[Editor's Note: This article originally appeared in the March 2011 issue of Classic Motorsports.]

It’s a common question in our world: Does this automotive widget work as promised? Roller rockers are among the more popular and often misunderstood widgets, and they promise seemingly magical gains with few downsides.

Do roller rockers really improve performance, save gas and make your teeth whiter? Well, it helps if you know how they work, when they’ll work for you, and when they won’t.

Let’s separate the poseurs from the rest of us right away. A common misconception is that roller rockers are better than their stock counterparts because they use bearings instead of bushings. The resultant loss of friction supposedly makes power.

That’s just not the case, as there’s a great deal more going on. The loss of friction may help things last longer, but it’s not going to measurably add power.

Before we get into the hardcore data, let’s understand what a rocker arm does. The camshaft controls the valves by pushing up on the lifter, which in turn pushes up on a pushrod.

This is where the rocker arm comes into the equation. The valve needs to be pushed down, so the rocker arm works like a teeter-totter to change the upward motion of the pushrod to the downward motion needed to open the valve.

Pretty quickly, engine designers realized that just as you can adjust the fulcrum point of a teeter-totter to get a desired ratio of weight and motion, you can also adjust the fulcrum point of a rocker arm to affect a desired ratio. Most rocker arms are designed to increase the lift of the cam by having a positive ratio. Rocker arms are commonly designed to increase lift at the valve by about 1.3 to 1.6 times the lift at the cam. This setup also slightly increases duration, but not by the same ratio.

Why use rocker arm ratios to increase lift instead of just increasing lift at the cam? First, high-lift cams tend to have much sharper radii and larger lifter travel distances. This increases the rate of wear and causes other unwanted effects.

Second, a higher rocker ratio helps the valve spring keep the lifter on the cam. For example, a 200-pound valve spring with a 1:1.25 ratio will give 250 pounds at the lifter, while a 200-pound spring with a 1.5 ratio will give 300 pounds at the lifter.

Here’s another way of thinking about it: You can use lighter valve springs with higher lift rockers because their net effect is increased. With these factors in mind, engine designers use a combination of camshaft specifications and rocker arm ratios to produce the best combinations of power, drivability and durability.

This brings us to the first thing that must be understood about most of the roller rockers on the market. In addition to offering roller bearings, most roller rocker setups are designed with a more aggressive rocker ratio. For example, they’ll sometimes go from 1:1.4 to 1:1.5. It is this change of ratio that can provide power increases—don’t worry, more on this soon.

Now let’s talk about the rollers in these rocker arms. Factory rocker arms usually have a fulcrum, or pivot, that’s made up of either stamped steel or a bushing of bronze or Oilite. The tips of most factory rocker arms slide slightly across the valve as they go through their motion. Aftermarket roller arms sometimes replace the pivot with a set of needle bearings and usually put a roller tip on the end that interferes with the valve.

The needle bearings have debatable value. While common sense says they should reduce friction and last longer than stamped steel or a bushing, in reality that isn’t always the case. Most needle bearing setups are designed to rotate completely around an axle, not just move slightly back and forth as they do in a rocker arm. Used in an incorrect application, these needle bearings may wear—and cause wear on the rocker shaft—faster than standard bushings.

The roller tip, on the other hand, makes good sense. At a standard ratio, the tip of a rocker arm slides across the top of the valve. To aid the sliding, this tip is rounded and contoured to maintain consistent contact with the valve. It’s also designed to run with a thin layer of oil between it and the valve stem.

However, as the rocker arm ratio increases, angles get sharper, lift gets higher, and the tip has a harder time maintaining the right geometry to last as long. Replacing the contoured tip with a roller compensates for this problem at the cost of more complexity and weight. The additional weight is often compensated by a switch from steel or cast iron to aluminum, but this comes at a cost as well—usually financial.

Going Past Eleven

Of course, there’s one big question surrounding these aftermarket roller rockers: Do they work?

The answer, like so many others out there, isn’t simple. Basically, it depends.

It depends on whether you’ve chosen a quality set of rocker arms and whether your engine is designed to take advantage of them. If so, they work. But if you’re just sticking them on a stock engine with no other modifications, there’s a good chance they’ll actually cost you power—and hundreds of bucks.

Adjusting a rocker arm ratio is really similar to playing with camshaft specifications. The general rule: If you increase lift and duration, you’ll gain power at high rpm and lose power at low rpm. If you increase your rocker arm ratio, you’ll usually pick up some power up high at a cost of some low and midrange grunt.

And this is where you can get into trouble. Most of the engines in our classics are already designed with pretty aggressive cams and rocker arm ratios. In short, they’re made to produce good power up to the redline and no more. If we increase lift or duration without increasing the redline, we’re pushing peak power to or beyond the redline. That means we usually won’t be able to take advantage of the increases.

To put this in perspective, we made two sets of tests on the A-series BMC engine we built for our Modern Midget project car. This 1380cc engine ran a 10.25:1 static compression ratio and APT’s SPVP3 cam with the following specs: 286 degrees of nominal duration and 0.319 inch of lift at both the intake and exhaust.

We made the first set of tests with a stock cylinder head and the second with a highly modified head that had received extensive porting and larger valves. The results were predictable—in each case, the engine made more power at high rpm and lost some power in the lower ranges.

For our first set of tests with the stock head, we compared stock rocker arms with a 1:1.26 ratio to the 1:1.5 ratio roller rockers. The ratios increased the 0.295 inch of lift to 0.372 inch and 0.446 inch, respectively.

The high-ratio rocker arms did well at the peaks, picking up about 5 percent more torque and power. However, we suffered in the midrange, losing more than 5 percent. This is a prime example or robbing Peter to pay Paul.

For our second set of tests, we used our trick cylinder head with three rocker arm setups: stock (1:1.26), stock with offset bushings (1:1.35), and our rollers (1:1.5). The ratios increased the 0.295 inch of lift to 0.372 inch, 0.398 inch and 0.446 inch, respectively.

We had similar results when fitting roller rockers to our modified head: We gained nicely at the top end while giving up power and torque in the midrange. Percentage-wise, our top-end gains were not as strong as our midrange losses. But if we’re looking for power up high—think about a race car gobbling up a long straight—then it’s worth the loss down low.

While we didn’t test a bone-stock engine, this data and other experience tells us what would have likely happened. Our losses would have been similar and our gains probably would have been unrealized due to the fact that stock engines aren’t designed to run much above 5000 rpm—where all of our theoretical gains would have happened. In the case of a completely stock engine, the high-ratio roller rockers probably would have only lost power.

Ready to Rock

With most classic cars, recipes for power usually go in this order: Start with the cylinder head. Then, go to more compression and more cam. After that, reinforce the bottom end so it can be revved higher. Finally, start adding more trick parts.

That’s when high-ratio roller rockers usually work best—after the head, cam, compression, and bottom end have been addressed. In that context, they work really well. Out of that context, your time and money may be better spent elsewhere.

More like this

Comments

wspohn

Dork

8/18/20 12:18 p.m.

The use of roller tip rockers with higher than stock ratio will increase lift but also eventually wear out the valve guides (although not as quickly as high lift non-roller rockers would). I don't mean tomorrow, but 30-40K down the road, you may end up with guide issues. It sure works while it works though.

Just don't be 'that guy' that buys valve train components from three different manufacturers because they save $5 doing it, only to find that they ended up with valve spring 'crunch' when the spring is compressed fully with coil touching coil and the rest of the valve train si still trying to compress it more - I've seen that and it isn't pretty.

As noted, increasing rocker arm ratio increases valve lift. Increasing valve lift also reduces valve-to-piston clearance. No, you don't want your valves to touch your pistons - bent valves or punctured pistons can result. This could be a concern if you already have a high lift cam, high compression pistons, a milled head, or a decked block.

dougie

HalfDork

8/29/21 11:54 p.m.

In reply to jefeingold :

Correct , you need to do the math and double check everything for clearances. When done right, the gains can be huge....

wspohn

SuperDork

8/30/21 11:39 a.m.

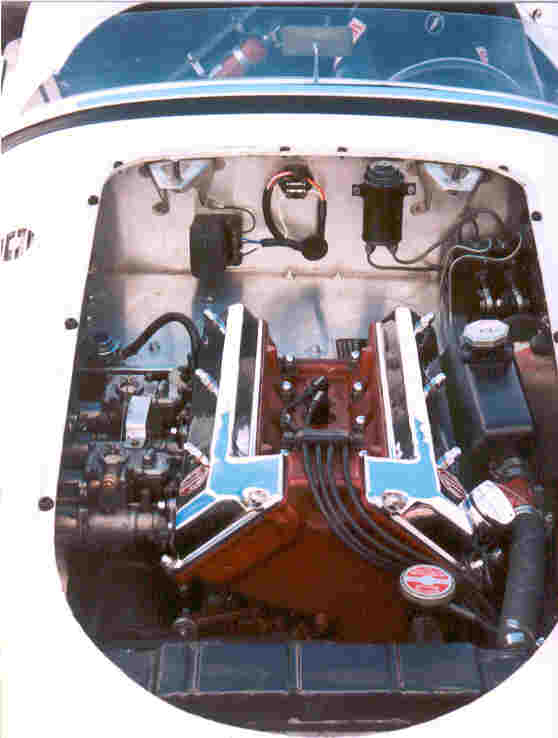

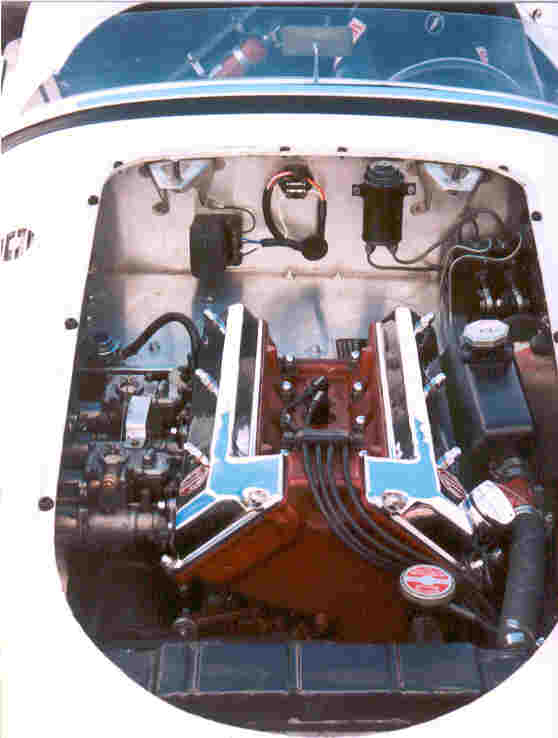

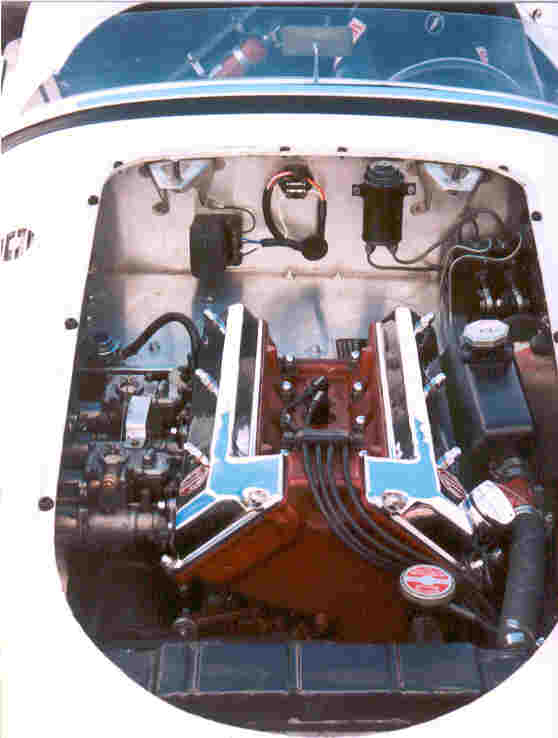

Let me guess, Dougie - do you cover all that with a nice alloy cover? They certainly are pretty.

Of course the best rockers are none at all.....

dougie

HalfDork

8/31/21 12:08 a.m.

wspohn said:

Let me guess, Dougie - do you cover all that with a nice alloy cover? They certainly are pretty.

Of course the best rockers are none at all.....

That would be true if your car sat in the garage or only saw the grass of a static car show.....I exercise mine on the track regularly as the upgraded engine was designed for.....

That would be true if your car sat in the garage or only saw the grass of a static car show.....I exercise mine on the track regularly as the upgraded engine was designed for.....

Nice driving Dougie.

Maybe I'll see you out at PIR one of these days. If I can get my car together...

you can waste horsepower with too stiff valve springs

Roller rockers were once suggested by a cam grinder named Racer Brown, who was also an advocate of roller tappets for street motors. This was from an issue of Hot Rod probably in the very early 1960s.

Racer Brown was the originator of the statement, "If a little is good, a lot is better, and WAY too much is... usually... just enough." Interesting guy!

dougie said:

In reply to jefeingold :

Correct , you need to do the math and double check everything for clearances. When done right, the gains can be huge....

Thank-You for my new screen saver. Simply meticulous work sir.

Of minor interest. Roller rockers were suggested in the early 1960s by Racer Brown, a can grinder who was an advicate of roller tappet cams for the street. It was an article in Hot Rod Mag. Included in the article was a quote from Racer Brown that I've used a thousand times. "If a little is good, a lot is better and WAY too much is...usually...just enough."

Displaying 1-10 of 11 commentsView all comments on the CMS forums

You'll need to log in to post.

By Carl Heideman

By Carl Heideman