The rear coilovers were a great success. The extra inch or so of ride height made all the difference, and the ride quality is pretty good for a hot rod. No more bottoming out so far.

The exhaust has been banging against the frame, so I finally solved that by screwing a thick high-temp silicone strip to the frame cut-out. This also made a huge difference in overall enjoyment of the car.

All the bottoming out has been damaging the exhaust hanger, which was 1/4-20 rivnuts. One of them had pulled out and the other wasn't far behind. I replaced them with thru-bolted 3/8" flange head bolts to match the rest on the car.

Turquoise Ford trucks!

Next up is parking brake. I have new Ford axle cables and the original Lexus hand brake. I finally joined them. First I moved the cable bulkhead holes to the body instead of the trans tunnel.

That bracket was sometimes contacting the driveshaft! Lucky I didn't bend the shaft. Another problem fixed by the ride height, though I went ahead and grinded out the old bracket anyway.

The Ford cables pop in just above the trans tunnel, where they join to the Lexus handbrake cable. A new bracket welded in just the right place makes it all function.

Between the adjustment on the handbrake and the drum adjusters, I was able to tune the system just right. I should have welded the bracket in with the handbrake adjustment all the way "loose", but it all works fine now. I plan to cover the tunnel with a center console, including a padded armrest on a hinge for storage, and cupholders.

I plan to cover the tunnel with a center console, including a padded armrest on a hinge for storage, and cupholders.

look at S10/Sonoma/Blazer/Jimmy in the junkyards. you might find a good fit lengthwise that just needs height trimmed to fit.

Some stuff arrived. In the top are laser-cut nitrile cork gaskets that fit the ITB's perfectly. The yellow acrylic piece is a test-fit template. I thought it would be useful for it to be see-through.

With a little persuasion, the ITB's can be put into a position where all 6 insert nicely into the template. Each throttle body is attached to the rack by some kind of flexible bushing.

I am still a little off on the cylinder head mounting holes. I had to over-drill the stud holes to do this. All of the ports seem to match up. I plan to manually port-match the final part, which will be 1/2" or 3/4" 6061 aluminum.

Integrated EGR blockoff is pretty close

This is the real problem. ITB mount wants to live where the coolant neck gasket currently seals. I will probably overlap these parts, machining some thickness away from each, with the coolant neck still maintaining full contact to the head. The other option is make the coolant neck integrated into this adapter, with a tube welded on for the radiator hose. Not sure yet.

Since BMW engines are leaned over, these ITB inlets droop downward slightly. That should be okay.

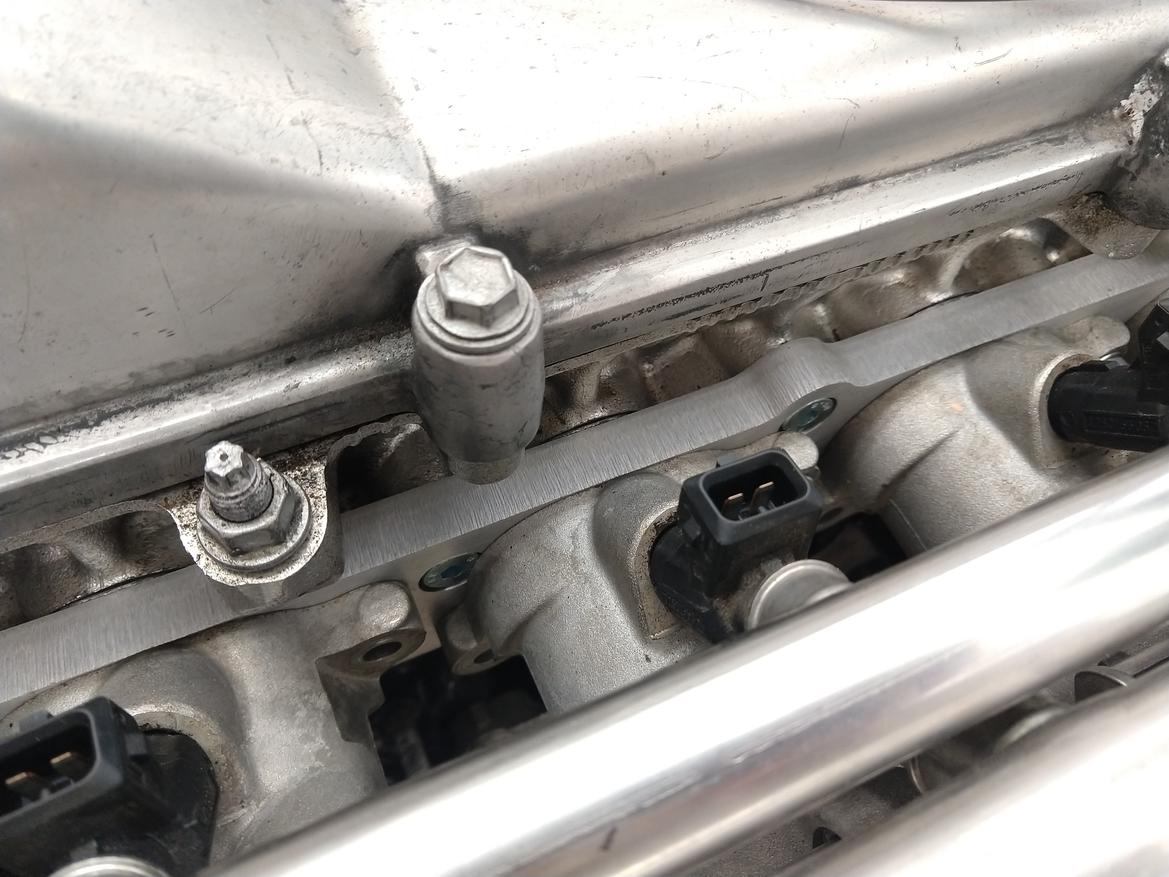

I love the aesthetics of the 3 parallel tubes - two stainless ones for fuel rail and vacuum manifold, and the plastic harness cover.

This was only meant to be a test-fit exercise, but I have a feeling the old intake is never going back on. Which means it's finally time to install the Microsquirt. Which means I can delete the distributor while I'm at it. Parts cannon has been fired at a very unique coil-on-plug ignition upgrade and some other aftermarket ECU sensors. More on that another time.

Why am I seeing some 45-60 degree inlet elbows with the ITB's on top? Yes this adds to the complexity, but from an aesthetic aspect (eyes squinted) IMHO this would be WOW.....YMMV luv it carry on

If your adapter is 3/4-1" You can likely just thread for NPT for the coolant nipple. Might be a bit easier and reduce opportunities for warping.

Okay, just talking back seat driving again here, but...

I gotta agree with Shavarsh. Assuming you are tapping into the adapter to mount the throttle bodies to it, It seems like this one bolt hole has a high potential for a leak.

However, if you made the adapter cover that water passage, you'd have plenty of support for that errant TB bolt hole.

Maybe sandwich the plate with your original water fitting, after some grinding, of course.

I gotta ask, is a tahrbo still on the wish list? I mean, ITBs are damn impressive, and I really don't think this thing is lacking power, but what kind of enabling is that?

As long as I'm potentially adding stuff to your plate, It would be relatively easy to have a a 10 degree angle machined on the face of a 1" adapter to level the TBs out. (Not the water fitting part, obviously, if it is to be used.)

I have every confidence that whatever you are cooking up will exceed my musings, I just like the project, and enjoy adding my opinion to the mix.

In reply to Rigante :

Get out of my head. That's exactly what I had in mind once it's turbo time. Nice job with the illustration.

In reply to maschinenbau :

The finned airbox that deliberately looks like a Chevy valve cover, hell yes. Level or downward is good, the stick em up guys are asking for a gravity induced failure.

TurnerX19 said:In reply to maschinenbau :

The finned airbox that deliberately looks like a Chevy valve cover, hell yes. Level or downward is good, the stick em up guys are asking for a gravity induced failure.

TX19 sent you a pm

Coil on plug conversion. These early non-turbo 2JZ-GE engines came with a distributor. There are many options for converting to coil-on-plug, but off the shelf kits can be pricey. Many of them use Audi R8, Nissan R35 GT-R, IGN-1A, or even Chevy truck coil packs. Except for the GM parts, none of these are easy to find used or in your local parts store. I wanted to use the GM coils, but the aftermarket bracket doesn't fit my earlier head. I almost started building my own brackets for the truck coils. I definitely didn't feel like blowing $600+ on hard-to-find supercar coils and brackets, so I found an alternative. Apparently the VQ37 engines used the same coil internals as the R35 GT-R, but with a different shorter plug boot/stalk. These have been tested to be about as powerful as you can buy, short of the aftermarket IGN-1A coils (full video of tested coil packs: https://youtu.be/4d3nrBZjYKA). I found out that you can pull the boot off a 370Z coil and replace it with one from a BRZ/FRS. So this means I can just buy a set of 6 used 370Z coilpacks off eBay for $100, and a set of BRZ boots for $3 a pop on Rockauto that make them fit my engine, and always able to replace a coilpack at any parts store or junkyard. I don't know for that this will work, but it all fits together nicely.

You can see how much shorter the BRZ boots are compared to the 370Z ones. Even if you buy GT-R coils, you still need shorter boots, which the aftermarket kits provide.

With some trimming, the valve cover covers will still fit. I will modify the sheetmetal tray with some nuts for the new coils to screw into.

Soon: converting that distributor to a cam position sensor is as simple as dithcing the cap and rotor, and adding a nice cover plate.

Cuts have been made - Toyota ECU is out, Microsquirt going in. This is probably the bare minimum amount of I/O to run this engine, and with only 2 fuel and 3 spark channels is not ideal, but it has been proven to work on 2JZ's. It is also extremely cheap but with great support, so we'll see how it goes.

The BMW intake has a nice tubular plastic harness cover, which will be great for tucking the wires.

The BMW fuel rail is returnless, but the 2JZ system was return. I plan to install an aftermarket regulator with return, and have the output on a short dead-head to the BMW rail. Should be able to tuck the regulator under the ITBs.

Too rad! I see you've got one of the bolt in split wire grommets there in your picture. Has it worked out well for you?

Fantastic as usual. I don't know where you got your laser cut stuff but if you need something in the future, let me know.

I've been using sendcutsend for online laser cutting. They have a rubber cork gasket material that I used for the throttle body gaskets.

I like the split harness gasket. It's definitely not watertight, but I'm obviously not driving this car in bad weather. I just drilled the rivets out to remove it.

Parts stack is getting out of hand!

Here's my idle air control strategy, the classic Ford 2-wire solenoid. The early 2000's 4.6 V8's have a nice 3/4" hose barb. Then you attach a crankcase breather filter. Planning to weld an SS adapter plate to the vacuum tube.

Here is my fuel strategy. The squiggly bent SS tube is the factory BMW supply line, which attaches nicely to the fuel rail. Turns out 8mm = 5/16", so a compression fitting adapts it to -6AN.

What better place to mount the regulator than the factory regulator mounting holes. The new intake should hide my amazohn brand shame. This is the knockoff recommended by the Sloppy Mechanics folks.

I finally mounted the Nissan VQ37 coilpacks properly. Some M6 threaded standoffs and random OEM bolts from my collection.

I like how they fit and look. Hopefully they actually make electrical contact with the spark plugs. With all this money I'm saving by doing things the wrong *ahem* I mean the grassroots way, I splurged and bought a nice billet distributor cover. Don't worry, I also replaced that crusty distriubtor connector with a new one. Turns out 3VZ-FE uses the same style connector, so the plug with pigtail is much cheaper.

Version 3 finally arrived. Apparently they only cut acrylic at their Nevada facility, so shipping takes much longer than from the Kentucky location. But it fits and I'm ready to order the metal version after some minor knickpicky adjustments.

I also did my first-ever AN hoses. I never imagined how satisfying it would be!

Now I'm re-doing the electrical power distribution. Better fuse blocks, different routing strategy, better connectors, etc. I am really enjoying this project, again.

Yeah, Send Cut Send and competitors is why I sold off my large plasma table. I cant compete on custom stuff. I have received some really good advice on some simple chassis building items that would likely sell.

before you go too far down mounting that ford IAC, maybe look into ITB mode on the microsquirt, and using ignition idle control. there's a recent thread where it's discussed.

Metal version has arrived. 1/2" 6061 lasercut aluminum from sendcutsend. I added the counterbores and it all seems to fit nicely. Now I just have to grind clearance for the coolant neck and port match to the gaskets.

I took the vacuum and fuel rails off I can make a few modifications and clean the gunk out of the throttles.

You'll need to log in to post.