You can use it to weld studs to steel and then GENTLY pull the sheet metal a bit at a time till you get it close to where you want it. Using studs is particularly handy for places you can't get to the back of the panel. Then depending on your skills you can massage the metal some more with various other tools so you'll use the least amount of filler. They work better on old school thickness sheet metal than on the thin modern stuff (for me at least). I like the glue-on's for thin metal.

While you can grab the studs with vice grips and yank it's much better to use a tool like the one below my bud Jeff (RIP) is shown demonstrating. You'll have more pulling force because of the leverage it provides against the panel and be able to control the pull more effectively. The area where the dent is Jeff was working out is boxed in by the inner wheel well and trunk drop off so no access from behind.

You can also use that stud gun to install new short studs for window trim, moldings, etc. that were used on old cars. Should you need any of the short studs send me a PM and I'll mail ya a few. They're only available by the hundred and most people only need a few.

[URL=https://hosting.photobucket.com/albums/ff292/NOTATA/The%2014%20Car%20Performance%20Therapy/.highres/003_zpsbf3b229a.jpg?width=1920&height=1080&fit=bounds] [/URL]

[/URL]

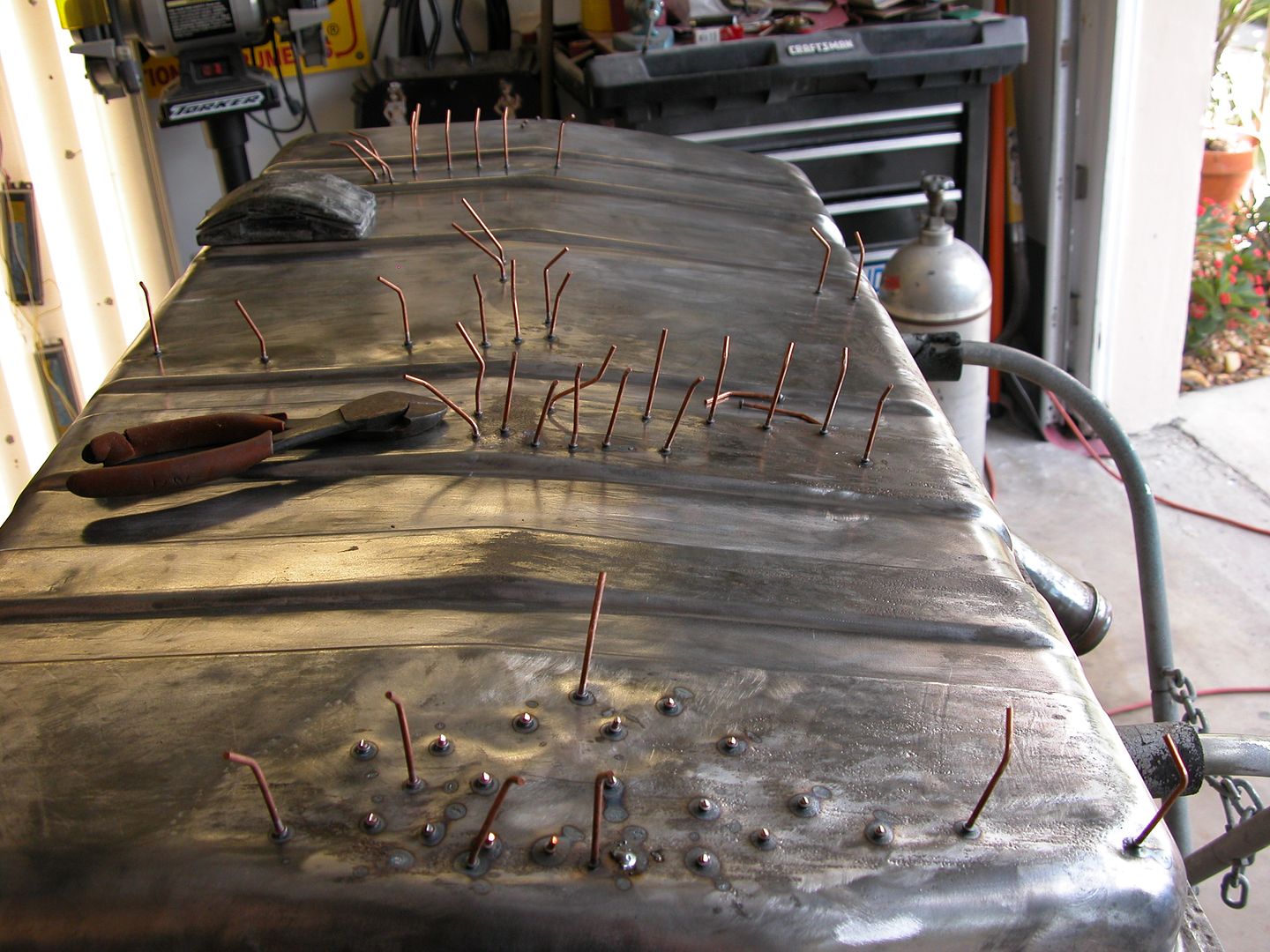

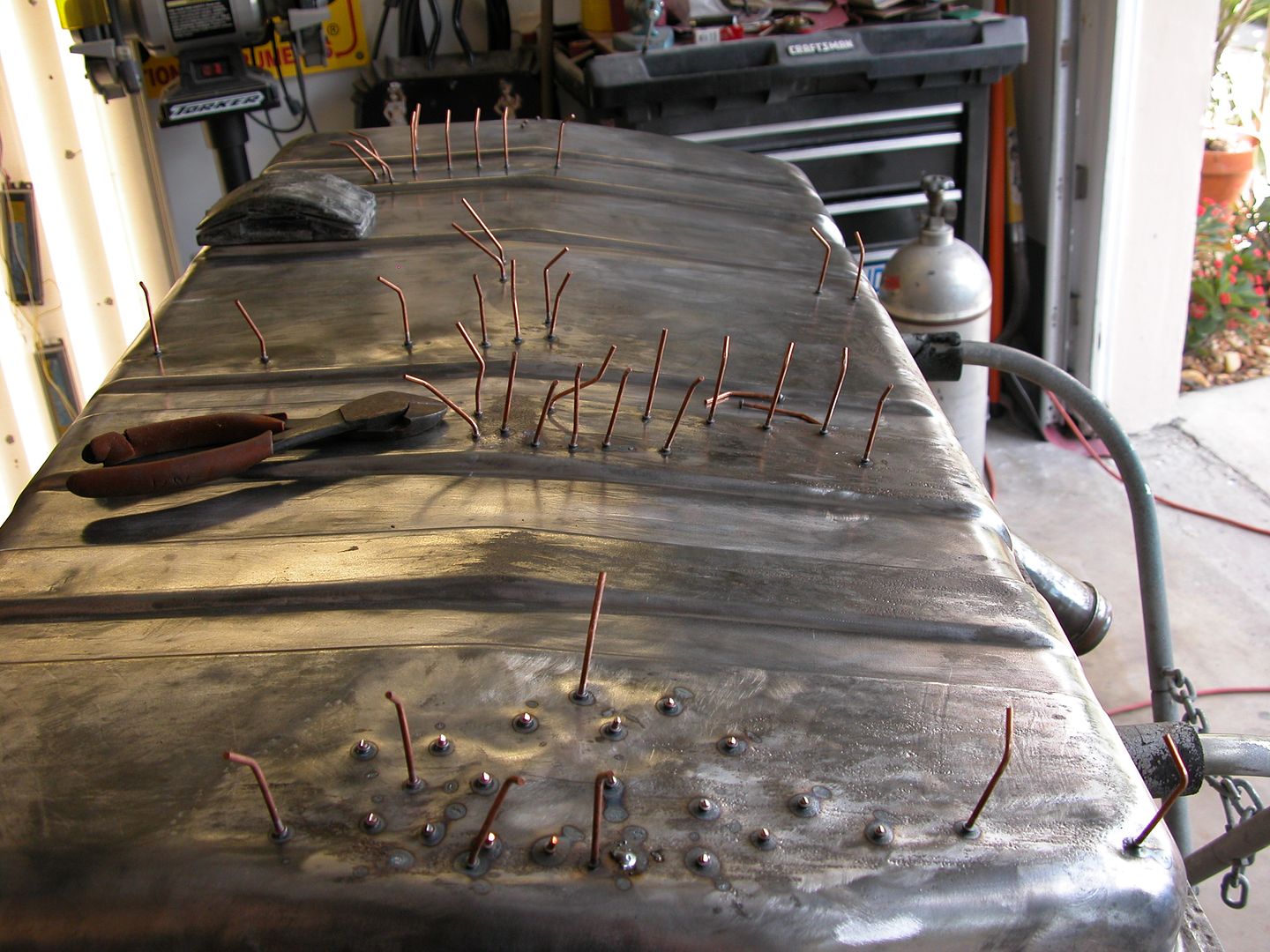

Here's how I use them on gas tanks.

Weld studs & pull, keeping in mind that if it's a wide area you may need to work your way out from the middle so you can reach them with a stud puller.

Clip off studs with a side cut plier then grind till low enough for filler.

Fill & block sand.

Epoxy primer then sand and apply whatever top coats you want to use.

Like many things there's more than one "right" way and as an example some folks prefer to epoxy prime before body filler work. I use both methods depending on the job. The tank below was very clean metal and I used an etching filler.

[URL=https://hosting.photobucket.com/albums/ff292/NOTATA/The%2014%20Car%20Performance%20Therapy/.highres/009_zps106a9234.jpg?width=1920&height=1080&fit=bounds] [/URL]

[/URL]

[URL=https://hosting.photobucket.com/albums/ff292/NOTATA/The%2014%20Car%20Performance%20Therapy/.highres/010_zpsbada5bcc.jpg?width=1920&height=1080&fit=bounds] [/URL]

[/URL]

[URL=https://hosting.photobucket.com/albums/ff292/NOTATA/The%2014%20Car%20Performance%20Therapy/.highres/001_zps516776aa.jpg?width=1920&height=1080&fit=bounds] [/URL]

[/URL]

[URL=https://hosting.photobucket.com/albums/ff292/NOTATA/The%2014%20Car%20Performance%20Therapy/.highres/002_zpsede4a8e4.jpg?width=1920&height=1080&fit=bounds] [/URL]

[/URL]

[URL=https://hosting.photobucket.com/albums/ff292/NOTATA/The%2014%20Car%20Performance%20Therapy/.highres/001_zpsbd8978b5.jpg?width=1920&height=1080&fit=bounds] [/URL]

[/URL]

[/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL]