JoeyM

SuperDork

7/12/11 8:13 p.m.

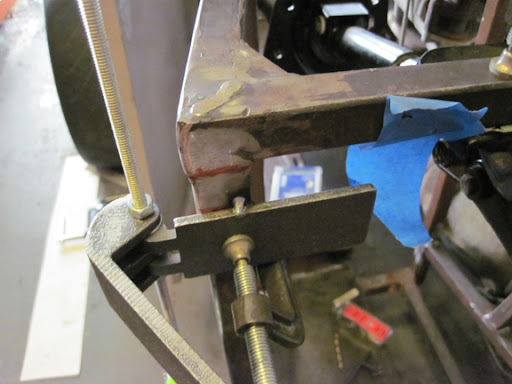

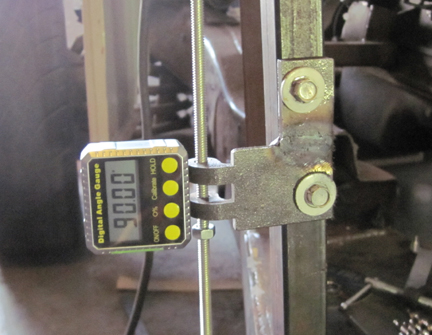

OK, enough nonsense with van hinges that can't have the pins pulled out. Now I'm test fitting street rod hinges. I pulled the center pins and put a pair of hinges on a 1/4 rod. (Thanks, Transmaro.)

After everything was where I thought it should be, I tacked them into place so they would not move when I drilled them to hold bolts

After everything was where I thought it should be, I tacked them into place so they would not move when I drilled them to hold bolts

JoeyM

SuperDork

7/23/11 8:06 p.m.

A friend just gave me the metal cover off a broken A/C air handler. It is nice thick steel, and should work nicely for door skins. I'll need to get rid of some right angles in the metal, but that's probably not a major issue

JoeyM

SuperDork

7/31/11 1:18 p.m.

The upper hinge is modified. I'm not putting the second hole in until the lower hinge is in place

JoeyM

SuperDork

8/6/11 9:08 p.m.

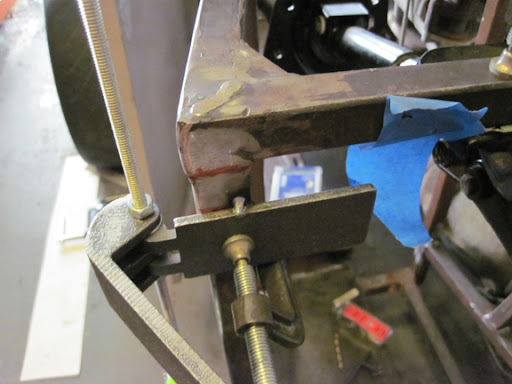

OK, both hinges for the driver's door are modified and bolted into place on the cowl. I still need to modify the other side and bolt them into place on the door. (...which will require door modification, too.)

The cowl is only made of one inch tube (i.e. standard locost construction) and the door matches it, which makes the door VERY thin. As a result of this, the stock speedway hinge extends far into the car

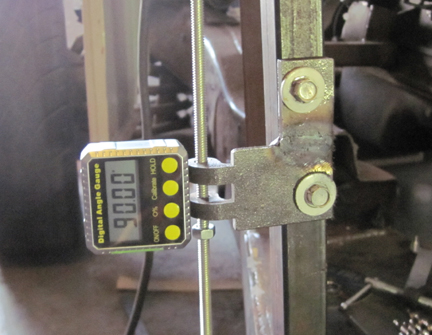

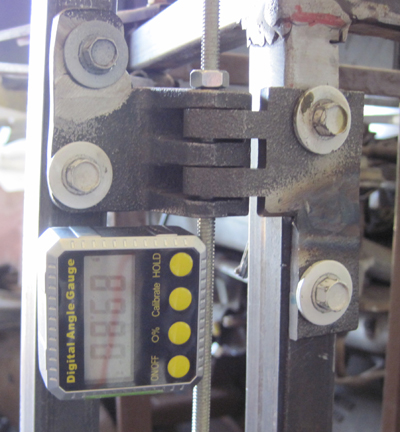

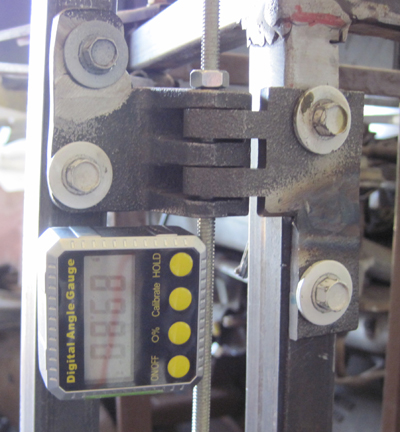

I cut the extra off and welded a bit of it back on at a 90 degree angle so that I could fit two bolts into it

I cut the extra off and welded a bit of it back on at a 90 degree angle so that I could fit two bolts into it

Naturally, I beveled the edges of the two pieces to get better weld penetration

When I drilled the first hole in the first hinge (the upper one) the bolt would not hold; i.e. the hole was a little oversized. I didn't want to move the hinge location, and didn't want to weld it up and re-drill it. My solution was to cut the tube open and weld nuts inside the tube so the bolts had something to hold them.

nice keep the updates coming!

JoeyM

SuperDork

8/7/11 3:20 p.m.

Both hinges for the driver's door are mounted to both the cowl and to a tube that will become part of the door frame.

The two 90 degree turns point in opposite directions so that I can space the bolt holes in a way that keeps the bolt heads from colliding when the hinge is closed.

The two 90 degree turns point in opposite directions so that I can space the bolt holes in a way that keeps the bolt heads from colliding when the hinge is closed.

JoeyM

SuperDork

8/10/11 9:47 p.m.

I cut an opening in the tube so I could weld nuts to the inside so as to better support the door hinges. Tomorrow I will cut an opening for the lower hinge nuts, weld the nuts into place and weld the tube closed again. After that I can make that tube part of the door frame...

JoeyM

SuperDork

8/13/11 8:47 p.m.

The driver's door frame is mounted to the hinges, and it moves freely. In order to do that, weld nuts to the inside of the vertical tube at the front of the door frame and then weld the tube shut again. (Photos later)

Next up, fabricating the sheet metal skin that covers the outer surface of the door. After that, mounting the door latch.

JoeyM

SuperDork

8/14/11 6:48 p.m.

From yesterday.

Today, I did the same thing for the cowl side of the lower hinge. (I actually had to cut the tube open twice because the upper nut came loose.) I also cut the cover of an air handler in half and hammered it out flat. There's plenty of metal to make the door skins out of it:

Wally

SuperDork

8/14/11 8:10 p.m.

I love seeing the updates on this car, I wish I had half you vision and talent.

Bud Light's Real Men of Genius said:

Bud Light Presents: Real Men of Genius

(real men of genius)

Today we salute you, Mr. 1932 Datsun Replica builder.

(1932 Datsun Replica builder)

Many people have been satisfied restoring a rusted out car and getting it back on the road, but not you. You tirelessly comb threw piles of old appliances collecting parts to build a car most of us have never even seen, or known existed. A Maytag out in front of the Johnson's place? Not for long. Daddy needs a hood and firewall.

Soon you'll have a unique car and when people ask "What is it?" You can say a Water heater, two air conditioners a gas stove, and some other bits.

So crack open an ice-cold Bud Light, Mr Datsun Builder, and save the can. I'm sure you'll find a use for it later.

JoeyM

SuperDork

8/15/11 6:40 a.m.

Wally wrote:

I love seeing the updates on this car, I wish I had half you vision and talent.

So crack open an ice-cold Bud Light, Mr Datsun Builder, and save the can. I'm sure you'll find a use for it later.

Thanks, Wally. I appreciate the encouragement.

Here's what rat rod crowd do with their beer cans.

JoeyM

SuperDork

8/27/11 4:21 p.m.

His morning Gertrude and I went to check the water level in the river...it was higher than it had been for months, so I decided to spend the afternoon kayaking. Instead, I made a poster board pattern for the door skin. I then placed the posterboard pattern on the flattened out air handler cover, traced the pattern, and cut out an oversize piece of sheet metal.

pictures later.

JoeyM

SuperDork

9/5/11 11:52 a.m.

Do you guys know what is better than trimming a door skin? Doing it while a cheesey scifi movie is playing in the garage :-D (5th element)

Luke

SuperDork

9/5/11 12:06 p.m.

That all sounds like a rather nice way to spend an afternoon. Cool project, cool dog, '90s sci fi film that stands up really well today  .

.

Are you still making the Challenge with this car, (albeit not completed)?

JoeyM

SuperDork

9/5/11 3:24 p.m.

Even better...Dad came over to help roll the bead along the top of the door. (He has helped me with the beads on the grill inserts ,hood, rear quarter panels, back, and now the door...the onlybody panel I rolled without his help is the cowl.

it feels good to look at the beads and think, "I did that with my dad!"

JoeyM

SuperDork

9/5/11 3:40 p.m.

Luke wrote:

That all sounds like a rather nice way to spend an afternoon. Cool project, cool dog, '90s sci fi film that stands up really well today  .

Are you still making the Challenge with this car, (albeit not completed)?

.

Are you still making the Challenge with this car, (albeit not completed)?

I am nowhere near having it running in time for this year's challenge. Gainesville is only a couple hours away, though, so I plan on coming up to meet everybody and see the challenge cars....I am toying with the idea of borrowing a trailer and hauling it up there anyway so people can see what I have built so far

JoeyM

SuperDork

9/5/11 6:24 p.m.

bead rolled in the skin, the top bent over to hold it in place

bent with wooden hammers because the door is too wide to fit in my sheet metal break.

slits cut to let the door skin still curve when I put the 90 degree bend in

JoeyM

SuperDork

10/21/11 6:24 p.m.

Javelin

SuperDork

10/21/11 6:37 p.m.

Nice! I was just thinking about your project...

JoeyM

SuperDork

10/21/11 10:37 p.m.

Javelin wrote:

Nice! I was just thinking about your project...

Thanks.....I still need to add two tabs and some captive nuts before I can weld it into place. With luck, I may have the dood latch functioning within the weeknd. Then I can start thinking about the lower edge of the door skin...

4g63t: I appreciate the enthusiasm, but the GRM forum has people who are much better fabricators than me. Did you see the suspension on Bryce's $2011 Honda?

4g63t

HalfDork

10/22/11 10:39 a.m.

JoeyM, the talent in this forum never ceases to amaze me. If somebody put a washing machine in the nines and spent $100K I could point out ten people around here who could do it for the price of a used hand grenade, AND it'd look like it could qualify on the front row at Indy.

)

After all I am the guy who made his own thread repair insert for a highly critical use because a keensert was just too expensive [....] Yes that is for a rocker stud. Yes I am dumb, Yes it worked perfectly and cost me about 15 cents to make.

![]() Color me impressed

Color me impressed

After everything was where I thought it should be, I tacked them into place so they would not move when I drilled them to hold bolts

After everything was where I thought it should be, I tacked them into place so they would not move when I drilled them to hold bolts

I cut the extra off and welded a bit of it back on at a 90 degree angle so that I could fit two bolts into it

I cut the extra off and welded a bit of it back on at a 90 degree angle so that I could fit two bolts into it

The two 90 degree turns point in opposite directions so that I can space the bolt holes in a way that keeps the bolt heads from colliding when the hinge is closed.

The two 90 degree turns point in opposite directions so that I can space the bolt holes in a way that keeps the bolt heads from colliding when the hinge is closed.