Checked a bunch of items off the list last night. For the first time, the car is really starting to feel like a race car, which is great.

Got the seat cover reinstalled and put in the harness. Sub belts and lap belts are on latching anchors so they can be removed/swapped/adjusted easily for different drivers during the race.

I also installed the cage net. I'll need to figure out better mounting to the dash bar, but wanted to see how it would work out.

Spent a lot of time working on the battery relocation/kill switch wiring. I want to have the battery in the trunk and needed to run the cables for that.

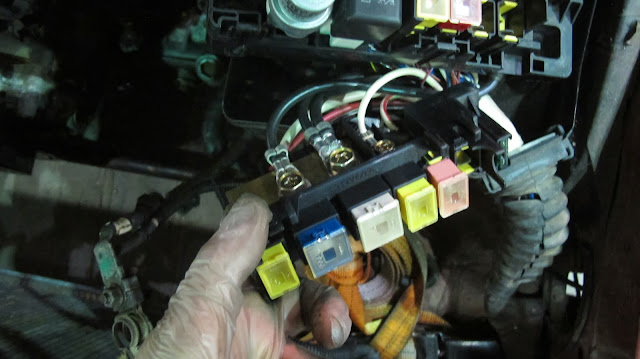

At the front of the car I had to disconnect all high-amp cables for the alternator, OE battery cables, and starter so that everything could be routed through the kill switch.

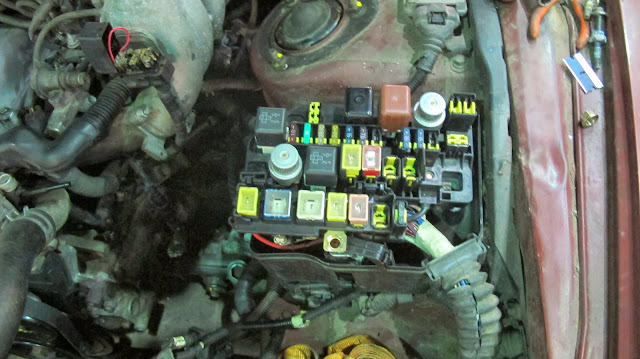

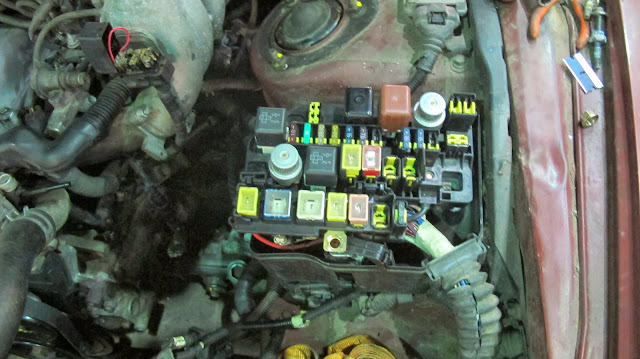

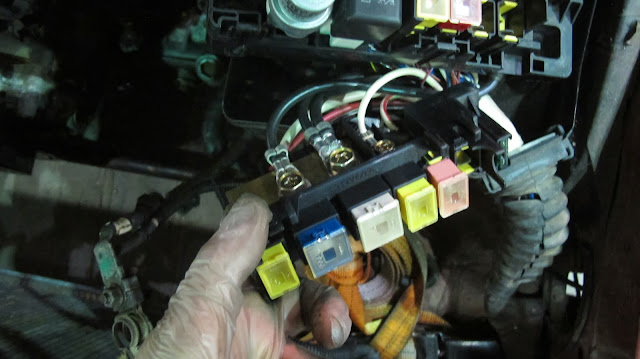

Had to dig into the fuse box to get the alternator cables.

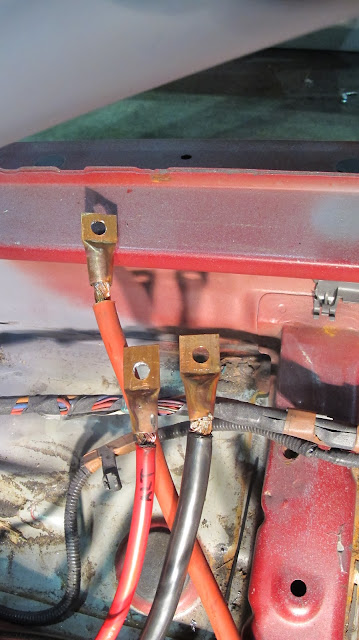

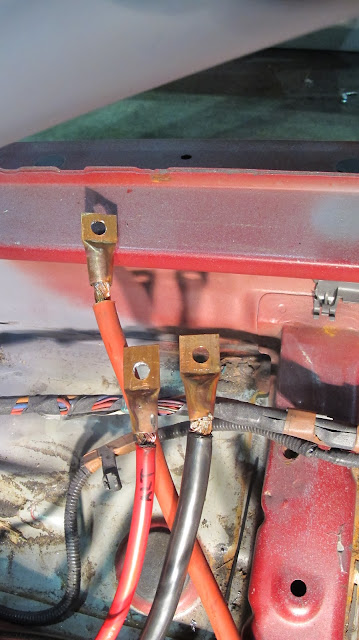

To connect all the load wiring (main harness and starter) and add some length to the various cables, I made up a few copper lugs out of some spare tubing.

The lugs were heated with a propane torch and filled with solder, then the bare cable ends were inserted to make a solid high-current connection.

Here's the extension for the alternator positive terminal.

This one joins the starter and main harness loads and extends the cable so it can reach the kill switch.

The lugs were wrapped with electrical tape, then plastic loom casing before bring installed. The cables were routed through the firewall through the grommets/boots for the main harness on either side of the engine bay.

In the passenger compartment, the battery cable, alternator cable, and load cable needed to be connected to the kill switch. To do this, I made up three more lugs that I drilled to bolt to the switch.

Here you can see the switch in front of the shifter. I still need to make the mounting plate for it, but this shows the rough location. Gave it a test run and it worked fine.

It's a simple setup and there are more complex ways to set this up that offer some additional benefits, but I've used this arrangement on several cars before, 2 of which use the same type of alternator and starter and never had any problems, so I think this should work out well.

I have a second switch and at some point, I'll probably add it in series at the base of the windshield on the driver's side so a safety worker could easily activate it.

Engine bay, sans battery.

Since I was messing with safety equipment, I got out the fire system and was trying to figure out the best location for that. Obviously, I'm really trying to work on the weight balance and want as much stuff at the rear of the car as possible. Turns out the actuator cables and tubing are plenty long enough to have the tank in the trunk as well.

I'm planning to run one of the cable pulls to the passenger's door opening and one to the dash bar on the driver's left, both of which could be activated from outside the car. For the nozzles, one will be aimed at the driver's window area, the other will be in the engine bay aimed at the top of the engine, per ChumpCar rules.

Cleaned up a little of the surface rust that had just started forming in the tire well and rattle canned in some paint real quick. Here's the battery mounted. Used an aluminum L-extrusion for the top bracket. It's quite sturdy and as easy or easier than the OE mounting setup to remove/install.

Cleaned up a little of the surface rust that had just started forming in the tire well and rattle canned in some paint real quick. Here's the battery mounted. Used an aluminum L-extrusion for the top bracket. It's quite sturdy and as easy or easier than the OE mounting setup to remove/install.

You can see in this shot that I also moved the coolant overflow tank to the location originally occupied by the A/C and PS components. I'm really trying hard to move as much weight down and back in the chassis. I still need to figure out some mounting brackets for the tank, but it fits well in that location and the OE hoses work fine.

You can see in this shot that I also moved the coolant overflow tank to the location originally occupied by the A/C and PS components. I'm really trying hard to move as much weight down and back in the chassis. I still need to figure out some mounting brackets for the tank, but it fits well in that location and the OE hoses work fine.