MOD 6: Dual-Feed Direct Clutch (Part 2)

I removed the center lip seal in the drum, which is part of dual-feeding the Direct apply piston. This removes the separation between the Direct and Reverse sections of the apply piston.

MOD 7: 6-Clutch Direct

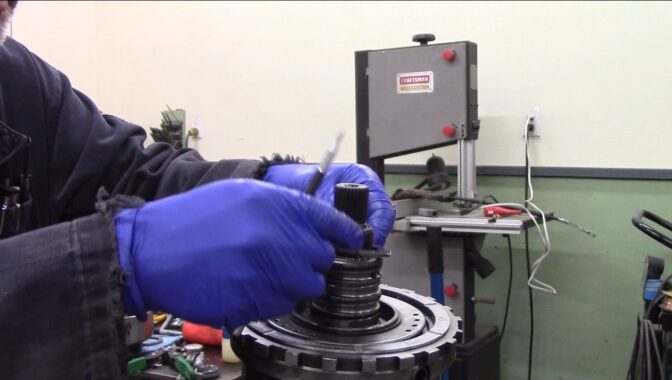

Lots of internet opinion between running a TH400 direct piston, vs just keeping the 4L80E bonded piston. I kept the bonded piston, tossed the wave plate, and squeezed in six frictions by using six 0.077" forward steels. Clearance ended up a perfect 0.060" (0.010" per clutch).

MOD 8: Rollerized Forward Hub

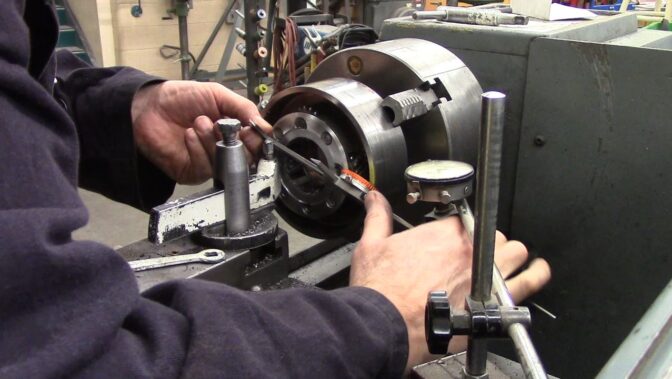

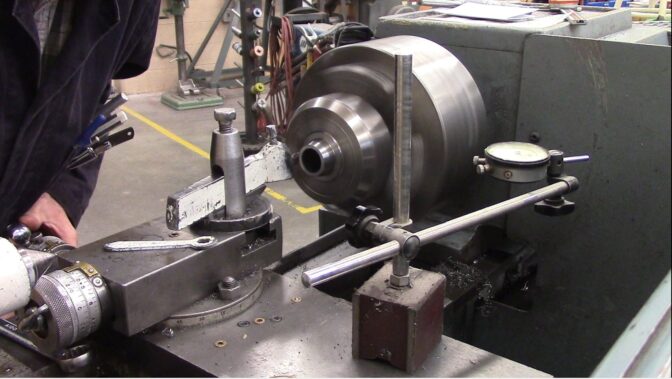

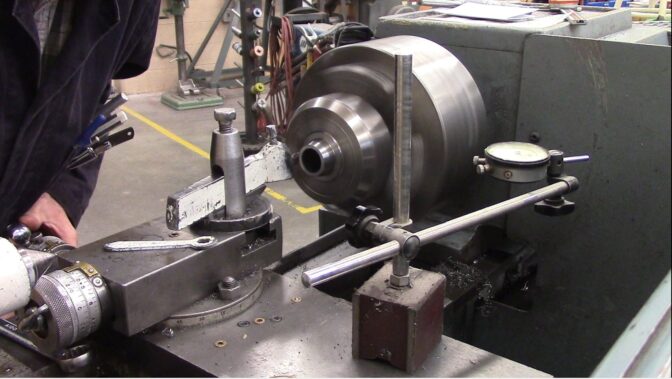

The Direct Drum is pretty sloppily supported. We are going to reduce the slop, and add a Torrington to better support the Drum.

Following Interweb advice....

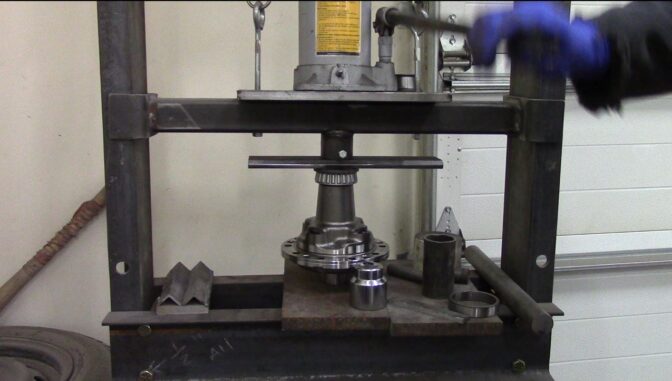

To do this, the Forward Hub "shoulder" gets machined to fit Ford AOD Torrington bearing (I used 1F1Z-7F404-AA). The "shoulder" is machined down: (bearing thickness) minus (original thrust bushing thickness) minus (about 0.030" clearance reduction), which in my case should have been 0.050", which I thought I initially cut. I may not have.

Now, you also need to know that Direct Drum to Forward Hub clearance should be 0.003-0.008" when rollerized. I'm not exactly sure how to measure this, you can't exactly get a dial indicator in there. Machining the shoulder more, should move the Forward Hub closer to the Direct Drum. With what I had initially cut, there was a noticeable amount of drum-to-hub play. I also ended up with ZERO front end play in the trans.

I don't know if this is correct, but I measured the distance from the Direct Hub to the mainshaft, and got 1.911"

I installed the forward bearing (0.143" thick) and got 1.933"

Again: I don't know what I'm doing.

The difference was 0.022", and in my head it made sense to cut 0.017" more off the Forward Hub (0.005" clearance), which makes NO sense to me right now. But this gave me 0.010" front end play in the trans, which is bang on what I wanted (.005" more than the rear). I hope this works.

NOTE: The 0.050" cut will get you in the ball park. You really need to assemble the trans and check the Front End play, and machine the shoulder to get the end play where you want it.

Front end play should be 0.002-0.005" GREATER than the rear end play (if you are NOT lifting the output shaft to take up rear end play. If you ARE lifting the output (all output end play is taken up), then I think you need would just want to see 0.002-0.005").

4th clutch installed:

Overdrive installed:

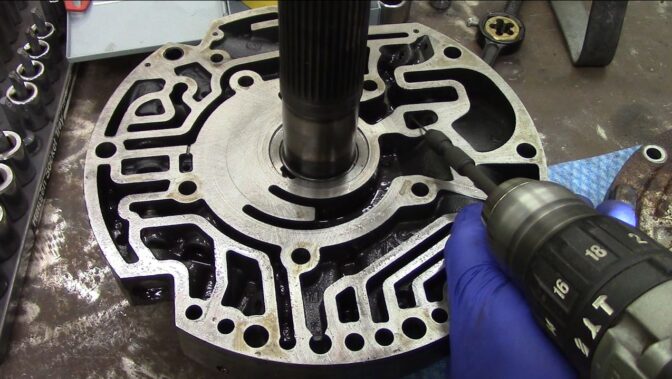

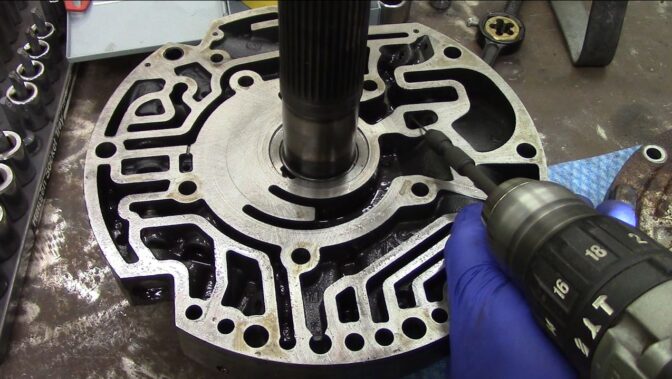

MOD 9: Overdrive Lube Feed

Overdrive lube hole drilled out to 1/8":

MOD 10: Converter Charge Line

Drilling a 0.050" hole provides the converter with charge oil regardless of pressure regulator. This will increase pressure in the converter, and more oil drain back.

MOD 11: Converter Oil Drainback

The existing drain might not be large enough for the increased oil, so we'll drill it out to 1/4".

MOD 12: Pressure Regulator & Boost Valve

This is just remove and replace. I used the one in my TransGo kit. Allegedly Sonnax is more desirable, but my interweb research suggests it really doesn't matter which one you use. This was annoying to install.

Pump installed:

Rear seal inserted ONLY enough to allow the snap ring to snap into place (makes sure oil gets to rear case bushing).

Extension Housing installed.

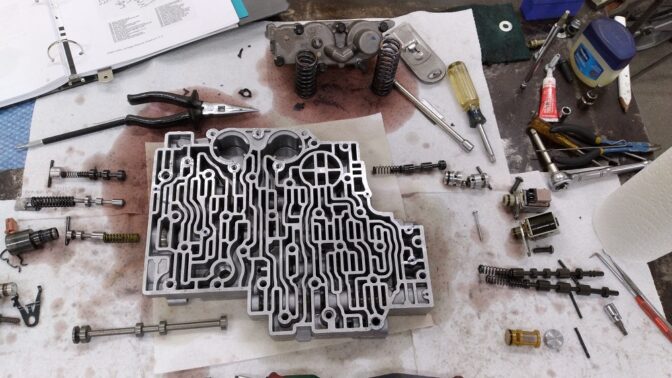

Next, I'll be getting into the valvebody with some changes.