AngryCorvair (Forum Supporter) said:

Was it originally an AC car? Or was he planning to add it? I see a compressor and an evaporator and some hoses.

Originally no AC

PO before PO planned to convert to AC.

He collected all of the OEM hard parts (case controls, wiring, etc) and ALL of the actual refrigerant system parts brand new (evap, STV, drier, condensor, compressor, hoses) that were compatible with 134a. Lots of $$ in the new kit parts from old air products.

I am not converting it. I like the bare bones aspects of this car with the 350/350 4speed and optional 3.55 ratio.

My buddy is going to use the parts and the kit to convert one of his coupes.

So, after a claybar wipedown (step 3) and one pass with the 3m cutting compound (step 4)... still just a little mottled, but it is cleaning up nicely. This will meet driver standards after a few more steps.

5. 3m polishing compound - multiple passes

6. a final shine / seal / wax.. product yet to be selected, for depth and gloss....

Improved....

I have to quit messing around with little paint experiments and get down to work.

So this was sort of a big deal:

These are right and left body mounts 3 and 4.

The nuts for these are in cages. Welded to the frame. If these break off or spin the nut, you have a lot of extra work to do.

Mounts 1 and 4 are a little more forgiving.

Thats four answered prayers right there.

Mice.

Everywhere...

That's one of the two drains in the rear cabin vent. Both drains were blocked. They are supposed to look like this:

They drain the rain water out that runs in the air inlet grates on the rear deck.

I was looking around and I think that there is a mouse house in both doors. We all know that there will be one in the heater core...

What is the function of the rear deck air inlet grates?

In reply to OHSCrifle :

I think they serve as outlets when the heat is off to promote cabin ventelation.

Woody (Forum Supportum) said:

Your pace is impressive!

Thanks. I really want to get to a stage where some tasks are completed... but this kinda requires doing a number of things all at once. I want to have everything clean and functional in the cabin and with respect to the body and mountings as stage 1. Lights, wipers, heater, gauges, radio, horn, crack in driver's floor board. etc..

I think stage 2 is going to be brakes... but I may be doing the booster and the hard lines (including fuel) in stage 1 while I have the body lifted from the frame with room to work.

Stage 3 engine and transmission.

Stage 4 suspension.

You buy a project... you buy parts.

I of course have a number of new parts on order for the body bushing replacement and some other inner tub refurbishments.

However I have stumbled on an interesting consequence to selecting to preserve the appearance of the the car without overtly restoring it.

I needed to replace the front hood emblem, because there isn't one. So of course I did not want to slap a brand new shiney one on there... it would look out of place.

A quick trip to ebay, and I had this ordered up via buy it now.

This will be a perfect match! AND its cheaper than a reproduction!

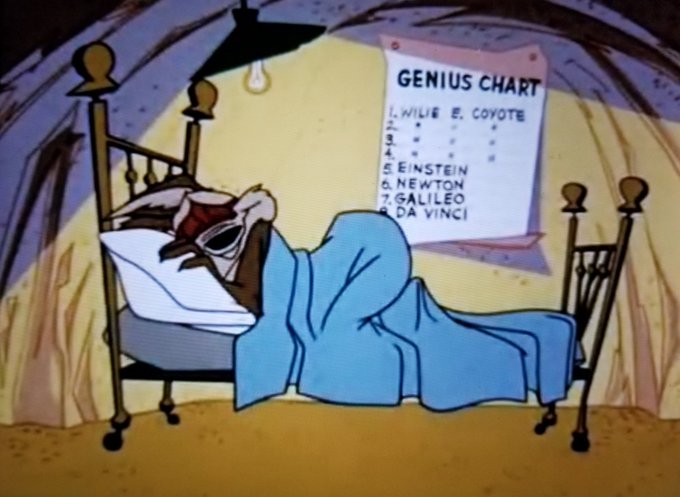

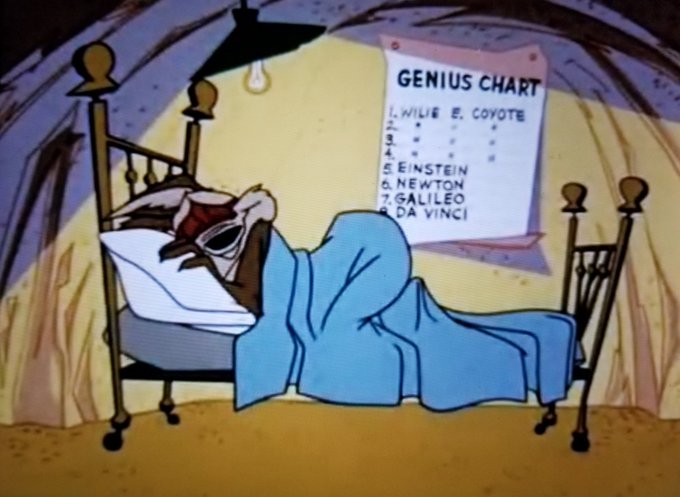

I'm a genius!

(in that coyote self defeating kind of way...)

While I was there, I also scored this:

County code 13 - Leon County,,, where I grew up!

In Florida, you can have old dated tags inspected and re-issued for use. :)

First small surprise... drivers door is gold!

That explains why it was not aligned.

We'll fix that.

And of course, this is no surprise...

Mouse house number.... aw heck I've lost track..

Both door panels are probably original, both were made in April 1969.

Tag arrived today...had to dream a little.

So parts of this thread will be for me to keep track of information I find while I am taking the car apart.

Such as the glass date codes.

I don't need the glass codes to be "correct" to be happy with this car, however decoding them can tell a little about what the car has been through.

So to start off I know the passenger glass is wrong. It isn't tinted. The fact that it's in a gold door that is also not original makes sense. But to be consistent, here is the code:

AX - September 1968 Probably originally installed in a car mid production for the 69 model year.

So for reference this car was ordered 2/26/69 and scheduled for build with an unknown anticipated build date of 00/00/69 according to the tank sticker. The body tag says April 3rd was the build date. But there was a strike in 1969 and the St Louis plant was interrupted in the spring and summer of 1969 to the extent that no cars were built in May. The NCRS shipping data (came with the car) says that the car was actually built June 19th, 1969. That implies that this car may have been stalled in production for some time during the strike. That may make for interesting interpretation of some date codes.

Back to the codes, this is the drivers window.

XV - Feb 1969

Makes sense, and it's the correct tinted glass. Probably the original piece for the car.

The windshield:

UN-July 1971

Windshield is the correct type and tint but it's from a 71 or 72 Corvette.

That may explain some of the mild windshield frame rust as it appears that when the windshield was replaced the top header trim was reinstalled without being resealed properly.

And that lack of detail in replacing the windshield is one of the many reasons why we work on our own cars isn't it?

If we keep looking at numbers and production dates the engine is an "HW" coded 350hp 350 destined for a manual transmission car and was built at the Flint plant June 12, 1969 and is clearly stamped with the cars serial number.

The M20 transmission also carries the serial portion of the VIN number , and is coded as having been assembled March 29th, 1969 at the Muncie plant

So if we go back and assume that the April 17th door panels are correct, and knowing that the engine and transmission are correct by the stamped serial numbers, the car and the NCRS documentation tell us that this car began production April 8th and then stalled before the door panels were installed as they were built April 17th. Perhaps production was just slowed? But we do know that the line was closed for all of May. This explains the engine being made in June. These engines were also used in the Camaro, so their production went right along. The transmission how ever may have been specific to Corvette, explaining why new ones weren't on the line when Corvette production resumed in June.

It looks like when interpreting the dates on this car the sequence of assembly and supply will have to be considered as the car was in production from April 8th to June 19th!

I love the internet,

Here is 1969 Corvette Production by month (ending serial number for the month coupes and convertibles):

Yep , ole yeller was commenced April 8th, 1969 and did not roll out the door until June 19th 1969!

If you look at number per month, before April, the line was averaging 2900 cars per month.

In April they built 771. So the strike impacted April in a significant way, curtailing production after about the first week of April.. exactly when my car went to production.

I've never done a concours restoration, but I went through a phase of great appreciation for casting dates and VIN stamps and ink dots and chalk marks. In my career I've been to a lot of assembly plants and have seen up close and personal all sorts of paint dabs and dots and marks to identify a fastener has been torqued and checked by a supervisor, or a revised part has been introduced mid-year, etc. Nowadays we document *everything* via change control process. Back in the day, a lot of these things were done by word of mouth.

From another internet posting:

During the 1969 Corvette model year production stopped April 9 and resumed June 9. Without doing more research than I want to this late at night I can not tell you if this was a local issue or more widespread, nor can I confirm reasons for the work stoppage at St Louis Corvette.

a_florida_man said:

Tag arrived today...had to dream a little.

MONZORA plate had 4 expired renewals before she made it out of the garage under her own power. I wish you a more speedy build, my friend. 🤘🏻😳

In reply to a_florida_man :

The transmission how ever may have been specific to Corvette, explaining why new ones weren't on the line when Corvette production resumed in June.

also, this was before the just-in-time era, and transmissions may have shipped in larger batches, maybe only arriving monthly vs weekly, etc.

AngryCorvair (Forum Supporter) said:

I've never done a concours restoration, but I went through a phase of great appreciation for casting dates and VIN stamps and ink dots and chalk marks. In my career I've been to a lot of assembly plants and have seen up close and personal all sorts of paint dabs and dots and marks to identify a fastener has been torqued and checked by a supervisor, or a revised part has been introduced mid-year, etc. Nowadays we document *everything* via change control process. Back in the day, a lot of these things were done by word of mouth.

It is interesting, and fun to decipher. Im not looking to do a restoration, and certainly not a concours restoration. But I like to know as much about the history as I can on some of my projects. It won't really change my plans... and I won't generally br chasing any date code correct parts, but at the same time I'll try not to muck it up too bad for the next guy.

AngryCorvair (Forum Supporter) said:

In reply to a_florida_man :

The transmission how ever may have been specific to Corvette, explaining why new ones weren't on the line when Corvette production resumed in June.

also, this was before the just-in-time era, and transmissions may have shipped in larger batches, maybe only arriving monthly vs weekly, etc.

Absolutely, especially so for vehicle specific applications. While at the same time, the engine was a week old when it went into the car. That's from a plant 540 miles away!