Crankshaft end play on the new engine: .005" measured on a dial gauge. I can't find any E30-specific specs, but that seems reasonable on other engines? More BMW frustrations--There's nothing in the Bentley manuals about rebuilds or specs like crankshaft end play. Is there an actual factory service manual available for these things, or is that in German?

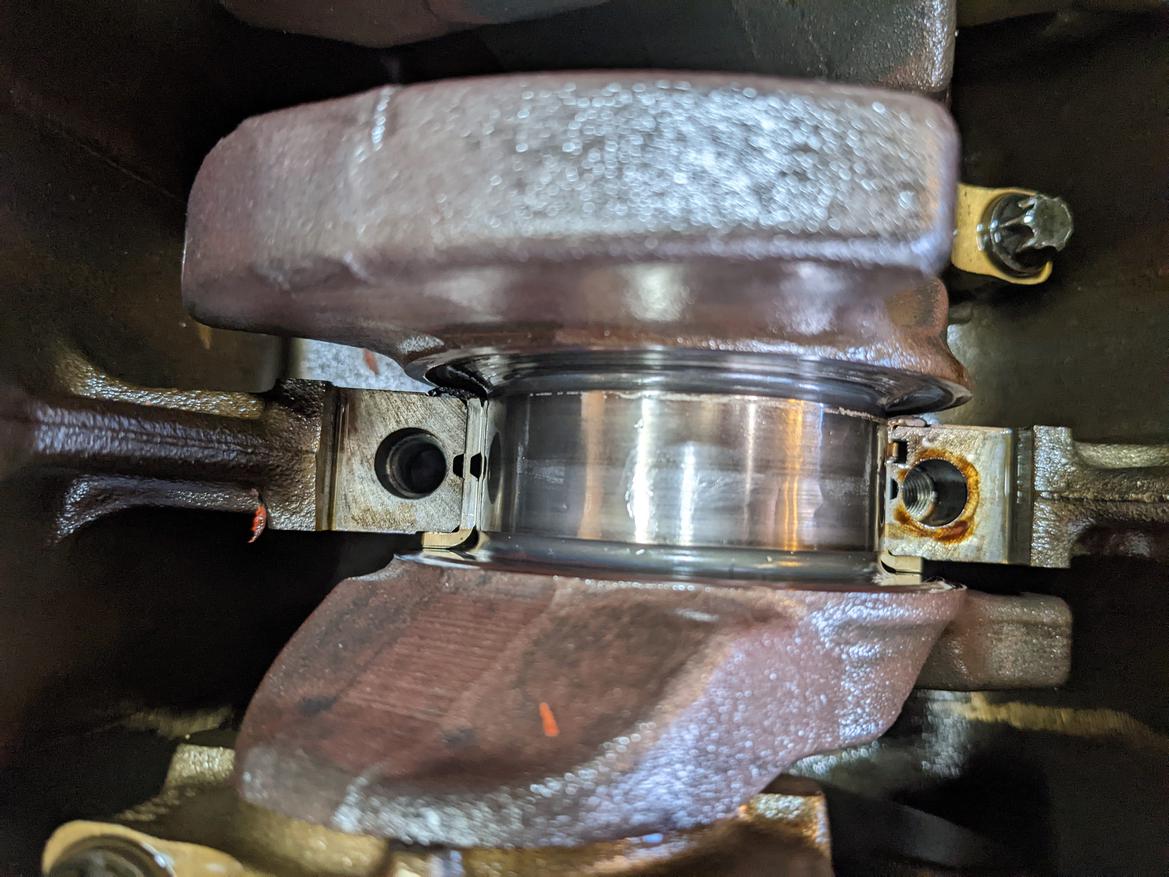

So, yeah, my 1/8"+ end play on the old engine revealed a totally destroyed thrust bearing that in turn trashed the crankshaft.

It's, of course, trashed on the flywheel side. I wonder how much of this can be attributed to running an E36 M3 clutch on an M42? The pedal didn't feel heavy at all, but it's got to have more clamping force than the M42 clutch did?

In any case, the valve failure was just the first thing to go. I don't know how long you can run with no thrust bearing or what the failure mode is, but I'm guessing I would have found out in short order.

I note that new bearing sets come with a 360 degree thrust bearing shell, instead of the 180 degrees BMW saw fit to provide initially. This makes me wonder if it's worth doing this upgrade since I'm going to pull the new engine apart somewhat anyway. If it were simply a matter of buying a bearing set, pulling the crank, putting the bearings in and bolting it back together that would be fine. But, from what I can tell, that's now how this engine stuff works. There's 3 different colors of bearings... you have to put the yellow ones in with some plastigauge, measure the clearance, then order different bearing colors based on the current clearance. This sounds like something I'm sure to screw up? Can't I just replace the existing bearing with one of the same color, or do the crank journals wear? Could I do just the thrust bearing? Even better--could I do just the bottom half of the thrust bearing, which is the half that's missing the thrust facing? Then I wouldn't have to pull the crank and buy new rod bolts and such.