Engine Initial Firing.

Apologies in advance for the length of this entry, but there is a story here that needs to be told fully in order to allow the reader to understand. This entire process took place over about six weeks but in the interest of brevity I will try to give you the short version which will still be long. That said lets begin.

Having worked diligently on the car for the last year and a bit you can imagine how I looked forward to being able to turn the key and have the engine come to life.

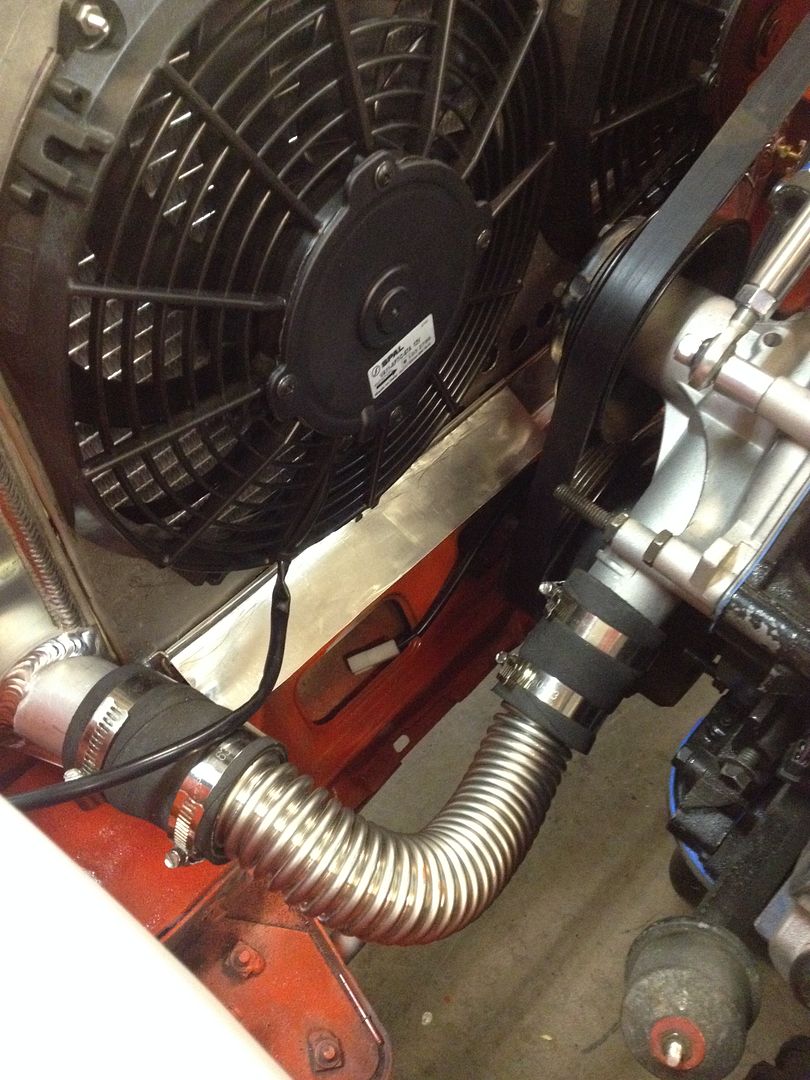

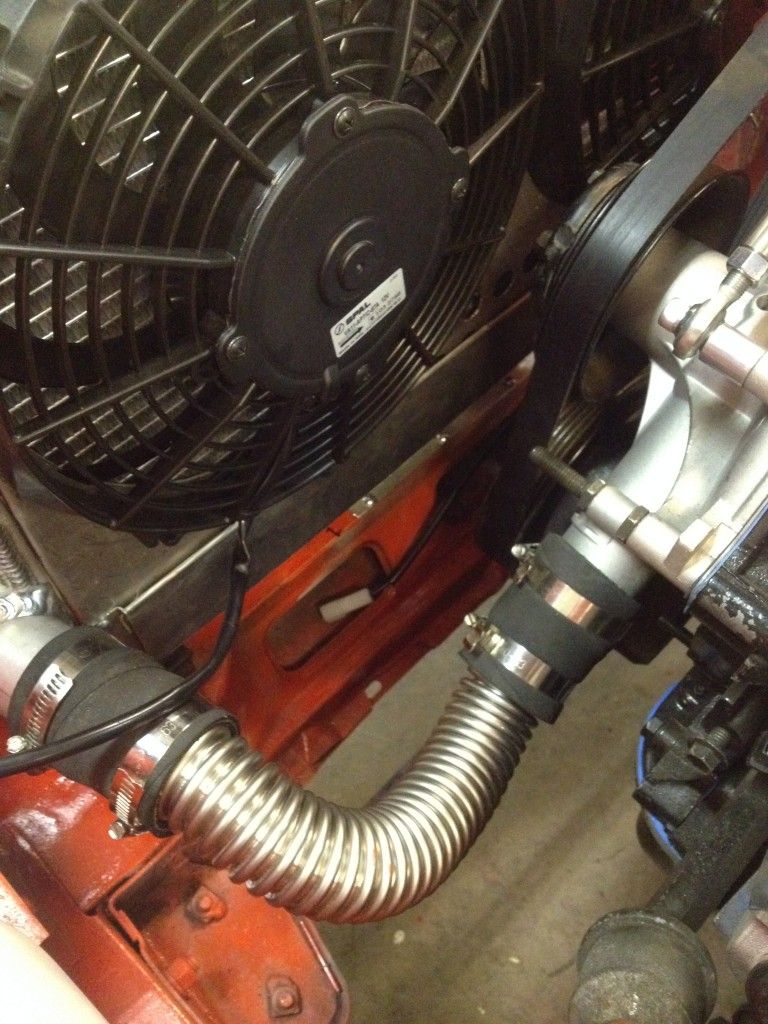

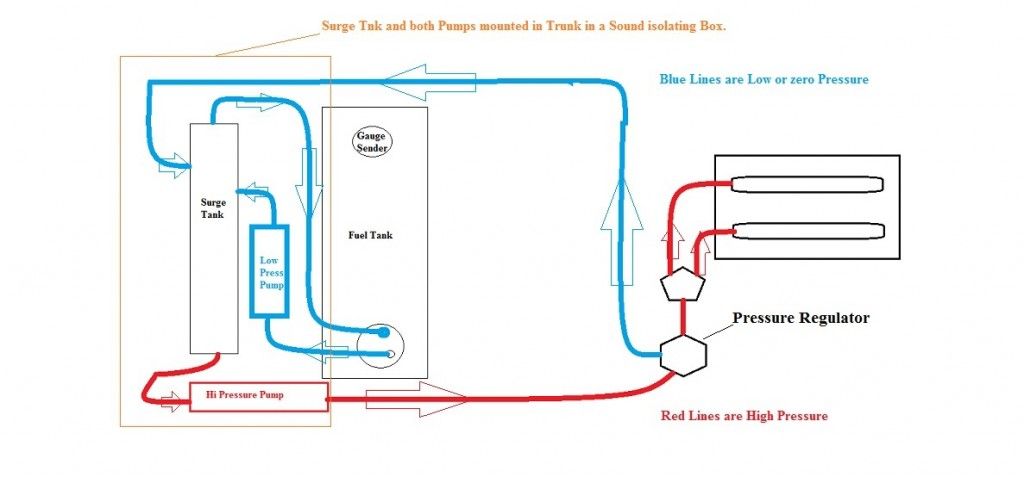

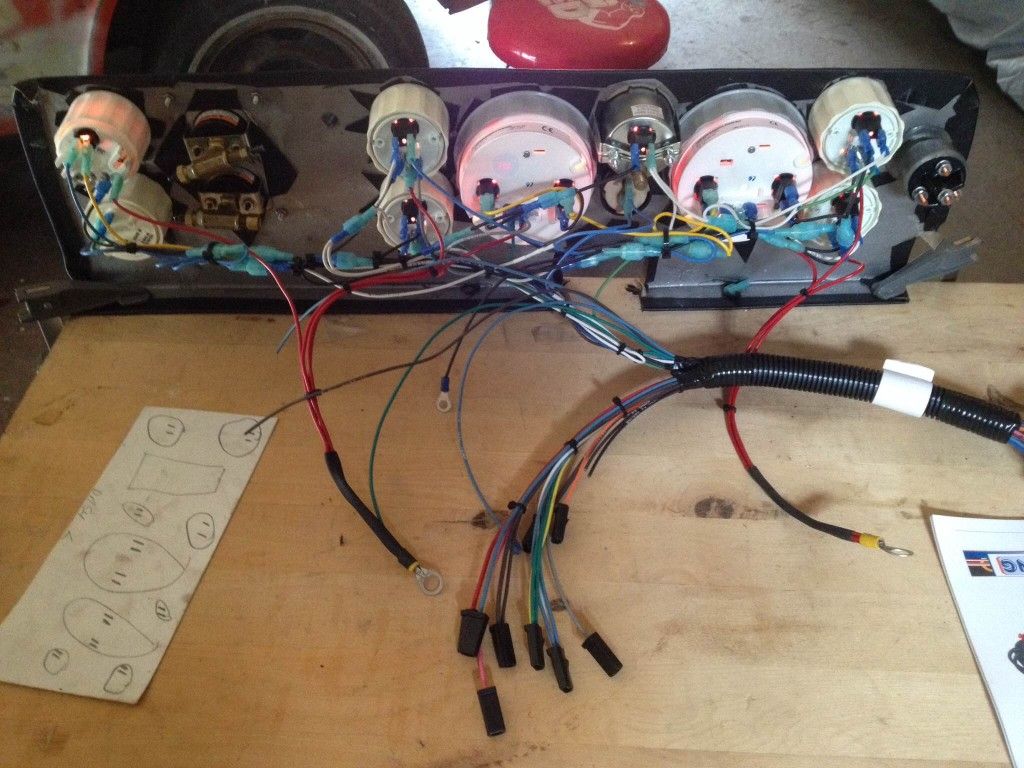

With the fuel system figured out and tested for pressure and integrity, the cooling system plumed and filled and the wiring done and tested it was finally time to bring the entire package to life.

So with a mixture of excitement, and apprehension I hit the key and was rewarded - with about one half seconds cranking and then nothing!

WTF???????

Initially I figured I had a bad ground that had only momentarily connected and then collapsed (electrically) under load so I disconnected the battery and proceeded to check all of the grounds and as insurance added a second engine to frame ground fabricated out of a piece of welding cable. With that done I tried it again.

Same result?????????

At seeing this I stood beside the car and observed the engine while trying one more time. What I noticed is that if I held the key in the start position the engine would initially crank and normal speed then stop and then VERY slowly continue to turn over????

After thinking about this for a while I decided to pull the plugs and see if the engine would turn over without compression. As soon as I hit the key with the plugs out the engine turned over freely and sprayed the entire shop with raw gasoline. The issue was that the engine was hydro-statically locked up with Raw gasoline!!!

Now I was really Puzzled. Remember, I had an Ingelese 8 stack induction system on the engine at this point and this was a new beast to me. I talked to the suppliers tech department and as I would soon learn they gave me their standard advice for all problems related to their EFI being "you have a bad ground somewhere". Checking, rechecking and then doing it all again showed that there was no ground issues??????

As all of this was going on part of the process involved turning on the ignition to check various connections and power sources. Somewhere along the process I noticed that when running the fuel system was at the prescribed 42 PSI but as soon as the key was shut off it immediately dropped to zero. From previous experience with other EFI systems I thought this strange as an EFI Fuel system will typically hold some pressure for a good length of time once the pump is shut off.

At seeing this I contacted the manufacturer to ask about the chance that one or more injectors were stuck open and was told that while possible it was highly unlikely if I had started with a clean fuel tank and new lines (I had), they suggested - wait for it - a bad or missing ground.

Throughout all of this I did manage to get the engine to run but just barely and with so much black smoke that it looked like a diesel with a plugged air filter. After each running session - typically less that 10 mins in length I checked the oil and found it to be overfull and fouled with gas. so we changed the oil an filter. I total this happened four or five times for a total run time of less that one hour.

Throughout all of this my big concern was what the gas was doing to the cylinder walls, rings and bearings and sure enough on the next session the engine developed a solid bearing knock!!!!

ARGGGGGG!

So, in a matter of several weeks and less than 2 hours of running we had burned out a really strong running 5.0L engine. Needless to say I was disheartened.

After pondering the whole situation for several days I called a mechanic friend in Calgary to bend his ear and share my woes. At hearing what had transpired he said in jest, I'll take the 8 stack system off your hands if you want. (He is a mechanic by profession and knows EFI systems well). At hearing this I called his bluff and told him if he sent me everything I needed to put a Holley 4BBL on the car I would send him the entire 8 stack system in trade. We agreed and the deal was done.

Financially this deal made no sense for me as he got about 4-5 times the value that he gave me in return, but from my perspective it made good sense as I did not have to put out more cash for he carb setup and I got an induction system that I understand and can work on.

So, with the deal done I started to dismantle the EFI system and package it for shipment. The first thing I did was unplug the 56 pin connector from the ECU and when I did I noted that one of the pins had been pushed back into the plug! At seeing this I got out the wiring schematic and discovered that the pin that was not connected was one of 5 that controls the injectors!

Upon discovering this I pulled the pin out until its lock snapped into place and plugged the connector back into the ECU. When I turned on the system the fuel system now charged and upon shutting off the fuel pump the presssure dropped from 42lb to 30lb and held like it was supposed to.

So, what was going on is the missing pin was causing four injectors to open and remain open thus dumping raw fuel into those cylinders as fast as the pump could provide it. This was born out by the engine builder who confirmed that when he tore the engine down four of the cylinders were glazed and the rings worn out as a result of fuel washing.

So, after three weeks the rebuilt engine was back, installed, wired and plumbed abd fired right up. It has run flawlessly ever since and though I lament the loss of the sex appeal the 8 stack system would have provided I am more than happy with the Holley/Edelbrock system.

As a final act in this little subplot I wrote the manufacture and let them know what had transpired, what I had discovered and what it cost me. I never received so much as a thank you, apology or acknowledgement I guess I should not be surprised, but a simple acknowledgement and thank you for the comments on their quality control would have been appreciated!