slefain

PowerDork

11/8/18 10:30 a.m.

So this week I'm driving a 2019 Ram V8 with the eTorque system:

This thing fascinates me. The alternator/generator kicks in an extra 130 lb-ft of torque. The entire package with battery adds about 100 pounds of weight.

So when will we see these things stripped down to a simple "on/off" switch that kicks in whenever the driver wants an extra power bump? The system is 48v, but I can see keeping a 12v alternator to run the rest of the car, with the alternator/generator in charge of keeping the 48v 430 watt-hour battery pack topped up.

Robbie

UltimaDork

11/8/18 11:53 a.m.

That is awesome. I have considered powering the alternator on a challenge car for an extra boost (or at least stop the alternator dragging on the motor), but Ive not done it yet.

NickD

UberDork

11/8/18 12:12 p.m.

Didn't BenModified use an alternator as a reverse mechanism on one of his little trucklets?

I want to hear more about powering the alternator. This could get fun. Like an almost free electric supercharger....

Driven5

SuperDork

11/8/18 12:48 p.m.

Isn't that basically the same type of 'mild hybrid' system that GM has had for around a decade or so now?

So it's basically a reverse supercharger? it helps take of some of the engine's load which translates to more power output to the ground? am i understanding that correctly?

Robbie

UltimaDork

11/8/18 1:20 p.m.

edizzle89 said:

So it's basically a reverse supercharger? it helps take of some of the engine's load which translates to more power output to the ground? am i understanding that correctly?

yep! except it could add more power than just the accessory load. Since it is turning the front crank pulley theoretically it could drive the car around with the engine freewheeling.

Robbie

UltimaDork

11/8/18 1:21 p.m.

Driven5 said:

Isn't that basically the same type of 'mild hybrid' system that GM has had for around a decade or so now?

If so, what cars did they come on since I need to go check junkyards...

Driven5 said:

Isn't that basically the same type of 'mild hybrid' system that GM has had for around a decade or so now?

This is really what it is. I think they are pretty neat- much more effective in time to torque than any e-boost system, and much more efficient way to get some electrified power.

Also- there's no need for a 12v system- just run a regulator that drops down to 12v- as this IS the starter, and everything else is a minor compared to that. Or even up all of the electronics to 48V, which would let the wires shrink due to the lower current for the same power. I'd like to see something like that put onto a smaller engine, and use it to boost it to be capable of towing. That would be really cool.

been looking into converting an alternator to run a modified powerwheels. I have doubts it would make enough power to have a noticeable difference.

Driven5

SuperDork

11/8/18 2:28 p.m.

Robbie said:

Driven5 said:

Isn't that basically the same type of 'mild hybrid' system that GM has had for around a decade or so now?

If so, what cars did they come on since I need to go check junkyards...

https://en.wikipedia.org/wiki/BAS_Hybrid

slefain

PowerDork

11/9/18 9:13 a.m.

I'm doing an article on the 2019 Ram so I'm emailing my FCA rep a list of questions about the system.

Interesting that the 3.6L eTorque unit is mounted in front of the engine, while the 5.7L unit is mounted up top like a normal alternator.

Vigo

UltimaDork

11/9/18 9:43 a.m.

The 3.6 has a ton of room between the engine and the radiator. The alternator also hangs off the front side of the belt drive on the 3.6 Wrangler.

Yes, it is a belt-assist mild hybrid system. I think what is probably better about it now than when GM originally did it long ago is that it's being used on vehicles that really need the help, and it is probably used in a much more thorough way. You can use a system like this in all manner of ways, like giving immediate throttle response with the e-torque while ramping up actual engine throttle slowly to have minimal throttle tip-in emissions, etc. There are some youtube videos where FCA reps talk about how it is used, although I havent seen one where they aren't dumbing down their explanations somewhat. I suspect there are a LOT of different things being accomplished from an engine management and emissions perspective.

As far as when will they be hot rod parts? Probably never except for like 12 people who have self-educated enough to reverse engineer it. The implementation of electric drive systems is far, far outpacing the growth of electric related knowledge in the car enthusiast community in general. At the rate that 'normal car guys' are learning about electric motor controls and battery management etc, it will be illegal to humanly operate a project car on a public road before John Doe Car Enthusiast could rig this up to his car.

As far as using an alternator as a motor, you have to rewire it a bit in the back cover and use a 3 phase motor controller to run it. I actually think modifying a cars stock alternator to be a motor/generator through a motor controller to a separate higher-voltage battery pack is sort of feasible as a DIY project. The question would be whether you would add enough torque for it to be useful other than as a learning experience. Driving from the alternator to the crank would benefit from something like a ~5:1 pulley ratio so if you could make an alternator put out 20 lb ft it would be 100 at the crank, but I just don't know what kind of outputs are possible so i cant even ballpark it with my limited knowledge.

Robbie

UltimaDork

11/9/18 11:21 a.m.

Vigo said:

The 3.6 has a ton of room between the engine and the radiator. The alternator also hangs off the front side of the belt drive on the 3.6 Wrangler.

Yes, it is a belt-assist mild hybrid system. I think what is probably better about it now than when GM originally did it long ago is that it's being used on vehicles that really need the help, and it is probably used in a much more thorough way. You can use a system like this in all manner of ways, like giving immediate throttle response with the e-torque while ramping up actual engine throttle slowly to have minimal throttle tip-in emissions, etc. There are some youtube videos where FCA reps talk about how it is used, although I havent seen one where they aren't dumbing down their explanations somewhat. I suspect there are a LOT of different things being accomplished from an engine management and emissions perspective.

As far as when will they be hot rod parts? Probably never except for like 12 people who have self-educated enough to reverse engineer it. The implementation of electric drive systems is far, far outpacing the growth of electric related knowledge in the car enthusiast community in general. At the rate that 'normal car guys' are learning about electric motor controls and battery management etc, it will be illegal to humanly operate a project car on a public road before John Doe Car Enthusiast could rig this up to his car.

As far as using an alternator as a motor, you have to rewire it a bit in the back cover and use a 3 phase motor controller to run it. I actually think modifying a cars stock alternator to be a motor/generator through a motor controller to a separate higher-voltage battery pack is sort of feasible as a DIY project. The question would be whether you would add enough torque for it to be useful other than as a learning experience. Driving from the alternator to the crank would benefit from something like a ~5:1 pulley ratio so if you could make an alternator put out 20 lb ft it would be 100 at the crank, but I just don't know what kind of outputs are possible so i cant even ballpark it with my limited knowledge.

Alternator puts out say 100 amps at 12 volts? 1.2kw. Which is like 1.6 HP. If you upped the voltage to 36 or 48 volts maybe you get to 5-7 HP theoretical max (if the electronics inside the alternator can take it). But the good news is that you can get that bump WAY down low in the RPM range where the gas motor may only be making 35 HP.

Might not help so much on an LS. but on a miata 1.6 it could be a noticeable bump.

Vigo

UltimaDork

11/9/18 11:30 a.m.

I want to agree with you and build a hybrid miata with more torque and with almost nothing changed under the hood (that's such a cool concept) but i dont know if you can take alternator output and convert it to motor output at anything near 1:1. I hope someone that knows more about this will chime in. If there is a way to rewire your alternator and add a 48v pack and some motor controller stuff to the trunk of a miata and add 100lb ft at 1500rpm I will go buy one right now and try to build it.

Robbie

UltimaDork

11/9/18 11:48 a.m.

Apexcarver said:

https://www.youtube.com/watch?v=IKqy3rRWJQE

not a whole lot of power...

yeah, that guy is using a 1500W controller. 1.5kw or maybe 2hp. He ups the voltage to 48, but also has a 40 amp fuse so is not using nearly 100 amps.

I dunno how the alternator would handle 3kw or 4.5kw. It probably wouldn't. But that is I think minimum of what you would need to start feeling it.

I think the BAS hybrid alternators are probably rated a lot higher (I looked at some on ebay and they have BIG leads, like maybe 2 or 4 gauge wire, which means they can probably handle a realistic amount of juice to make some HP).

Robbie

UltimaDork

11/9/18 11:50 a.m.

In reply to Vigo :

doubt its 1:1, but that would be theoretical max. Most motors are in the 90% range though, so I'd be surprised if you couldn't get say 85% of the power into a twisting motion.

Also, don't think about it in torque (you don't know the RPM). it's the kW or HP that matters.

Vigo

UltimaDork

11/9/18 4:20 p.m.

Also, don't think about it in torque (you don't know the RPM). it's the kW or HP that matters.

Torque is what you feel, so that's how i conceptualize whether it would be worth adding as torque fill. Trying to add HP electrically is almost a non-starter because to sustain any real HP for a useful amount of time you have to have $$$$ in batteries. If you tell me a motor adds 5hp i will say "not worth all the effort". If you instead told me that the same motor was adding 100 lb ft (for example) at 2000 rpm on the ICE i would say "sweeeet", at least in the Miata example. Implied in all that is that you'd be getting all the benefit at part throttle because noone stays WOT and 2000 rpm for more than a brief second. If you want an electric system that will help acceleration over the long haul you start to run into what the true cost of electric horsepower is.

FCA hasn't even changed the HP ratings of the etorque models as far as i know. I suspect they haven't because they don't want you to do the math on dollar per horsepower. It is dismal, and that's before you find out the 48v pack probably can't do full assist for a single 0-60 run. Talking about adding the 100 lb ft here and there is selling the system on its strengths. I definitely wouldn't try to talk someone into converting their alternator to a 3-phase motor/generator on the idea that it will 'add hp'. This is mostly semantics, i know.

Robbie

UltimaDork

11/9/18 4:44 p.m.

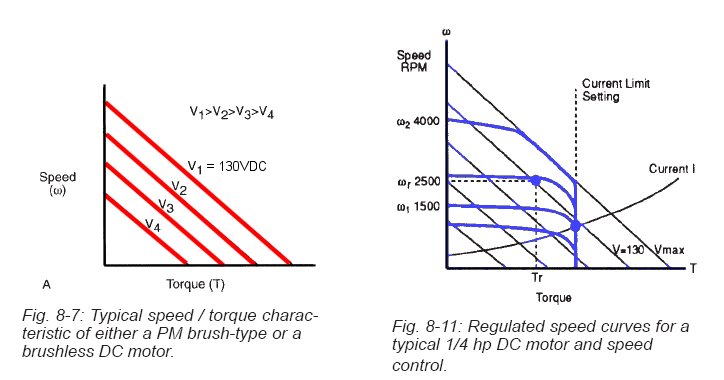

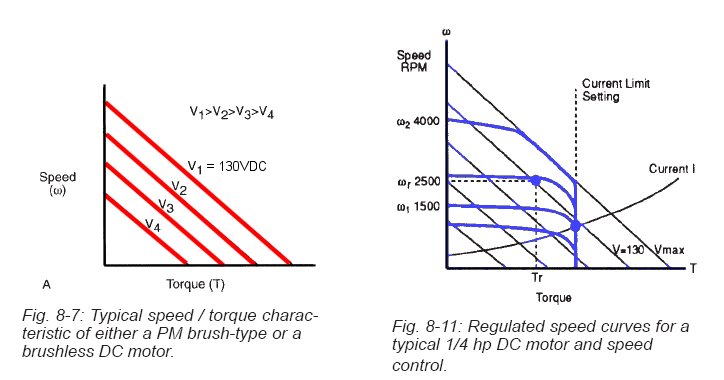

In general, the electric motor is a constant power device. That means it has huge torque at low RPM and zero torque at high RPM.

Like this:

If you gear it down 5:1, that means that at 2000 RPM engine speed, the electric motor is at 10,000 RPM, and it is definitely done producing any useful torque at that point.

So yes, maybe the motor adds 20 ft lbs of torque (at 0 RPM), but that isn't super useful in the general sense of a car engine. at 10k rpm what torque does it make? almost none, so even multiplying it by 5 you still have almost none.

Again, better to talk in terms of HP or kW since that is what is more 'constant' on an electric motor. (that is the 'flat' diagnonal zone on the blue line - you can see current limits the 0 RPM torque and each motor has an top RPM limit where it produces no additional torque). And ideal electric motor is like the red lines on the left but the blue lines are more realistic. If you gear the motor to stay in that flat diagonal area, it is producing constant HP, but the torque goes up and down with RPM.

I'll also bet that all these e-assist motors are very much 100% out of steam at the gas motors' peak HP level, and thus they add nothing to the HP 'rating' of the engine. But they add a lot of HP area under the curve much lower in the engine RPM range. Some people like to think of this as 'torque', but I always argue it is just HP at a lower RPM.

Robbie

UltimaDork

11/9/18 4:55 p.m.

Vigo said: If you tell me a motor adds 5hp i will say "not worth all the effort". If you instead told me that the same motor was adding 100 lb ft (for example) at 2000 rpm on the ICE i would say "sweeeet", at least in the Miata example.

What if I just said the motor adds 38 hp?

100 ftlbs at 2000 rpm is 38 hp. But the hp stands by itself without an RPM value, while torque does not. 5 hp is in fact equal to 100 ftlbs at 263 RPM.

I can make 2000 ftlbs by hanging on a 10 ft bar. But I can't use said bar to fling a dragster down the strip in 5 seconds because my torque is at 0 RPM, and therefore 0 hp.

Not trying to make this a pissing match, but it is odd to me that people choose to say "I have this torque at that speed", instead of just saying I have this power. It's like saying I'm 4 seconds tall at 45 mph, instead of just saying im 5 ft tall.

Vigo

UltimaDork

11/9/18 7:49 p.m.

It is a matter of my preference because I personally feel it is easier to correlate numbers to physical sensations through torque values than through HP, particularly since almost noone even among car enthusiasts know what HP their drivetrain produces below about 2500 rpm. Most dyno pulls don't even go WOT at the rpm's I was talking about in the miata scenario. A car enthusiast can calculate it if they care to, or they can ballpark it off the fact that most normal production car engines will produce at least 80% of their peak torque right over 1000 rpm and have a 'good enough' number without doing the extra step. 50% more than 100 lb ft at 2000 rpm is also 50% more than 38 hp at 2000 rpm, except one requires more math because good luck finding the 38hp number (ICE's hp at 2000 rpm) without doing the math yourself since ICEs don't come with a dyno graph that starts at 0 rpm. If the subject of the thread did anything meaningful at higher rpm it would be a lot easier to mesh the motor and ICE numbers using HP as the unit. I guess you could say it is just coming at the motor from an ICE perspective vs coming at the ICE from a motor perspective. Just a matter of preference.