Brake fade.

Car projects are, by their nature, a journey to a journey (or many, if you don’t succumb to the temptation to finish the car, drive it twice, then sell it to fund the next project).

Being a journey, a succession of events, often things change - our priorities are re-ordered, the goalposts are moved. There are also many temptations - bigger is better being the one that troubles me repeatedly.

An example of this is to be found in the cars wheels and brakes. My car currently has both wheels and brakes, indeed I actually have two sets of wheels - an early manifestation of this problem, I admit.

What could I want to change? It turns out, quite a lot - and each decision has an ever ramifying set of consequences and dependencies, until the initial thought (“PCCB’s look like an interesting option, I bet they’d save a load of weight”) has turned into a spreadsheet detailing new uprights, adapter brackets, new calipers, spacers, new wheels, new tyres, rolling the arches, do I need to book it into the paint shop again afterwards, etc etc. To save a few kilo’s I now appear to have committed myself to spending over ten thousand pounds, and both scouring the worlds classifieds sites and commissioning much refurbishment of second hand parts to hold it to that ten thousand - blowing past twenty thousand is quite possible if going for new parts and paid-labour, which is, by every definition, insane.

And for what? It strikes me that the best route to what I wish to achieve would be to swap the 18’s that the car currently sits on to the 17’s that I have in my garage. In other words to go back to what the car came into my possession with, a redo-from-start that would see the car on the lightest wheels that Porsche produced for the 996, with all the dynamic benefits that that brings - less to accelerate, less to turn, less to stop. I could then really push the boat out and get some two-piece floating rotors to drop some more unsprung weight, and hopefully gain a degree of fluidity and adjustability that the move to larger rubber removed.

What I need to do is add simplicity - what I want to do is add complexity.

I think that there’s also a degree of small-boy pointing at planes here, which I hope I’m self-aware enough to deal with - I admit I’d enjoy someone saying “look at this plonker, he’s got a boggo 996 but he’s painted his calipers yellow, who does he think he is! Oh, wait a moment, actually those are ceramics. Oh.”

Which would be a momentary (and likely totally imaginary) feeling of having achieved something nebulous (and possibly shameful) but in any case 100% pointless, for a very great deal of money.

So what does this teach me? That every decision has to be scrutinized, and that I will lie to myself about my own motives with great facility, frequency and enthusiasm. That simplicity is often the best answer, but the hardest for me to accept.

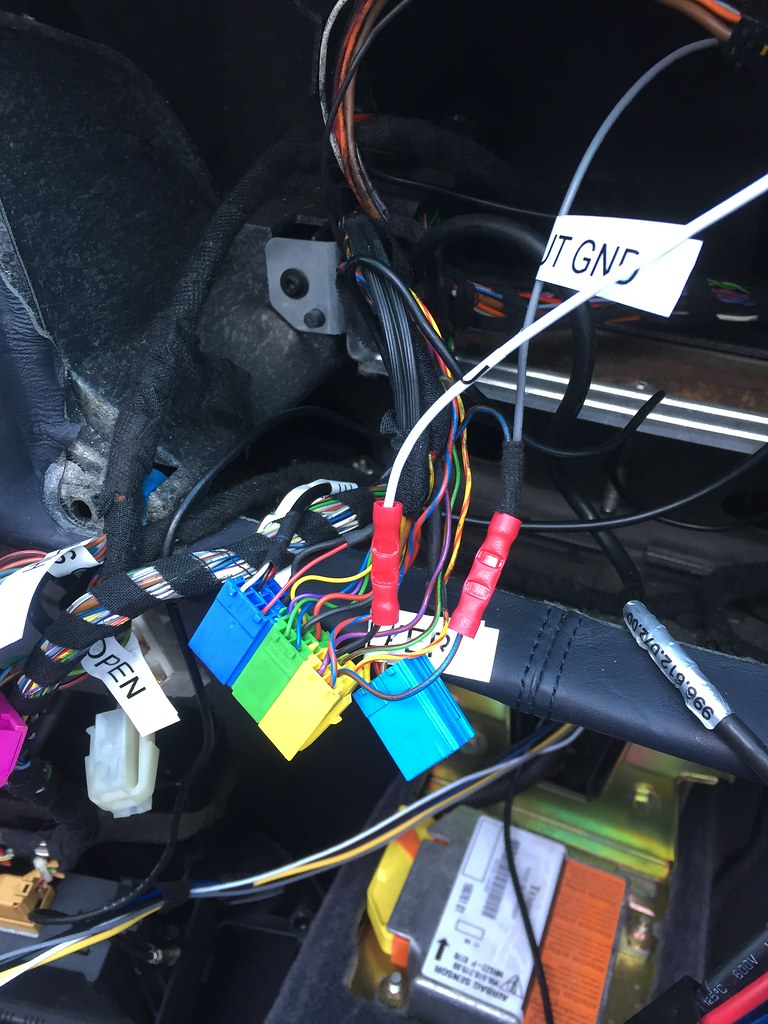

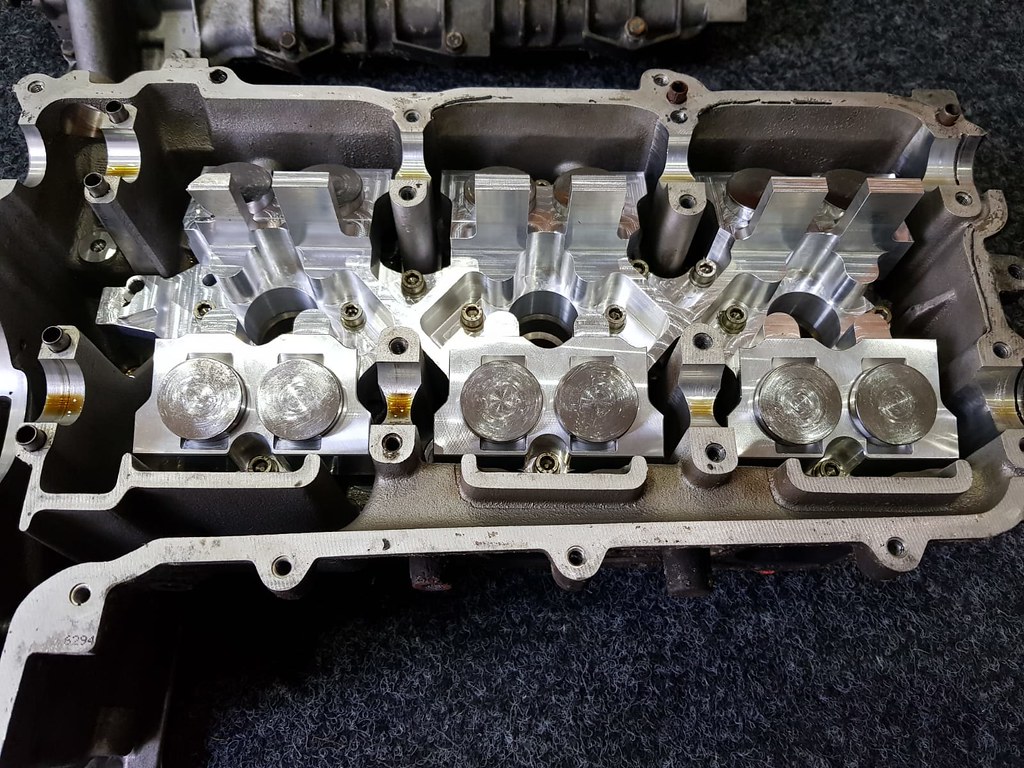

I suspect that some reading this may (by this point, and possibly for some time now) be shaking their heads in disbelief whilst muttering “what about the engine then?!”, and I’d answer that what we’re doing there IS the simplest way to hit our goals - that the sauronic howl and comedic power we seek has to be supported by a degree of complexity, but even there we have tried to steer a simple path - we’ll strive to use flat tappets rather than domed ones until the point (if it ever comes) that the choice essentially makes itself. Complexity is not in of itself bad, but it must be justified, that unnecessary complexity is the enemy, and must be shown no mercy.

And I now have a use for the wheels in the garage.