I'm a noob. When it comes to metal work, i haven't done it. Ever. I want to learn, so i got some books, got some tools, started making some others, and now it's time to start learning by doing. Hopefully this will start small and grow as i get more tools/skills/bravery, and any feedback will be greatly appreciated from greater and lesser dorks alike.

Of all the videos i watched, one common 'project' seemed to be turning a flat circle into a domed circle, so that's where i'm starting. First, I need a metal circle. I got some aluminum sheet (0.025 i think), drew a 6" circle on it with a compass, and cut it out with some snips:

From what i understand, 'doming' the metal is done by stretching the center, and shrinking the corners. I will start the way a few videos start, and use this:

It's a leather bag full of sand, and the wooden mallet i made in the wood working thread. First, a test hit:

Yep, that looks like a dent. Mission accomplished! The soft aluminum doesn't seem to have affected the hard hickory hammer in any negative way:

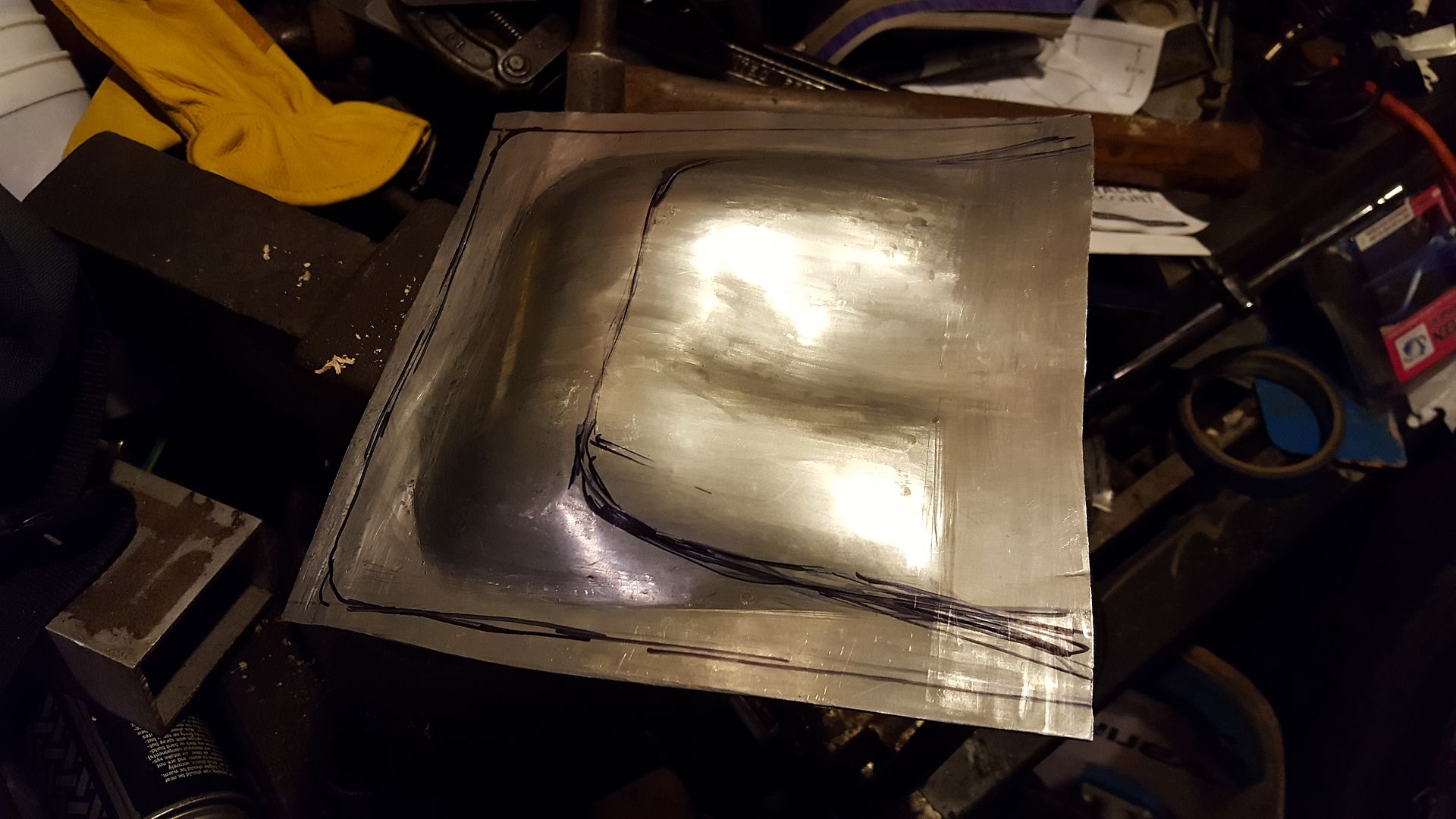

More hammer time later and i have a lumpy, wrinkly piece of metal:

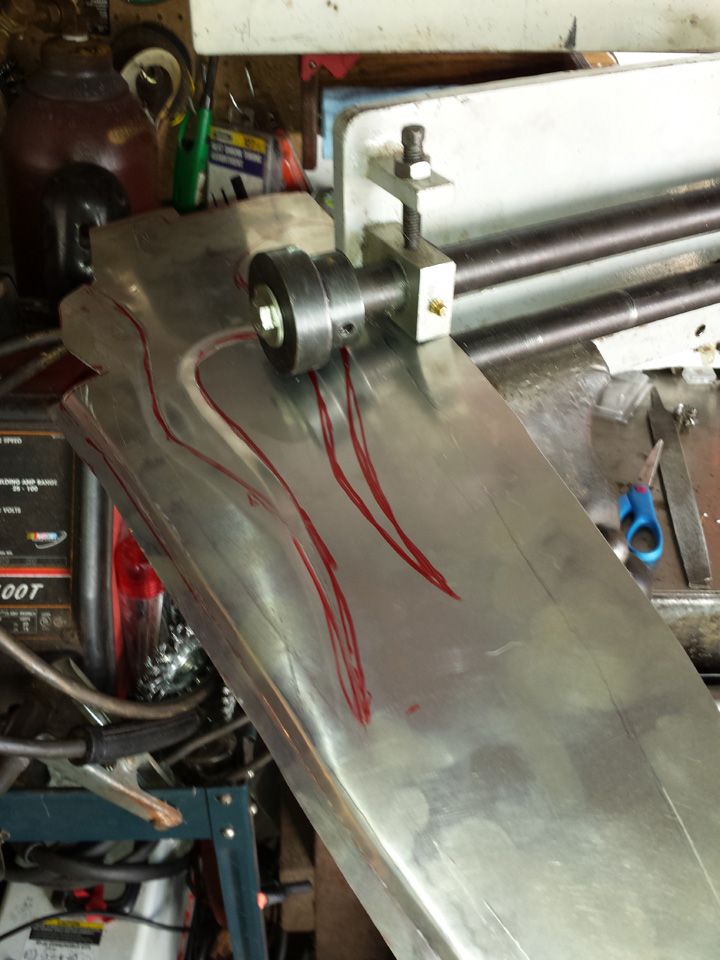

i wasn't hitting it as hard as most of the videos seemed to show, but i'm a bit tentative in my noob-ness. Next, i want to smooth the lumpiness. I've seen this done with hammers and some kind of shaping anvil or dolly. Cue another tool i purchased, and another one i made out of wood:

I think the key technique here is to put the bent up piece over the wood, and tap the high points down using the hammer. The wood will push the low points up as the hammer pushes the high points down, thus evening out the lumpy surface. I think this is called 'hammer off dolly', right? (serious question, i need someone experienced to confirm what i'm saying here)

After some hitting;

Not as lumpy! Success! Now more mallet time:

And smoothing (planishing?):

The edges are getting wrinkly, so i see an opportunity to try tuck shrinking:

I added some more shape using pliers:

and tried hammering it flat in a manner shown in one of the books:

The pliers i used left some marks in the surface, and the folds in the metal are still visible. I don't know if i did any shrinking or if it simply flattened out the shape, but it did end up less wavy at least here:

I used no heat in this since i don't yet have a torch, but i read that aluminum is more easily cold shrunk than steel. Also i read it works more easily, hence my choice to start with an aluminum dish.

I tried another tuck, but this time bending inward:

Again, not sure how much it shrunk, but it seems to have done something perhaps...

Another round of mallet:

more smoothing and tucks:

and it seems to be laying somewhat flat now after some (guess)work:

At this point it was shower/bed time, so i stopped. I usually have such small chunks of time, i'm surprised i got this much done in one go!

My wooden tools also stood up without a problem. They got some black stuff on them (maybe oil from the metal surface?) and the anvil got some light scratches from the edges of the metal, but there are NO dents in the hickory at all. As for the grease and scratches, i can think of no better wood finish than the patina of actual use.

I learned some things:

1: This is really fun. Hammering stuff is great.

2: This is really loud. Hammering stuff requires hearing protection (which i used after about the 2nd hammer hit)

3: I could feel the effects of work hardening. attempting to tuck a section i already tucked required noticeably more force.

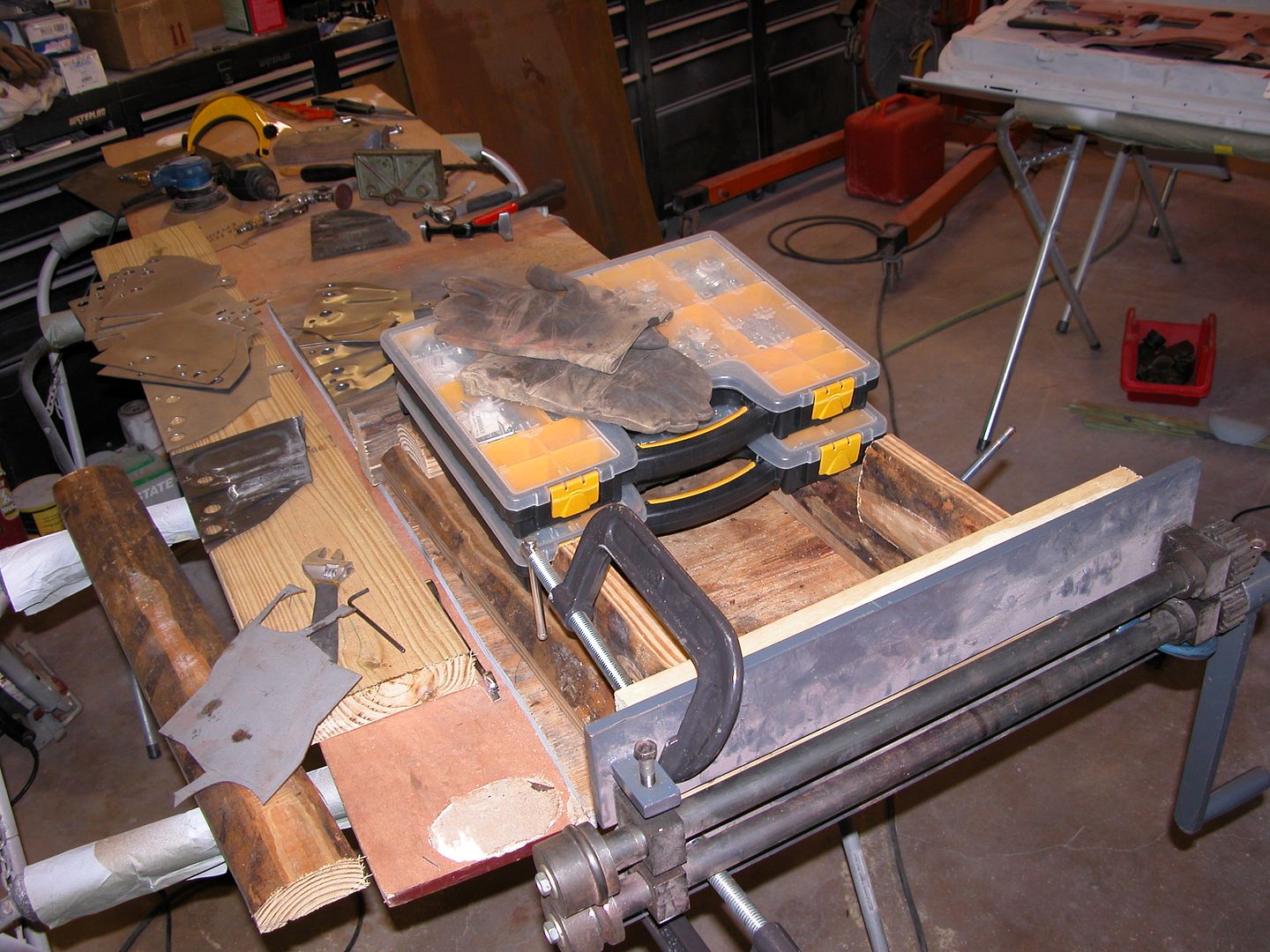

4: Cold shrinking is hard. One book i read showed the use of clamps or other means to hold the aluminum in place. That would help, i think.

5: I tried a hammer-on-dolly technique i saw for stretching metal, but hickory isn't hard enough. The examples i saw used a metal hammer like mine hitting metal on a metal surface. Wood is to soft for effective stretching, but i guess i'll never accidentally stretch the metal using wood in this way, so i have that going for me.

6: For hammering inside, i need a hammer with a little more crown.

7: The irregular curve in the wood anvil is actually helpful.

8: The pointier end of the wood mallet is too pointy. It just puts in little dings.

9: My shallow bowl is still lumpy as e36m3

I also have some questions for the experienced:

1: Would a slapping spoon help smooth out the bumps more? I've heard they smooth high spots more effectively but i didn't try. I do have one, though.

2: How much crown could i get out of this without annealing?

3: Is tuck shrinking worth doing a lot, or should i just save up for a stretcher/shrinker? I still want to learn to actually do it the old school way, though. Keep in mind my end-goal here is work with steel.

4: what is a good progression of simple tasks to learn the basics? The books seem to progress right into english wheel/power hammer stuff, but i have neither of those tools at the moment. Maybe i'll look into an english wheel at some point, but not in the near future (or even medium-term future).

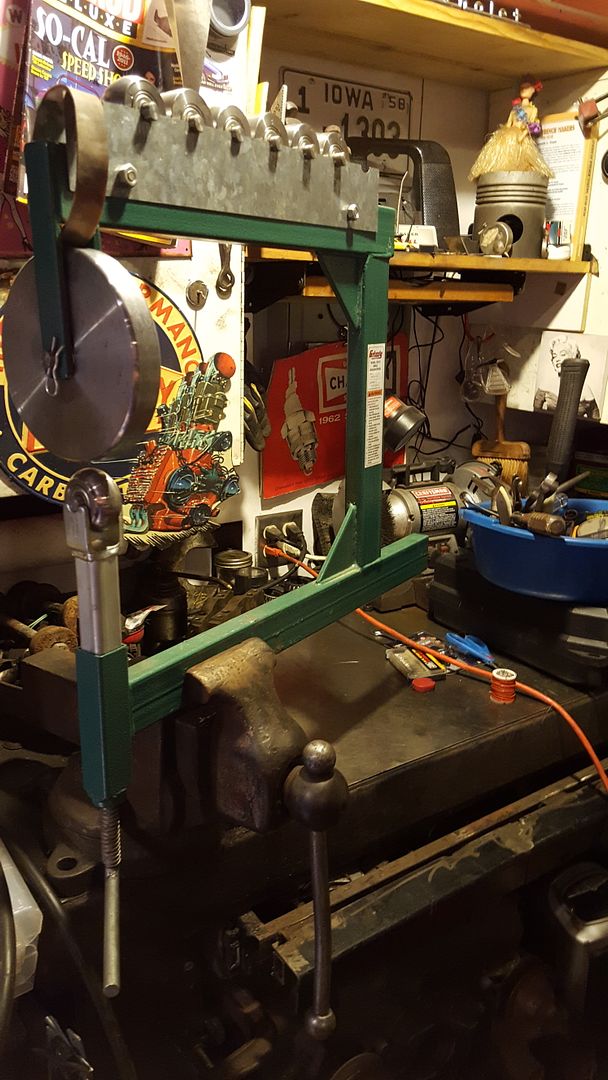

Since i mentioned tools, i'm working on a couple more wood ones, but i'm also looking at the stretcher/shrinker, and maybe a bead roller because of the versatility with all the dies available. There are also some tools you guys suggested in this thread that are on my list, but i'm just trying to put them in the order i'll need them. Of course that depends on what i plan to do next. Any suggestions?

[/URL]

[/URL]