I finally got started on the Accusump install. I've been going back and forth on where I want to mount for the last year and simplicity finally won out. I was looking around the shop to see what metal I had laying around and then I saw my old strut tower bar laying there and took it as a sign.

I cut the ends of the bracket off and drilled some new bolt holes. Then I made some brackets out of angle iron to weld on so I could mount the tank. Some people asked why I didn't mount the tank in the car. I wanted to keep the lines as short as possible and I didn't want a possible oil leak inside the car. If this were a max effort race car then I could see merit to moving the weight to the back but I'm a big fan of simplicity. Putting the tank inside the car would add many more feet of expensive and heavy AN lines plus multiple potential leaks at the bulkhead fittings.

After I got the brackets welded on I completely stripped the old paint off and reshot it with some self etching primer and cast coat aluminum spray paint.

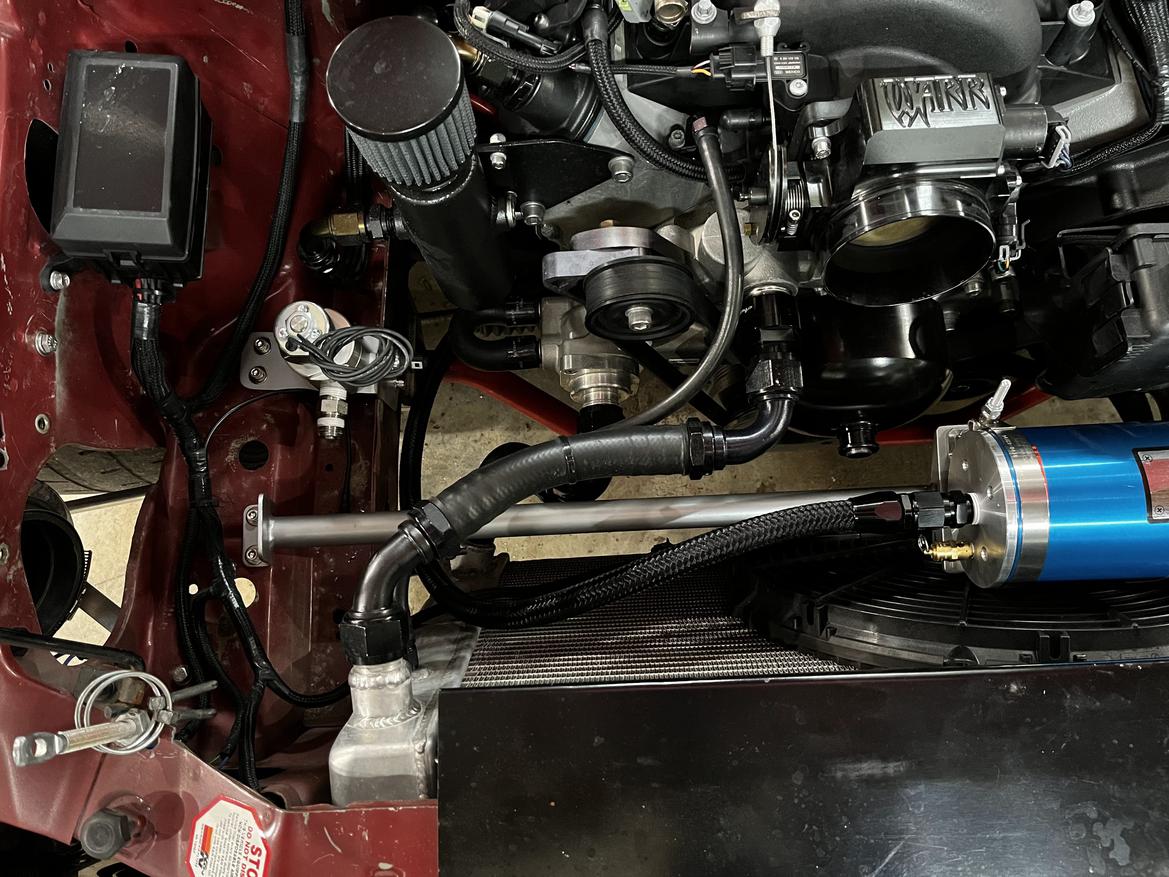

The installation directions want you to mount the control valve directly to the tank. This caused a clearance issue with my intake tube so I elected to mount the valve remotely.

The valve already had some 1/4" bolt holes on the bottom for mounting so making a bracket was pretty easy. I used a piece of 1/8" x 2" strap and bad a bracket to fit on top of the "frame rail". This puts the valve right next to my auxiliary fuse box so wiring it in should be pretty simple. I screwed up and didn't think about the hole being mirrored on my template so now I have extra holes(weight reduction).

Here's what it looks like all mounted up. Plenty of clearance to moving parts and I can still get to my brake bias valve.

I was originally going to T into my oil cooler lines but I've decided to run it strait to the block instead. I think this gives the system the fastest possible reaction time if there were a drop in oil pressure and also eliminates more potential leaks. Now I just need to order a few fittings to finish it up.