Try drinking the same wine in different glasses side by side, the flavor changes.

I have to start posting updates more often to keep this thread on track! But unfortunately I'm moving next weekend, so expect no progress until after I get settled in. I did some careful measuring to confirm the Europa will fit will excess in the back of a 26' Uhaul box truck. I already attached furniture dollies to the fiberglass shell so I can just roll it up the ramp. Moving the Avalon powertrain unit will be a different story...but there is a plan in place.

I hear wine helps with moving woes.

maschinenbau said:I hear wine helps with moving woes.

We call that the 'Industry Diet'- 2 glasses of wine/beer, and an aleve.

NOHOME said:In reply to RandolphCarter :

Say you drink half the bottle. ( No idea how that can happen) and you want to save the wine for next weekend cause you don't drink during the week (no idea how that could happen).

The "no idea how that can happen" part was the joke I was trying to make.

But I appreciate the explanation!

NOHOME said:In reply to TurnerX19 :

I use this same trick with POR in the can; never remove the lid, just punch two holes that can be taped over with aluminum tape. Then store in beer fridge.

With any of the long term storage of paint like products or resins, I just turn the can upside down. There's no way for air to leak in that way so the only air in there is what's on top of the liquid. Seems to work. For aerosol weld through primer with a lot of solids in, those cans get set on their sides so the solids are easier to mix back in to the paint.

Moved! Finally set up the new workspace well enough to work on the Lotus. First order of business - chop that cart down smaller.

Though it's a fiberglass car, what little metal it has is pretty rusty. This is a classic Colin Chapman "backbone" frame (upside-down in the above). Made of nothing but 16ga steel, folded and stitch welded. The body attaches with roughly a dozen bolts. 4 of them are up front. 2 of those are above the upper arm mounts, and at least 2 are in the "flap". The "flap" is just an overhanging piece. Not very strong, and prone to causing cracks in the T-shaped joint of the frame. A common mod is to reinforce the flap with gussets. My flap needs complete replacement, along with the bottom sheet of the front frame area. Vague descriptors, I know, but I've never encountered a chassis like this.

The common frame crack, below.

And looking inside, it's clear the bottom sheet also needs to go.

Pizza box patch template, with integrated flap gussets

Glued in

Still a ways to go. Who knew a fiberglass car would need so much sheetmetal work?

In reply to maschinenbau :

The problem is not the fiberglass, nor is it the sheetmetal. It's the expectation of 16ga to fulfill a structural capacity. (On the part of the original engineering team...)

Recon1342 said:In reply to maschinenbau :

The problem is not the fiberglass, nor is it the sheetmetal. It's the expectation of 16ga to fulfill a structural capacity. (On the part of the original engineering team...)

Somewhere there was probably a Lotus Europa frame made out of 18 gauge sheet metal that failed because that's how Lotus added lightness.

Recon1342 said:In reply to maschinenbau :

The problem is not the fiberglass, nor is it the sheetmetal. It's the expectation of 16ga to fulfill a structural capacity. (On the part of the original engineering team...)

It was the bonding of the fiberglass to the steel in the S1 that was intended to be structural. When people/body shops/insurance companies had to start dealing with repairs, Lotus started just bolted the two together - however there still is combined strength from the way the tub is snugly fit to the backbone.

I mean, yeah, it's still a death-trap...it's a Lotus. But they attempted to prevent it from being a wet noodle, as cheaply as they could.

Keep in mind the original curb weight was under 1600 lbs, so it didn't really need much structure. I am aiming to keep it under 2,000 lbs, with almost all the weight added over the rear axle. Modern sticky tires will also increase loads everywhere on the chassis, so I am planning to reinforce the rear Y split. Behind that, it will be mostly tube frame anyway to accommodate the Avalon subframe.

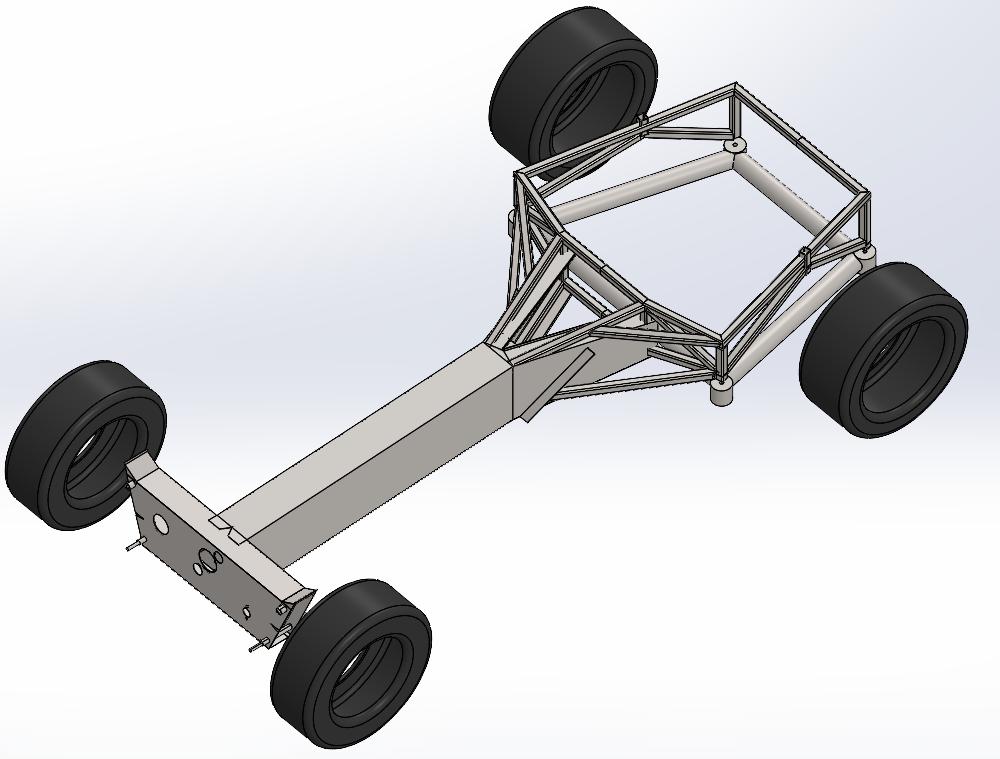

Teaser...very early in design

Banks did something similar for a transverse fitment:

Though they used bespoke suspension bits rather than an adapted subframe with suspension.

maschinenbau said:Keep in mind the original curb weight was under 1600 lbs, so it didn't really need much structure. I am aiming to keep it under 2,000 lbs, with almost all the weight added over the rear axle. Modern sticky tires will also increase loads everywhere on the chassis, so I am planning to reinforce the rear Y split. Behind that, it will be mostly tube frame anyway to accommodate the Avalon subframe.

Teaser...very early in design

This 3D rendering looks similar to a VW Beetle pan with the floor halves cut out

First some actual progress. I reinforced the steering rack mounts, because the sheetmetal was bent at the mounting holes.

For fun here's a size comparison to a ND Miata. The Lotus body is on furniture dollies, slightly above target ride height, and it's still about 6" lower than a new Miata.

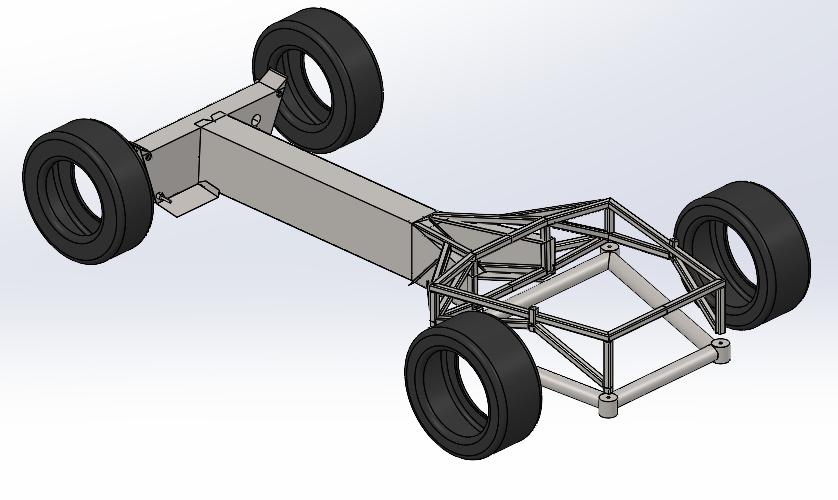

More rear frame progress. I would like to model the powertrain, but it may not be necessary since I know the entire powertrain is contained within the perimeter of the subframe. The belt assembly will be right next to the sqaure tubing on the passenger side. Driver side has a lot more room since the trans is there.

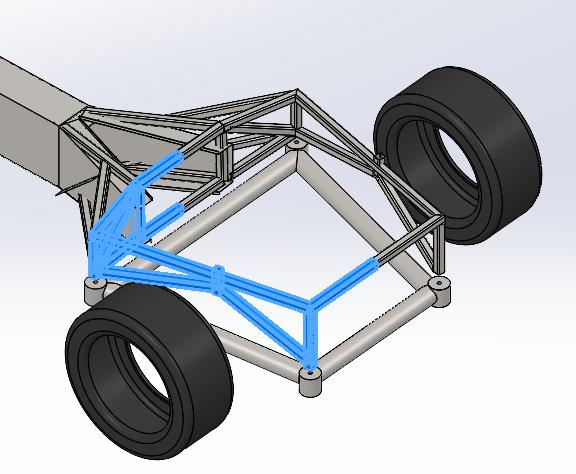

In practice, I will probably build the rear half of the frame independently (highlighted below), with the combine powertrain and running gear still installed. That way I can create a rear-half roller that will definitely clear the powertrain, and finish the front-half roller separately, then merge them via the middle tubes once the wheelbase is correct.

First I'd like to model the Avalon control arms, knuckles, and mounting locations so I can set the rear geometry and try to match a frame to that. And oviously still plenty of sheetmetal work on the Lotus frame.

Any inclination to make the rear end "splittable" for concours? It would certainly be a good party trick to present the car that way.

Another thought- where's the fuel tank going?

In reply to ¯\_(ツ)_/¯ :

All great questions. Body will probably stay in one piece for simplicity. The trunk opening is large enough to show off the custom stuff. The gas tank is behind the driver seat. The front left corner of the subframe interferes with it, so I will have to cut out the rear right corner of the tank and add a corner pocket. Otherwise it may need a custom tank possibly relocated, which has its own challenges and benefits.

In reply to maschinenbau :

I'd imagine the fluid capacity of that 16Ga hollow steel tube running down your car is some favorable non Zero number of gallons.

I would consider raising the too rail of your chassis addition. Also could you repurpose the cut off angled horns as the sides of your subframe support. If you move them high enough they might be able to avoid your suspension/engine/trans.

What software are you using?

Was thinking about that sheet metal last night. I've got one of these for 3" holes (I think its that size) https://www.summitracing.com/parts/hck-pf4a?seid=srese1&gclid=CjwKCAiA-9uNBhBTEiwAN3IlNE777CW9nl62VZ0utisCHinobZ266mySEJUP1mQfQPr5RzXFeHgDFBoCoHwQAvD_BwE

Want to borrow it for speed holes?

Thank you for the offer, but I am hesitant to put any more holes than necessary in the backbone frame. I might overlap a few joints with more 16ga though.

Gas tank inside the frame backbone...that's a clever idea. Unfortunately two long aluminum coolant pipes, both heater pipes, brake lines, wiring, and shifter linkage all have to live inside that space too. I'm debating whether to move fuel tank and battery up front to help the weight distribution, or just lean into the rear weight bias since I'll be tire limited up front. Porsches do it, right? I also suspect the stock front suspension won't want any more weight than necessary. Total ballpark guess would be

I agree the top perimeter members should be as high as the body allows. This will help the section modulus of the side trusses, and also locate the upper coilover mount to keep the spring as vertical as possible. Doing so will minimize twist on that truss from the spring forces. I do not have a coilover picked out, but will be some kind of sport bike rear shock. I also have to be careful to include this rear body mount.

I'm using Solidworks.

This is "only a challenge car", right?

would 2.5gallons suffice for "any one time"? If so, you might look around to repurposing an old/used/bashed corny keg.

In reply to sleepyhead the buffalo :

I still have the stock 7 gallon Lotus tank, which looks like this and is mounted behind the driver. Need to notch a corner for clearance to the new tube frame.

maschinenbau said:I'm using Solidworks.

Must be on an older version...this sketch looks a little rough. ![]()

You'll need to log in to post.