Grassroots college.

I was in 8th grade when ny dad and I started to rebuild the duster for my daily.

Keep ot up man.

And remember to teach him: safe, reliable and cool. In that order.

Dusterbd13 wrote: And remember to teach him: safe, reliable and cool. In that order.

That's the basic plan. The only hard and fast rule is that the engine/transmission stays. We also have to fix/maintain the stock systems before upgrading. There is a high liklihood that the car will get disk brakes before he ever drives it to school, but we're going to understand the drums first. It's one thing to say "disks are always better" but another to be able to say "drums can work fine for a cruiser, but they're a pain to work on and overheat when autocrossing".

Long term we're looking at headers and bags and awesomeness, but for now, we're learning.

We decided Sunday night would be our off night to get rested for the week. Then yesterday lice showed up on one of the Deucelings again so I spent the evening picking through them like a monkey instead of working on the car. The boy is itching to get back at it.

TunaDad hated working on my stuff. He built a '66 GTO when I was the age of your kid, and I didn't get to touch it.

When I came to driving age, I forced a father-son project and he hated it. Not a workday went by without screaming, and most of the time he just pushed me out of the way and did it for me saying "you don't need to learn this E36 M3".

I guess I am saying "Good job, Mazduece!"

my dad could not teach me at all. a memmory of mine proves this.

I'm working on the left front brakes, dad's on the right rear since he's finished the right front already. Doing a caliper swap.

me"dad, i cant get it loose, which bolt do I need to take out again?"

him"I dont know?"

me "you just took it out!"

him"I dont remember."

me "you just took it out!"

him: much screaming, comes over, shoves me out of the way and looks at it and then does it.

I learned critical thinking and problem solving from dad. oh and to remember how the hell I did it so I can do it again quicker.... Dad could teach by doing it and you watching. He could not tell you how to do it at all.

mazdeuce wrote: Then yesterday lice showed up on one of the Deucelings again so I spent the evening picking through them like a monkey instead of working on the car. The boy is itching to get back at it.

On Mad_Ratel's story, i've noticed now from being an automotive instructor that you really take for granted how much you know and getting out of your OWN awesome head is pretty much the hardest part of teaching. I'm constantly surprised by how often i have to go back to really basic basics. If i ever stop being surprised it'll mean i got better as a teacher.

As far as using a hammer, there are a lot of things that are very hard to teach because they are so based in tactile sensation. I didn't get really comfortable swinging a hammer at a car until i was 21 (and i remember this because it was revolutionary and amazing to me). Now i go around demonstrating it all the time to the suspension/brakes students. I don't know how you teach it except by showing them that you can usually hit it a LOT harder than they usually are without hurting it, and just save them a lot of time working themselves up to those 'real' swings. I guess one of the only tips i can think of is to keep in mind which parts you need to reuse and which you don't. ![]()

my dad was much like the fathers above but I got used too it. Even if I did have to sell the car before I had my license I learned a lot and thank my dad for it often! im hoping atleast one of my boys will someday have an interest in cars.

i dont know about yall but I still have to use right hand rule for tighten/loosen

lefty loosy never made sense to me. but turning my right hand clockwise with my palm in the axis of teh bolt does...

If he's not confident with the hammer, you can always ditch the picklefork for the more controlled solution. Also won't tear up a boot on a part you intend to reuse like the fork will.

http://www.harborfreight.com/3-4-quarter-inch-forged-ball-joint-separator-99849.html

I learned all the basics and much more handing my dad wrenches, then helping turn them, and then turning them on my own car under his teutlage. I was blessed with a great teacher.

Back at it tonight. After determining that end links were $2.81 each (or something insanely cheap like that) we decided to just cut them off with the Sawzall rather than fight with them. I helped a bit but he did enough to comment that it shook the crap out of him. Then we pulled the brackets and snaked the bar out of the car. I assigned him the job of wire wheel cleanup guy.

I took the backing plate off and called it a night. Rock Auto sent us a 5% coupon so we're going to assemble a front end parts list soon.

I took the backing plate off and called it a night. Rock Auto sent us a 5% coupon so we're going to assemble a front end parts list soon.

Nothing tonight. The boy lost a tooth right before bed time and was so excited about getting money from the tooth fairy (which he has no issusions about and enjoys the cash) that he put on his PJ's and climbed into bed and it was only when I was tucking him in that he realized that we hadn't gone out. A good reminder to me that he's still very much a kid.

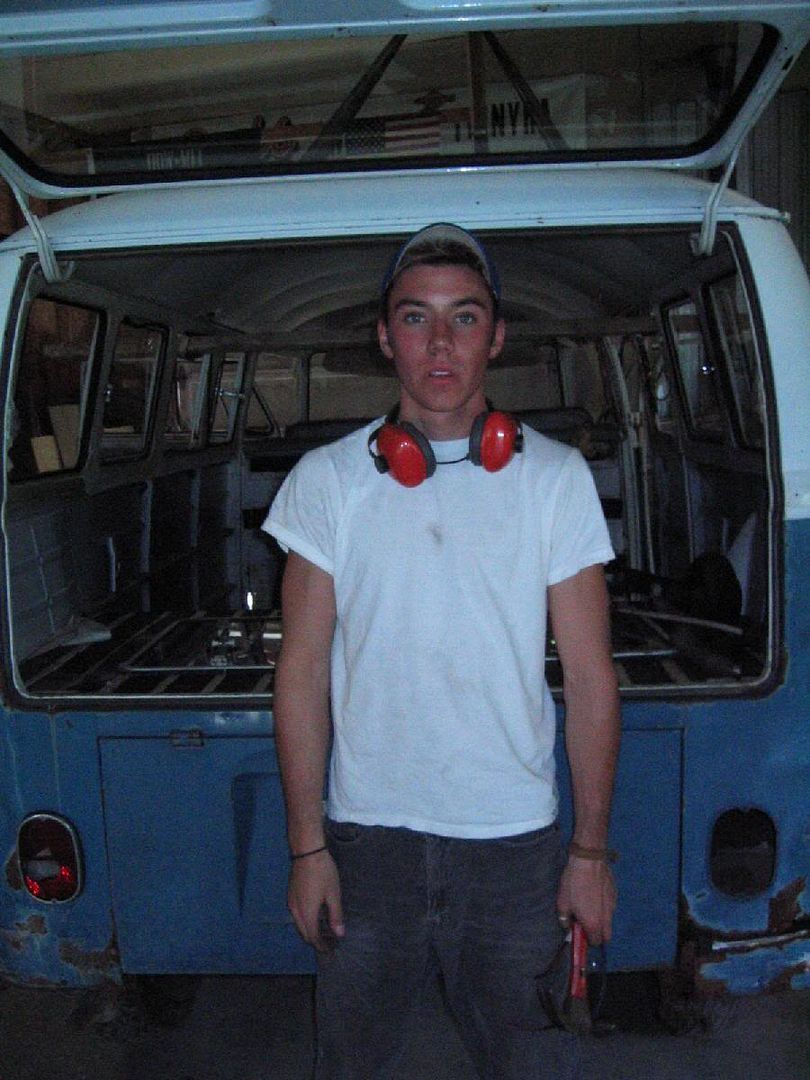

My son was a big help on the $2004 BatVan. You can see by the look on his face that he was occasionally stupefied, sometimes awed, and once in a while impressed.

10+ years later he still talks about it, claims the work we did helped him befuddle his way through the School of the Museum of Fine Arts. To this day he sends me links to C-List finds we should bring to Gainnesville.

Enjoy the ride ....... ![]()

tuna55 wrote: TunaDad hated working on my stuff. He built a '66 GTO when I was the age of your kid, and I didn't get to touch it.

At least your dad could work on cars. My father was at the end of his mechanical knowledge once he put gas in a car. How he ever worked on B-52's and F-4's during Vietnam is beyond me.

mazdeuce wrote: Back at it tonight. After determining that end links were $2.81 each (or something insanely cheap like that) we decided to just cut them off with the Sawzall rather than fight with them. I helped a bit but he did enough to comment that it shook the crap out of him. Then we pulled the brackets and snaked the bar out of the car. I assigned him the job of wire wheel cleanup guy.I took the backing plate off and called it a night. Rock Auto sent us a 5% coupon so we're going to assemble a front end parts list soon.

Since the wire wheel is a gateway drug to my arch nemisis the 4.5 inch angle griner (I have 3 one with a wire wheel, one with a cutting wheel, one with a flap disk) this is a good time to get him into the habit of working in gloves. I have the scars to prove what happens when you are an idiot like me and dont!

Great job getting him involved though. My mother always thought it was great that dad and I "had our car stuff" together but the truth is my old man has no mechanical skills or knowledge and "our car stuff" consisted of him coming home from a drive in whatever vintage toy he had and saying "brakes are weak, go look at it" Luckily I was able to learn on my own.

May want to get the boy some steel toe boots. I have a permanent mangled right big toe from dads education on coil springs. I have worn steel toe boots every single day since.

And gloves/good safety glasses. Get him in the habit early.

But enough safety nazi from me.

Ian F wrote:tuna55 wrote: TunaDad hated working on my stuff. He built a '66 GTO when I was the age of your kid, and I didn't get to touch it.At least your dad could work on cars. My father was at the end of his mechanical knowledge once he put gas in a car. How he ever worked on B-52's and F-4's during Vietnam is beyond me.

My dad was similar. He knew that an engine needed fuel and spark, but he didn't have any idea how those two things arrived in the engine. My most memorable experience with this was a dead rototiller. This was a massive post WWII two stroke beast of a machine. It wouldn't start. He pulled the plug to see if it was fouled. He didn't think so, but he called me over and had me hold it while he pulled the starter cord. When I jumped and screamed he decided that it had spark. Not cool.

Last night we had a school thing and by the time we could go out the boy asked if he could go to bed instead. Sure. So I went out and organized the tools and cleaned up the mess. I'm trying to only do real work on the car when we're both there together. This project might make Tuna's build look like a quick resto.

And yes, gloves, good advice. Thanks.

A year later. Time to pick up where we left off.....

Part of the point of Fergus is to keep me from buying other projects when I get bored or agitated with life and think a new car will fix everything. I'm currently bored and agitated, so I finally finished pulling the suspension apart.

The ball joints, upper and lower, are rivited to the arms. My assumption is that means these are the factory parts and I need to grind the rivets off and replace them with parts that bolt in place. Having never messed with stuff this old, I'm going to be asking a lot of simple questions like this.

The ball joints, upper and lower, are rivited to the arms. My assumption is that means these are the factory parts and I need to grind the rivets off and replace them with parts that bolt in place. Having never messed with stuff this old, I'm going to be asking a lot of simple questions like this.

mazdeuce wrote: My assumption is that means these are the factory parts and I need to grind the rivets off and replace them with parts that bolt in place. Having never messed with stuff this old, I'm going to be asking a lot of simple questions like this.

Correct assumptions. If they're riveted on they are original, and the replacement ball joints will come with bolts.

Thanks! I feel at least moderately justified in taking everything apart for proper inspection and replacement now. The ball joints felt good, but the boots are terribly leaky and all of the rubber bushings are rapidly turning to dust. Ordering parts tonight!

Yay, updates.

Correct, you have to grind/chisel the rivets off and bolt the new part in, those are the original joints, at least to that arm. I know GM did it that way into the 2000s.

You'll need to log in to post.