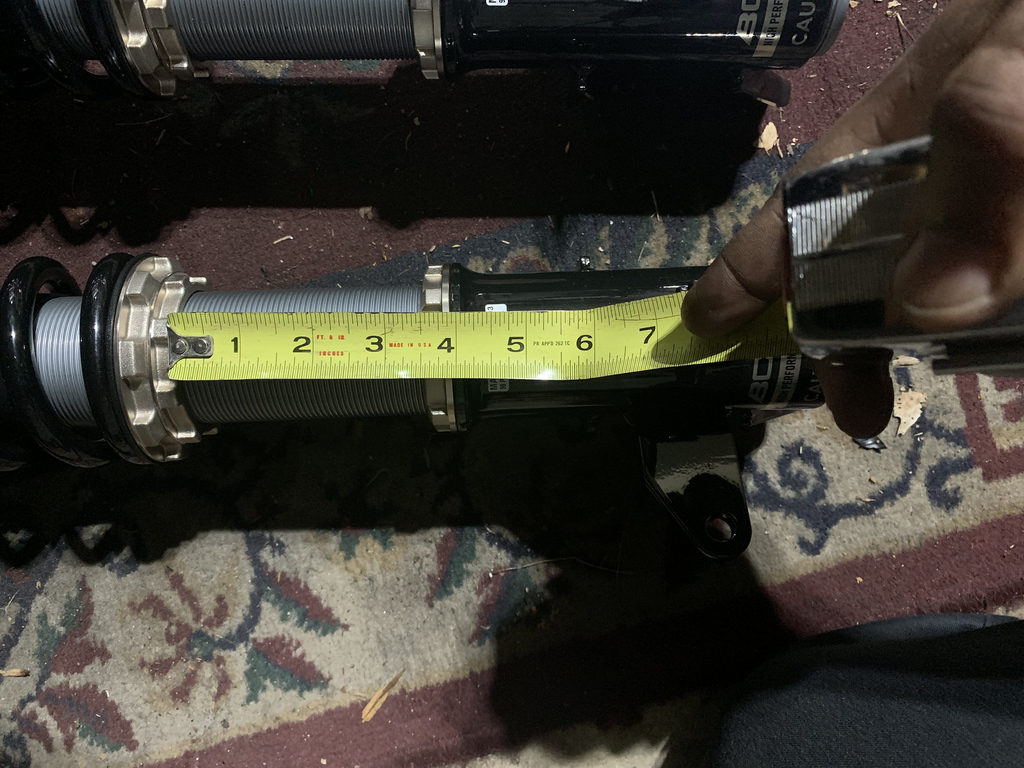

The DS Series strut body is a little larger then the BR Series, and the threads are silver, opposed to the black threads on the BR Series.

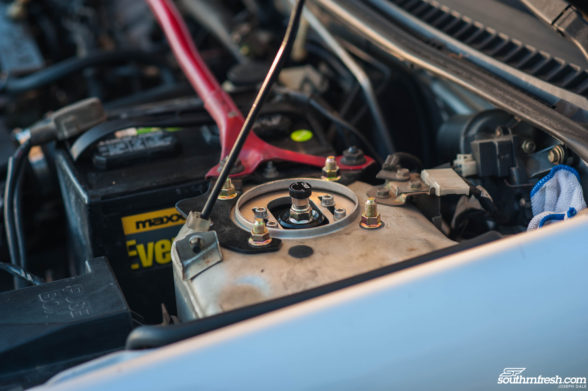

The DS Series strut body is a little larger then the BR Series, and the threads are silver, opposed to the black threads on the BR Series. The front coilovers offer a camber plate, and also with most BC Racing coilover kits they have adjustable compression and rebound adjustments.

The front coilovers offer a camber plate, and also with most BC Racing coilover kits they have adjustable compression and rebound adjustments. Another plus, was that the coilovers come already pre-loaded out the box and were set with 6k / 8k springs. So that saves the hassle of doing it incorrectly, and having a terrible ride. When I received my old set a few years ago, the pre-load had to be done by the user, as far as I knew. Now it seems that they do it out of the box, and advise installing them as they are, and adjusting once installed. It really saves the trouble and hassle of potentially ruining your ride by not knowing how to set up the coilovers out the box.

Another plus, was that the coilovers come already pre-loaded out the box and were set with 6k / 8k springs. So that saves the hassle of doing it incorrectly, and having a terrible ride. When I received my old set a few years ago, the pre-load had to be done by the user, as far as I knew. Now it seems that they do it out of the box, and advise installing them as they are, and adjusting once installed. It really saves the trouble and hassle of potentially ruining your ride by not knowing how to set up the coilovers out the box.

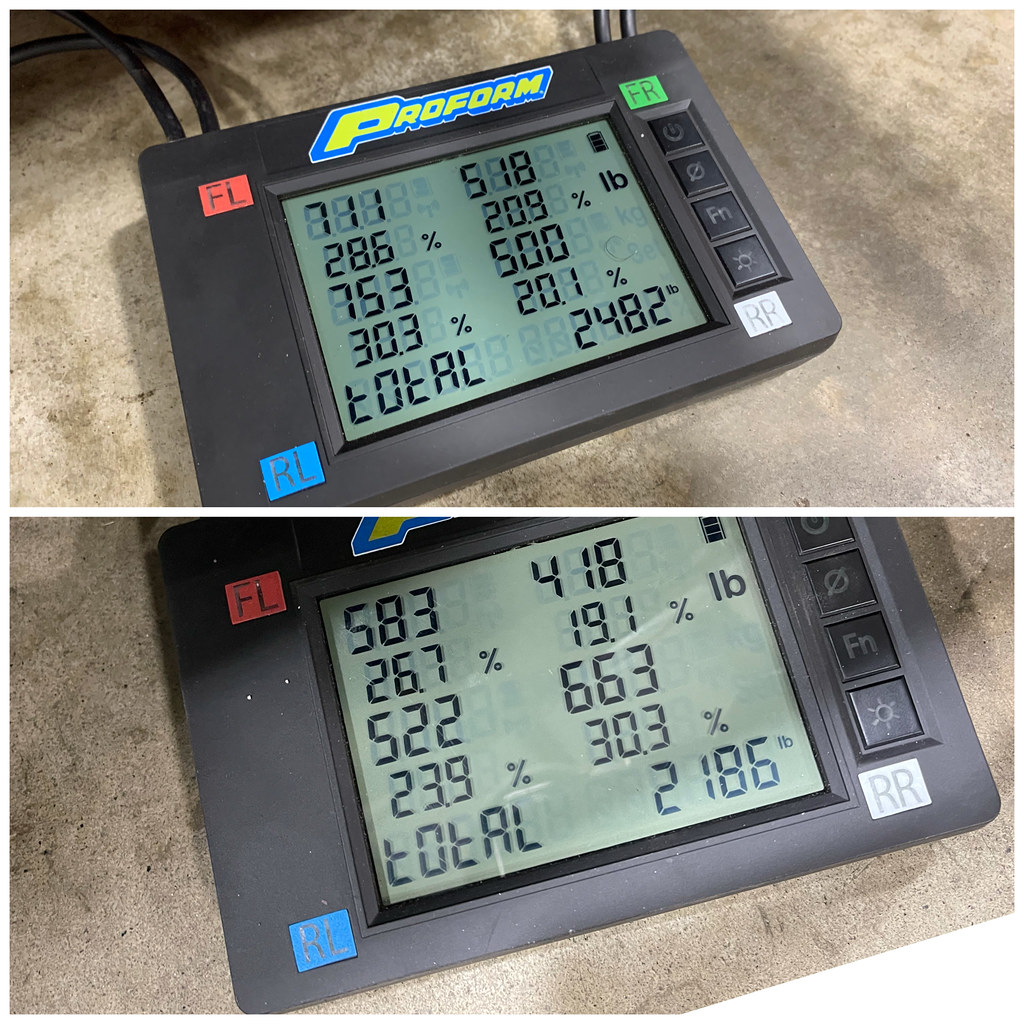

Like they said, both front and rear were set, pre loaded , and dead even front and back out of the box.

Like they said, both front and rear were set, pre loaded , and dead even front and back out of the box. Old 17 year old 289k mile Struts..

Old 17 year old 289k mile Struts..

Fitment was good no issues.

Fitment was good no issues. Brake hose fits back in the oem place no issues.

Brake hose fits back in the oem place no issues. Everything in all good no issues.

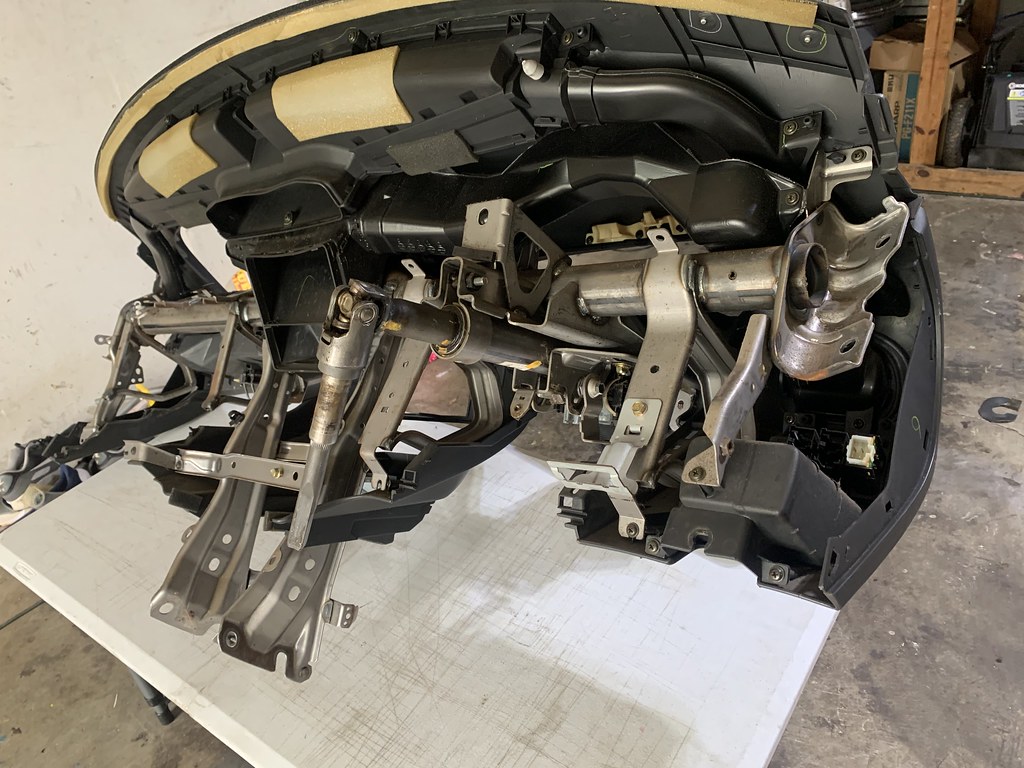

Everything in all good no issues. Most of the rear interior panels have to be removed to get to the rear struts, so we made the decision to go ahead and remove the seats, and all the panels in the rear for the track day.

Most of the rear interior panels have to be removed to get to the rear struts, so we made the decision to go ahead and remove the seats, and all the panels in the rear for the track day.

The protege 5 is built of the protege sedan chassis , and shares pretty much everything with it. Except that the rear is slightly more narrow, and shorter then the Sedan. So it makes wheel fitment a little different. So we had to roll the rear fenders to clear the tires.

The protege 5 is built of the protege sedan chassis , and shares pretty much everything with it. Except that the rear is slightly more narrow, and shorter then the Sedan. So it makes wheel fitment a little different. So we had to roll the rear fenders to clear the tires.  Finally the car was looking sporty and sitting lower. First trip was to the car wash for a quick bath.

Finally the car was looking sporty and sitting lower. First trip was to the car wash for a quick bath. The car rode really well, but as specified with the style of coilover at slow speeds it was really stiff, but with any sort of speed and quick turns everything smoothed out, and the car was planted, turn in was sharp and all the unwanted body roll disappeared. Very impressed how the car drove out of the box.

The car rode really well, but as specified with the style of coilover at slow speeds it was really stiff, but with any sort of speed and quick turns everything smoothed out, and the car was planted, turn in was sharp and all the unwanted body roll disappeared. Very impressed how the car drove out of the box.

While installing the stainless steel brake lines i ran into a issue trying to bleed my left front caliper, because the bleeder screw was stripped. I had to get the fluid replaced anyway so I limped to Atlanta Speed Company and had them replace the fluid with some Motul 600. We had planned to use hawk DTC-60 pads on the car, but we had a mix up on part numbers since the car has Mazda 6 front brakes. So we just stayed with generic blank rotors, and ceramic pads from the local part store.

While installing the stainless steel brake lines i ran into a issue trying to bleed my left front caliper, because the bleeder screw was stripped. I had to get the fluid replaced anyway so I limped to Atlanta Speed Company and had them replace the fluid with some Motul 600. We had planned to use hawk DTC-60 pads on the car, but we had a mix up on part numbers since the car has Mazda 6 front brakes. So we just stayed with generic blank rotors, and ceramic pads from the local part store. Time was up and it was time to put it all to the test. We had arrived at Atlanta Motorsports Park for the

Time was up and it was time to put it all to the test. We had arrived at Atlanta Motorsports Park for the

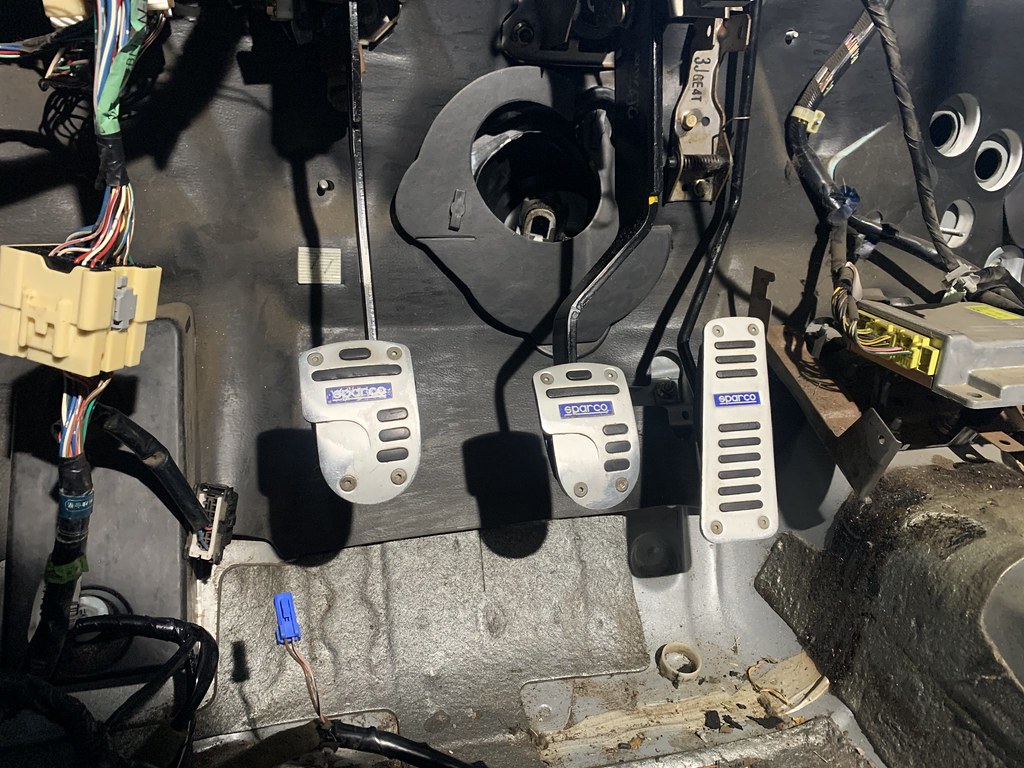

Once the meeting was over, our beginner group went to another room and had another brief meeting to meet our instructors for the day. My instructor was also driving that day in his Mini Cooper. Henry's Mini was a terror on the track. The biggest things were his brakes, power, and racing seat and harness. It's crazy how much proper seats and a harness changes your experience, and allows you to focus more on driving...

Once the meeting was over, our beginner group went to another room and had another brief meeting to meet our instructors for the day. My instructor was also driving that day in his Mini Cooper. Henry's Mini was a terror on the track. The biggest things were his brakes, power, and racing seat and harness. It's crazy how much proper seats and a harness changes your experience, and allows you to focus more on driving...

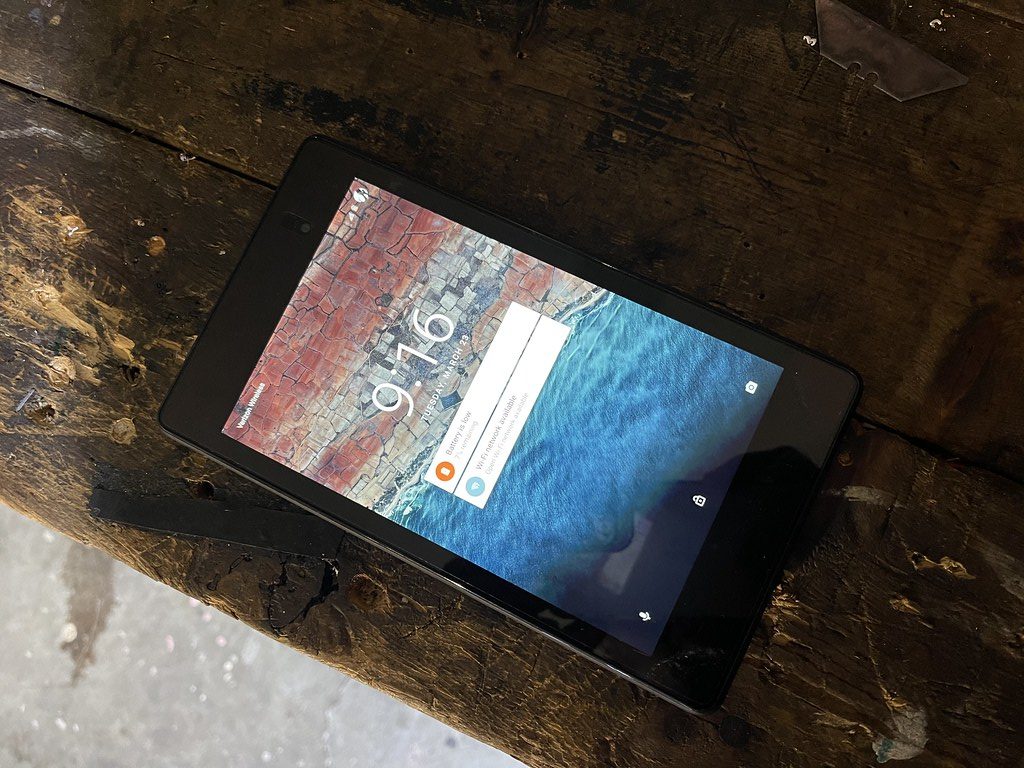

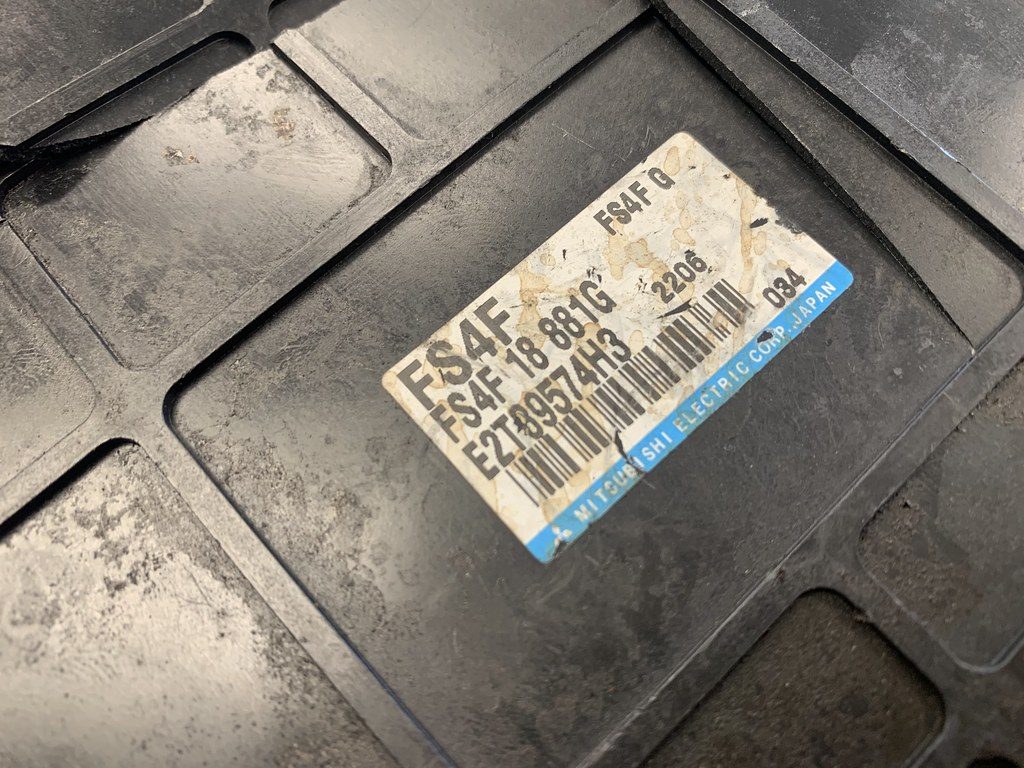

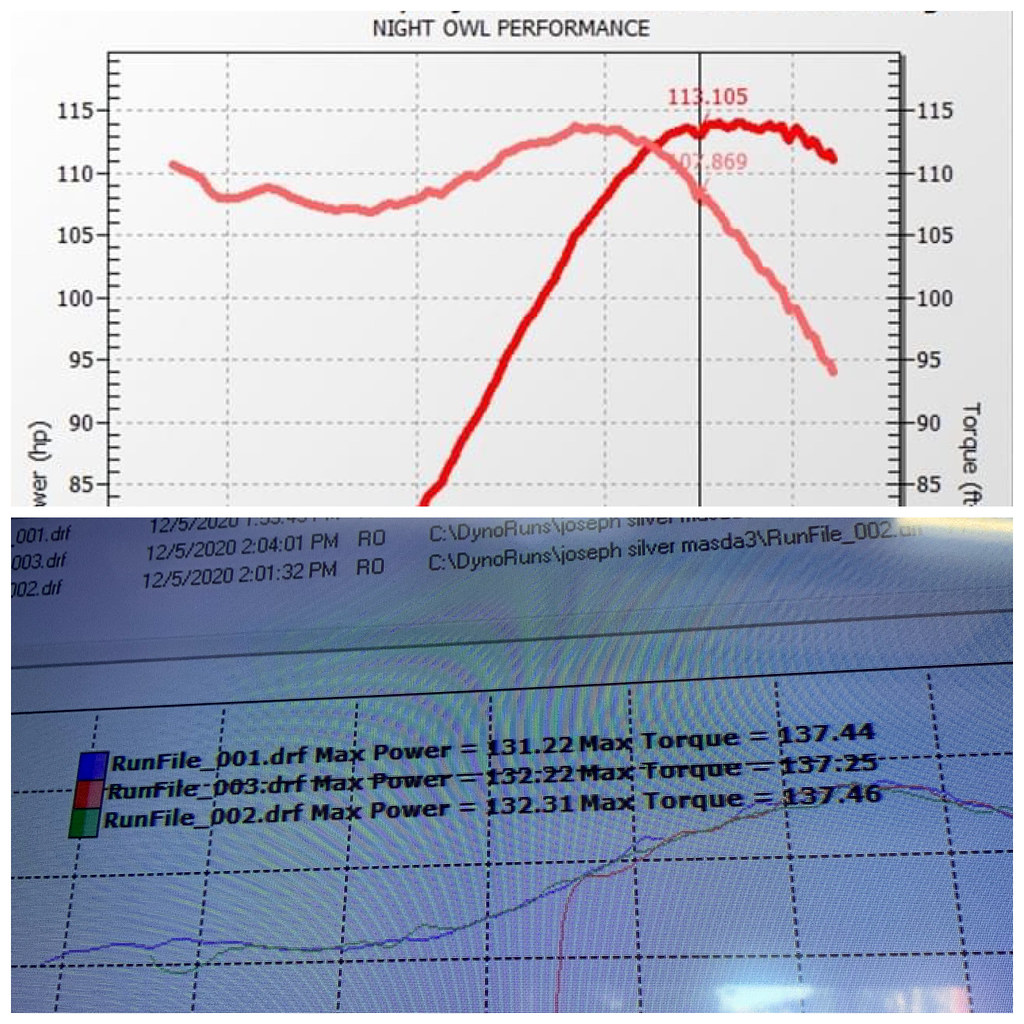

As mentioned before, this engine is a

As mentioned before, this engine is a

Finished a good

Finished a good

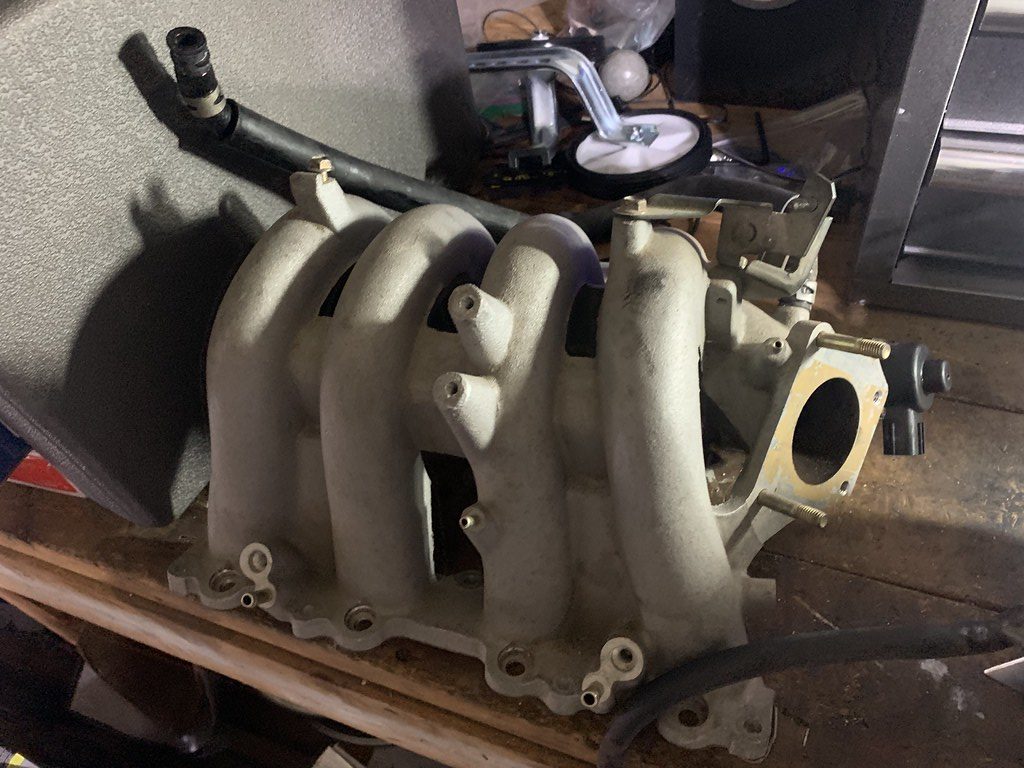

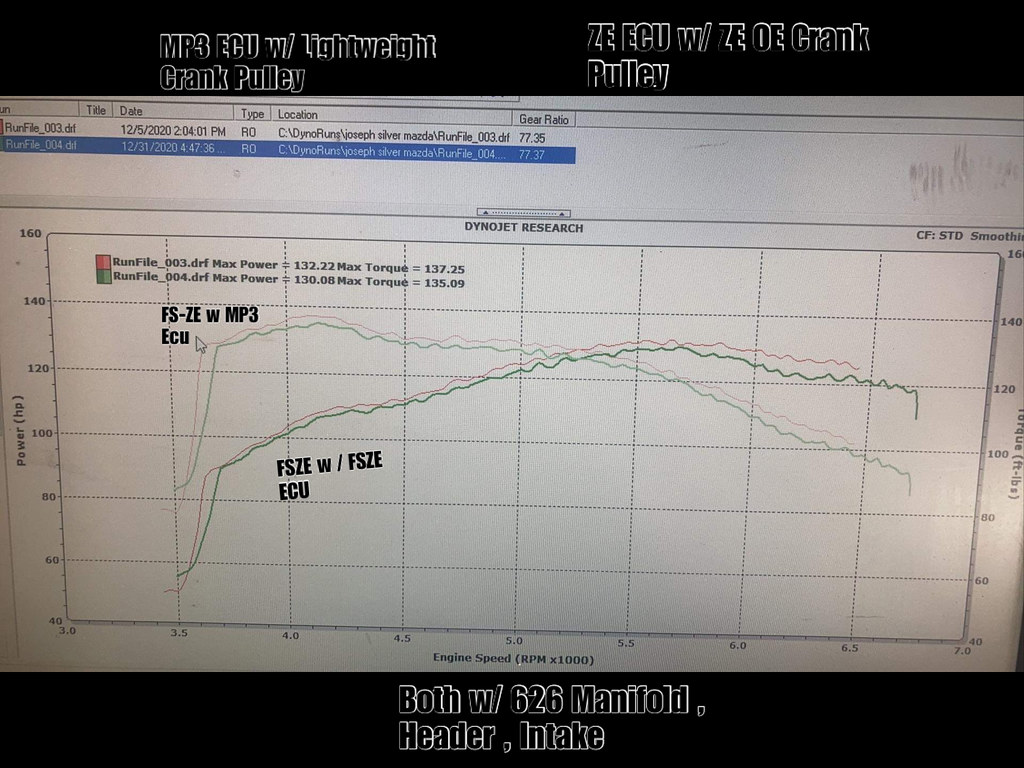

There was a final piece to the JDM puzzle that I needed to experiment with on the dyno. And that is the intake manifold, which features a resonance chamber to match the performance of the FSZE engine, which may make up for the loss of power in the higher rpms.

There was a final piece to the JDM puzzle that I needed to experiment with on the dyno. And that is the intake manifold, which features a resonance chamber to match the performance of the FSZE engine, which may make up for the loss of power in the higher rpms.