EvanB

MegaDork

10/29/18 6:35 p.m.

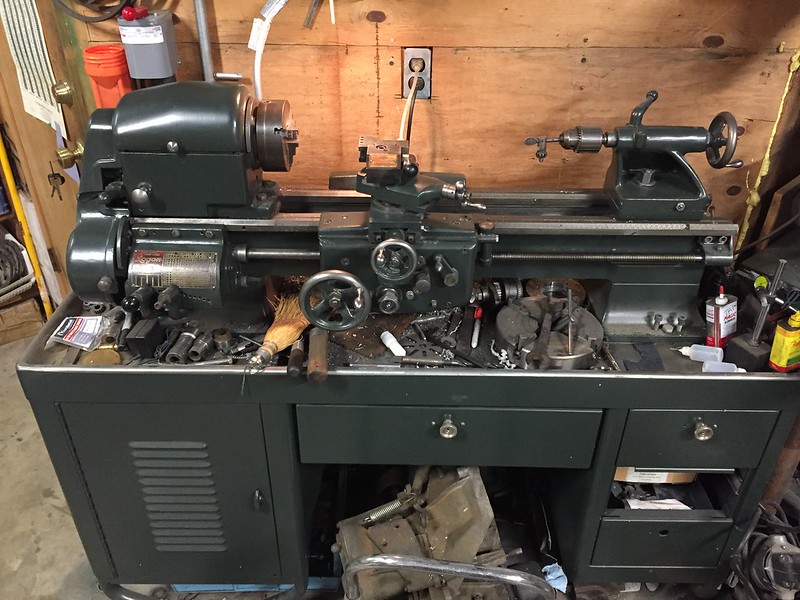

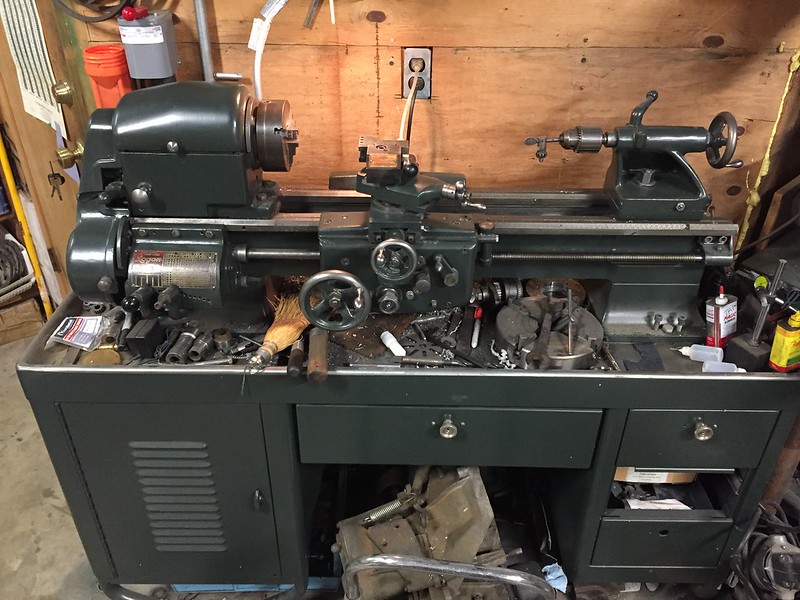

I picked up a lathe today from GovDeals. I happened to take a look for anything close by and found this with only 2 days left on the auction. I won it for $510 on Thursday and picked it up today.

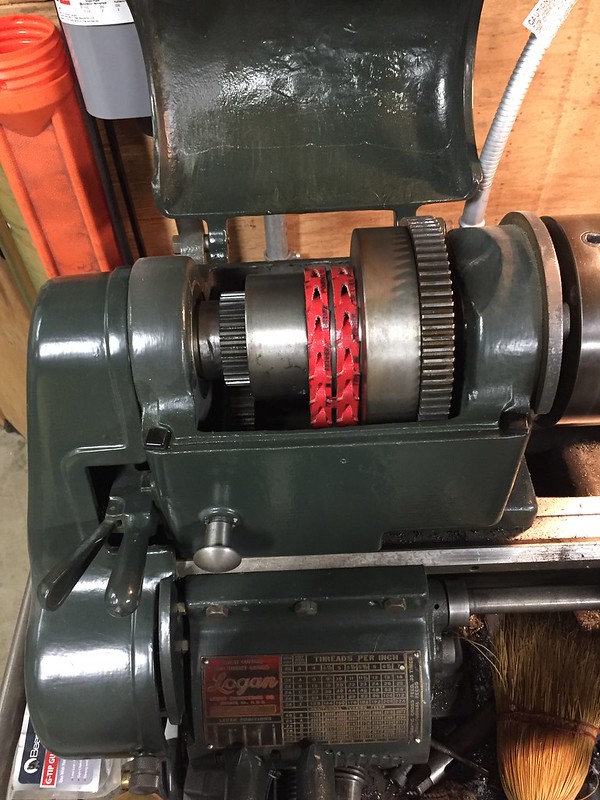

It is a Logan model 1922, 11" swing, 36" between centers.

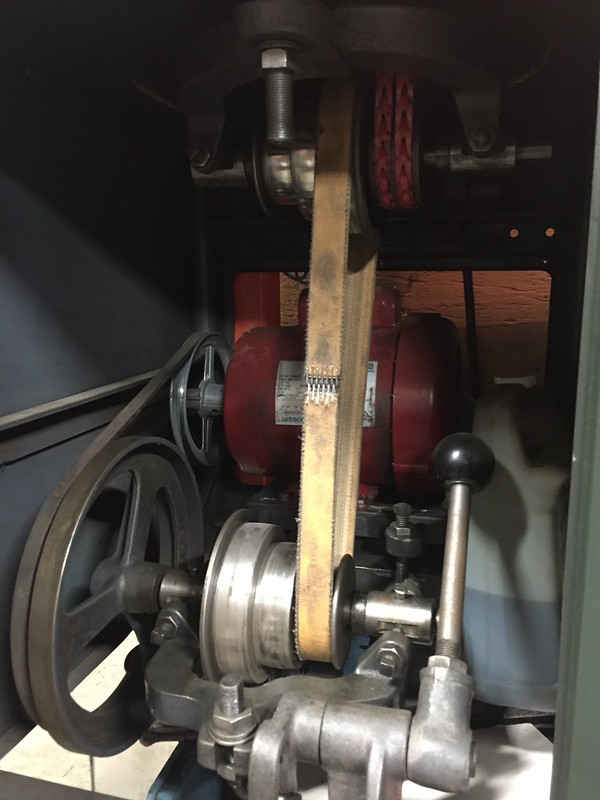

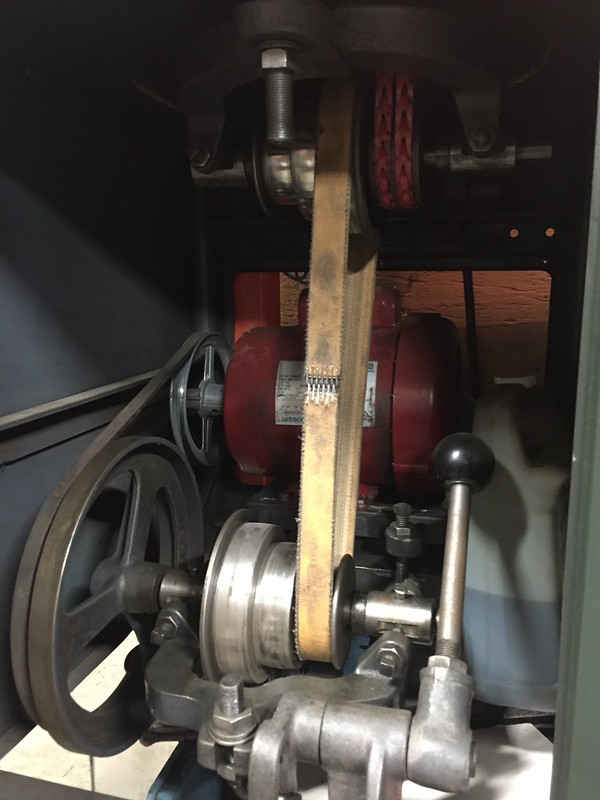

The auction only listed it as single phase so I was happy to find that it has a 115v single phase motor that looks newer. The motor and pulleys are supported by an additional leg and hang off the back. The two mounts for the motor were broken and it was sagging down supported only by the v-belt. This is possibly why it was up for auction. The brackets look easy enough to make from some angle iron if the factory replacements seem too expensive. The nice thing about this one is that the company still supports them with parts.

After a couple hours of work we got it down into the basement (my phone takes terrible pictures).

I'm going to clean it up and repair the motor mounting before moving it to its final home (adjacent room in the basement that needs to be cleaned).

The listing said that it did not come with any tooling. When I was getting it loaded the worker at the surplus warehouse said that they had a box of stuff that they thought went with it so they brought it out. It has some tools and some of the wrenches and keys that go with it along with some other things I have not yet identified.

I will probably upgrade to a quick change tool post at some point.

Looks good! Those are nice sturdy lathes with plenty of room to do real work.

Quick change tool-posts are great, and I'm very fond of indexable carbide tooling. I can grind a tool OK, but the inserts cut so well.

CDCO Tools is good for cheap Chinese tooling.

Carbide Depot has a very nice selection of inserts.

Digital axis read-outs are very helpful. I think I got mine from I-Gauging.

If you have any questions on your box of extras, I think I know what everything is there.

Have fun!

EvanB

MegaDork

10/30/18 10:43 a.m.

In reply to TVR Scott :

I believe I have figured out most of them. The steady rest looks like it is complete, just needs some assembly. I'm not sure what the large round plate with 4 slots is. There is also a smaller one with only one slot. There is one piece next to the t-handle square drive chuck wrench that I am not sure about, I can take a better picture.

I ordered the instruction manual and parts list. The one piece I found on the site that looks like the motor mount bracket is listed as a hinge bracket so I believe that is the smaller one that holds the hinge for the pulley/belt cover. It is $65 so I assume if they have the ones for the motor they would be similarly priced.

http://store.lathe.com/lp-1459.html

Looks like I will be making those from some angle iron.

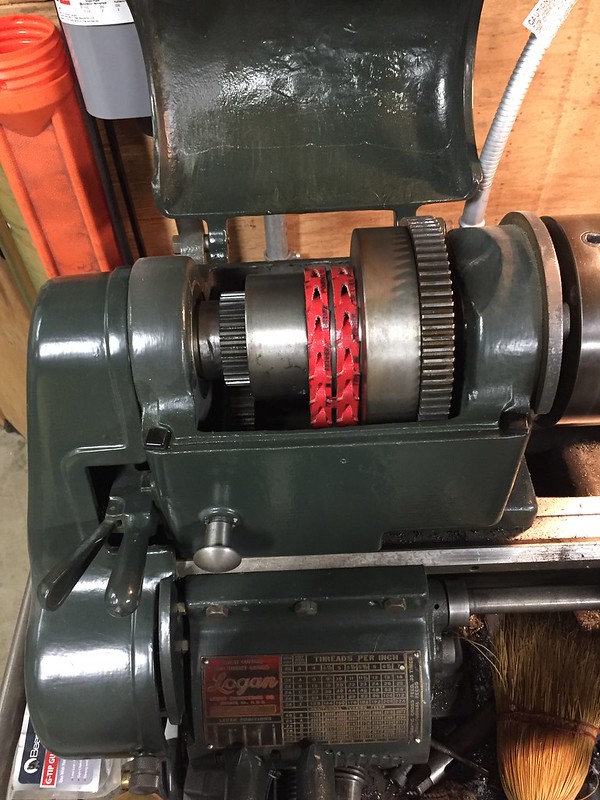

Good score! The only issue I've ever had was with the drive thingie popping out. It sits on the big gear behind the chuck and connects tht gear to the V-Pulleys behind. It usually only happens on the finish pass..... =~ (

I restored the 1942-ish version of that machine. My ways are pretty worn, but this machine serves me really well. I've still got a spare leadscrew and gearbox that I need to sell, among a few other odds and ends.

" />

" />

I had to replace the back gear (on the right in the image below). The only one I could find on eBay at that time was for a smaller bore. I rebored it and cut a new key. Good as new.

I also gave it a new drive motor.

I bought mine from the original owner! It was a baking equipment manufacturer. Took me months to scrape all the grime off of it and get it cleaned and painted. Modernized with a new reversing switch, KDK tool post, and a lamp.

The round plate with the slots is a face-plate. Goes on the headstock instead of a chuck. It can be useful for boring bearing races and such on a big flat plate. It can also be a good way of flinging parts and tooling across the shop. Use caution!

I think I've only used my face plate a couple times.

I think I know which other part you were wondering about. Hard to tell, but it looks like a "lantern-style" tool holder to me. Compare it to the part holding your tool on right now. Looks the same. Gives you rotational and tilt adjustment on the tool. I'm sure some people use them to great effect, but I'm very happy with and quick-change post and indexable tooling.

EvanB

MegaDork

10/30/18 5:49 p.m.

TVR Scott said:

I think I know which other part you were wondering about. Hard to tell, but it looks like a "lantern-style" tool holder to me. Compare it to the part holding your tool on right now. Looks the same. Gives you rotational and tilt adjustment on the tool. I'm sure some people use them to great effect, but I'm very happy with and quick-change post and indexable tooling.

You are correct, I didn't think of that not having seen it as part of the whole assembly.

I've been following this guy on Youtube: https://www.youtube.com/channel/UChFKw4ONO7ys2oXAndTROMw/videos He has a Logan lathe and has built some neat parts for it.

EvanB

MegaDork

10/30/18 7:32 p.m.

In reply to stuart in mn :

I hadn't seen that one yet, I'll have to watch some of his videos.

Also you mentioned a small face-plate with just one hole. That'll be for turning shafts between centers. I see in your picture there that you've already got a live center. You clamp a lathe dog to the shaft and that face-plate drives the part.