In reply to thewizard:

Wow! Thanks for chiming in. It's very odd to look around the car and see such a good cage and seam welding and evidence of really top notch prep and try to reconcile that with the butchery that we see. I get goosebumps watching the video because it's so obviously the same car.

Did the crash damage on the driver's side happen after you sold it? It has JVL struts on the front but the rear looks stock. What did it run in the rear? Engine/transmission changes?

It runs and drives now which it hasn't done in at least five years. The last time it was registered was 2010. We're working to track down the title and hopefully the log book, we think we know who had them last.

Anything about the car really. Informstion, stories, any of it.

In reply to mazdeuce:

Front and rear had JVABs aka Jvl struts. Paul, the owner is a Motorsport engineer and thats why you see good stuff that was done/on it or at least whats left of it. There used to be a CF intake which seems to be missing. Engine was stock but there was a 6.33 FD and a Kaaz diff if i remember correctly.

Cage was done by a guy named Chris (cant remember last name) in his shop in CT.

The damage to the driver door happened at RNY (ESPR now)fall of 08 due to a late call on a 'R4 tightens downhill'. Brushed up against some skinny trees and was stuck. I wasn't codriving but was at the event crewing for him. Funny thing is 2 years later at same event we were able to recover the mirror and rear valance while recceing same corner.

The guy Paul sold the car to didnt even know how to drive a 5 speed as he got a call while they were trying to start it when the truck delivered it and couldnt due to dead battery. Guy had bought it without looking at the car, sent a truck to pick it up and later complained about a bunch of things.

We had issues with Suspension bolts on ears loosening up in the front so be weary of that. Besides that and the serpentine belt not being but on correctly at RTN 2009 we had no issues. Paul did have issues with gearboxes prior once at Sandblast loosing drain bolt and once at RallyWest Virginia when the box locked up. The gearbox on it was replaced however.

BTW,That terrible trip never worked properly if memory serves me right it would just shut off randomly.

This was the year he hit the tree:

https://www.youtube.com/watch?v=wj7rXfVtrD0

Prior to going white:

https://www.youtube.com/watch?v=3cd99pDDPfM

There are more videos on my YT channel in that car from Rally TN. We were planning on running a WRC event in a rental so to get a bit more acquainted with each other we entered RNY. Car got sold/picked up 6 days prior to event so we ended up running my GTI that wasnt even prepped since last event! lol

Did Paul work in sales at Performance Friction in 2009-2010?

AngryCorvair wrote:

Did Paul work in sales at Performance Friction in 2009-2010?

Yes and later in the UK Division...

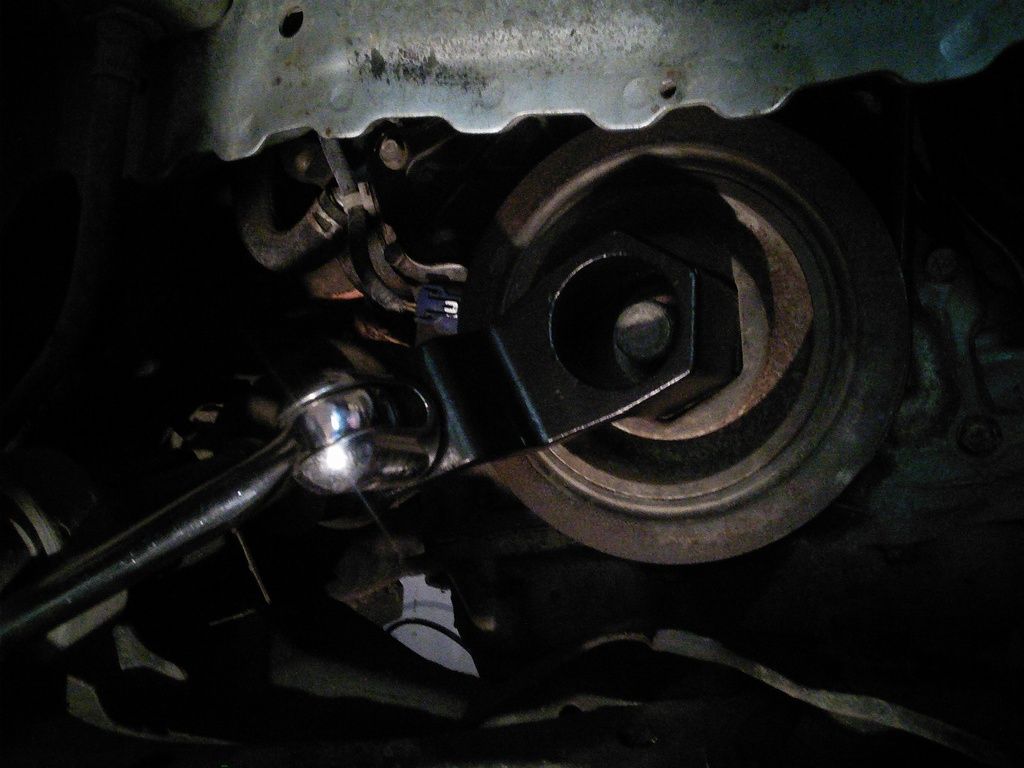

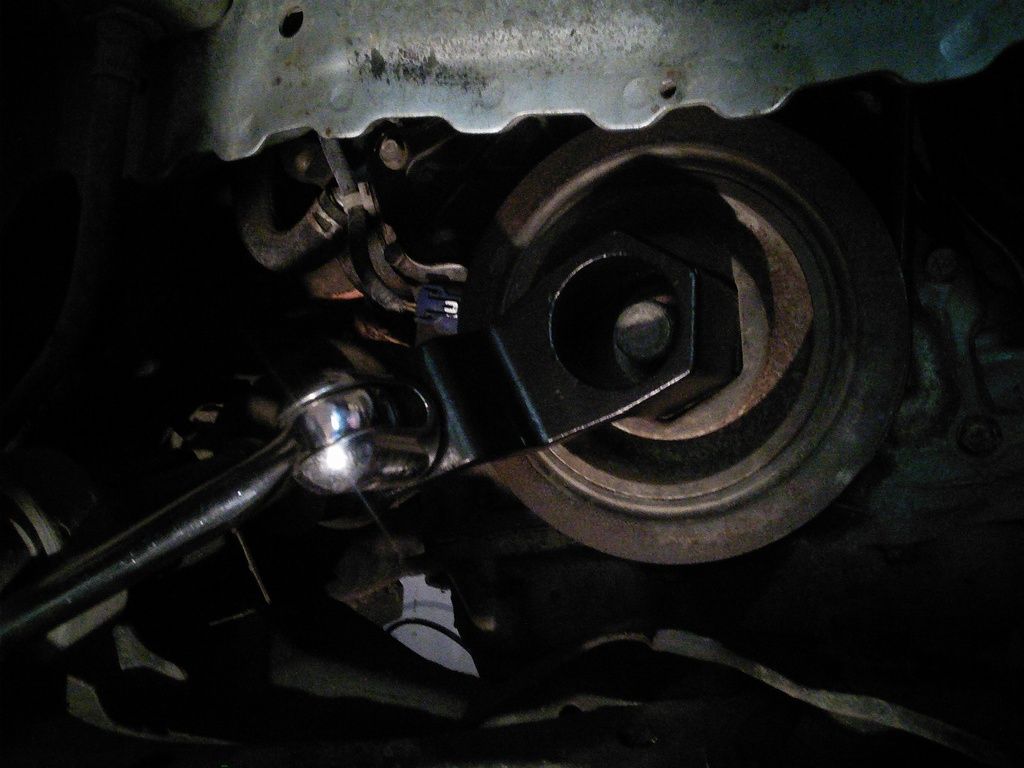

Spent an hour and a half this morning trying to get the crank pulley bolt out without spending $30 on the proper tool. Spent $30 and got it out in two minutes. Lesson learned.

RedGT

HalfDork

11/28/16 3:41 p.m.

I used that tool once in 2005 and once again in 2010...been four years now since I owned a Honda but every time I see that tool kicking around the 'impact socket' drawer of the toolbox I am reminded how important it can be to have the right tool for the job.

In reply to thewizard:

Wow, you are the man! A complete history off the top of your head. How do you remember all that?

Also I didn't know you had a GTI- that is cool. I may have questions for you when I get in a jam on my Rabbit.

In reply to mazdeuce:

Your progress is inspiring! I don't know how you have the energy (or the time) with kids, working on the house, etc. to get that much work done on the Acura.

-Brian

thewizard wrote:

AngryCorvair wrote:

Did Paul work in sales at Performance Friction in 2009-2010?

Yes and later in the UK Division...

Small world! Paul and I overlapped by several months at PFC in Clover SC.

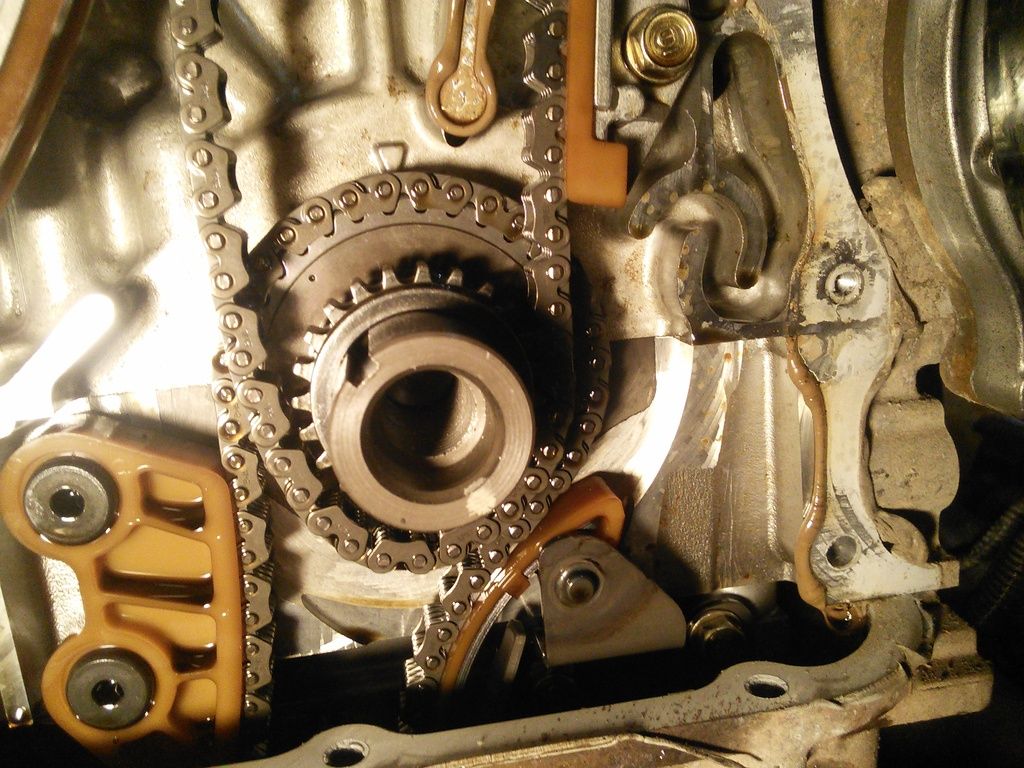

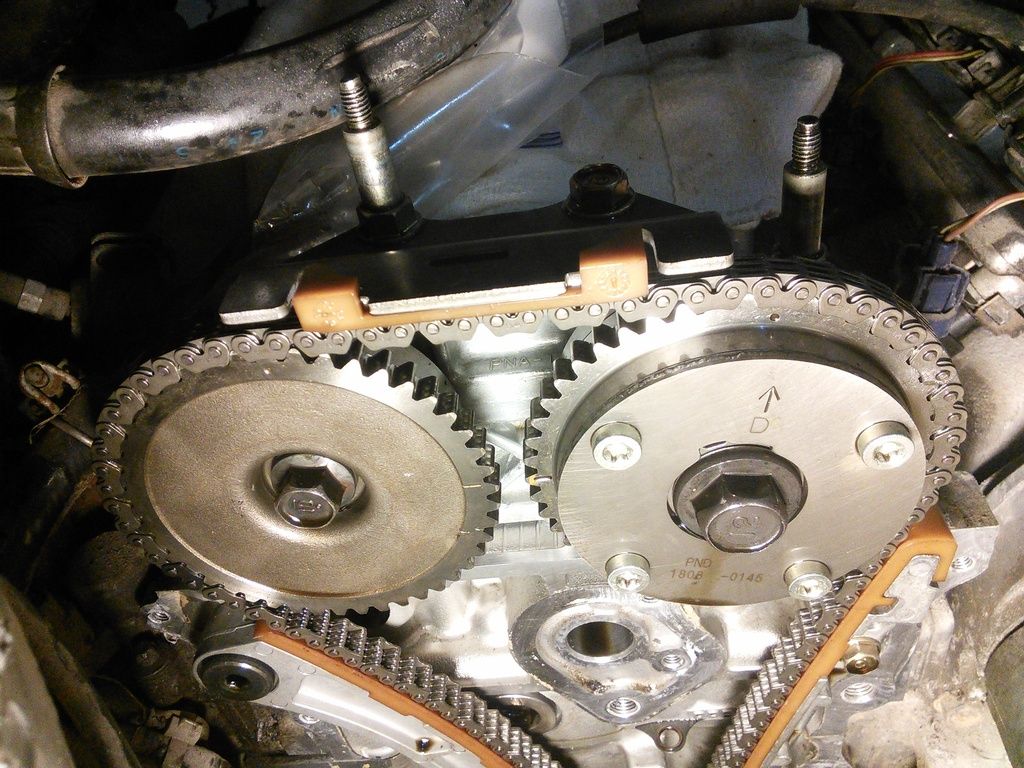

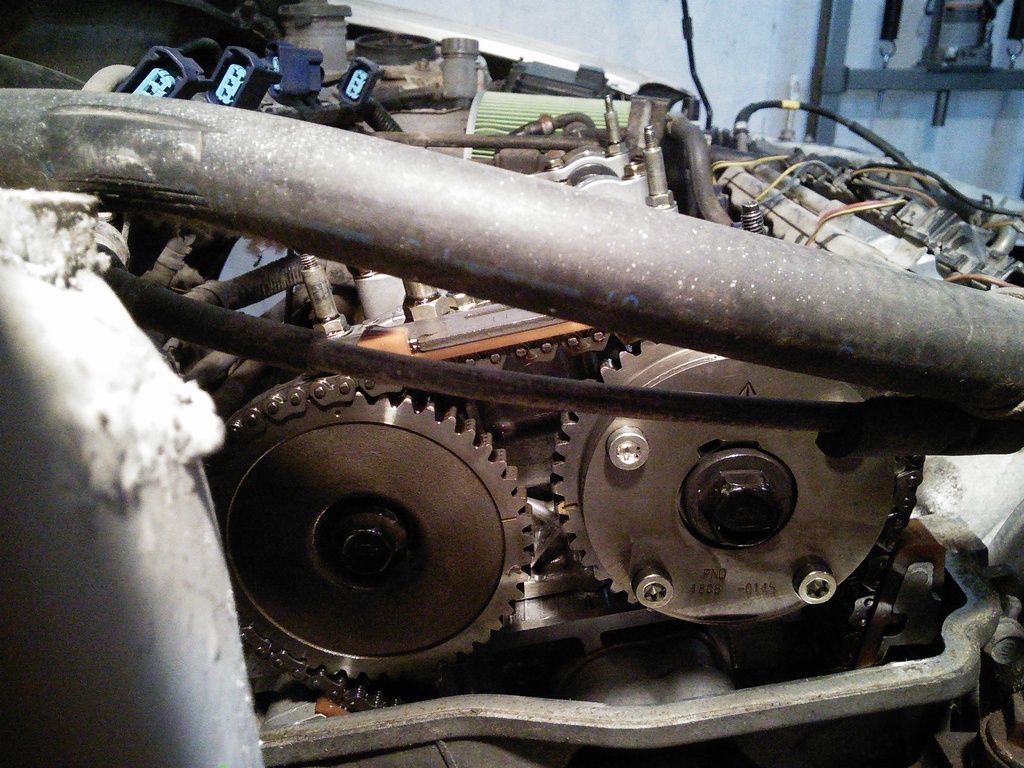

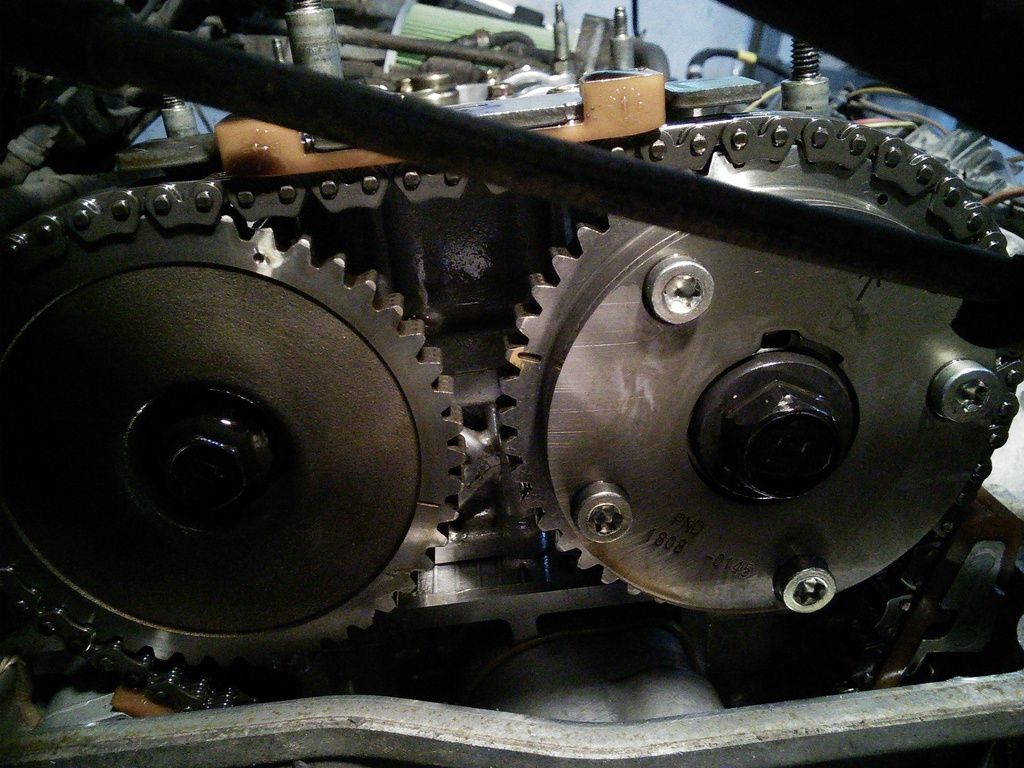

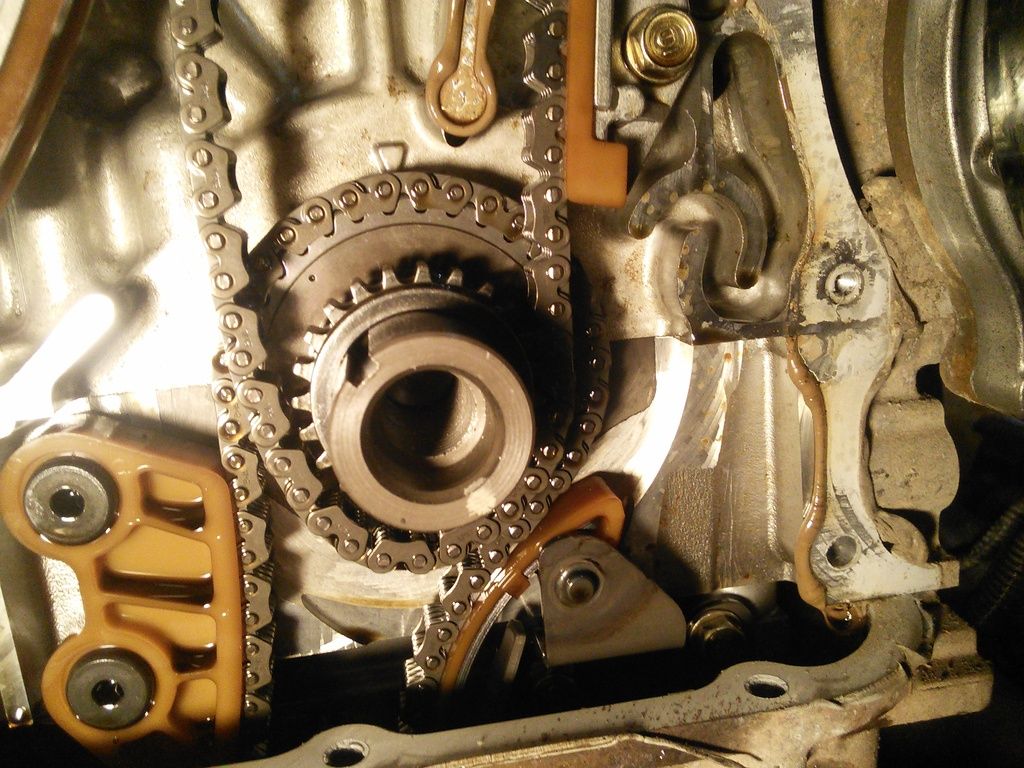

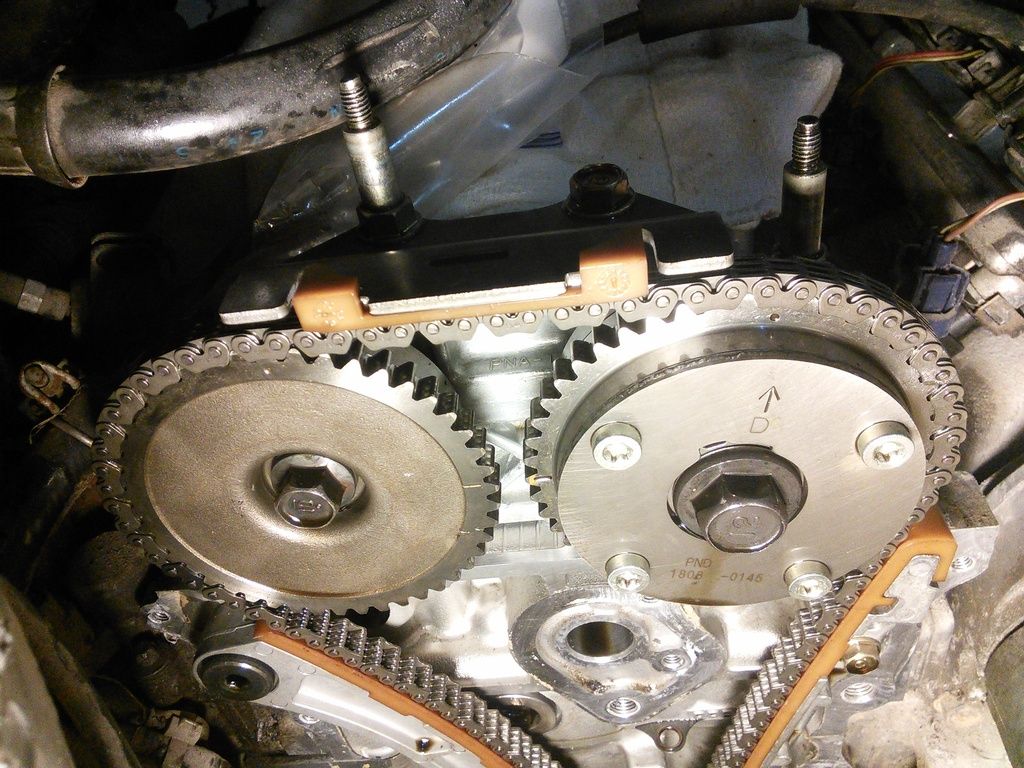

Pulled apart evening that lets me muck about with the timing chain. Found this. The chain is about four teeth off.

Tensioner is still in spec. Guides look brand new. Still can't get everything perfectly lined up.

Tensioner is still in spec. Guides look brand new. Still can't get everything perfectly lined up.

Either someone replaced the guides and left an older chain, or the head/block has been trimmed. At this point, who knows. At least it's back in time and hopefully I can get it buttoned back up tonight and see what else is broken.

I can't get the O2 sensor out and the exhaust is welded into one piece from the flange to the end, so I'm going to have to deal with that before it runs properly too.

Either someone replaced the guides and left an older chain, or the head/block has been trimmed. At this point, who knows. At least it's back in time and hopefully I can get it buttoned back up tonight and see what else is broken.

I can't get the O2 sensor out and the exhaust is welded into one piece from the flange to the end, so I'm going to have to deal with that before it runs properly too.

Two hours from the time I started applying the gasket goo stuff to putting it back on the ground 'together'. Pulled fuse #16 so hopefully it will forget all of the bad things it learned about the cams being out of phase. I would start it now but the gasket goo says to wait. So I will.

oh the suspense! I hope it starts well tomorrow!

hhaase

Reader

11/29/16 9:28 p.m.

Those don't look like the Team Dynamic wheels anymore .....

Those are spares that the co-owner had sitting in his backyard that were spare rallycross wheels. The Team Dynamics only sort of hold air and are harder to push the car around on so they're stacked in the corner until we get back on dirt.

Started it up. Runs......it runs.

Other than the 2k idle turning into a massive surge from 1k-3k after a minute or so. Only codes are O2 related. I think I'm chasing vacuum issues. Probably clean the air idle control valve and move from there. Of course I also have NO vacuum lines on the car. Just an intake tube with the ports blocked.

Throttle body is held on with two bolts and two studs. Or it should be. Mine was one bolt and one stud. Need another bolt and another nut. Who does this?

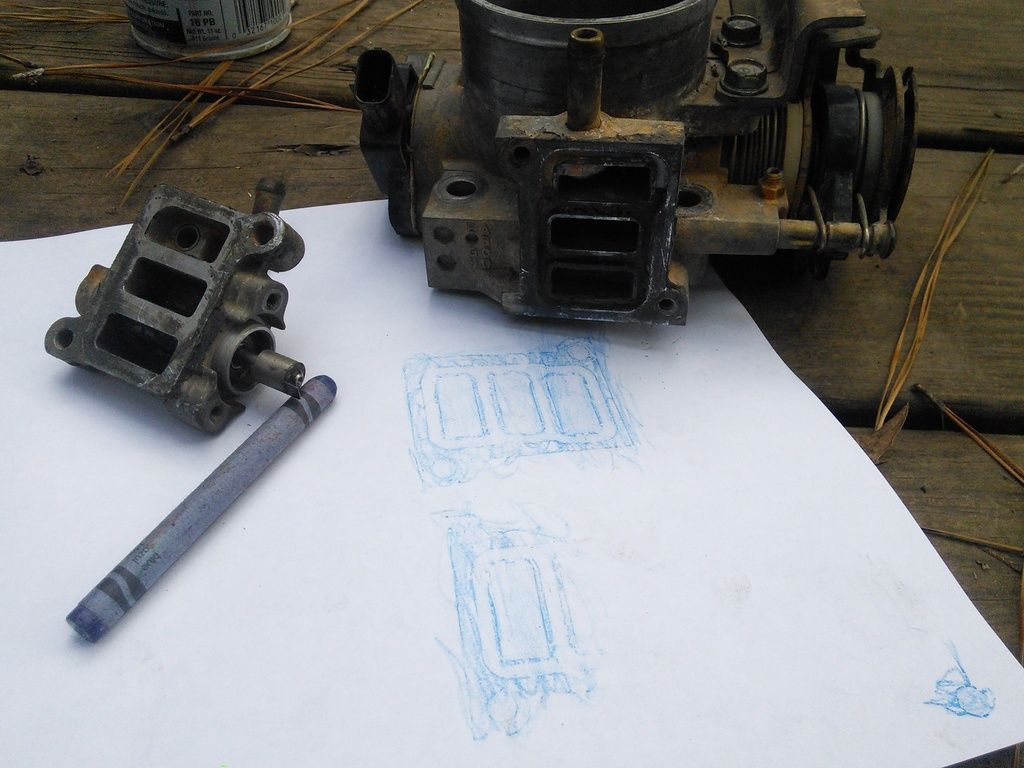

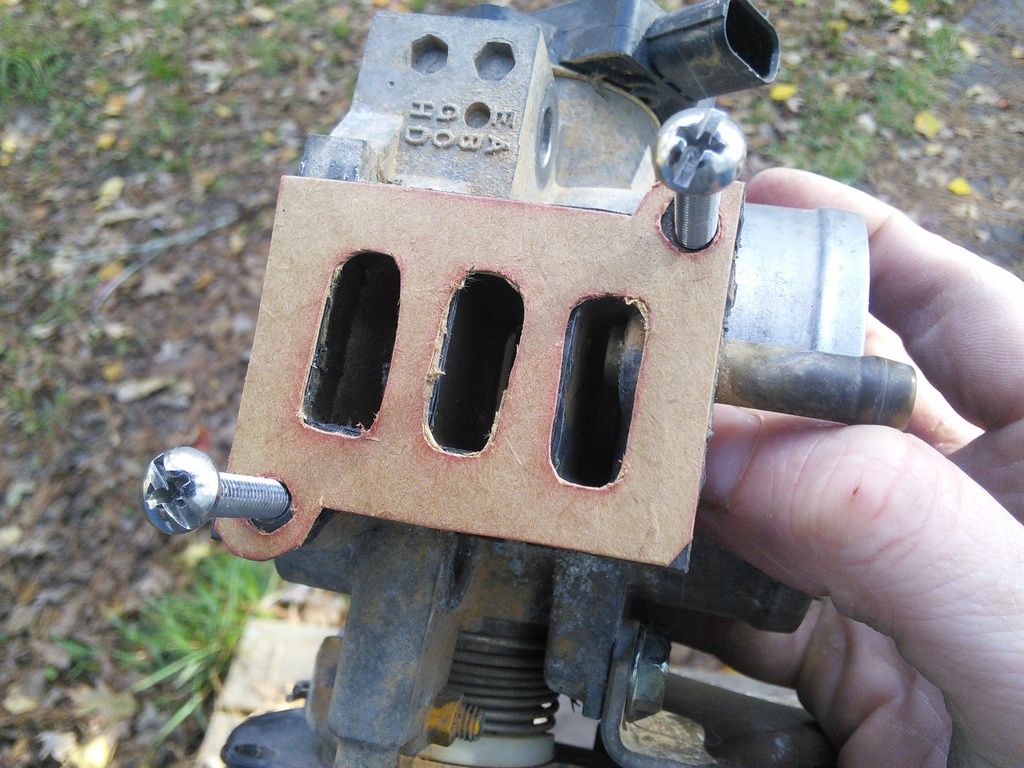

Also the 'gasket' between the TB and the intake is this.

A piece of what looks like uhmw plastic. There is evidence that there used to be a paper gasket here. I can't quite believe that I could get the plastic to seal even with all four fasteners. We'll see.

A piece of what looks like uhmw plastic. There is evidence that there used to be a paper gasket here. I can't quite believe that I could get the plastic to seal even with all four fasteners. We'll see.

This is how the AICV was held on, because berkeley the next guy.

It couldn't have been leaking because both intake nipples were packed with mud dauber mud. It was locked up solid with goo and rust. I have it moving again, but I need to work on it more.

I should be able to get the proper screws and bolts locally to make it all work. Then we test again to find the next problem.

It couldn't have been leaking because both intake nipples were packed with mud dauber mud. It was locked up solid with goo and rust. I have it moving again, but I need to work on it more.

I should be able to get the proper screws and bolts locally to make it all work. Then we test again to find the next problem.

I wonder though, if it has a bunch of unmetered air causing the idle to surge, how does it know that's the case if the O2 sensor is bad?

It probably doesn't, but it knows the RPM and will do other things to get the idle back down? Purely a guess.

It idles in warm up mode fine as the mix is much richer generally.

Once warm: it leans out, unmetered air leans out more, which increases revs, add fuel which corrects, yeah who knows.

That's what I was thinking. It reverts to tables which run it rich, extra air makes the idle higher, then it tries to sort things out and can't. Maybe.

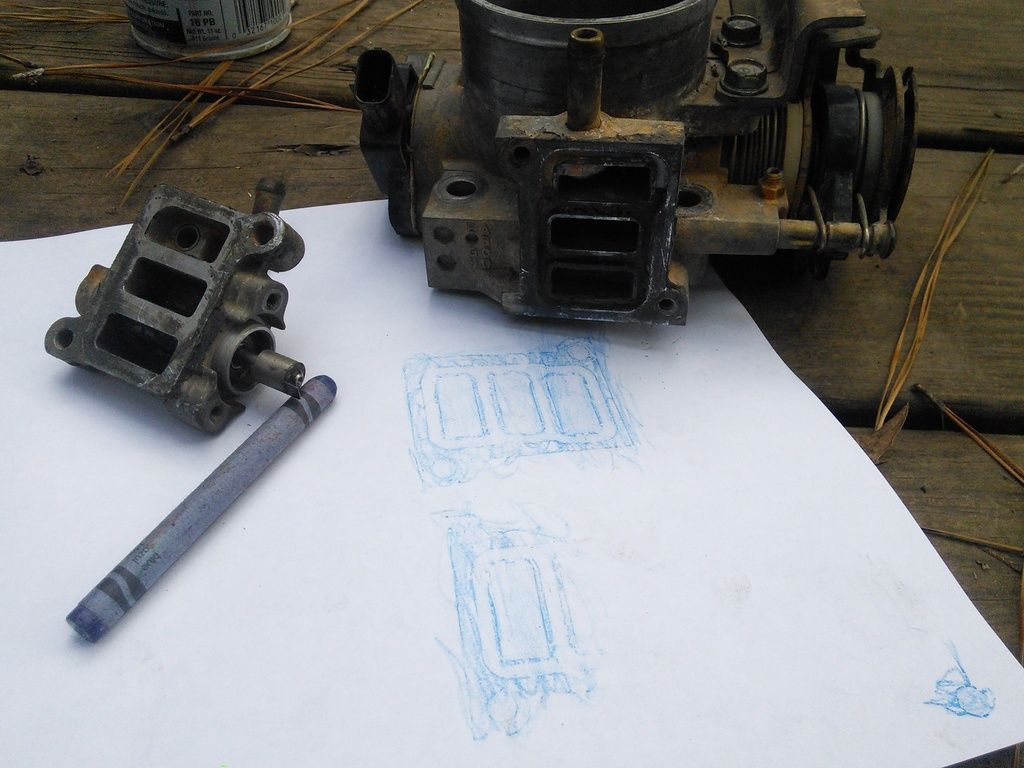

Got everything apart and cleaned. Unsurprisingly the IACV was locked up solid. Sorted that and drilled out the broken screw chunk. Next was the missing gasket. Originally it used a rubber O ring assembly thing, which is of course gone. The PO used gasket maker which might work, but you guys have taught me that making your own gaskets is fun and easy, so I got out the craft supplies and went to work.

Crayon rubbing on paper. Took me a few tries.

Cut that out taped it to cardboard, I know I should have used proper gasket material, but I didn't, and painted.

Cut that out taped it to cardboard, I know I should have used proper gasket material, but I didn't, and painted.

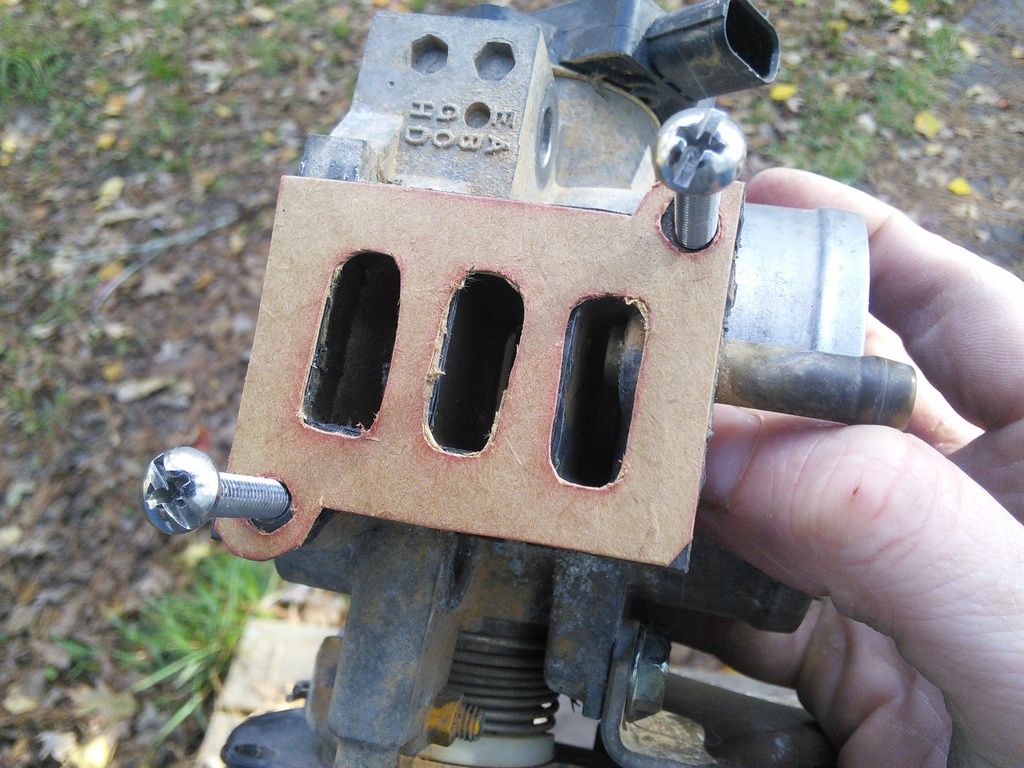

And it seems to fit well! I did clean up those burrs.

[URL=http://s1153.photobucket.com/user/mazdeuce/media/Mobile%20Uploads/IMG_20161201_101922_zpsxeszujq6.jpg.html]

And it seems to fit well! I did clean up those burrs.

[URL=http://s1153.photobucket.com/user/mazdeuce/media/Mobile%20Uploads/IMG_20161201_101922_zpsxeszujq6.jpg.html] [/URL]

Very thin smear of gasket goo on each side, assemble, put in the hardware store bolts I bought this morning which make it so that you need a 12mm and a 13mm to pull the throttle body (which I will fix) and.....it runs fantastic!

[/URL]

Very thin smear of gasket goo on each side, assemble, put in the hardware store bolts I bought this morning which make it so that you need a 12mm and a 13mm to pull the throttle body (which I will fix) and.....it runs fantastic!

Idles at 600rpm, comes up to temp and coolant circulates. Drives back and forth down the driveway. It's like a real car!

The only codes are 02 related. Not that something else won't pop up when it's ready for a proper shakedown, but I'm berkeleying ecstatic. Only took me 100 hours of work and $1000 in parts to get the car where I hoped it was when we bought it.

This is great news ... but ... I think you said you wanted to get it running so that you could start work on the R63. Looks to me that now you are trying to find any little problem in order to avoid the van

C'mon man! We want to see the van fixed! If you have not started by Jan I will fly out there and help you pull that engine

I need the RSX to go away to my co-owner. That means it needs to be functionally road worthy. The last thing I think I need to do on the lift is the exhaust, once that is done I'll move the van in and start at step 1 in the service CD. The plan is to get the RSX back to Austin before I leave for Christmas and devote January to the van.

In reply to mazdeuce:

I'm just messing with you ... should I fly into Bush or Hobby?

But when I rotate the engine so the crank is at TDC, I get this. Which is bad.

But when I rotate the engine so the crank is at TDC, I get this. Which is bad.

Which means the guys who did the timing chain replacement didn't do it quite right, so I get to take it apart. Yay. But we're loading up the Grosh truck and heading to the Grand Canyon for a week, so the rally car will have to wait.

Which means the guys who did the timing chain replacement didn't do it quite right, so I get to take it apart. Yay. But we're loading up the Grosh truck and heading to the Grand Canyon for a week, so the rally car will have to wait.

Tensioner is still in spec. Guides look brand new. Still can't get everything perfectly lined up.

Tensioner is still in spec. Guides look brand new. Still can't get everything perfectly lined up.

Either someone replaced the guides and left an older chain, or the head/block has been trimmed. At this point, who knows. At least it's back in time and hopefully I can get it buttoned back up tonight and see what else is broken.

I can't get the O2 sensor out and the exhaust is welded into one piece from the flange to the end, so I'm going to have to deal with that before it runs properly too.

Either someone replaced the guides and left an older chain, or the head/block has been trimmed. At this point, who knows. At least it's back in time and hopefully I can get it buttoned back up tonight and see what else is broken.

I can't get the O2 sensor out and the exhaust is welded into one piece from the flange to the end, so I'm going to have to deal with that before it runs properly too.

A piece of what looks like uhmw plastic. There is evidence that there used to be a paper gasket here. I can't quite believe that I could get the plastic to seal even with all four fasteners. We'll see.

A piece of what looks like uhmw plastic. There is evidence that there used to be a paper gasket here. I can't quite believe that I could get the plastic to seal even with all four fasteners. We'll see. It couldn't have been leaking because both intake nipples were packed with mud dauber mud. It was locked up solid with goo and rust. I have it moving again, but I need to work on it more.

I should be able to get the proper screws and bolts locally to make it all work. Then we test again to find the next problem.

It couldn't have been leaking because both intake nipples were packed with mud dauber mud. It was locked up solid with goo and rust. I have it moving again, but I need to work on it more.

I should be able to get the proper screws and bolts locally to make it all work. Then we test again to find the next problem.

Cut that out taped it to cardboard, I know I should have used proper gasket material, but I didn't, and painted.

Cut that out taped it to cardboard, I know I should have used proper gasket material, but I didn't, and painted.

And it seems to fit well! I did clean up those burrs.

[URL=http://s1153.photobucket.com/user/mazdeuce/media/Mobile%20Uploads/IMG_20161201_101922_zpsxeszujq6.jpg.html]

And it seems to fit well! I did clean up those burrs.

[URL=http://s1153.photobucket.com/user/mazdeuce/media/Mobile%20Uploads/IMG_20161201_101922_zpsxeszujq6.jpg.html] [/URL]

Very thin smear of gasket goo on each side, assemble, put in the hardware store bolts I bought this morning which make it so that you need a 12mm and a 13mm to pull the throttle body (which I will fix) and.....it runs fantastic!

[/URL]

Very thin smear of gasket goo on each side, assemble, put in the hardware store bolts I bought this morning which make it so that you need a 12mm and a 13mm to pull the throttle body (which I will fix) and.....it runs fantastic! At some point someone cut the dash bar, presumably they pulled it for some reason. Then they put it back. They were not good welders.

At some point someone cut the dash bar, presumably they pulled it for some reason. Then they put it back. They were not good welders.

I was hoping I could figure out how to pull it so I could put in the bar that we got from the junk yard, but the cage is well and truly in the way. I might be able to get it with a little bit of cutting to parts of the car other than the cage. We'll see. For now I needed to get the wiring sort of organized. It was bad.

I was hoping I could figure out how to pull it so I could put in the bar that we got from the junk yard, but the cage is well and truly in the way. I might be able to get it with a little bit of cutting to parts of the car other than the cage. We'll see. For now I needed to get the wiring sort of organized. It was bad.

Sorry for the sun dappled photos, it's a beautiful clear 74 degree day.

Sorry for the sun dappled photos, it's a beautiful clear 74 degree day.  Now I need to fix the tie rod end, put the radiator and fans back in properly and make sure the fans come on. Put the lights in. Bumper cover back on. Order the exhaust.......there's more, but the list is getting smaller.

Now I need to fix the tie rod end, put the radiator and fans back in properly and make sure the fans come on. Put the lights in. Bumper cover back on. Order the exhaust.......there's more, but the list is getting smaller.