Does anyone have a good online source to buy wing segments of a given profile? I am running a 24 Hours of Lemons car and want to add a wing. I need to keep the budget down, so I want to buy a good wing segment and then build the mount, end plates, etc.

Also, I am open to suggestions on what wing profile to run. I have a FWD car and am hitting a max speed of 110 mph in the straights.

In reply to ErrorMargin :

hatch, or sedan/coupe?

also, what's a 'convenient' width between the uprights?

I bought a cheapo megan racing wing on ebay and found the profile to be "not bad" with a couple places for pretty simple improvements. I've even seen these used on FB marketplace for 40-50 bucks.

https://grassrootsmotorsports.com/forum/off-topic-discussion/can-anyone-take-a-photo-and-turn-it-into-a-plot-of-points-xy-axis-wing-profile-content-inside/175500/page1/

In reply to sleepyhead the buffalo :

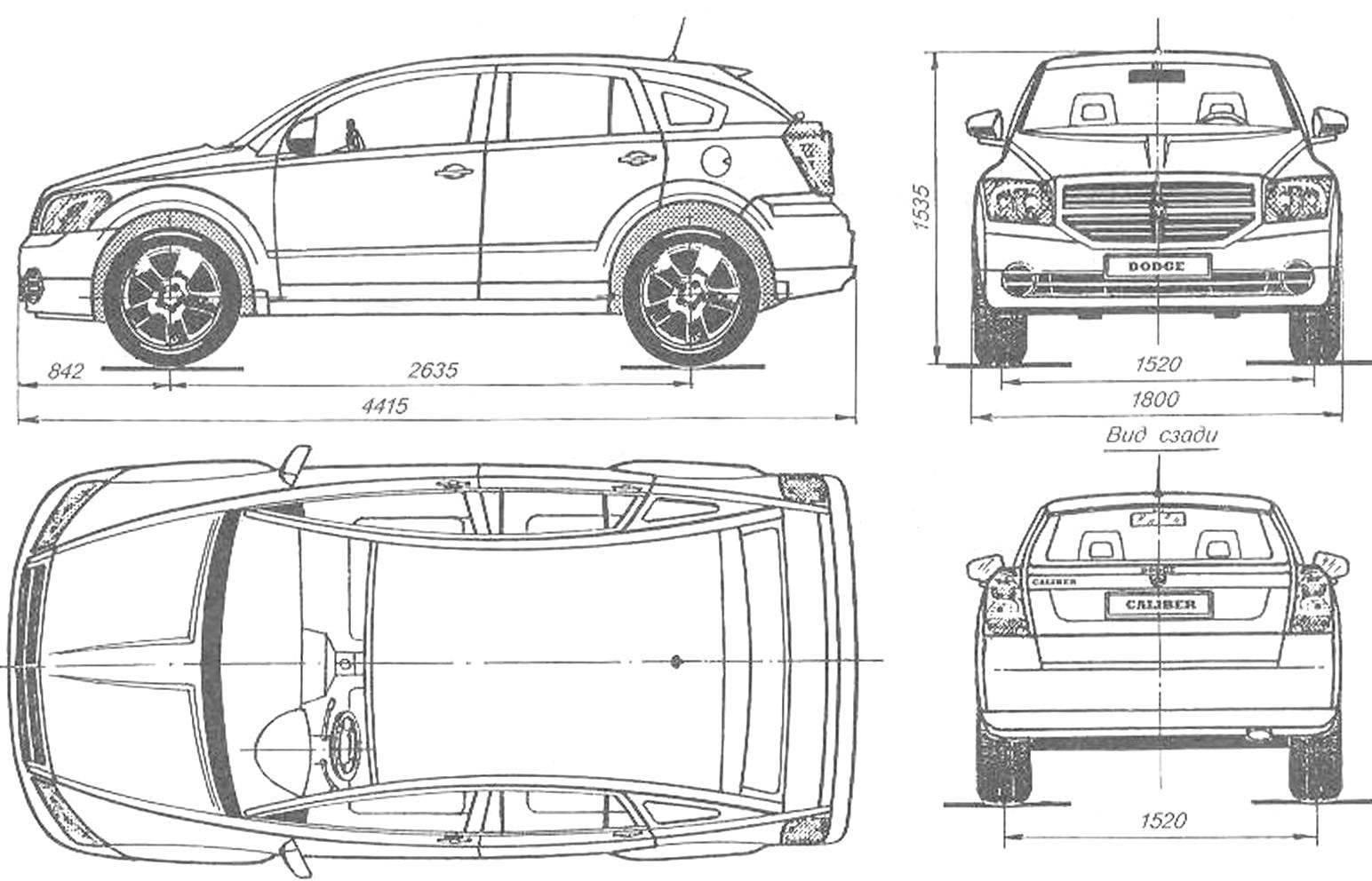

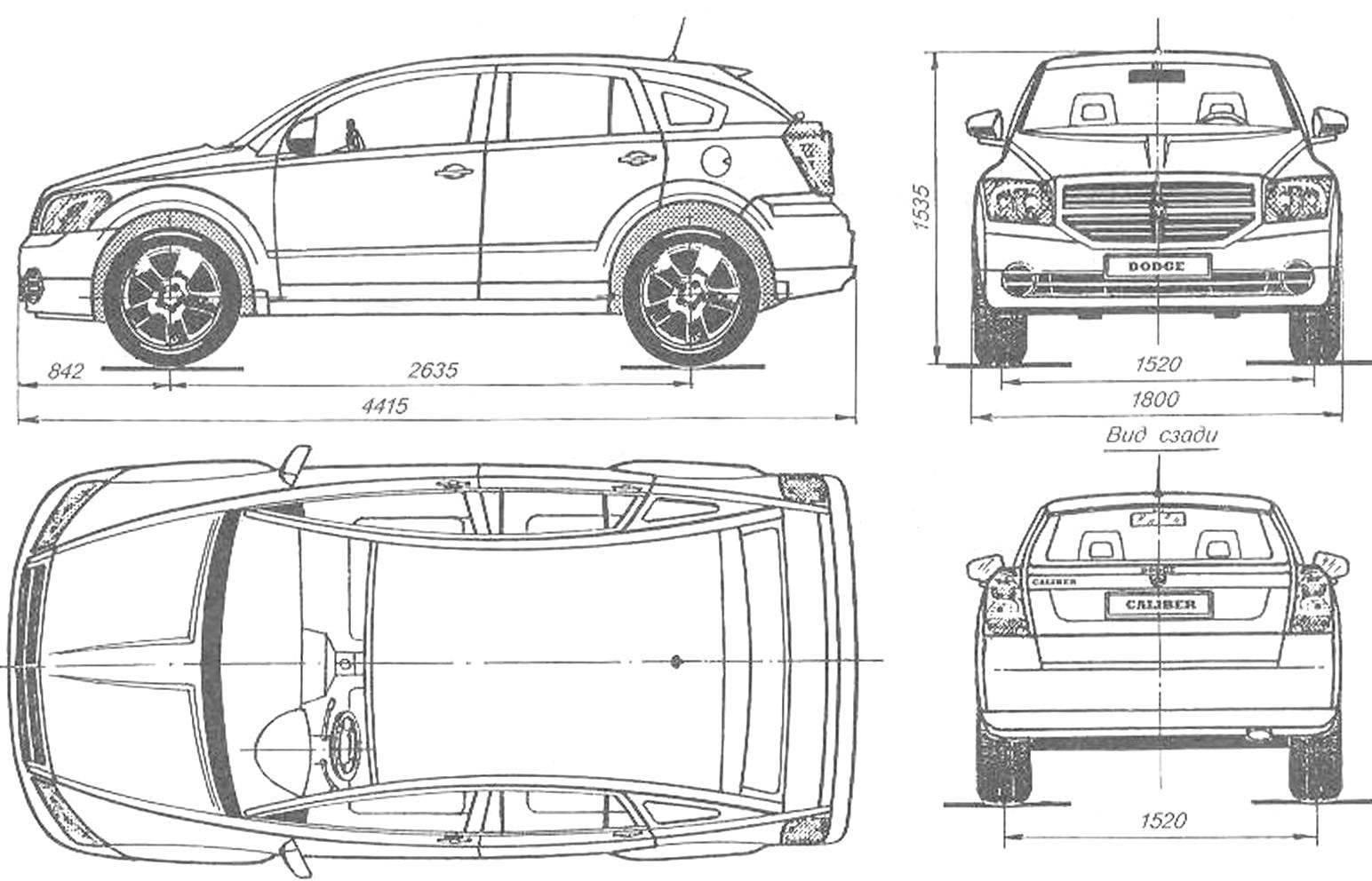

It is a hatch....a Dodge Caliber. I can take just about any width for the uprights.

looks like a 70" wing would "fit" in the width of the car... but anything greater than 60" is at the width of the stock rear track. and, being fwd, 60" will probably balance out most front diy grassroots downforce setups.

The cheapest way that I know to go about this is to buy 3-sections of "mini-wangs" from 9 Lives Racing, in the 21-30" range. These are off-cuts from their normal production, so you'll get anything between 21 and 30inches. Then I'd suggest taking the the longest section you get to be "placed" in the middle; then take the other two that came and cut them down to the same span.

Then it's just a matter of how you want to connect the sections together. There's some 'c' sections included into the internal structure of the extrusion that you could use to drive onto some aluminum dowels that extend out from either side and are bonded/welded onto the mounting plates....

the 'c' sections on these mini's were tapped for the screws.

or, you could try to use some square/rectangular section between the upper and lower skins either side of the vertical web at ~40% of the chord length.