I love me some f2t action, I had a 626turbo in highschool. Those flares look great, keep up the good work.

I love me some f2t action, I had a 626turbo in highschool. Those flares look great, keep up the good work.

Try as hard as you might, you never seem to make progress on these projects at the rate you want. Granted, I have been distracted.

I did a quick and dirty cat delete for a Friend with a 135i. Nice to have a few extra dollars for racecar things while I'm in school, but that obviously takes time away from finishing my own exhaust.

Untitled by James Onyschuk, on Flickr

Untitled by James Onyschuk, on Flickr

With that done, I could finish up my downpipe. Some fun was had trying to hold/purge everything properly without anyone helping me.

Untitled by James Onyschuk, on Flickr

Untitled by James Onyschuk, on Flickr

With the wastegate tubing finished, I started the slow and delicate task of making the wastegate/downpipe union. It's fun trying to make a precise hole that you can't actually see with everything in place.

Untitled by James Onyschuk, on Flickr

Untitled by James Onyschuk, on Flickr

A few hours of careful work with the air grinder later and the fitup was acceptable, so I tacked everything together. and set about final welds on the downpipe.

Untitled by James Onyschuk, on Flickr

Untitled by James Onyschuk, on Flickr

I knew it was going to be tight with how shallow I'd made the WG merge, but I didn't realize how tight. The last .5" of welding was hell. I had to hang the tugsten out waaaay too far and then get creative trying to shield it. I ended up getting it, but it's ugly in there.

Untitled by James Onyschuk, on Flickr

Untitled by James Onyschuk, on Flickr

Stainless likes to move all over the place when you weld it. Fitment of the DP isn't as perfect as when I had it tacked, but it's still very good. It'll do. With the DP done, I can finally get going on the easy part of the system. I won't be using any mufflers in the initial configuration. Law doesn't require a catalytic converter around these parts, so I won't have to worry about that either. I think the turbo will knock noise down enough that I won't mind and I'll probably be able to meet noise regulations at nationals.

I still haven't decided if I want to dump the exhaust with a turndown under the car just in front of the spare tire well, or if I want to order some oval tubing and do a side exit. The turn down is lighter and easier, but the in vehicle noise might be a deal breaker. The oval is harder, but side exits are infinitely cool, especially when the car is running "90's turbo" rich a la anything 503E powered:

Alright, maybe this isn't quite a factory hill climb effort or GTP car, but the dilemma remains. Anyone have input on how bad the under car dump really is?

The downpipe is 3.5", but I don't see the there being much advantage to using piping that large anywhere that isn't immediately post turbo. The rest of the system will be 18 gauge 3" to save weight. With that in mind, I got to work incorporating the 3.5" to 3" transition. +1 for Burns stainless. High quality stuff. -1 for their shipping. All of the tubing I ordered from them showed up with dents on the ends. That might be hard to avoid with the thinner walls, though.

Untitled by James Onyschuk, on Flickr

Untitled by James Onyschuk, on Flickr

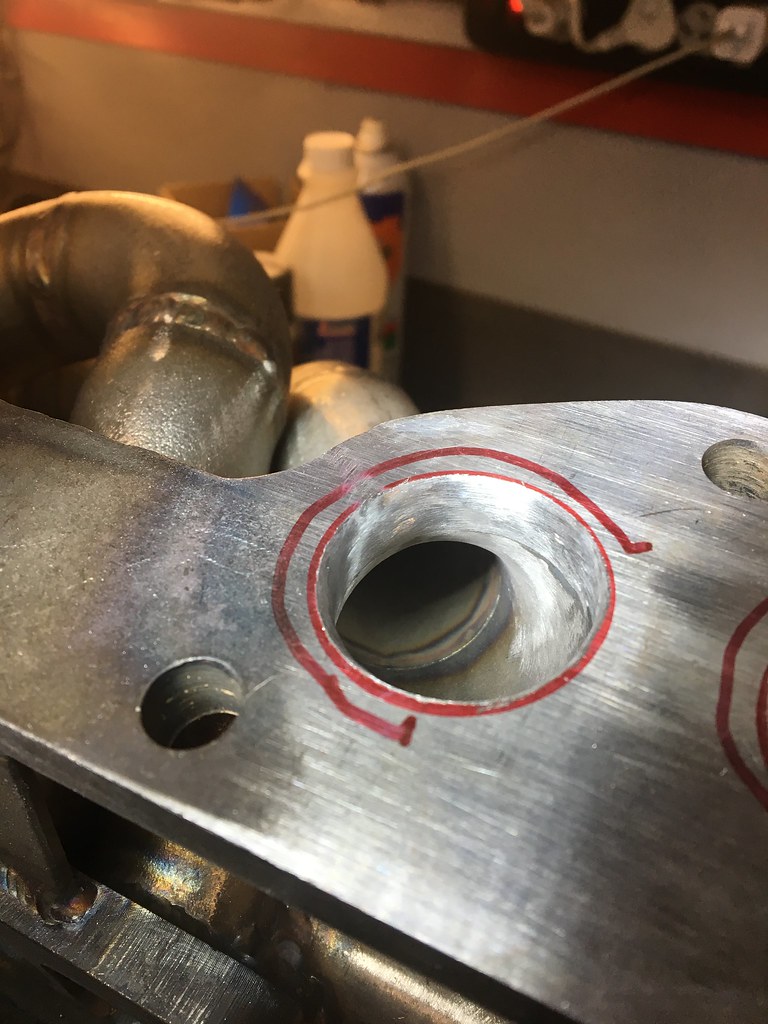

I bought a "laser cut" flange to build my manifold with. It WAS laser cut, but I have no idea who did the CAD for it because the ports aren't anywhere close. I'm at the stage where I could feasibly mount the exhaust manifold permanently, so I should take care of those ports. I still have a few hours of work left, but they're all roughed out now and just need some final shaping/polishing.

Untitled by James Onyschuk, on Flickr

Untitled by James Onyschuk, on Flickr

Untitled by James Onyschuk, on Flickr

Untitled by James Onyschuk, on Flickr

That's where it stands for now. Porting is tedious work with steel and I should really clean my bench. More to come in the near future.

Untitled by James Onyschuk, on Flickr

Untitled by James Onyschuk, on Flickr

Hey, so...

This project did indeed get finished. The car ran. On track multiple times even. Lots of things happened.

Then I accidentally plumbed the wastegate backwards at 2AM in a push to make it to nationals after DIYautotune provided me one of the worst customer service/product support experiences of my life and left me without an ECU for months.

That put holes in the pistons.

After that I ended up with an '81 Toyota pickup project that quickly became a complete frame off basket case. After that was driveable I moved stateside for a year before returning to university to finish the mechanical engineering degree I dropped out of at some point early in this build thread. That degree is nearly complete now, and I've been lucky enough (read as underpaid) to play with racecars in industry for the last bit, so I have many more tools at my disposal to make this thing better.

I'll be doing final assembly on the new engine for this thing in April when I get back out west. I might as well update/continue this thread then. The new engine will be able to provide more power than my current transaxle or fuel system can support, so there's lots of new problems to solve in the future. I'll also be adapting an electric steering rack to keep this thing SMF legal. I should have some pretty serious 3D scanning capabilities this summer, so some proper fenders and other composite parts are going to get designed if not immediately constructed.

This was it on track with the 2006-spec black/polished FN01R-Cs that have since been powdercoated silver.

You'll need to log in to post.