Thise look almost organic from that angle. Beautiful.

Tonights episode 4-2-1 .....er maybe later this week.....where AngryC goes full pipeweldporn (PWP)....in hopes of actually being present at the GWBW2021 challenge this October.

In reply to Dusterbd13-michael :

Thanks man, I'm pretty happy with it so far.

In reply to vwcorvette :

It is the way of the challenger.

In reply to 759NRNG :

later this week, for sure. instead of tacking things together, I decided to do some math on collector angles and make a practice piece. For practice, you know? I learned, or I should say I was reminded, that I need a Bridgeport.

Nice find on the extra set of Mag wheels. Don't go trading away those 18s this time. If you have no use for them I'll gladly take them off your hands.

In reply to RacetruckRon :

Fri 8:00 PM: Dude posted ad.

Fri 11:30 PM: I replied with full price offer.

Sat 8:00 AM: Dude says OK, Sun 12PM meet up.

Sat 8:01 AM: I confirm.

Sat 9:00 AM: I schedule Sunday brunch date with wife at a nice spot not far from meeting place (for metro Detroiters, can confirm Marine City Fish Co has outstanding food at reasonable prices!)

Sun 10:30 AM: I text dude I'm on my way.

Sun 10:35 AM: Dude replies "Great! I had to mark the ad Pending because I got about 100 messages about them!"

Sun 10:36 AM: I breathe sigh of relief that he didn't sell them to someone else.

Sun 12:00 PM: I had all $20s and Dude didn't have change. I said "OK, $260 then." He said "$240." Cool. He told me he didn't know anything about Corvettes, and asked me if they were Magnesium. Another prospective buyer asked him and he didn't know. I told him yes, and that Corvette people like them because they're lighter. He said "Huh, that's cool."

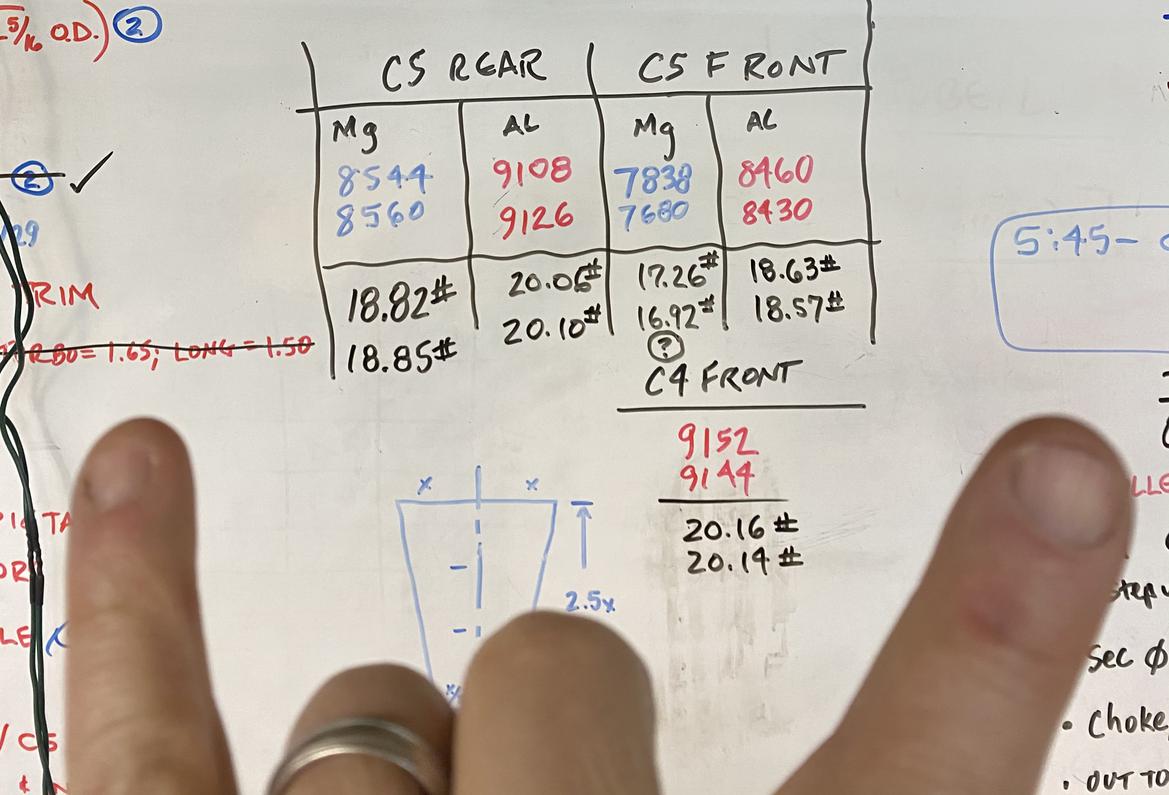

Honestly, I like the thin spoke aluminums better, but I respect the rarity and the weight save. I'm going to weigh them tonight, will post comparison of C4 Sawblade Front, C5 Aluminum Front and Rear, and C5 Magnesium Front and Rear.

Wheel weights by type and size:

I was surprised to see the difference in the two C5 Mg Fronts. I have a bunch more of them to weigh, and I'm curious to see the variation in a larger population. I weighed each of the above twice, so I trust the numbers.

I also played around with making a merge collector for my primary tubes. First I did a little math:

Then I marked the tubes and ran them through the band saw:

This is just a practice piece to experiment with the band saw. I am encouraged.

In reply to AngryCorvair (Forum Supporter) :

Yup. Something weird is going on with the new forum software. Maybe rehost with imgur till it gets sorted?

I just figured there was some reality distortion field affecting your thread. Seemed as likely a reason as anything else.

nothing here boss ....just your phat finnerz holding perfectly shaped metal shapes

to be joined together with prodigious amounts of heat/wire.....late

Distorted for me. This is the first photos that are distorted. A lot of others that people complain about look fine for me![]()

TurnerX19 said:Distorted for me. This is the first photos that are distorted. A lot of others that people complain about look fine for me

I posted from and viewed on my iPhone 11, and when I saw they were distorted I edited my post, deleted the pix, then added the pix and played around with height and width until they looked about right in the preview window. As they are now, viewing on my iPhone 11, only the end view of the collector looks too wide. The others look OK to me. Weird.

In reply to AngryCorvair (Forum Supporter) :

Recent update to the board software is not sizing pics correctly yet.

Super cool thing I just learned: I clicked the edit button under my post with the wonky pix, did not make any edits, clicked the Post button, and the pix updated to proper scaling.

In reply to AngryCorvair (Forum Supporter) :

I think there's something with the mobile version of the forum that does it. I uploaded pics on my phone and they looked weird, when I uploaded pics from my computer everything was fine

I need a Bridgeport. Cutting the tubes to make this one piece took way too long. And this is just a practice piece.

Lots of awesome little details. I love what you're doing with the exhaust. If I want to see this in person at the Challenge, what year should I be planning for now?

AAZCD (Forum Supporter) said:If I want to see this in person at the Challenge, what year should I be planning for now?

I almost said 2022 in my previous post. I'm working 10+ hours every day, and my boss chose me to represent our department on-site for the next 2 weeks at the vehicle assembly plant 3.5 hours from home. So between this weekend and the beginning of April, nothing's gonna happen here. :-(

Now with less painters tape and more tacks:

Spent more than a couple minutes getting the gaps super tight. As Carl Heideman says, "You can't weld air."

I revised the routings so the primary pairs will be stacked, purely for appearance. I'm so vain.

And of course I had to bolt it up and stare at it for a while.

in other news, I tilted a pipe too far while cleaning it on the wire wheel, and the wheel snagged it and smashed my finger into the grinder housing so hard I almost vomited from the pain. Fingertip looks pretty weird, and I'm definitely gonna lose the nail.

AngryCorvair (Forum Supporter) said:in other news, I tilted a pipe too far while cleaning it on the wire wheel, and the wheel snagged it and smashed my finger into the grinder housing so hard I almost vomited from the pain. Fingertip looks pretty weird, and I'm definitely gonna lose the nail.

Oh berk. Haven't had it almost cause me to vomit, but I did have such a shutdown from a hammer blow that missed the cold chisel that I forgot how to breathe.

It was probably cold still too. Berk all of that.

Is this a thing now? Finger damage from putting Chevy v8s where they don't belong?

Headers look good, and maybe by the time you finish this, I'll finish the Funderbird, and we can make fun of each other's welds in person in FL. Carry on.

In reply to wheels777 :

Rather than get used to it, I spent a couple hours trueing up the saw, then used one of the practice pieces to make a jig. Because engineer. I had a new helper today, a young engineer from work made the mistake of telling me he wished he had a shop to work in and a project to work on. ![]()

I set him on designing the jig while I cleaned up the welding table, then we reviewed his design. With a couple "experienced" suggestions, it turned out great.

and here's the resultant test cut:

It's really straight. Better than I could ever do by hand. You gotta look close to see any gap. I'm really stoked about this.

It's really straight. Better than I could ever do by hand. You gotta look close to see any gap. I'm really stoked about this.

In reply to AngryCorvair (Forum Supporter) :

Typical engineer overbuilding. I would have made that with a couple of scrap pieces of 2x4. I see shorts on your apprentice. Make him wear that for the look or getting warm enough to get back on it?

You'll need to log in to post.