In reply to mazdeuce - Seth :

You could probably put some holes in that bracket without weakening it. Would swapping down to 2 or 2.5" cooling hose aid things at all?

re:Splitter

It looks like you've got it sucked up against the radiator shroud too much in the middle, and it'll probably need to come down 3-4" to mate with the bumper cover.

and, hmm... interesting... the core support is actually angled... this car is practically begging for a smaller radiator ducted out the top of the hood... once you move the horns somewhere else

In reply to sleepyhead :

There is a LOT of mucking about that I need to do to figure out what level is and how to get things spaced properly to achieve that. This was just a test to figure out how big things need to be and what parts of the car will be useful for mounting. The next step should be plywood, actual mounts at the back, level out the plywood, spacers, struts, etc. The whole bottom of the car from the front of the bumper to the subframe is one big curve.

you might also consider breaking the splitter up into 4 parts. A strong central section with 3 "wings" coming out from it

would make replacing things easier, since the wings will be more likely to fail... and should minimize how big a of piece goes careening down the underside of the car

Cables if needed = good, let the leading edge of the nose of the splitter come up if it wants too.

Being attached to the subframe the splitter will already pretty solid in the back, I'd try to make the middle/frame horn mounts fairly stout as well.

We've had some pretty high speed offs into the grass and the splitter mount has pretty much always survived until the wall hit. my philosophy has been if we hit something nose first the splitter will...split it. Or we'll ride up onto it like a sled. I'd say nose off, or tail off slides are the most common incident (at least for us) so I try to build the splitter to survive those. Side collisions are a different animal and I want weakness there.

From the side my splitter is fairly weak, if we slide sideways into something the splitter should push without much issue and not bend the frame horns, which Matt proved out when he slid into the wall.

Probably 2 ways to effectively tackle this, either treat the splitter as a part you want to eject from the car in an shunt, or utilize it as a skidplate to protect more vital parts like oil pans. Organic composite fiber from HDracing is surprisingly strong once you start attaching it on all corners.

edit: I like the 4 piece idea that sleepy mentions too, I've been day dreaming about options for that as well, especially in a OLOA scenario, have the main splitter rigidly attached and follow the shape of the bumper, then have a front/2 sides that are quickly removable to travel in the car and regain approach angle.

I've used two different approaches to the brake cooling issue.

One is to fab up a duct that attaches to the spindle like the original backing plate that has a fitting for the hose. The disadvantages of that approach are added unsprung weight, challenging fabrication and the hose moves with the suspension and with the steering.

The other is to just get the hose as close as I can and call it good. With vented rotors and good hose inlet locations you can get away with a pretty good gap

Sonic

UltraDork

12/13/18 8:08 p.m.

I need to try to find pictures of how we did the splitter on the Civic, you’d like it. 3/8” plywood with one layer of fiberglass and epoxy on it for strength and weather resistance. The mounts on the car is a piece of 3/16” steel about 3x6” welded to the bottom of the tie down hooks. On the splitter, we sandwiched the plywood with 6x6” pieces of the same 3/16 with bolts, then on the top piece we had two vertical pieces of 1/8” bar stock that the 3/16” from the tie downs slotted right into. Then two bolts through each side with welded captive nuts. At the front we welded on a bracket and bent another piece of bar stock in a stretched out z that then bolted forward on the splitter. End result is a very solid piece that comes off easily with 5 bolts.

In reply to Sonic :

I'm spending a bunch of brainpower trying to figure out what will go happen if I hit a tire wall on day two (not that I"ve ever done that before) I need the splitter to not break something on the car that I can't fix, as well as have the whole system be simple enough that I can repair/replace it by stopping at a Home Depot. That's what I'm fighting with the brake ducting. Rubbing a hole through a CV boot isn't a trivial problem when in the middle of nowhere. I'm already thinking of carrying a spare universal split boot depending on what I come up with.

I would be absolutely shocked if you need brake cooling with those brakes.

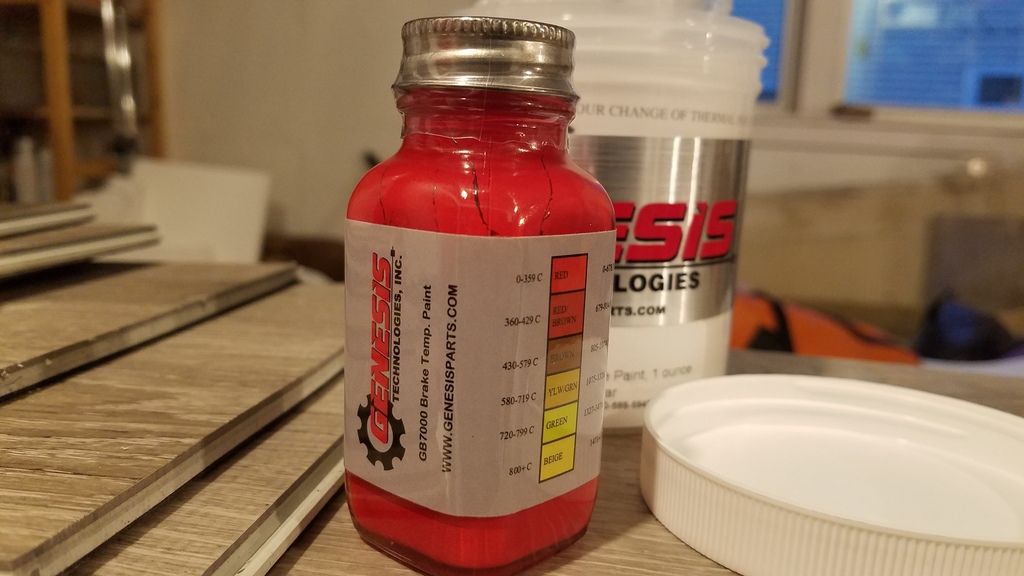

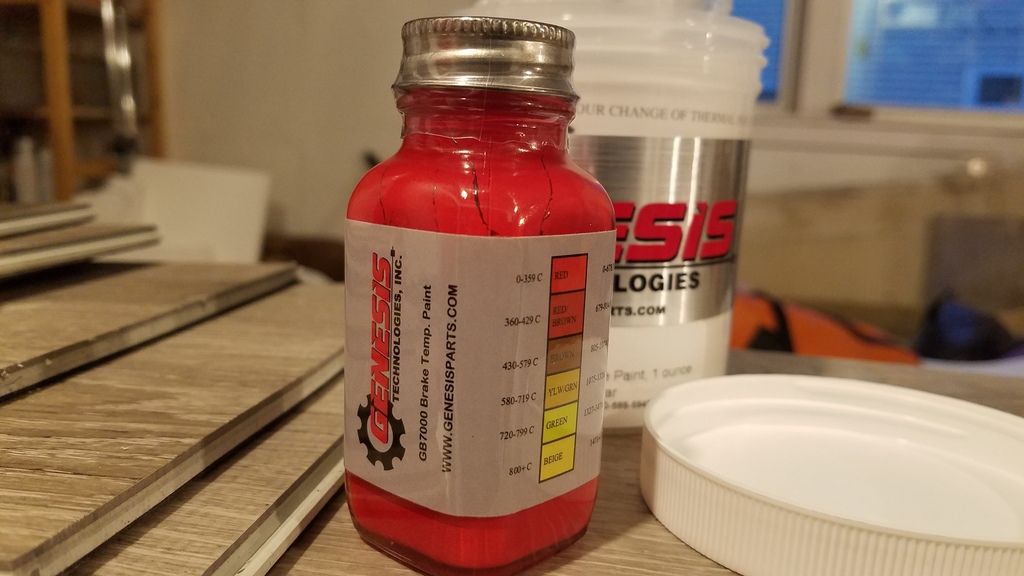

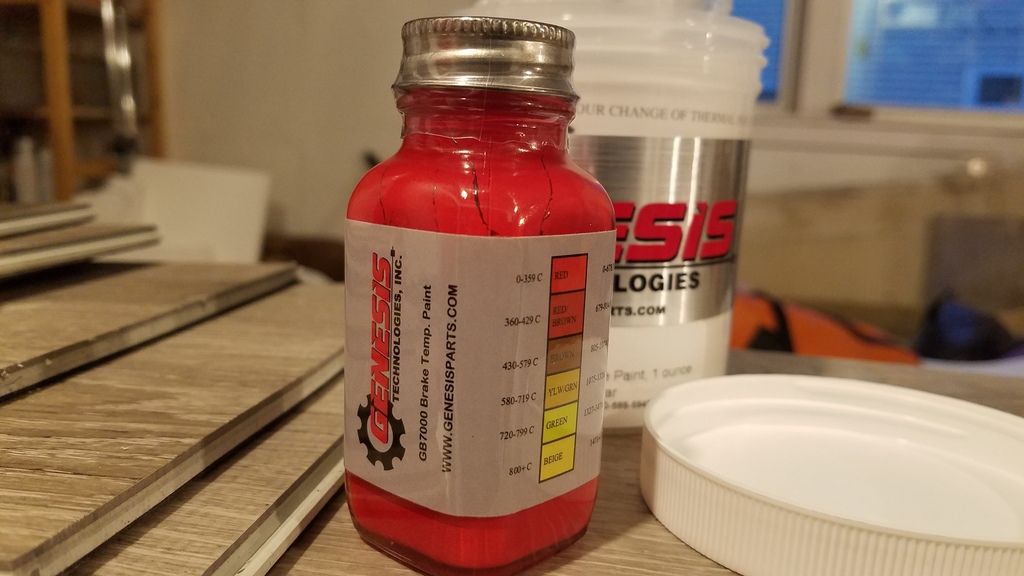

Get some brake temp paint and do a test.

^ what he said.

another idea, since you'll have a splitter helping smooth air under the car a bit would something like this work? https://honeddevelopments.com/product/honed-air-guide-kit/

Allows you to block off 2 more holes in the nose for reduced drag and their testing looks like they saw fairly noticeable gains in cooling, should be able to fab something more GRM for less. I know Porsche does something similar with some of their cars.

barring that working, another thought would be how much brake do you need and for which events? overcooling won't be of much help and 20-30 minute HPDE sessions in the Texas summer would perhaps require more cooling than 3 laps at a time in the midwest spring. If you know you can do 5-6 laps back to back without fade currently I'd say good enough for OLOA and leave off the parts that might potentially cause you to need a new axle boot.

In reply to klodkrawler05 :

Those air deflectors are pretty cool. I'm hoping that pointing the hoses at the center of the rotor will have a similar result. We'll see.

The plan is to apply the paint, do a couple sessions of the test track, tape over the ducting, see if there is a change. It's a fairly small track but it's hard enough on brakes that both of the Focus ST's were smoking and losing pedal by the end of their third lap.

In reply to mazdeuce - Seth :

Currently working on ducting on my 2005 Mustang GT. Luckily it is a path that many have been down before so lots of good options. My hats off to you when you pave the way into the unchartered.

Just a thought, were the Focus ST brakes smoking due to braking or was it due to the use of braking as part of their traction control algorithms? I have read that they can heat things up pretty severely just on traction control engagement alone.

In reply to fusion66 :

There were a bunch of theories floating around about the FoST brake issues. The traction control was turned as far off as possible. A couple of people think it's the remainder of the TC, I think it's just a matter of the brake pads not being up to the job. The above paint is going on the rotors of the Focus as well to see where they're actually at temp wise.

Still playing with the splitter. Trimming cardboard for tire clearance.

Eventually it was time to bite the bullet and drill some holes in the subframe and install nutserts. This is pretty cool.

Raining today so instead of getting an actual piece of plywood for the splitter I grabbed a piece of paneling from the kitchen. One step closer. I think doing this the second time will be easier.

mazdeuce - Seth said:

Raining today so instead of getting an actual piece of plywood for the splitter I grabbed a piece of paneling from the kitchen. One step closer. I think doing this the second time will be easier.

Looking at this... I think you might want to replace the white struts with "L-channel", or triangulate them both. I know you've got several bolts in the back, which should keep it fixed laterally... but you've got a fair amount cantelevered up forward, so it could swing in the {ahem} wrong conditions.

standard caveats: imho, iirc, just my $0.02, etc

In reply to sleepyhead :

and by "wrong" he means hitting the tires at Gateway

EDIT: Or he could also mean someone not setting the rear tire pressures correctly and looping it at NOLA.

In reply to sleepyhead :

Well, the white stuff is just plastic that I cut with scissors, so it's going to get replaced. I have some ideas.

mazdeuce - Seth said:

In reply to sleepyhead :

Well, the white stuff is just plastic that I cut with scissors, so it's going to get replaced. I have some ideas.

I don't know, looks pretty robust to me!!! hahaha

The amount of time it takes to make the initial splitter is insane relative to the time spent to make replacements. The first one took me a weekend, now I can make a replacement in an evening or including time for paint to dry and adult beverages.

Also, make sure you hold onto your template when it's done it's tough to eyeball a splitter from the remaining kindling scraps. I made that mistake the first time.

Looks like it's taking shape quite nicely though!

Woody

MegaDork

12/15/18 7:02 a.m.

You may not want to make the final brackets overly stiff. If they are too strong, they will transfer energy to much more important/expensive parts in a shunt. Make them strong enough, yet sacrificial.

Sonic

UltraDork

12/15/18 11:51 a.m.

In reply to mazdeuce - Seth :

If you use small-ish bolts to attach it, the bolts will shear on impact and the splitter will slide out of the mounts, especially in a frontal impact

mazdeuce - Seth said:

In reply to klodkrawler05 :

Those air deflectors are pretty cool. I'm hoping that pointing the hoses at the center of the rotor will have a similar result. We'll see.

The plan is to apply the paint, do a couple sessions of the test track, tape over the ducting, see if there is a change. It's a fairly small track but it's hard enough on brakes that both of the Focus ST's were smoking and losing pedal by the end of their third lap.

yeah, I was out there again today and the fluid is just done. and i got a lot of pad material transferring onto the rotors.

In reply to fusion66 :

the st brakes smoking is a combination of both, the course is small and tight with a 1/4, and 2, 1/8 mile straightaways that give me enough space to get some speed up. So the front brakes basically have about 15-25 seconds on the 75 second lap that they aren't engaged in some fashion and so it pushes them hard because i'm either accelerating out of a corner and the car is applying them to curb wheelspin or i'm trying to bleed off speed with full pedal application. I hit 90 MPH on the course today in CW direction.

also, the brakes only smoke if i pull right off course and park, and don't get some air flowing through the disks.

Sonic said:

In reply to mazdeuce - Seth :

If you use small-ish bolts to attach it, the bolts will shear on impact and the splitter will slide out of the mounts, especially in a frontal impact

How small is small-ish? The nutserts I just put in for the rear are M8 but my plan was to use the existing (and add a few more) M6 bolts for the pieces that will replace the white supports.

This is where the Spoon arms are hitting the upright. Kinda ugly.

They appear to only be hitting this nub that's cast into the upright. I can't find a structural reason for it to be there, so I chopped it off.

To make things pretty and easily be able to tell visually if things are still in contact, A bit of masking and paint.

I think the compliance bushings on the lower arms are showing their age. I can go stock rubber, some sort of upgraded rubber, of just bite the bullet and put in PCI sphericals.

Spherical all the things! this is a racecar right?..........right?