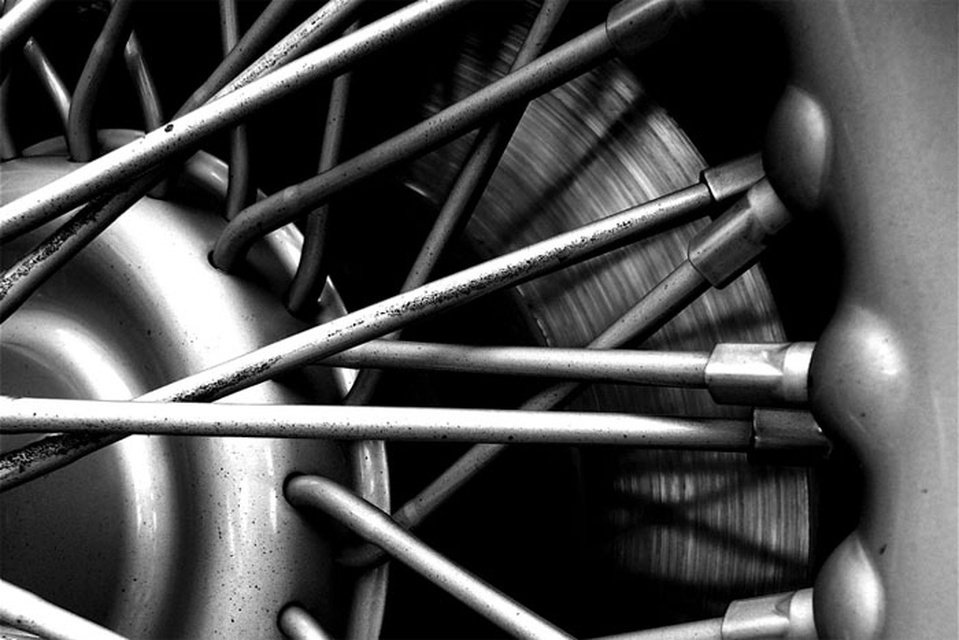

One of the things that distinguished the classic British sports cars from many of their contemporaries was their striking wire wheels. Usually laced with 48, 60 or 72 spokes, these wheels offered a performance boost as well as visual punch.

Back before the advent of today’s “mag-style” wheels, race…

Read the rest of the story

Great article, my opinion: wire wheels for show cars and disc wheels for daily drivers. Wire wheels are more trouble then an old whore for drivers. Working on the winged knockoffs I wrap the wing nut with ~ .050 th'k aluminum before the hammer use, saves the chrome plating.

Very comprehensive article, good job! Should be considered mandatory reading for anyone owning a wire-wheel equipped car, regardless of origin.

To secure and protect the finish on my chromed knock offs, I use the two (2) hammer method...

I hold a solid rawhide mallet tight against a k/o blade, and strike the opposite end of that with any of the appropriate lead or copper k/o hammers I have on hand. Since I installed these center-laced wheels in 2010, I have periodically rotated the five (5) wheels/tires around the car, and the k/os still look as perfect as they were when I received them__zero dents, zero compromised plating.

And they look great, seeing far more street use than show fields.

In reply to rdstr :

I raced a set of Dunlop wire wheels in my Blackjack Special for decades (1975-2001) then sold it and it raced several more years with the same wheels and hubs.

Regular greasing of the hubs with anti seize, checking of the spokes, and polishing ensured I was safe diving into turn 5 at Elkhart Lake at 155 mph lap after lap. That was using sticky Dunlop race tires as wide as was allowed.

In 1971 I converted my MGTD to 48 spoke wire wheels I took off a used 1956 MGA. I not only have driven that across country I’ve also vintage raced that as well, again using Dunlop race tires. Plus all the touring and car events I’ve attended.

wspohn

Dork

10/22/18 12:28 p.m.

It is worth noting that the popular trend of replacing wire wheels with splined mag wheels has one negative aspect, although it does eliminate spoke tuning. The solid machined wheel centre that bolts into the mag wheel makes the wheel assembly heavier (unsprung weight) than the wire wheel, which has the splines milled into a lightweight sheet metal centre.

Wire wheels, with a little maintenance, can stand up to long use quite nicely. They did service even on powerful and weighty cars like the AC Cobras, Aston Martin DB series through DB6, Morgan +8, and many Italian cars (the hub sizes on the Borrani equipped cars was identical to the British one used by all but Jaguar).

Toebra

Dork

10/28/18 7:50 p.m.

I had a set of toothbrushes that I modified to clean the wire wheels on dad's XKE. He would give me a couple of bucks for detailing his car, then we would go get ice cream, a caramel apple or something. There are roads between Sacramento and a variety of ice cream and candy shops in the Sierra Nevada mountains and the foothills that are something to experience in an open car making a great noise. If you have kids, you owe it to them.

In reply to Toebra :

I used to bring the wheels into my living room on a big piece of cardboard to polish the chrome. One wheel at a time, I’d watch a show or movie and carefully polish each and every spoke. During commercials I’d take one wheel down and swap it with another. By the end of the evening the wheels and knock offs looked pretty nice.

Now that the shop is turning into a man cave I can watch from down there.