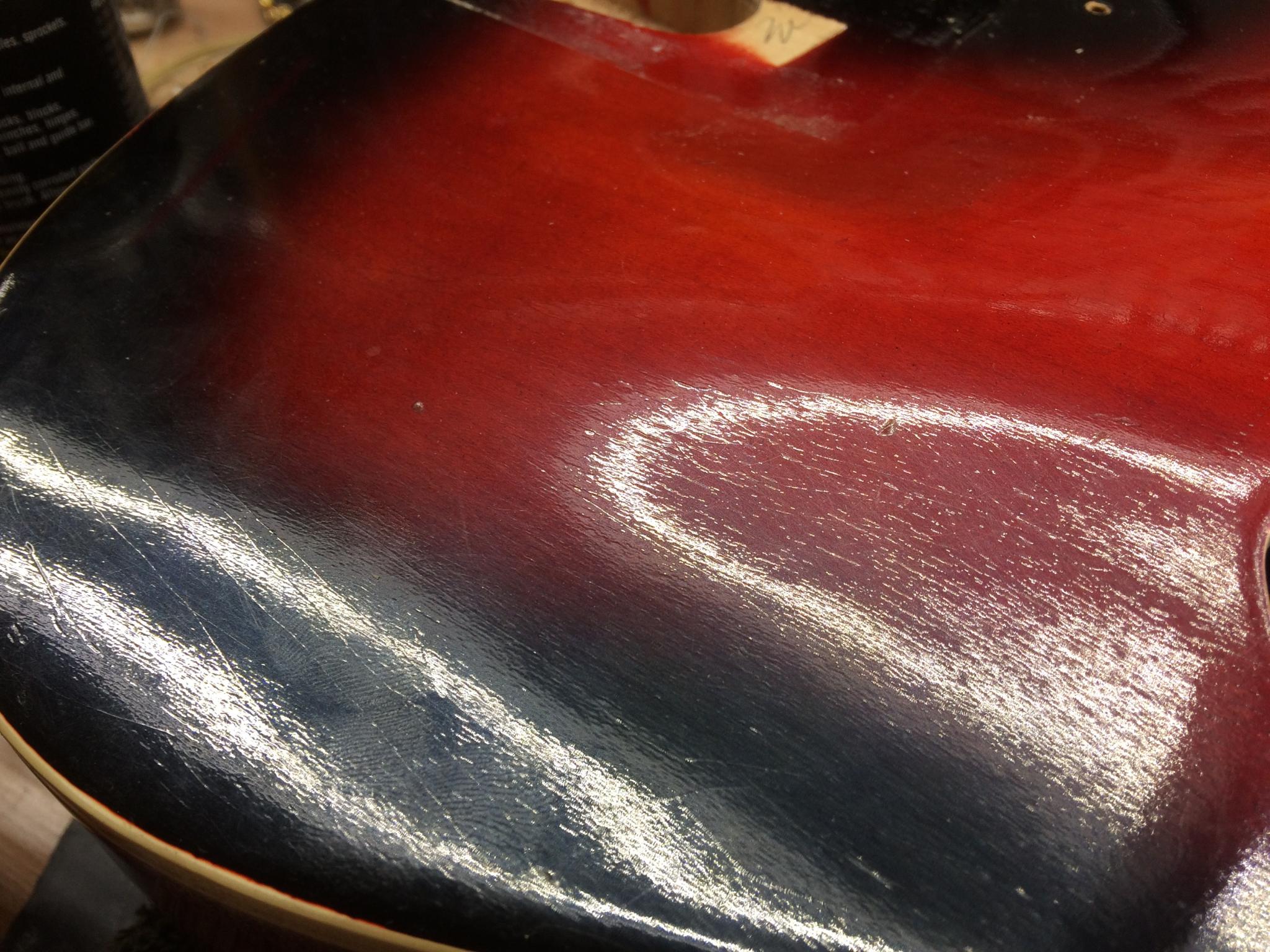

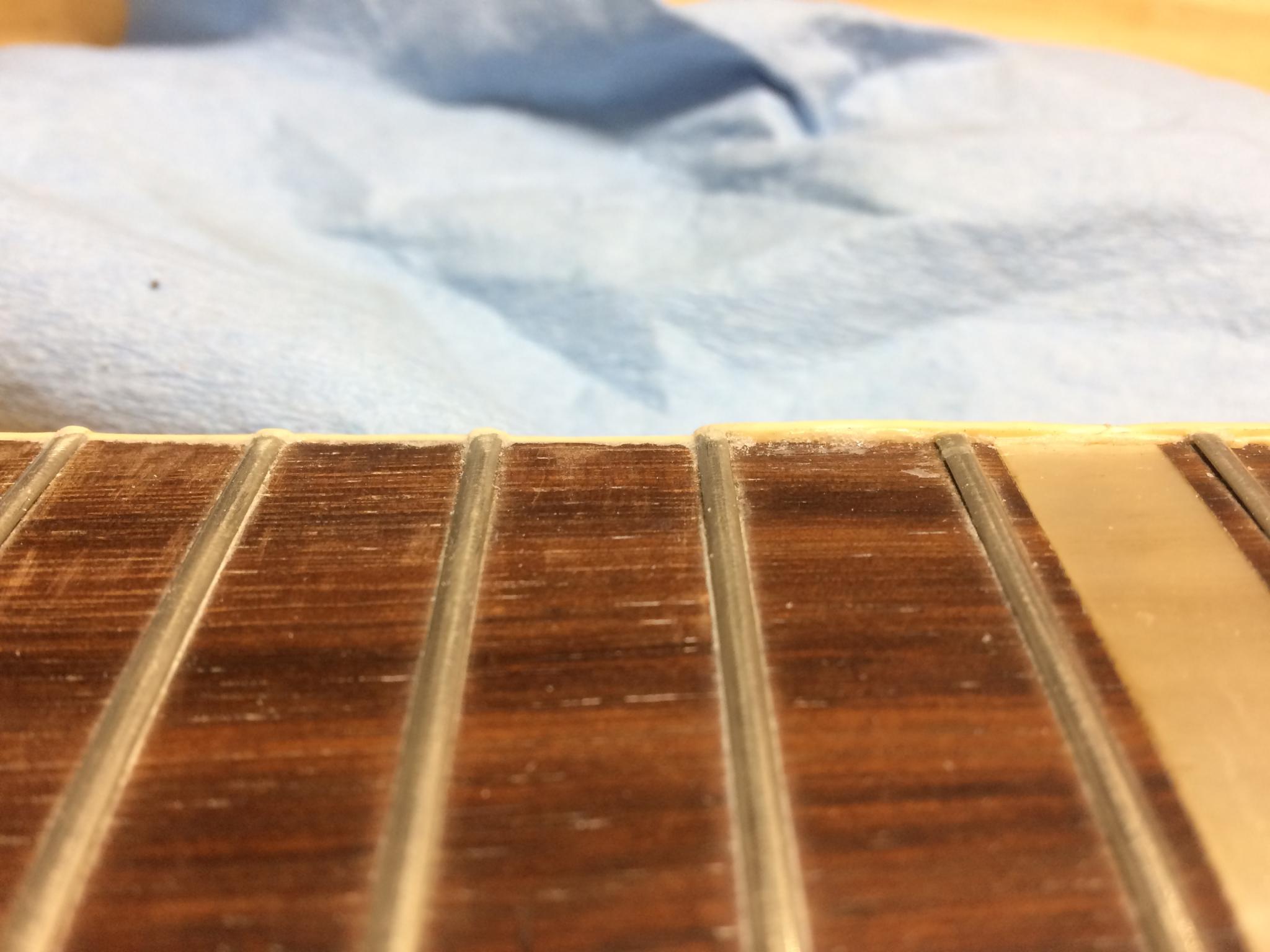

Time to make a pickguard! I spent a bunch of time looking at pictures of these guitars. Looks like they came with several different styles of pickguard over the production run. The holes in the body gave me clues. Here's what I had to start with.

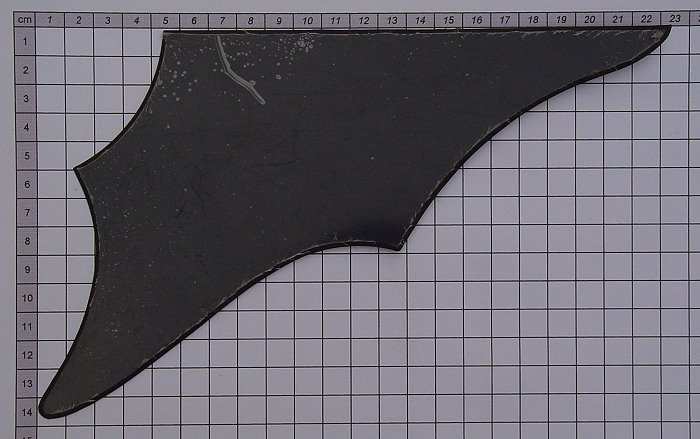

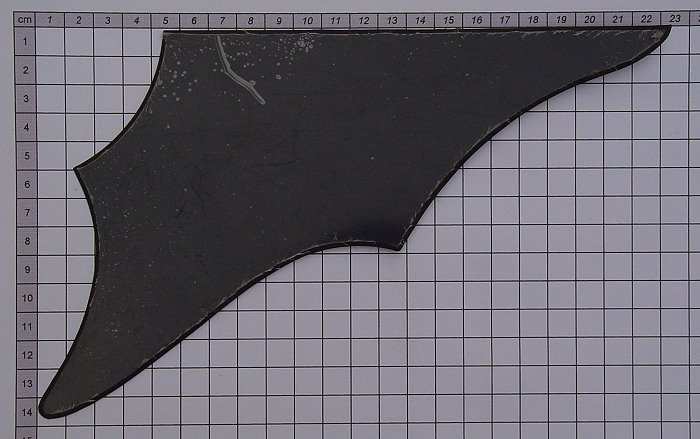

Looks like it was one of these.

This is a European replacement part. It's not quite right, but that dimensioned picture helped get the basic shape and scaling right.

I ordered some tortoiseshell to make the guard - then found another picture of it done in black which looked awesome. So then I had to order some black  This one even has the same...string anchors? I don't know the name. But it's obviously contemporary to time.

This one even has the same...string anchors? I don't know the name. But it's obviously contemporary to time.

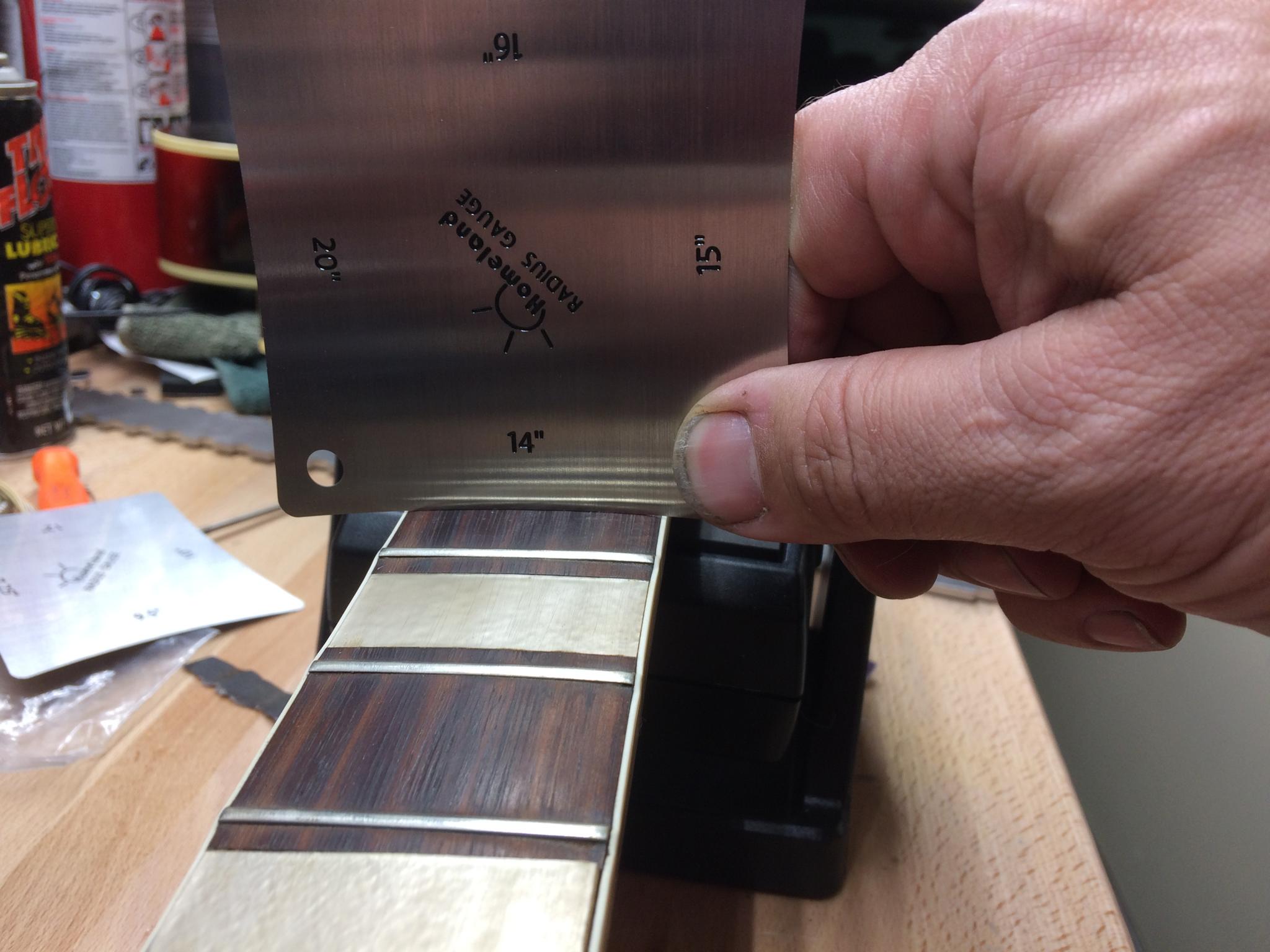

Finally, time to start working. Step one, figure out the shape.

I transferred that to some 1/4" plywood and cut it out.

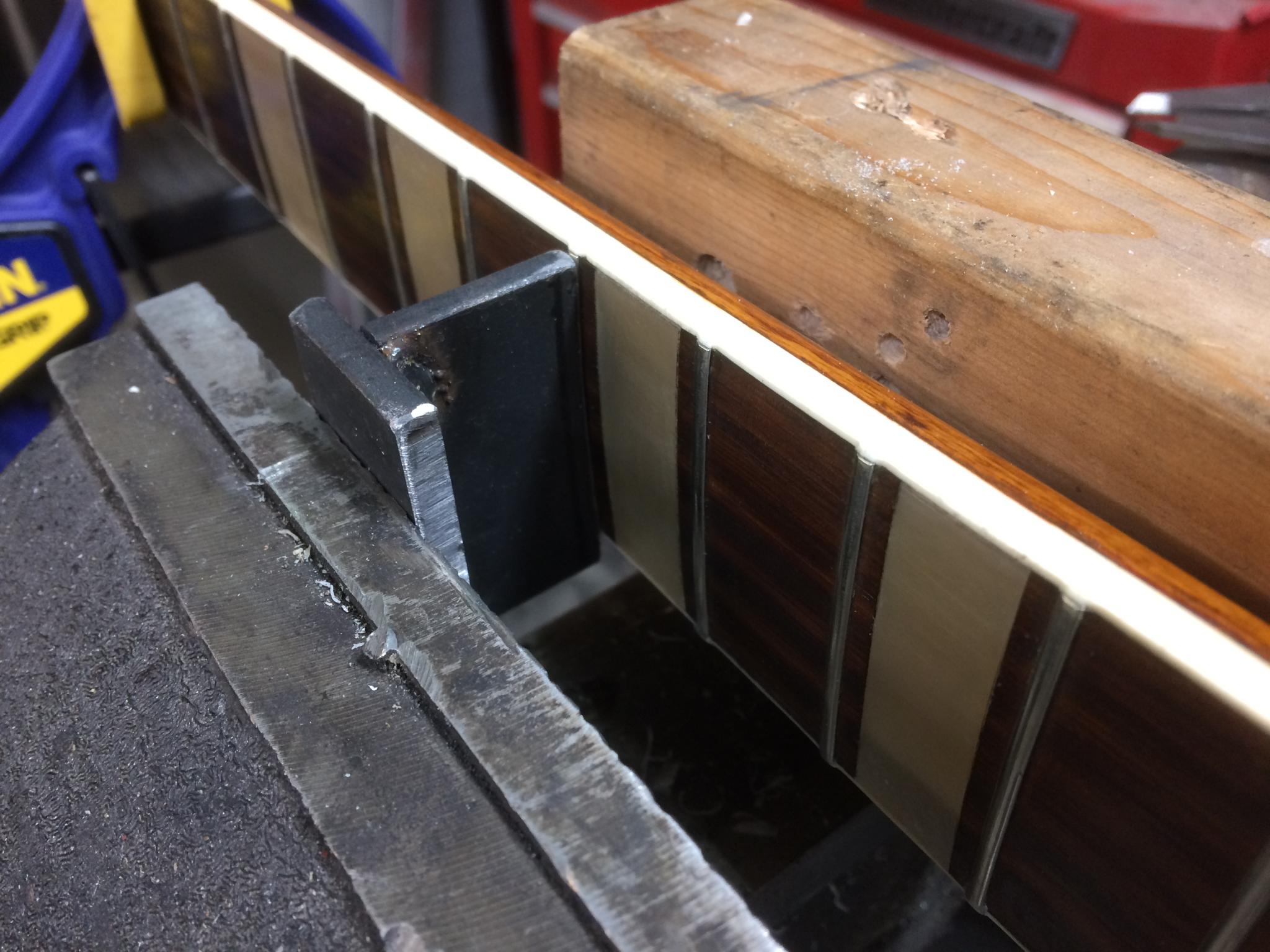

Spent some time fine-tuning the shape. The roller on the top of my belt sander sort of works like a moderately large diameter spindle sander, making it really easy to get good curves. Then I did it again with another template, and finally the third one looked the way I wanted. It's not a perfect copy of the original, but this one had the right flow to it.

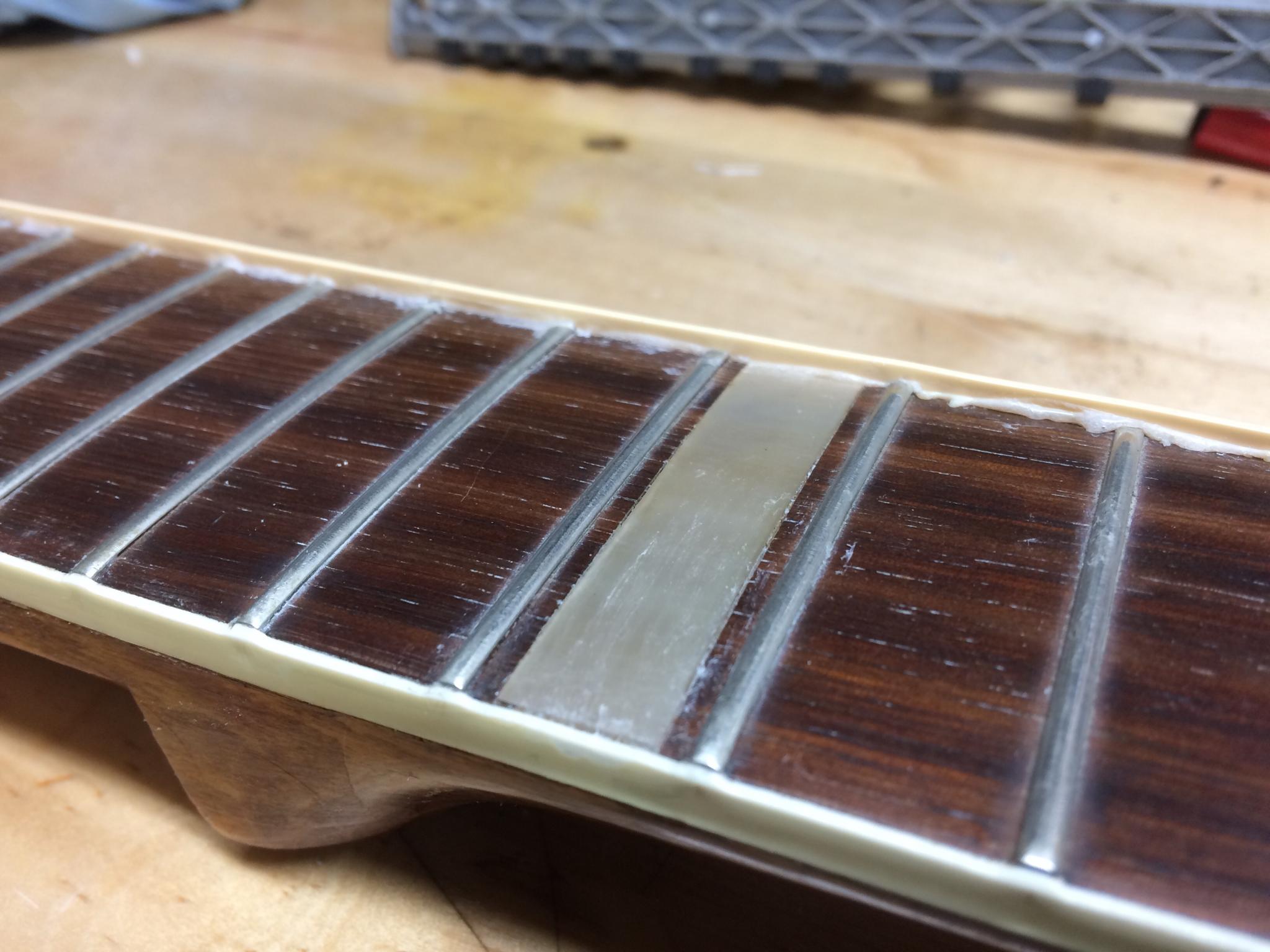

I used double-sided tape to attach the pickguard material to the template. Cut it out with the jigsaw, then used a flush trim bit on the router to make it a perfect copy. This shot is halfway through the flush trim, although you can really only see the rough cut.

Swapped out the bit on the router to a 45 degree and put a chamfer on it. After all the fine work on the template this was remarkably quick and easy, almost like I'd done it before instead of reading web pages. I only got my router about a year ago, I can't believe it took me this long.

It's not perfect at the rounded tip, but a careful touch-up with the sander sorted that out. There's a protective plastic film on top that's peeling on some of the edges, the black surface is perfect. That router bit gave a really nice finish.

Home Depot provided some nice stainless screws and some aluminum spacers to use as standoffs. After a bit of playing around with lengths, it's done. I'm amazed it worked out so well. Since I still have the template, I can easily make another if I need to for some reason. Maybe I'll make a tortoiseshell one just because I can!