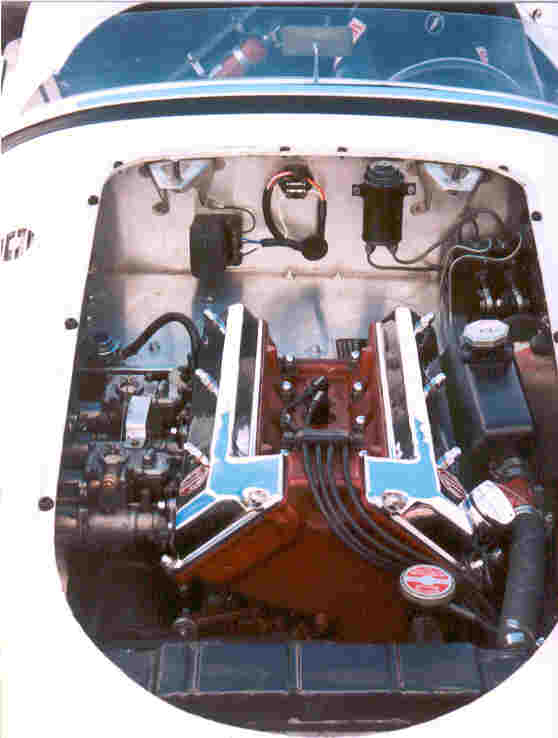

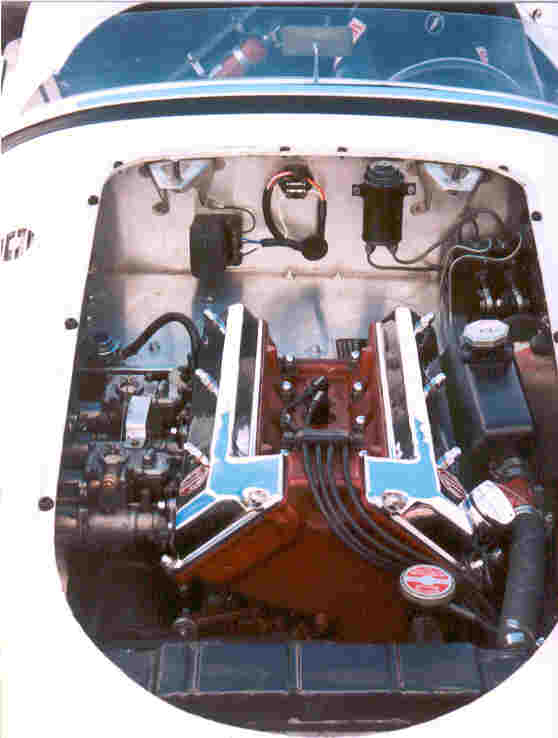

Our Bugeye Sprite’s body was just full of holes. Holes drilled for a fire extinguisher and a Panhard bar, holes drilled for an MSD ignition and a tachometer.

We had lots of holes.

As we’re putting this one back on the street, we needed to fill those holes.

The smaller ones could ju…

Read the rest of the story

nocones

PowerDork

10/3/22 1:17 p.m.

One great trick for making small patch panels like this is masking tape.

Here you can just see the outline of the rectangle I'm prepping to fill.

Masking tape over the hole and then razor blade it out as accurately as possible. Then since it's masking tape you can just stick it to scrap metal like a sticker. If I want to leave a gap and the shape is complicated I give the masking taped part a light shot with spray paint, peel off the tape and then bandsaw cut INSIDE the lines. The Paint won't lift like masking tape will as the metal heats. For simpler shapes you can get away with just using the masking tape.

The masking tape is also great if there is contour to the part. If your dealing with rusty metal before you cut it out, cover it in masking tape. Then scribe your cutlines through the tape. The masking tape is your pattern and when you try to force it flat it will tell you if you have a compound curve your dealing with. You can cut the maksing tape to flatten it and it shows you where to shrink, or anywhere the tape bunches you know you need to stretch. If the masking tape lays flat nicely you just have a simple curve and you can use whatever means to bend it.

In reply to nocones :

Good tip. Thank you for sharing the details.

In reply to nocones :

Yes, great tip.Never thought of that one.

In reply to nocones :

That is great stuff!!! If I ever get to a few of my way back burner projects, that'll save me some money

wspohn

SuperDork

10/14/22 3:09 p.m.

When building a race car (or returning one to the street) one must deal with uneeded holes in the firewall one way or the other - either plug them by welding or installing rubber plugs or wedling them up (or in the case of my TVR, glassing them up).

I took another route on another race car of mine, a vintage MG. I simply sheathed the firewall and heater shelf area with lightweight sheet alluminum.

Your way is better assuming that you have the ability to weld (or a weder that works for beer).

In reply to nocones :

Wray Schelin has a good video on making flexible patterns like this with masking tape:

https://www.youtube.com/watch?v=y-JQgPm4_7s

Patching Screw Holes

One Trick I learned is that self tapping Sheet Metal Screws can be used as well to plug holes. Simply start the sheet metal screw into the hole until it stops but do not force the screw to deform the surrounding sheet metal. Grab your right angle grinder with a cut off wheel and cut the top of the screw off leaving some exposed screw. Place the flat side of the cutoff wheel or a grinding wheel on top of the screw and begin grinding the post down. Screw will become red hot and will weld itself into place. Grind flush, prime and paint. Done

Jim Gruber

Apollo Beach, FL