I have a transmissionectomy to do this weekend, so it's time to do some work on the air lines. I'll beef this up with more pictures in a bit.

The compressor sits in the back corner of the shop - despite all the original plans earlier in this thread, that's where it ended up. The lift is about 20' away, and I want air at the big doors too. Plus the bead blaster. At my last place, I got a roll of rubber air line from HF and just attached it to the ceiling. That's not going to work here.

So I picked up a "master kit" from Maxline. Basically, plastic-covered aluminum tubing, a bunch of connectors, a distribution block and three drops. A bit of planning said it was perfect. I spent a couple of hours puttering around the shop thinking about the perfect way to lay it out and where I wanted everything, then started cutting.

It's really easy stuff to use. The piping is just the right combination of stiff and flexible, allowing you to shape it with your hands. The connectors are all compression fittings with double o-rings. It came with a cutting tool and a deburring tool.

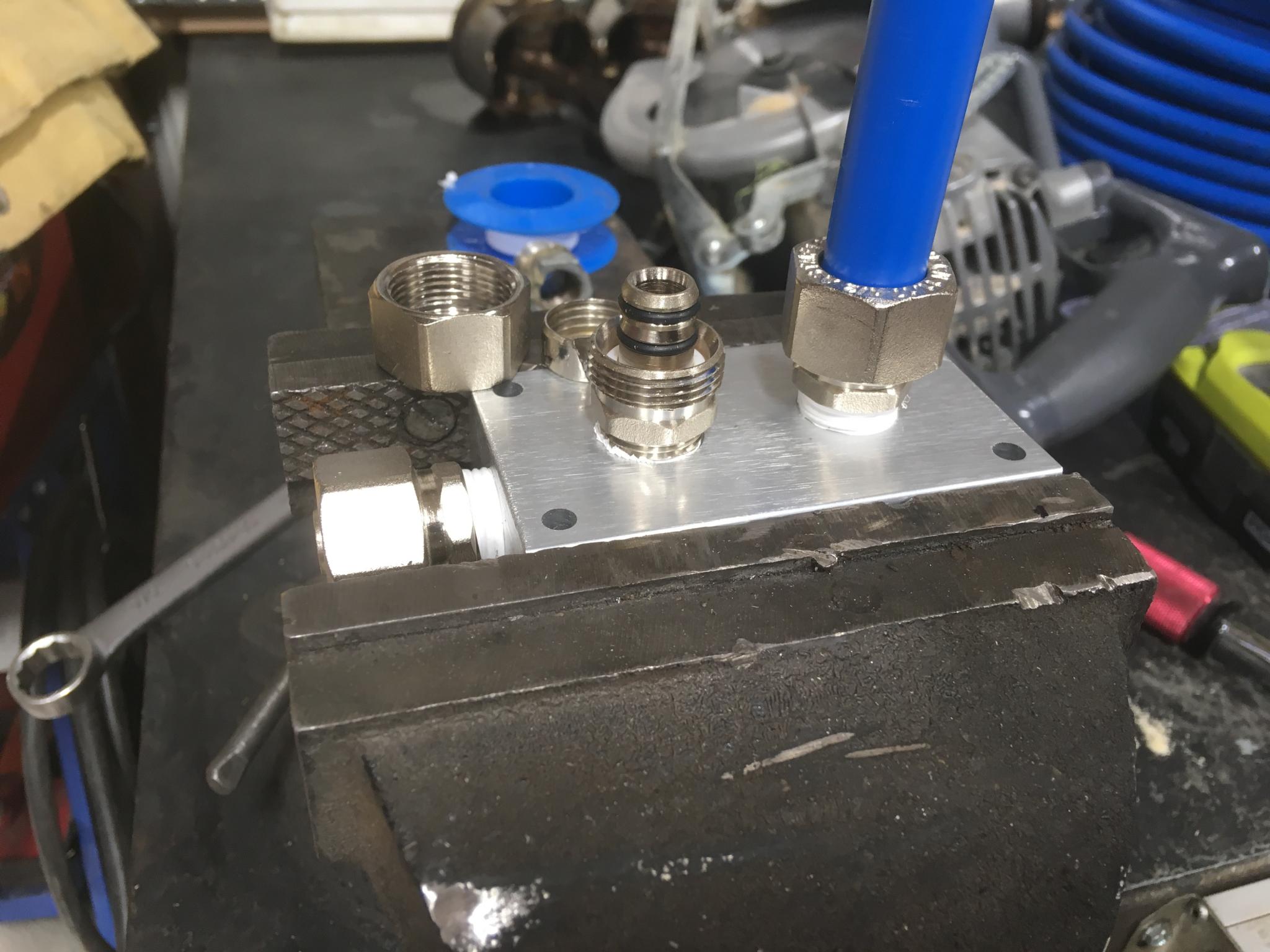

This is the primary distribution block getting assembled.

I'm using a 25' hose reel at the workbench right at the end of the lift and a 50' one at the main door. If I drag them towards each other, there's something like 35' of overlap ![]() Here's the one over the workbench. The drop has a drain on it.

Here's the one over the workbench. The drop has a drain on it.

The last leg was more difficult to install as I ran it up by the tall ceiling and around a couple of corners and through a little obstacle course, so I just plugged off the distribution block and filled the rest of it. Not a single leak first try. I could get to like this stuff.

More pictures later, including how I'm dealing with the blast cabinet.

We'll call the part of the shop that has the big doors the front. The front 20' is basically parking. Behind my small door (on the left in these pics, like the red Miata) we have long-term parking, behind the big door is the entry to the lift and cars that move in and out more often. There's a wall of shelves separating the first 8' of those two parking areas (basically, extending from the piece of wall separating the two doors) and the wall on the right side is heavy-duty shelves with all of the long-term parts storage.

We'll call the part of the shop that has the big doors the front. The front 20' is basically parking. Behind my small door (on the left in these pics, like the red Miata) we have long-term parking, behind the big door is the entry to the lift and cars that move in and out more often. There's a wall of shelves separating the first 8' of those two parking areas (basically, extending from the piece of wall separating the two doors) and the wall on the right side is heavy-duty shelves with all of the long-term parts storage.