No, because I'm sitting here on the computer recovering from the flu now instead of out there working in the 11 deg C/50 deg F rain

It would be really nice to get the floor tacked into place by the end of October, but that probably won't happen. If this was only project maybe, but my Sentra needs lots of attention too, with the same deadline.

Here's my rough mental timeline of things to come:

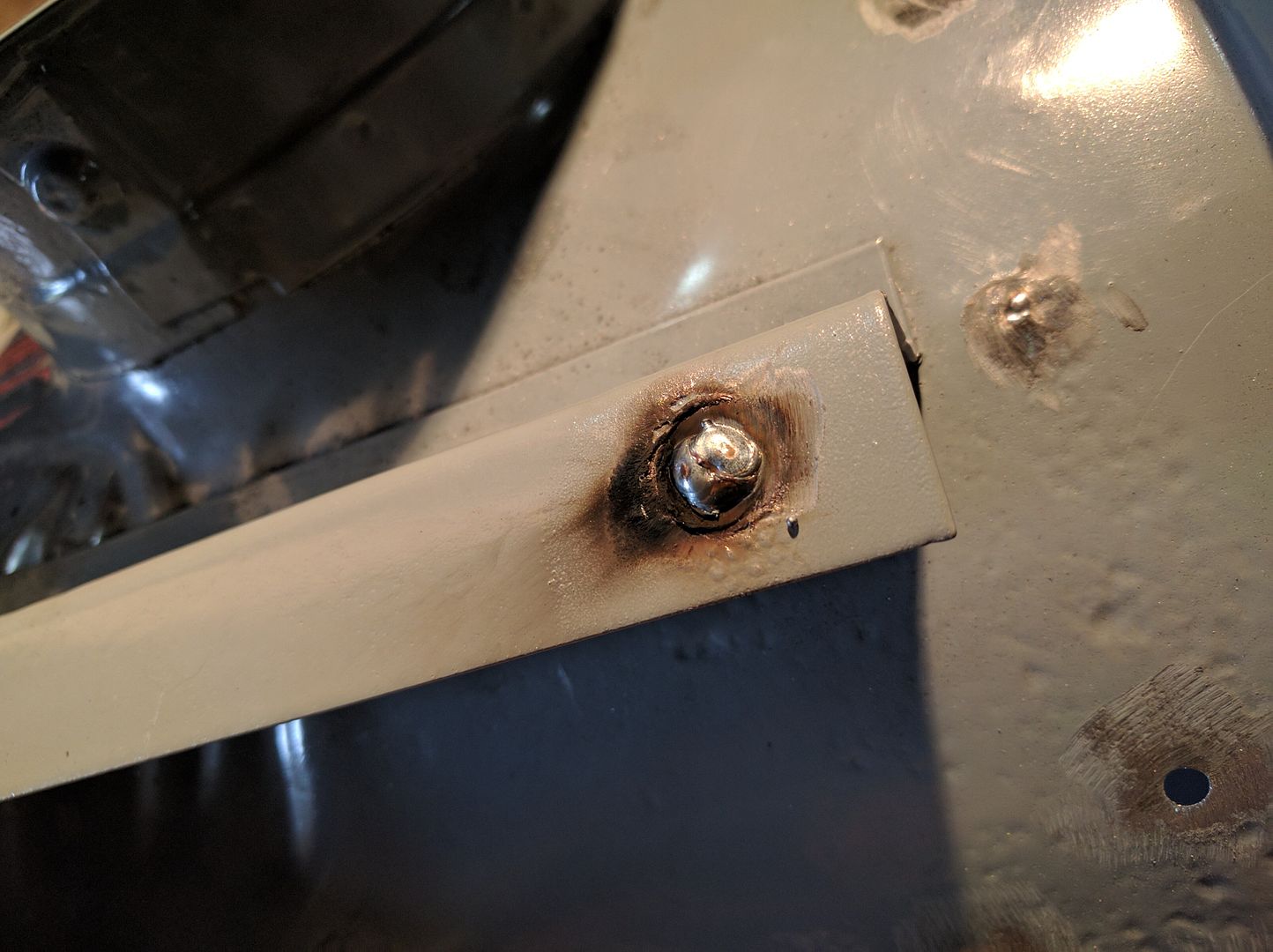

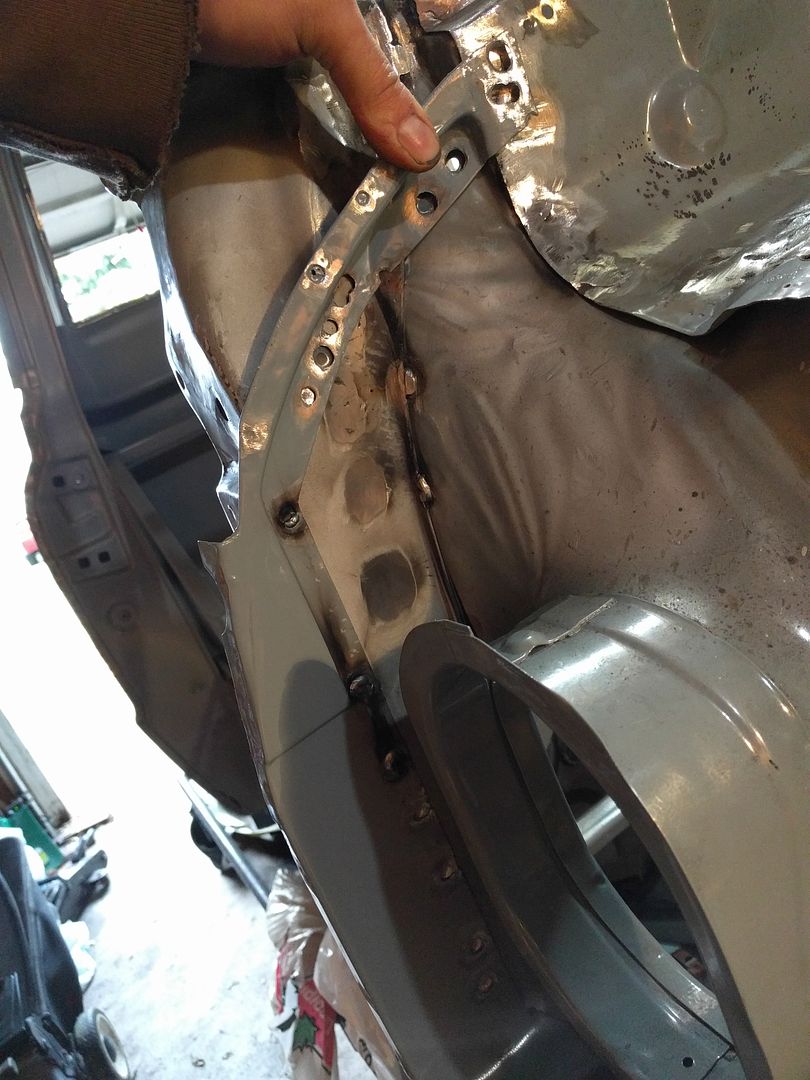

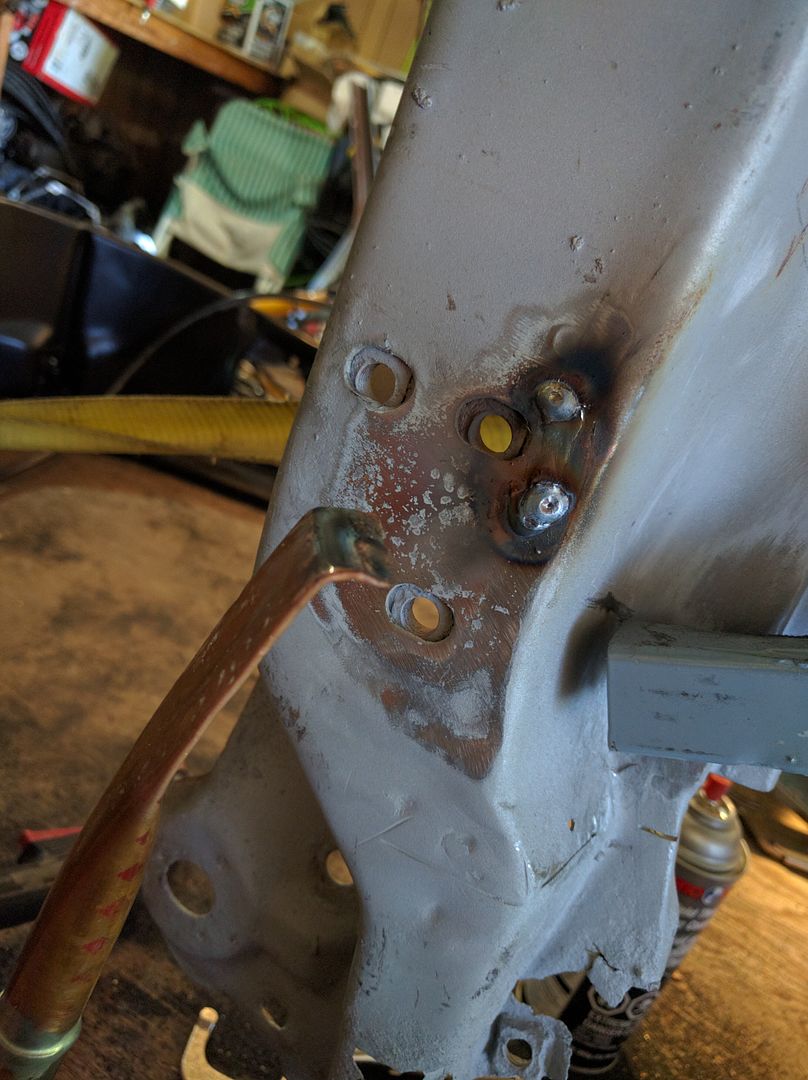

-patch up inner cowl, weld into place

-weld outer cowl side supports into place

-weld outer cowl on? or weld firewall on.

-weld firewall on? or outer cowl. Not sure which order is better

-mount floor to chassis, lower cab onto floor.

-measure things 1000 times, because can't hang doors with the way I braced the cab. Maybe put the front clip back on to check

-tack floor into place

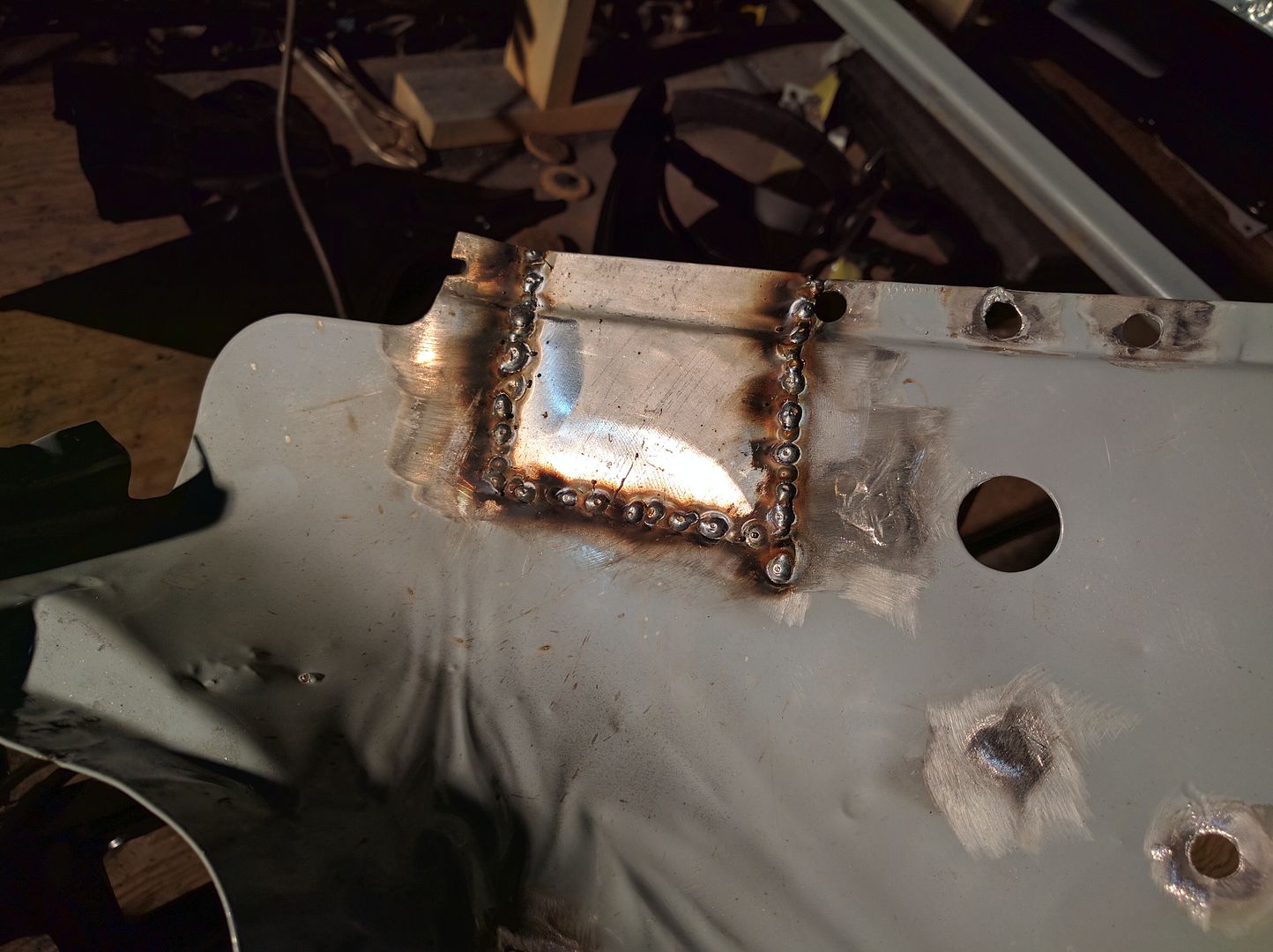

-weld in the floor extension pieces that run up the bottom of the firewall

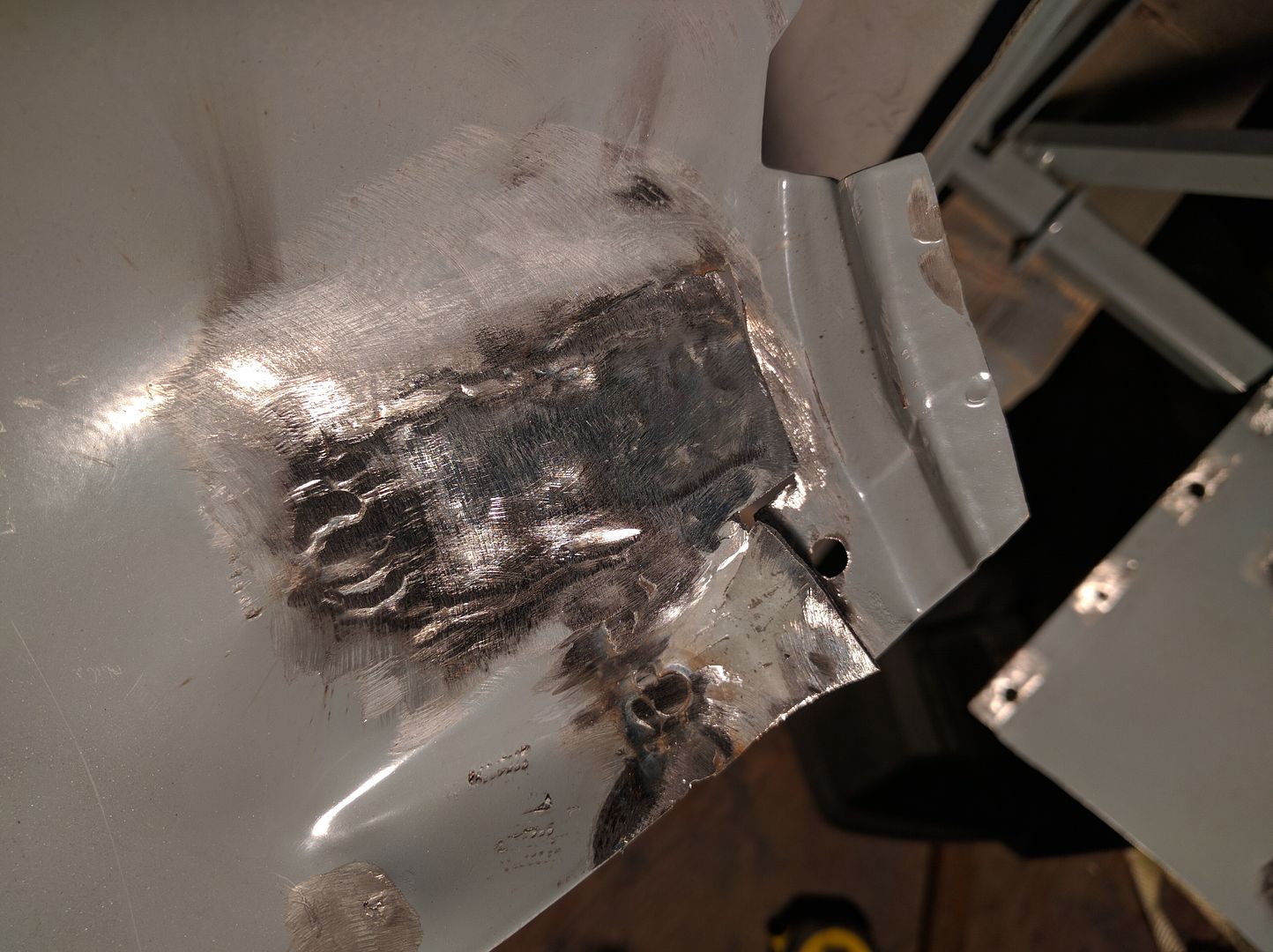

-weld seem between floor and firewall. There will be fitment issues here from the two aftermarket pieces, guaranteed

-remove cab bracing

-hang doors, cross fingers

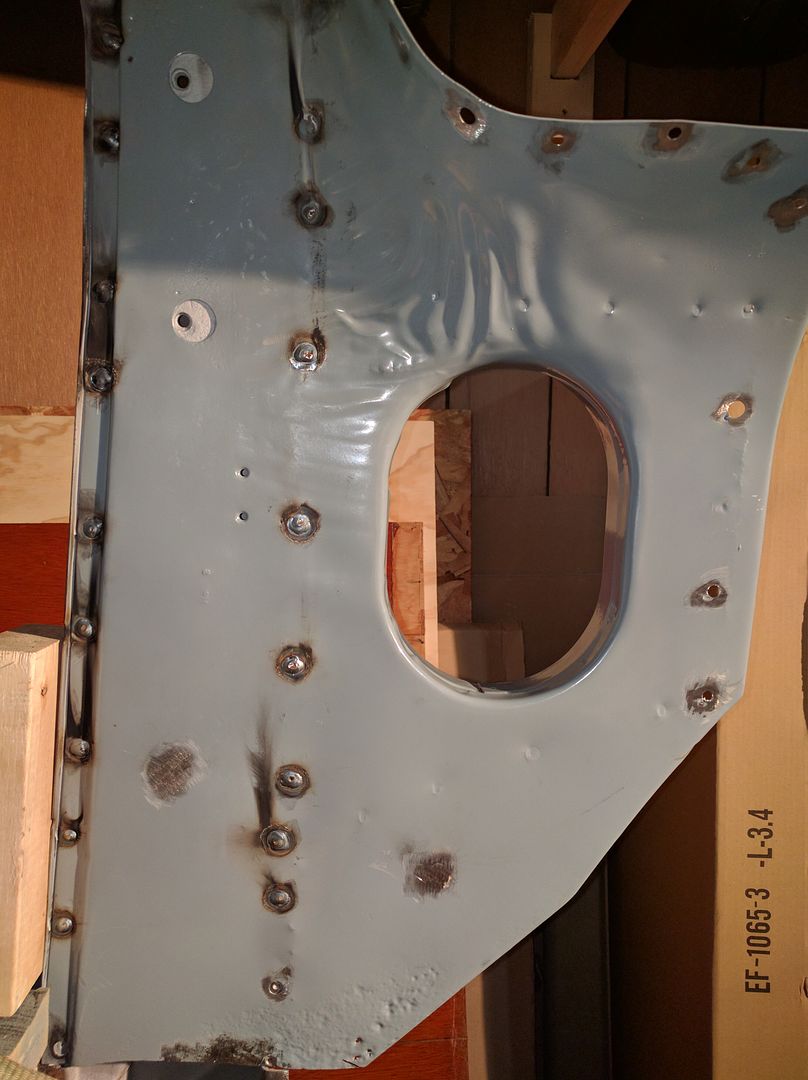

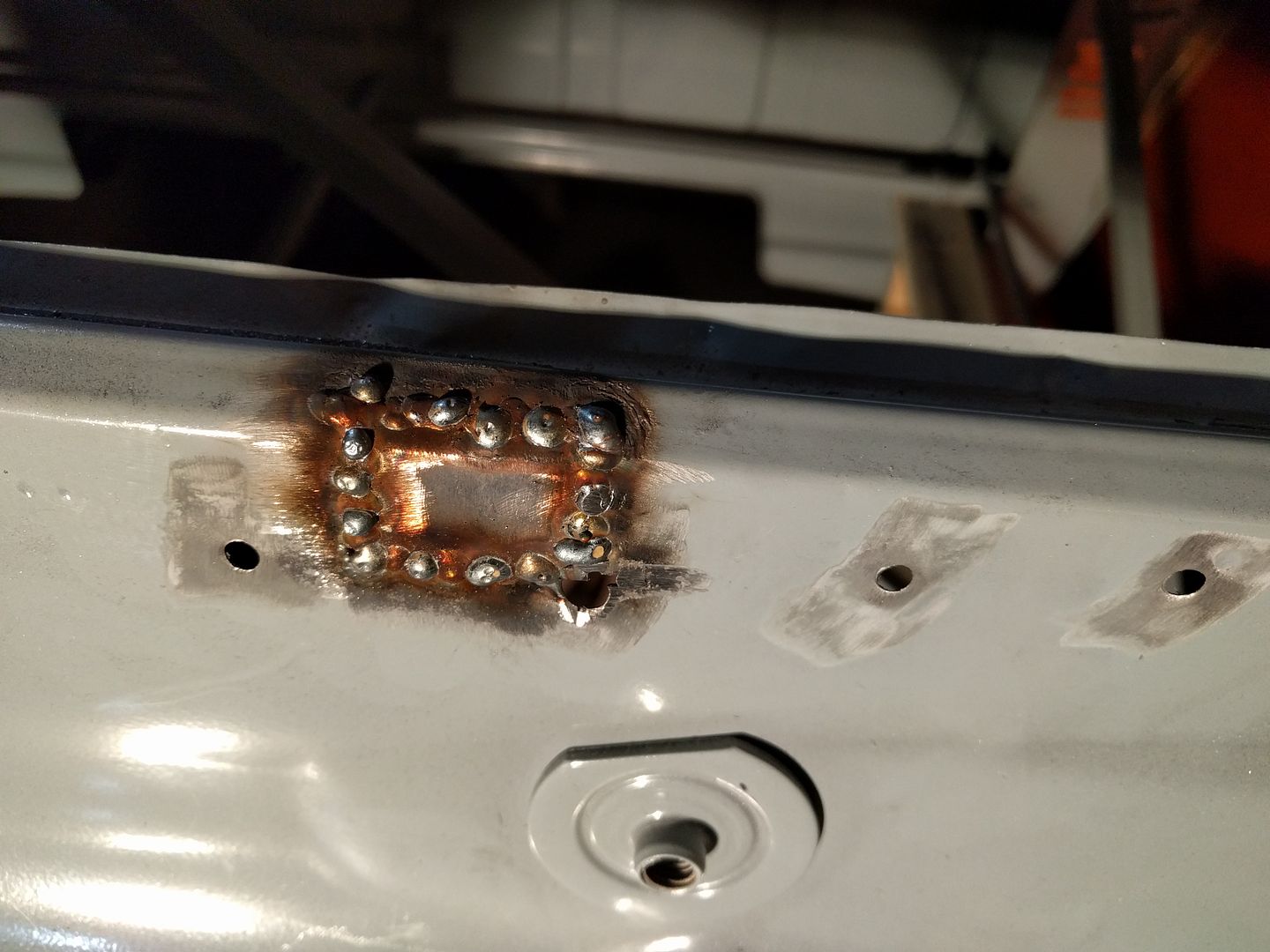

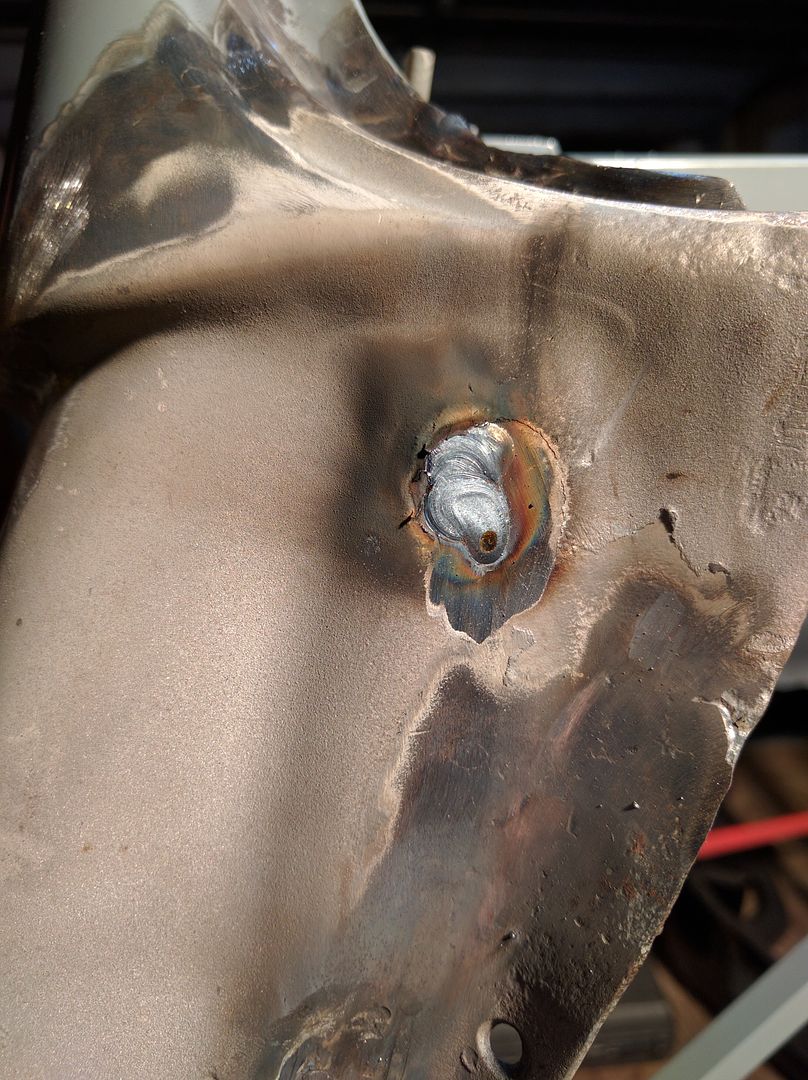

-if doors miraculously fit and if I don't have to slot out holes, shim things, and weld a bunch of filler rod to the edges of the doors to make things fit I can move on to patching small holes here and there

-replace/patch cab corners

-with doors in place, fit and weld in outer rockers

-fit and weld in dash

-paint

-assemble

All work will stop around when snow flies (~end of October/beginning of Nov) and only resume in spring. Wish I had a nice insulated workspace to keep plugging away at it all winter!

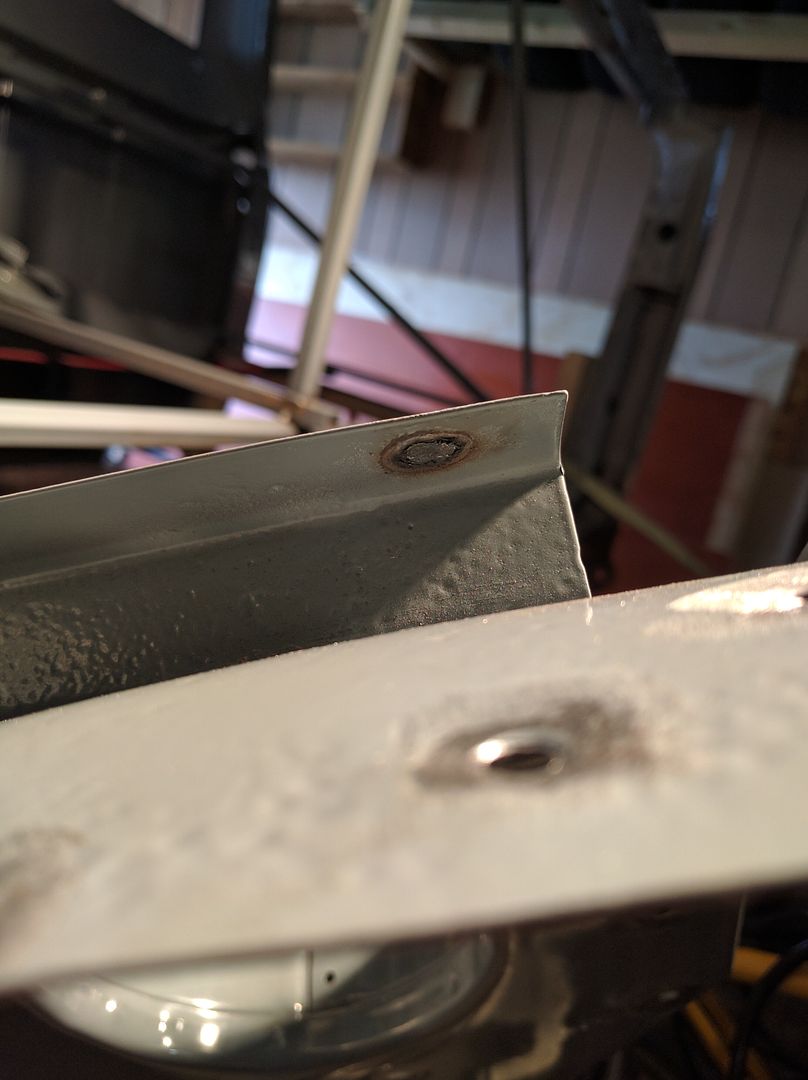

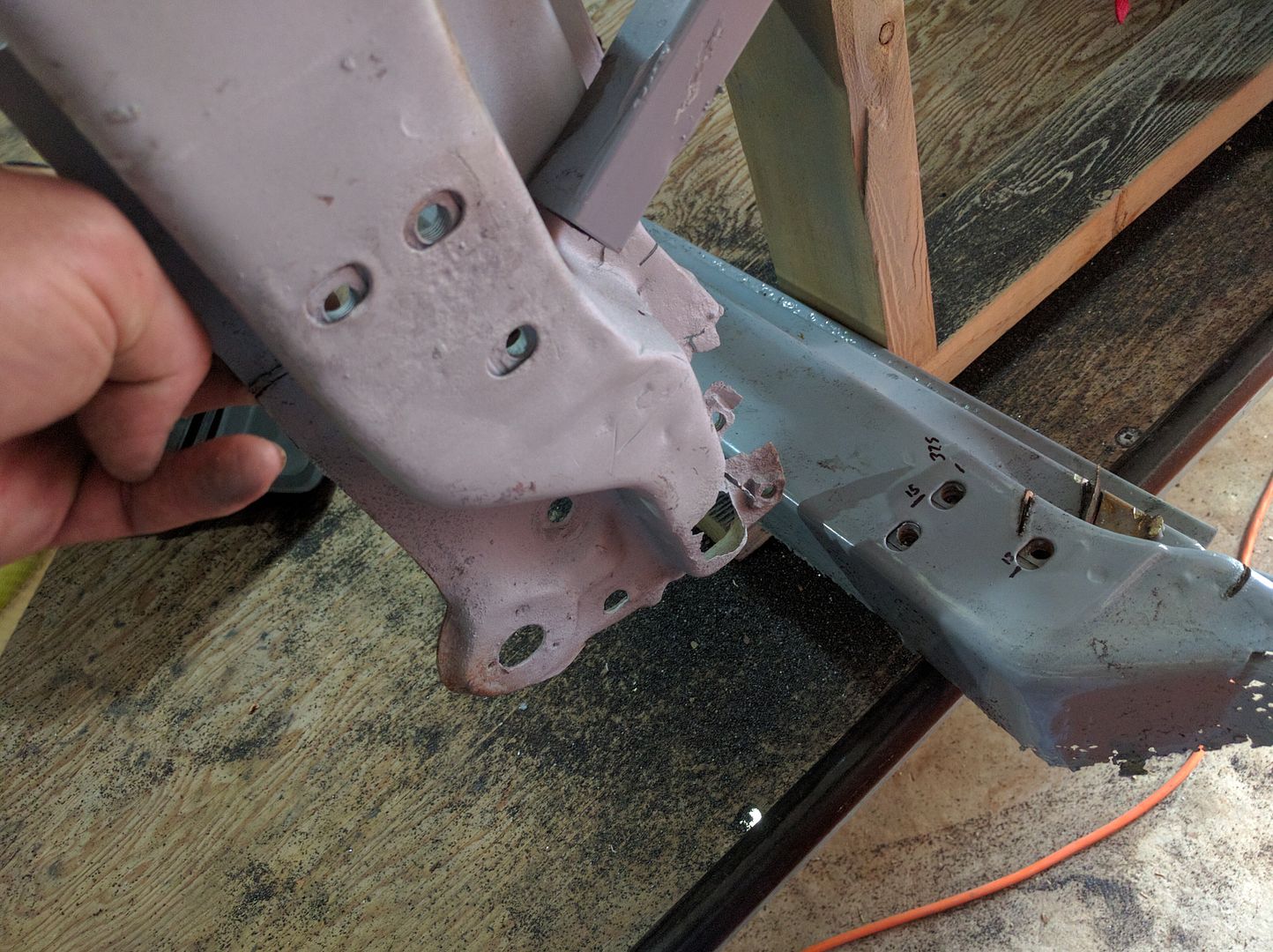

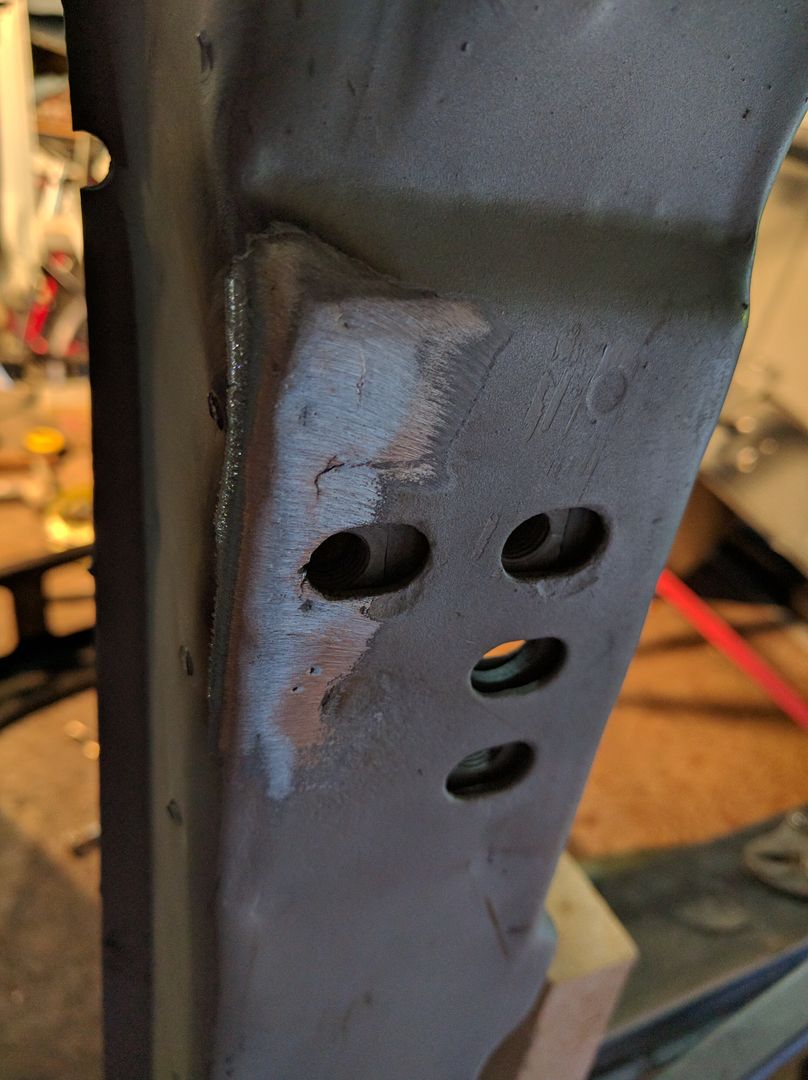

Then it's just a matter of lining up the old spot welds to fit it up

Then it's just a matter of lining up the old spot welds to fit it up