Pete. (l33t FS) said:

looks dangerous. In for video!

In reply to AngryCorvair (Forum Supporter) :

So the Plan was to bore through the bulkheads in the rockers and run the coolant tubes through.

Started at the back...

Hmm, the holes don't really line up.

Moving along, going to the front.

No hole to even start with.

Well, crap.

Pete. (l33t FS) said:2018 Impreza.

Note the ball joint pivot is massively lower. This is good if you had to mount your subframe too low so the engine accessories clear the hood.

Will the Neon wheels clear?

Yes. Barely. The tie rod is a very close fit, not sure what may happen at full lock. The rotor does not fit because it is too shallow. But this arrangement would allow me to build a stronger control arm. Yes, I know I spent a month of weekends building these.

It looks like I should be able to get rotors for a base '18 Impreza and machine the outside diameter down to 266mm. Hat diameter is the same. Not sure what these knuckles will do to track width, though: do the hub faces sit in or did Subaru move the caliper out?

Regardless, it's an option. Moving forward...

Similarities: The strut mounts the same and has the same height to the axle centerline.

Strut mount to hub face correlation is the same.

Axle splines and thickness of bearing (depth of axle mounting) are the same.

So, if the wheel is in the same place, the strut and the outer CV are in the same place.

On to the differences...

(and the browser updated while I was posting this and I lost all the pics and text... have to upload them againand write it up again... this makes me mad)

GD is 95mm from hub face to ball joint center.

G...whatever it is, is only 75mm. Clearly Subaru shortened the hat and changed the design to move the ball joint further outboard.

The center to the middle mounting stud is 65mm.

95mm from the ball joint hole to the hub face, the new setup is 140mm from center mounting stud to hub face, so I need to locate that stud 45mm inboard from the ball joint hole in the arms I made.

A little cardboard action gets us here.

And this will be spliced in to some .160" tube, and a Johnny Joint:

Need to locate a 3/4-16 tap to tap the tube deep enough to thread in all the way. I COULD just cut the last half inch of threads off of the joint, but I'd really like to avoid removing thread depth.

2018 Imprezas came with brake rotors no smaller than 276mm. We need 260mm rotors with 2018 depth hats.

Cut 2018 rotor on brake lathe until down to the fins, at which point the lathe got very unhappy. A couple minutes of cutoff disk in the angle grinder...

Bolt up to the 2018 knuckle and 1996 caliper...

Wheel fits beautifully.

Also, these high misalignment axles have a ton of articulation!

Tedious stuff.

But, these chunks of 3/8 thick A36 are cut to size, chamfered, etc.

I had a thought to measure the new axles vs the old ones. They have the same extended length. I checked the axle in the car on the right side. It's fully extended.

Hmm.

I made the arms the same length ball joint to front bushing as the WRX arms... but the original arrangement had the ball joint behind the bushing, this is in line or slightly forward. This makes the ball joints further out... even before figuring that the axle-ball joint-bushing triangle will have a longer hypoteneuse because the ball joint is so much further forward relative to the subframe and transmission.

Need to have some think. I think this will involve some mockup and plunge assessment.

In reply to Patrick :

I had been entertaining a potato fairy for the last month. We went to the RXNC together, which is a writeup I also need to do. She didn't kill me after riding in the RX-7 for 1600 miles, which is nice.

We are holding each other to a promise. She will finish the book she is writing, and Colin will be in Alabama this time next year.

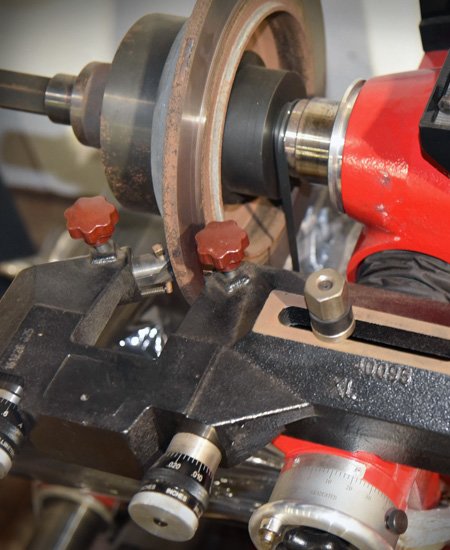

Pete. (l33t FS) said:2018 Imprezas came with brake rotors no smaller than 276mm. We need 260mm rotors with 2018 depth hats.

Cut 2018 rotor on brake lathe until down to the fins, at which point the lathe got very unhappy. A couple minutes of cutoff disk in the angle grinder...

Mounting the angle grinder to the carriage of the lathe is also a favorite for meatball surgery

I used the practically industry standard AMMCO lathe (i was using an old one when I started my career, in 1996!) to cut the rotors down to the vanes. There's no real way to mount any kind of stuff to the lathe's tool post except for the disc fixture or the drum fixture.

BTW - this is a photo op. That rotor is scrap. By the time you machine away the rust it will be too thin. And the process of machining the rust will destroy a set of bits. Just not worth the hassle of even trying.

Pete. (l33t FS) said:In reply to Patrick :

I had been entertaining a potato fairy for the last month. We went to the RXNC together, which is a writeup I also need to do. She didn't kill me after riding in the RX-7 for 1600 miles, which is nice.

We are holding each other to a promise. She will finish the book she is writing, and Colin will be in Alabama this time next year.

You realize now we HAVE to finish our stalled projects. Saying it makes it real

In reply to RBCA :

I'll be an accountabilibuddy for both of you if you guys help me stay on track with the Corolla

Moving right along, I had completely stuffed up the math for the lower control arms and made them an inch or so too short.

It took long enough but a new set of arms finally arrived. So starting over again...

Drill 3/8" hole 147mm from the correct end, then scribe lines out.

Cut and file to be close tolerance fit, add a hefty bevel, pair up everything for welding because I like symmetry:

And here we go.

Much nicer, yes?

I need to do more subframe clearancing on the right side, and touch up the clearancing on the left. The axle gets... tight.

This is one of those catch-22 things. Moving the hubs outward will reduce the angle of the axle and add clearance generally, except that the axle changes diameter RIGHT THERE.

It's sitting a lot further forward than Subaru intended...

Pete. (l33t FS) said:It's sitting a lot further forward than Subaru intended...

Given how absurdly far forward everything is in a subaru, this is an alarming statement.

¯\_(ツ)_/¯ said:Pete. (l33t FS) said:It's sitting a lot further forward than Subaru intended...

Given how absurdly far forward everything is in a subaru, this is an alarming statement.

Err... put another way, the drivetrain is a couple inches further back than the axle centerline.

For perspective, the ball joints are inline with the forward control arm bushings (now, properly called TCA bushings)

What's neat is the drivetrain's center of gravity is quite a bit further back than the CG of the Mini drivetrain that came out. Between that and other factors, this should have close to even weight distribution, and a lower polar moment.

Ah so all the heavy bits are further back, you meant the wheels are further forward. Excellent news.

In reply to ¯\_(ツ)_/¯ :

Even if the engine/trans/subframe weren't slotted back for hood clearance, the Subaru drivetrain has a CG much further back than any transverse layout. In practically all transverse engines the engine and trans are ahead of the axle centerline. Usually the inner CVs, too.

I don't have my notes handy, but the EJ205 weighs about the same as the R53 transmission, and the 4EAT weighs about the same as the Mini 1.6 engine. And the trans sits behind the axle, not ahead of it.

Weird trivia: some WRC cars like the Focus and the 206 had a longitudinal transmission! 90% on the 206, here's a pic of the Focus unit:

Swap THAT baby out in a 20min service ![]()

The Prodrive guys could do a Subaru transmission in five minutes. There's videos on YouTube. There was a documentary series where they followed the Subaru WRC team in, I think, 2006. They were chasing a handling problem all season, and at one rally (Japan?) they were switching Solberg's transmission at every service, going back and forth between different differential setups.

You'll need to log in to post.