This was my first time porting a head

I've read a lot about porting in these months since disassembling the engine, including David Vizard's book, performance automotive engine math, many GRM and turboford threads, and whatever websites with relevant information I could find. Also watched many youtube videos, even when most contained wrong advice. Initially I wanted to grind the bowls, but ended up doing a lot more work. The stock heads were pretty bad, I'm just hoping I did not make them worse

I used a pneumatic grinder with a mastercut SE-3MMDC for most of the work. That burr alone was enough, but grinding the ports would have been easier with a bigger, cylindrical one. The threaded rod with a cut was used to hold a piece of sanding cloth but it wasn't really needed. The wrench on the bottom came with the grinder, it got ground to the right size and used as a measurement tool for the exhaust ports. I kept grinding until the wrench went through and the end result was pretty round and even between ports. This job took longer than necessary due to using a small compressor, it doesn't replenish air at a fast enough rate and gets hot, needing some down time.

Tim Ottinger's thread on turboford recommends using a valve stem and dividers to measure the throat and bowl. Not wanting to cut a valve, I printed the following tool. It was good enough, but could be improved by getting a better fit into the valve guide

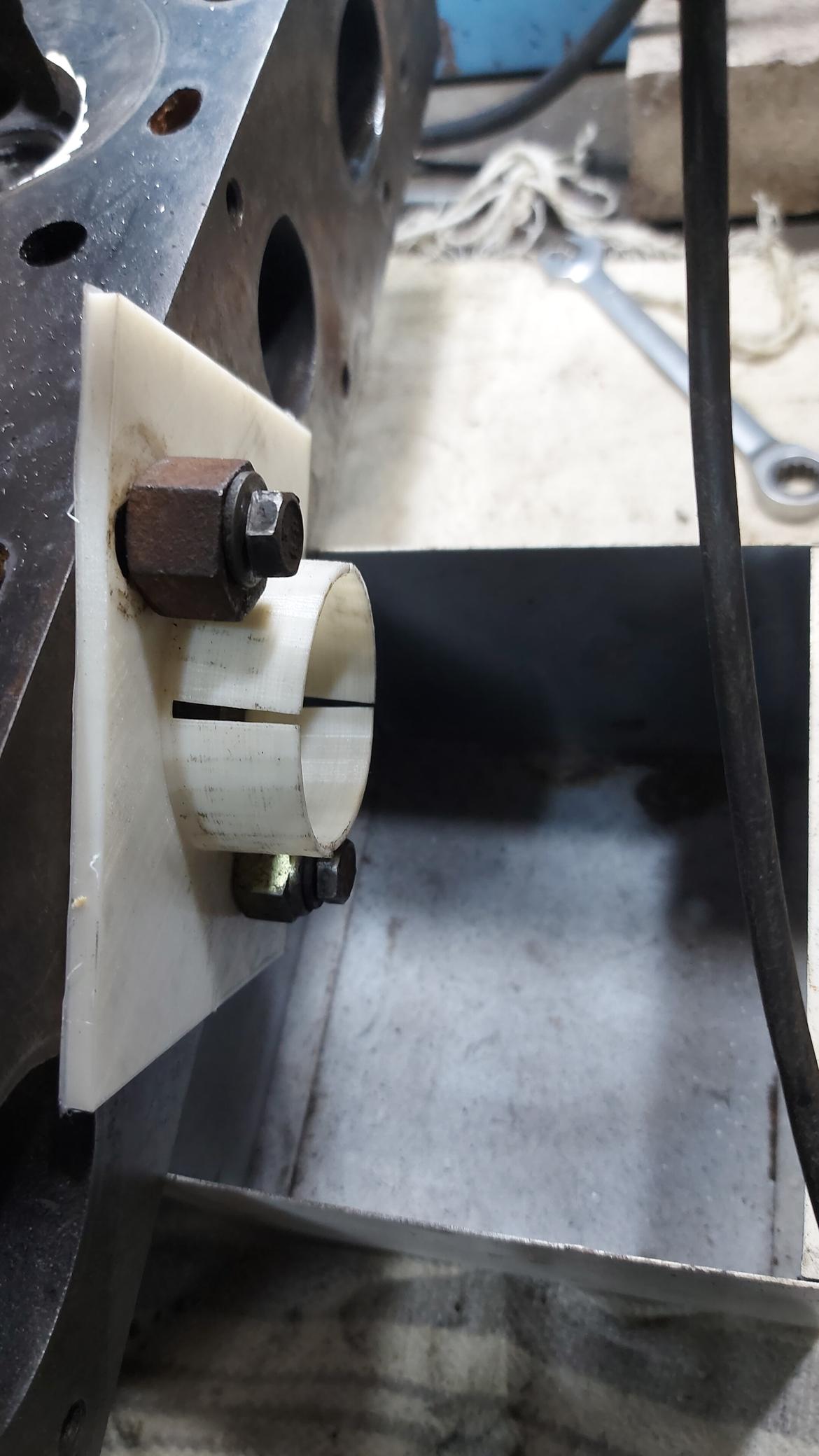

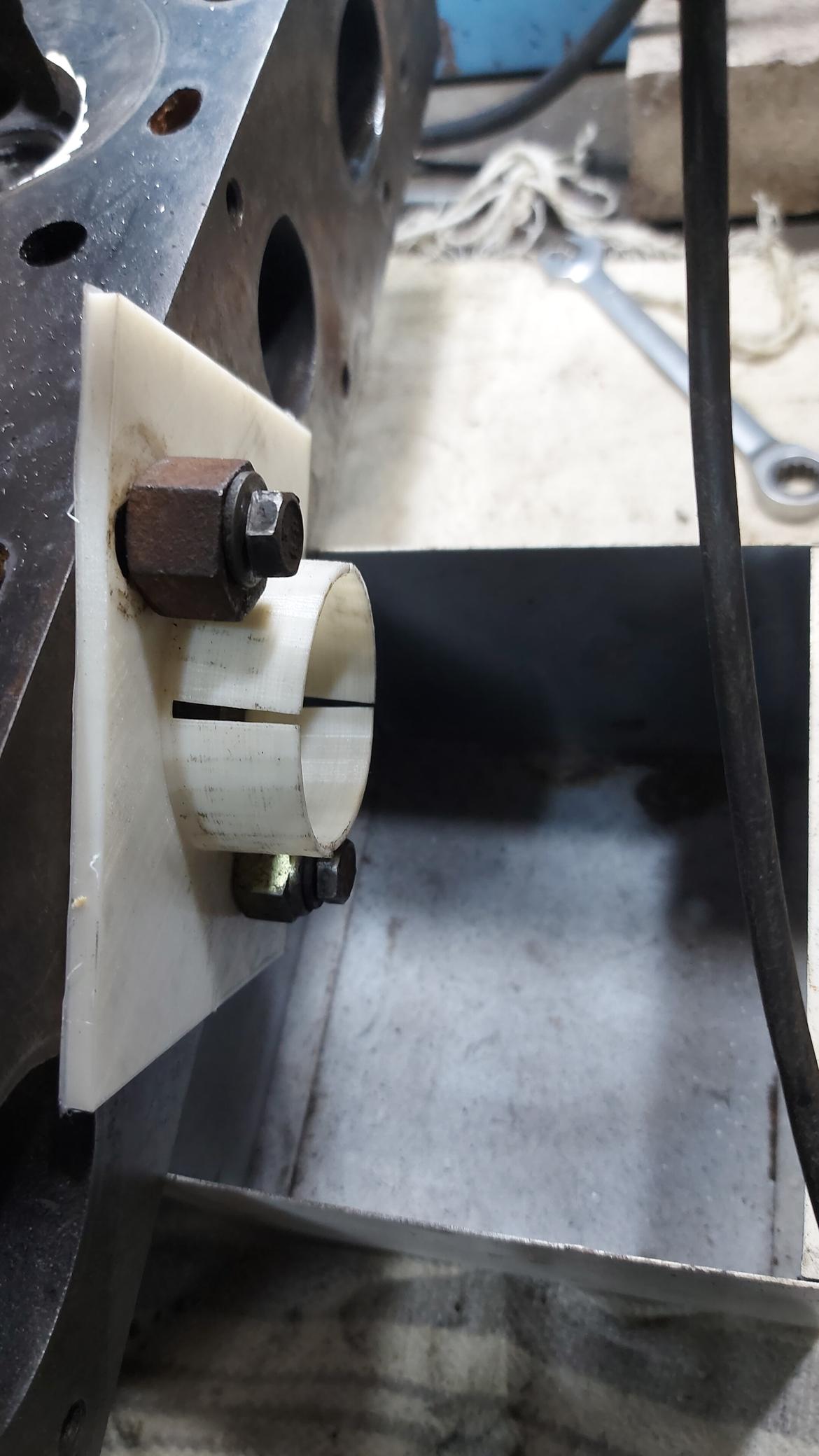

To keep the working space and my lungs and eyes clean of metal shavings, I made the following adapter. It attaches a vacuum cleaner to the head. It failed after some use, next time it will get some reinforcements. There was another version with provision for a light bulb, but that one failed even earlier due to issues with the printing settings. For the next head I will spend enough time to get this piece right, it makes a big difference

You can see I used correction fluid instead of machinists blue, it works

Some lessons learned:

Ear and respiratory protection are a must

Do a bit of work on one cylinder and repeat it on the others instead of doing one at a time

There is never enough lighting

Pressing the grinder switch with the index finger allows to release it while keeping a firm grip. Using the thumb makes controlling the grinder way harder when it tries to jump around

Everybody on the internet makes a big deal of trying to avoid the seats. It's pretty easy, I only hit one on the first hour of grinding