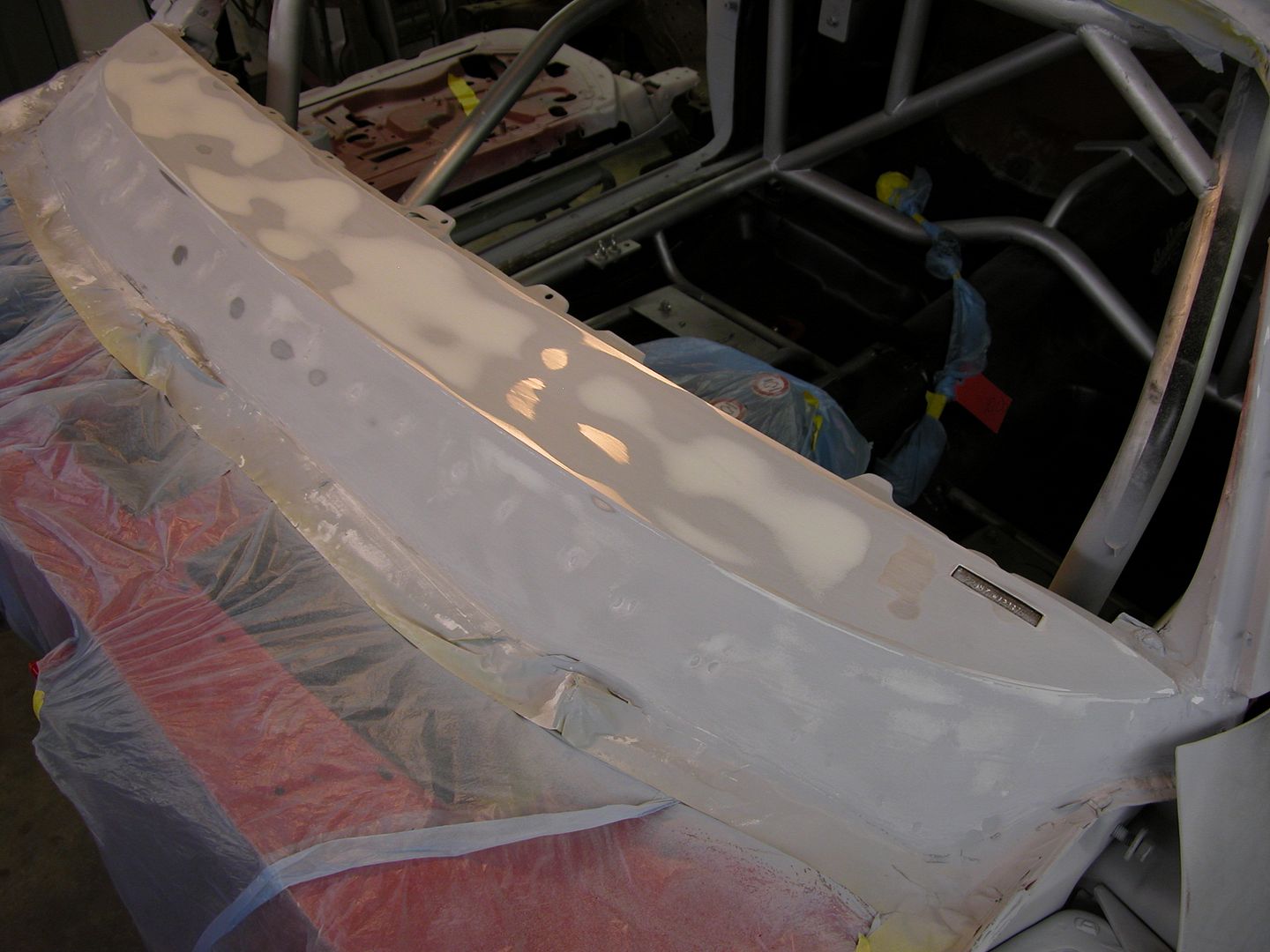

So onto window channel repairs. I'm waiting on weld in trim clip studs to repair the rear one so here's the front repair I needed to make. I have a new (well 20 years ago ahahaha) headliner it the car which is perfect and I don't want to damage or try to replace it with the roll cage in the way. So welding is something I wanted to avoid above the headliner plus welding creates the possibility of warping the roof skin in that area.

To get started the leftover urethane was scraped off with a scraper that holds razor blades using a plastic razor blade. If you've never seen them they are the same size as a single edge razor but without the very sharp edge, great for scraping stuff you don't want scratched (like paint) and don't dig in and snap like metal blades which is why I use them for scraping urethane window sealer. After scraping wax and grease remover with a bunch of rags will remove the remaining urethane then small wire wheels are used to remove the paint as well as any rust.

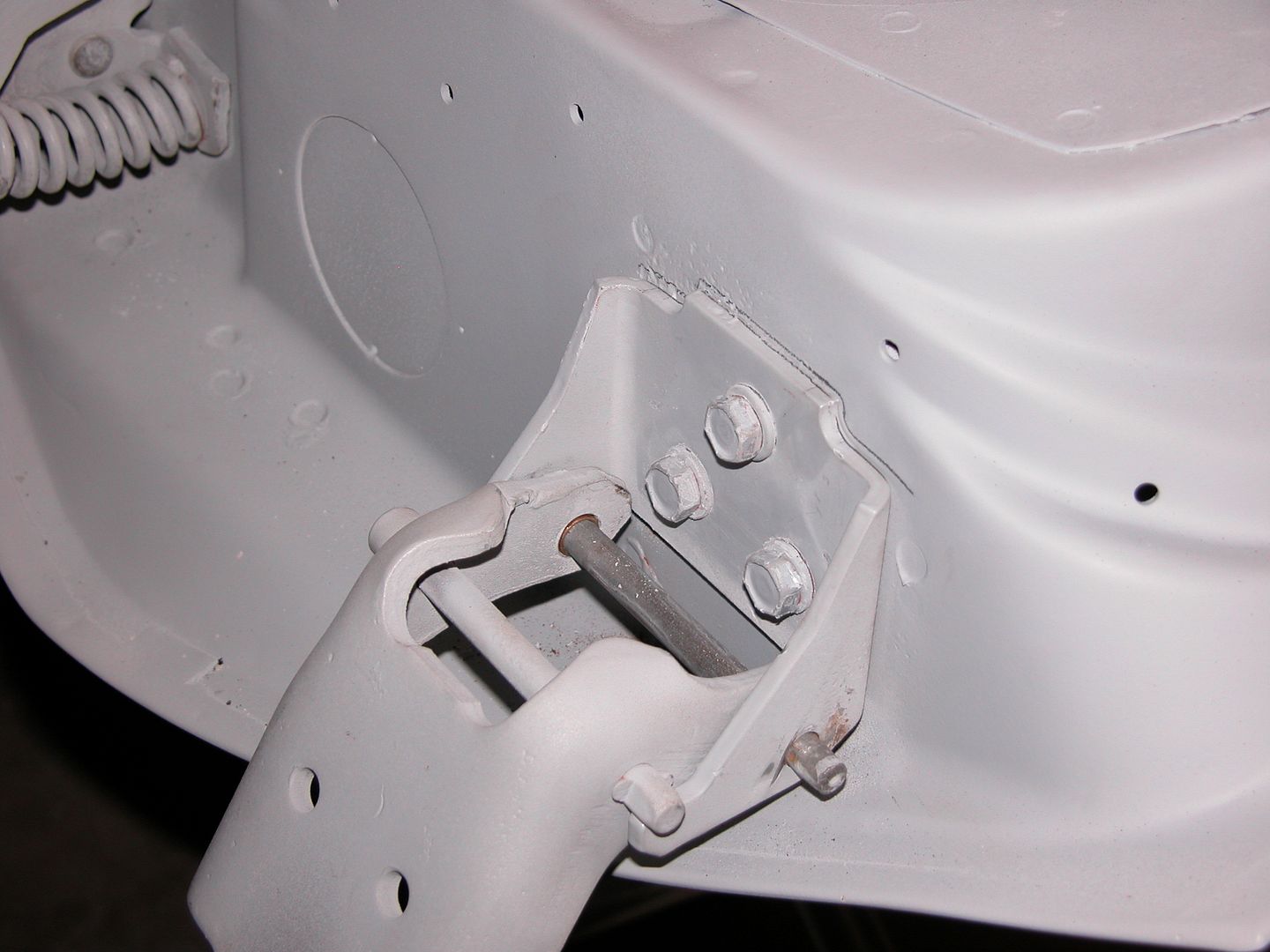

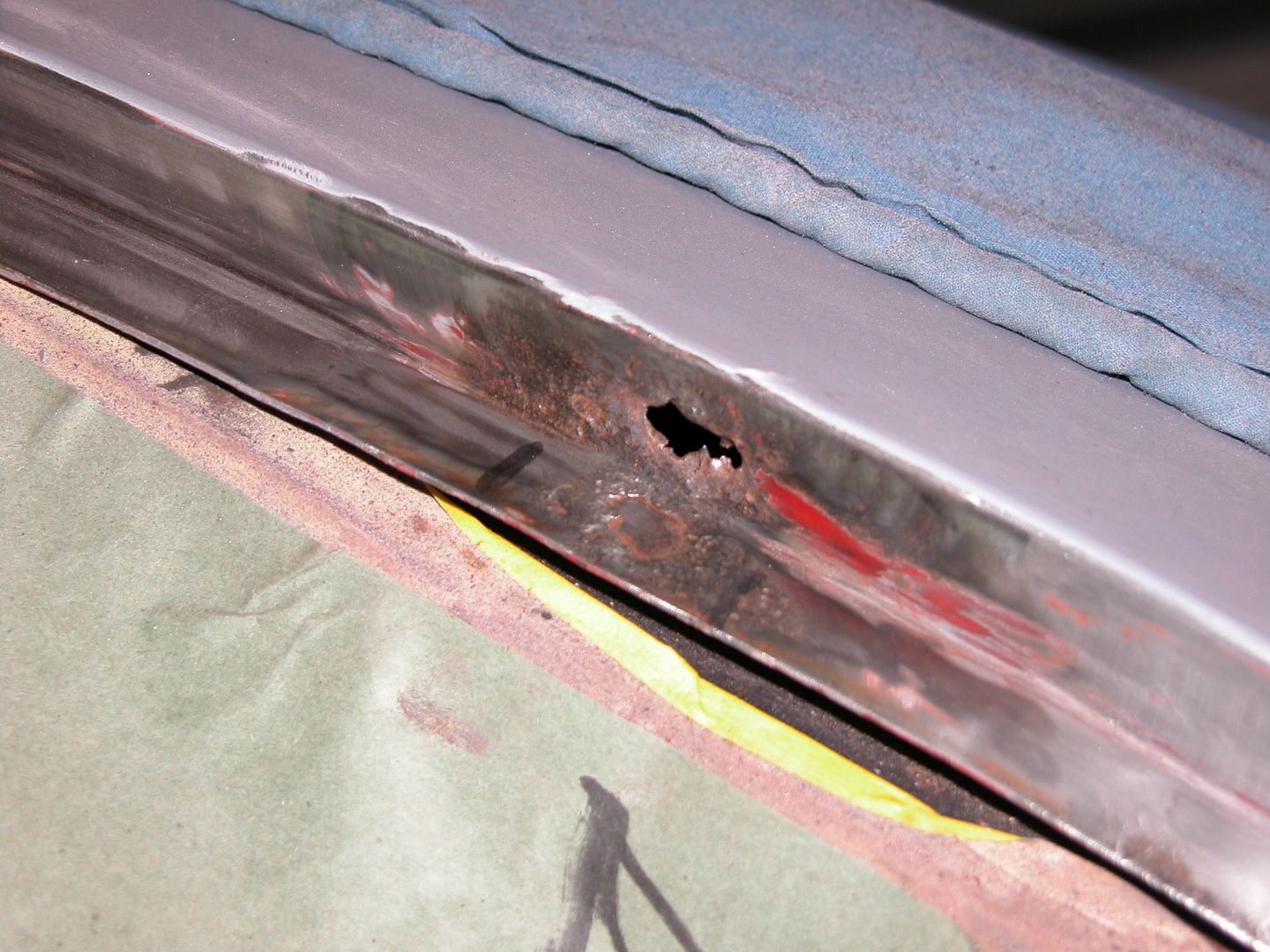

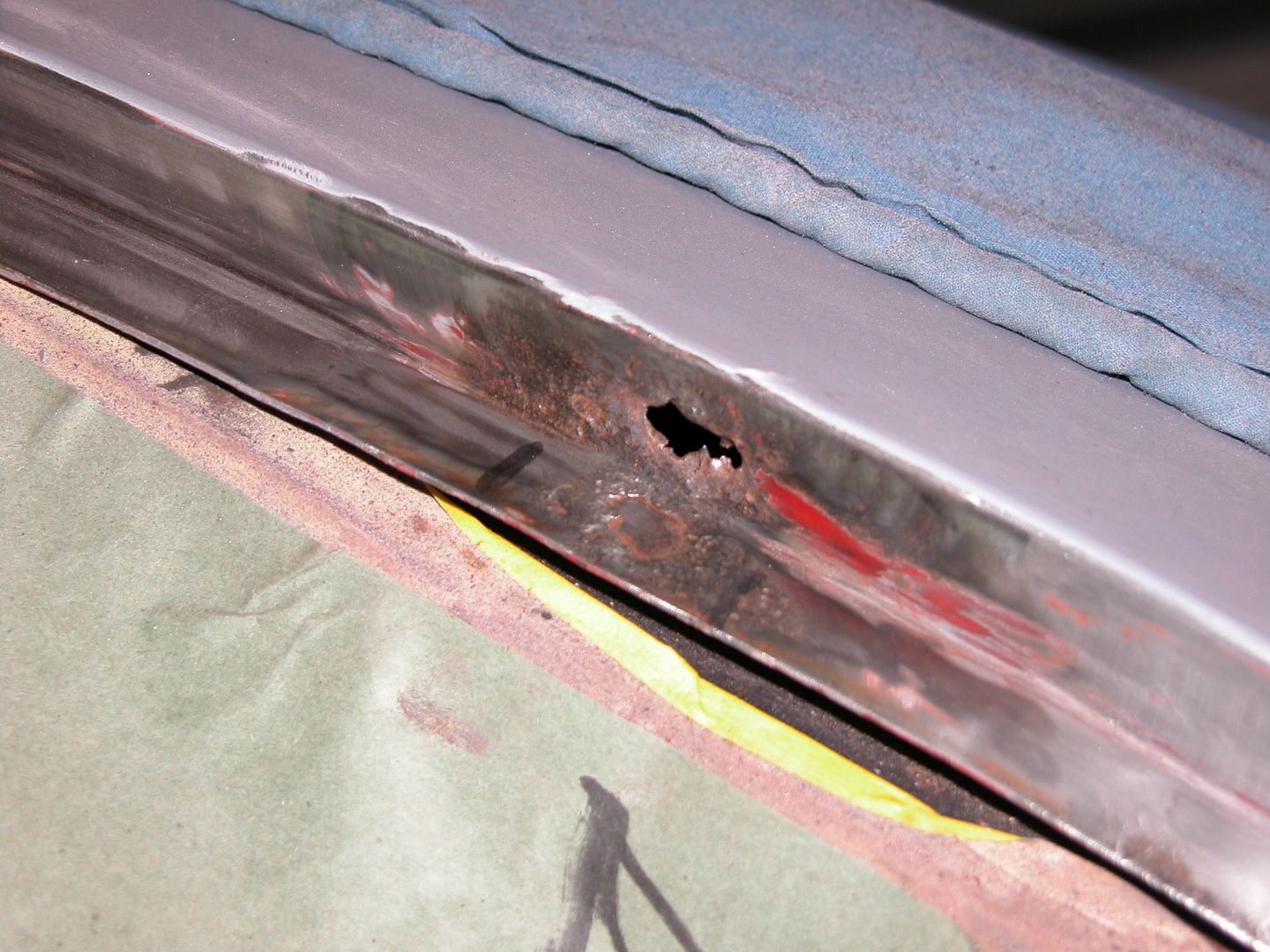

I found a small rusted area around one of the trim studs and several of the studs were missing. Now I know why the trim kept lifting over 100 MPH and had to be paped down! I'll clean off places to spot weld the new studs when they arrive.

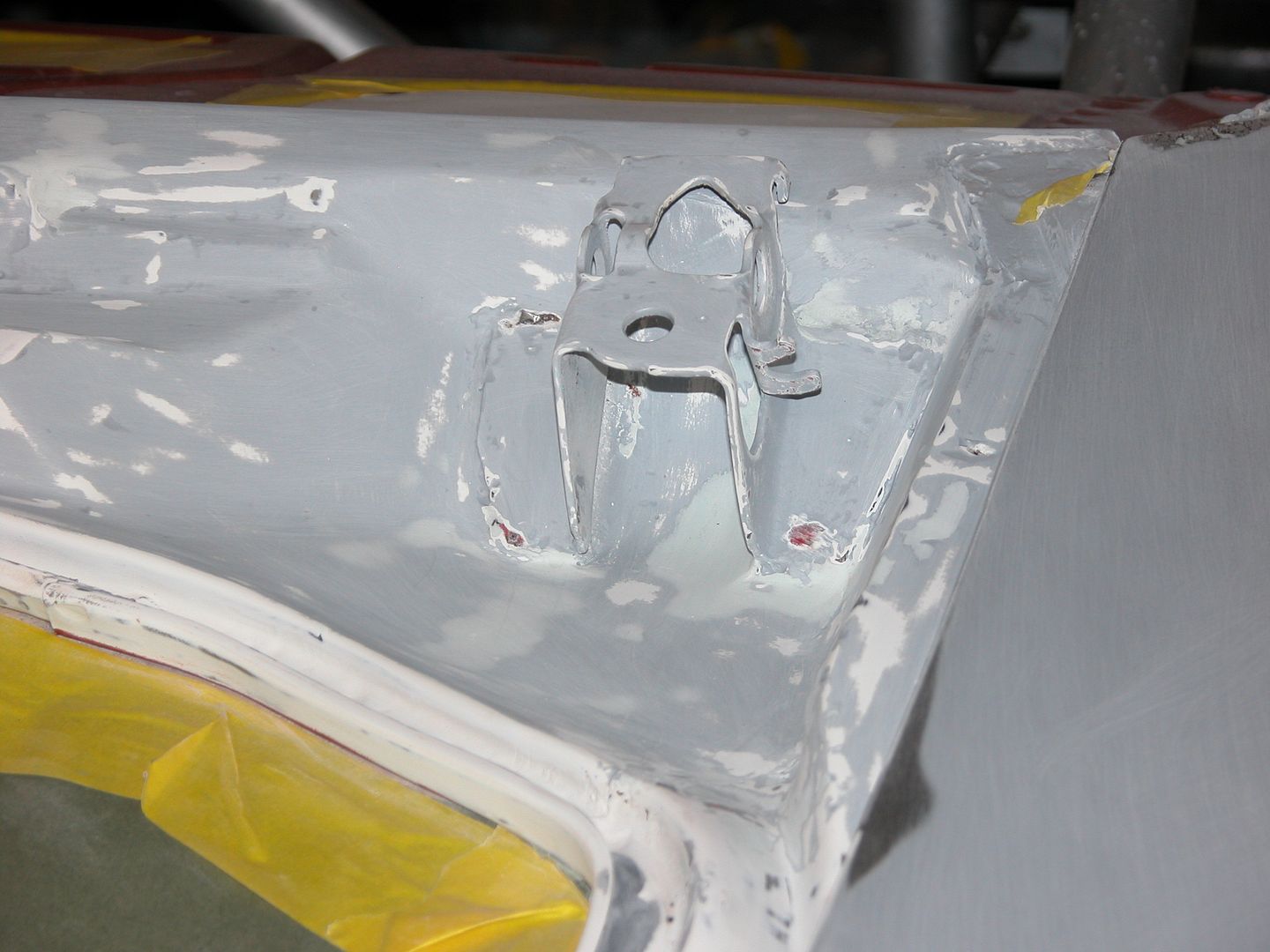

To fix the rust the area was cleaned well with a wire wheel. Then a carbide bit (like you'd use porting heads) was used to "thin" the sheet metal where the rust was taking it back to clean metal. Then that area was carefully dimpled in a little and a piece of sheet metal bonded in with 3M 8115. Once dry the panel bond was sanded flush and a little plastic filler skim coated on, sanded, and then the window channel epoxy primed.

The findings after cleaning the channel were rust around a stud and a few missing? I had used one of the screw in repair studs when I painted the car 20+ years ago where the small hole is left of the rust area but that one along with a couple others were MIA after removing the trim and window.

[URL=http://s240.photobucket.com/user/NOTATA/media/The%2014%20Car%20Performance%20Therapy/001_zps154539bc.jpg.html] [/URL]

[/URL]

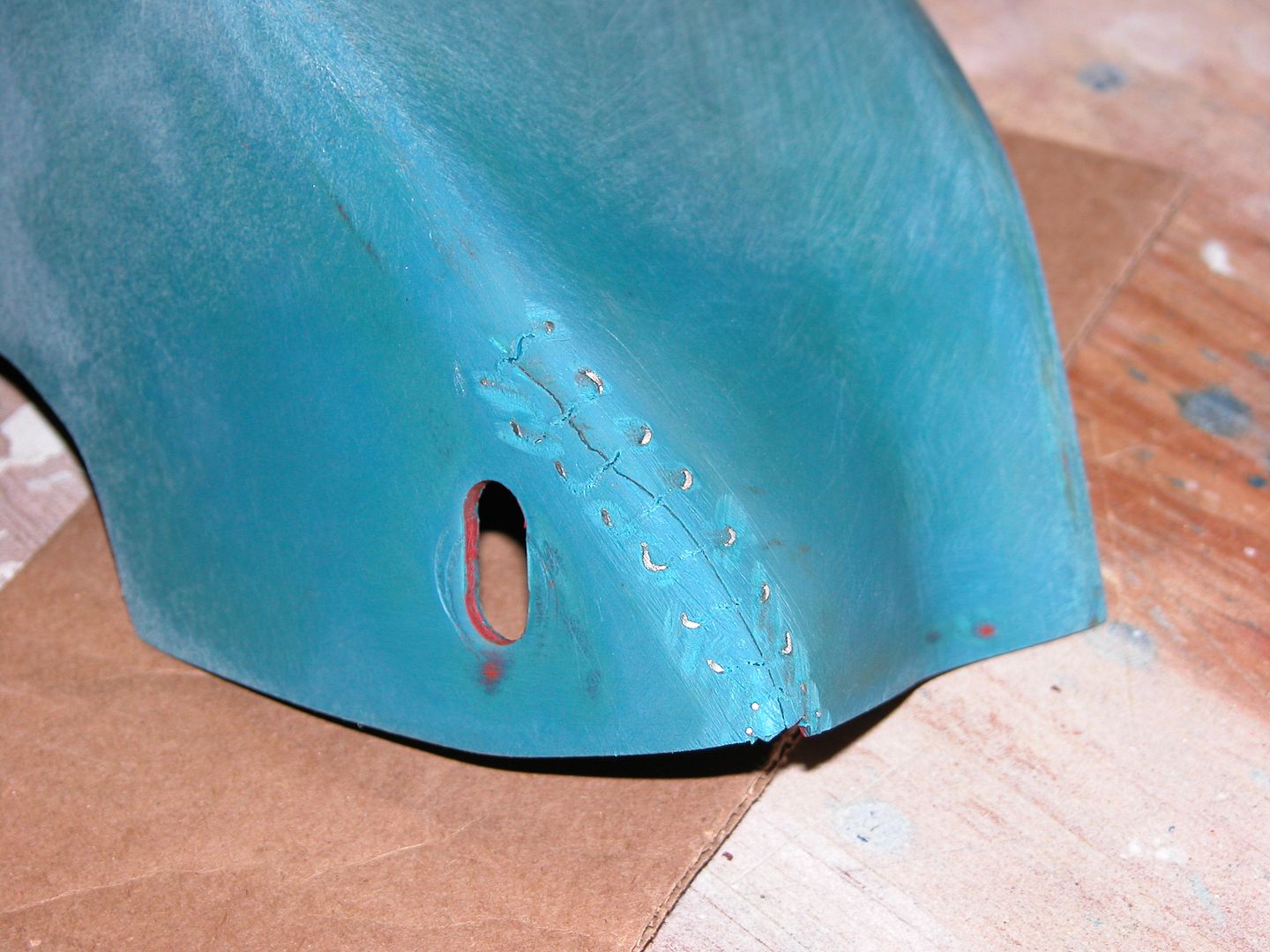

The rusted area after wire wheel cleaning marked to make a patch panel.

[URL=http://s240.photobucket.com/user/NOTATA/media/The%2014%20Car%20Performance%20Therapy/003_zps2b28294c.jpg.html] [/URL]

[/URL]

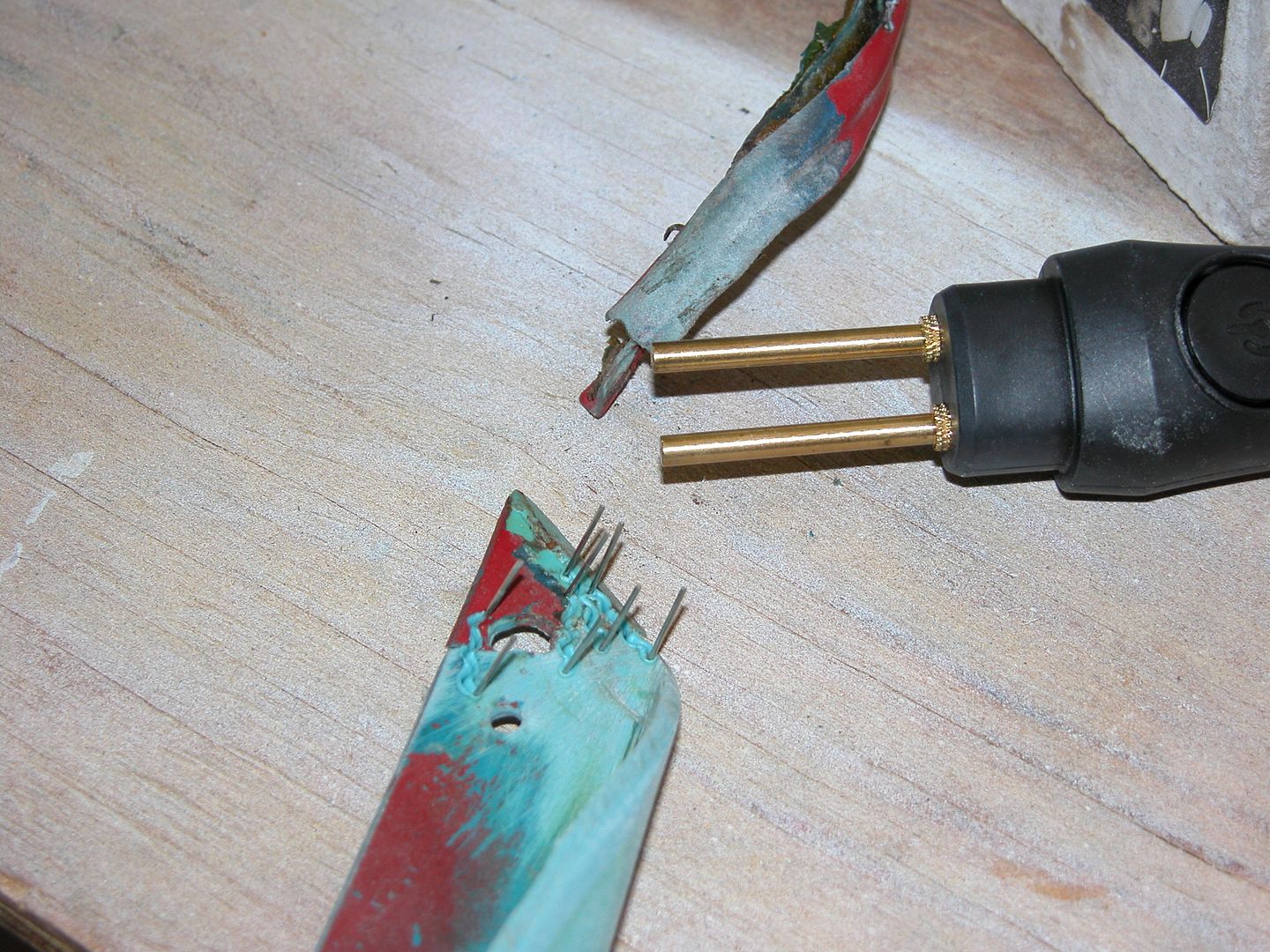

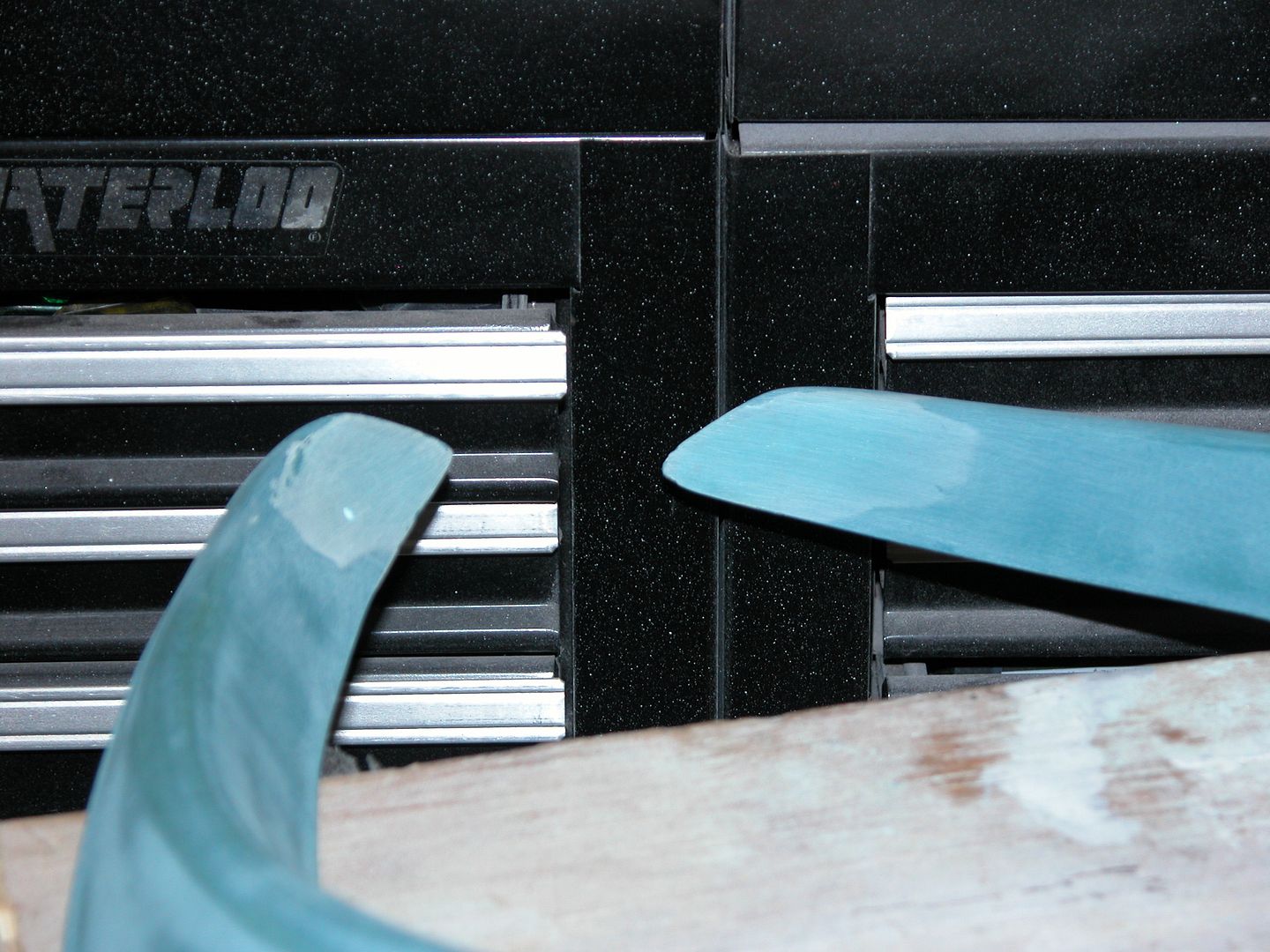

Patch piece and the area ground down for the patch.

[URL=http://s240.photobucket.com/user/NOTATA/media/The%2014%20Car%20Performance%20Therapy/004_zps01ea9ecd.jpg.html] [/URL]

[/URL]

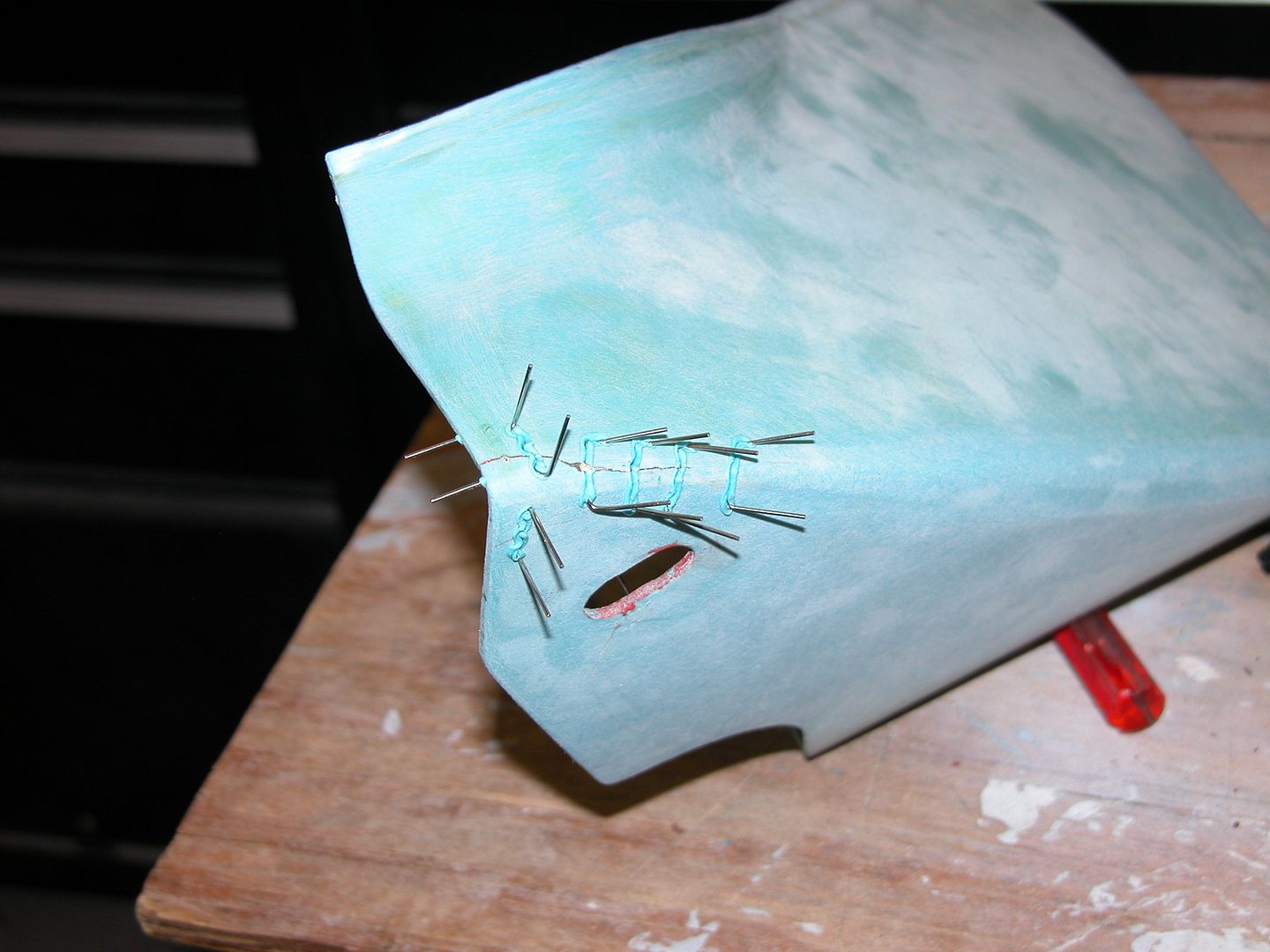

Patch installed with panel bond.

[URL=http://s240.photobucket.com/user/NOTATA/media/The%2014%20Car%20Performance%20Therapy/006_zpsa431cf6c.jpg.html] [/URL]

[/URL]

Extra panel bond removed.

[URL=http://s240.photobucket.com/user/NOTATA/media/The%2014%20Car%20Performance%20Therapy/007_zps4ea10d66.jpg.html] [/URL]

[/URL]

Plastic filler smoothed and the channel epoxy primed.

[URL=http://s240.photobucket.com/user/NOTATA/media/The%2014%20Car%20Performance%20Therapy/009_zps66f8ca7e.jpg.html] [/URL]

[/URL]

While doing the channel I also fixed some pitting in the lower corner of both sides that's common on 2nd gen F bodies. No new metal needed so pits were cleaned, panel bonded, smoothed, primed. Rear window channel needs more metal repair than the front did, will post when I get the studs I need to do it.

[URL=http://s240.photobucket.com/user/NOTATA/media/The%2014%20Car%20Performance%20Therapy/008_zps6963fae1.jpg.html] [/URL]

[/URL]

[URL=http://s240.photobucket.com/user/NOTATA/media/The%2014%20Car%20Performance%20Therapy/011_zpsd425b85e.jpg.html] [/URL]

[/URL]

[/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL]

[/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL]