GaryC83 said:

In reply to AWSX1686 (Forum Supporter) :

Speaking as somebody who welds a TON of tubing everyday, the only thing I would worry about is heat. Especially if your weld seam is an inch or so away, like a lot of the joints and stuff I deal with are.

The plugs I use are from TiCon. They're actually quite cheap in some ways - but expensive in others. I realize 300 for the set is pretty steep for a guy out of his garage buying a set of silicon plugs. But I use mine all the damn time and they are worth every penny.

What I would like to see and will probably work on myself - is an elbow cutting jig for making transitions & collectors, etc. THAT is the perfect application for 3d printing. I'll have to fire up fusion360 & my Ender3 and figure something out. lol.

I was apprehensive about 3dplugs for back purging exactly for the reason you stated. Heat. That aluminum gets HOT. Especially since I suck at TIG'ing. I haven't tried them for that yet since I also don't have a gas setup for it. But they did work reasonably well for leak testing. I printed a taper and a specific size plug for the intercooler since I was only initially testing one side and I had already chopped off the outlet tube of the opposite side.

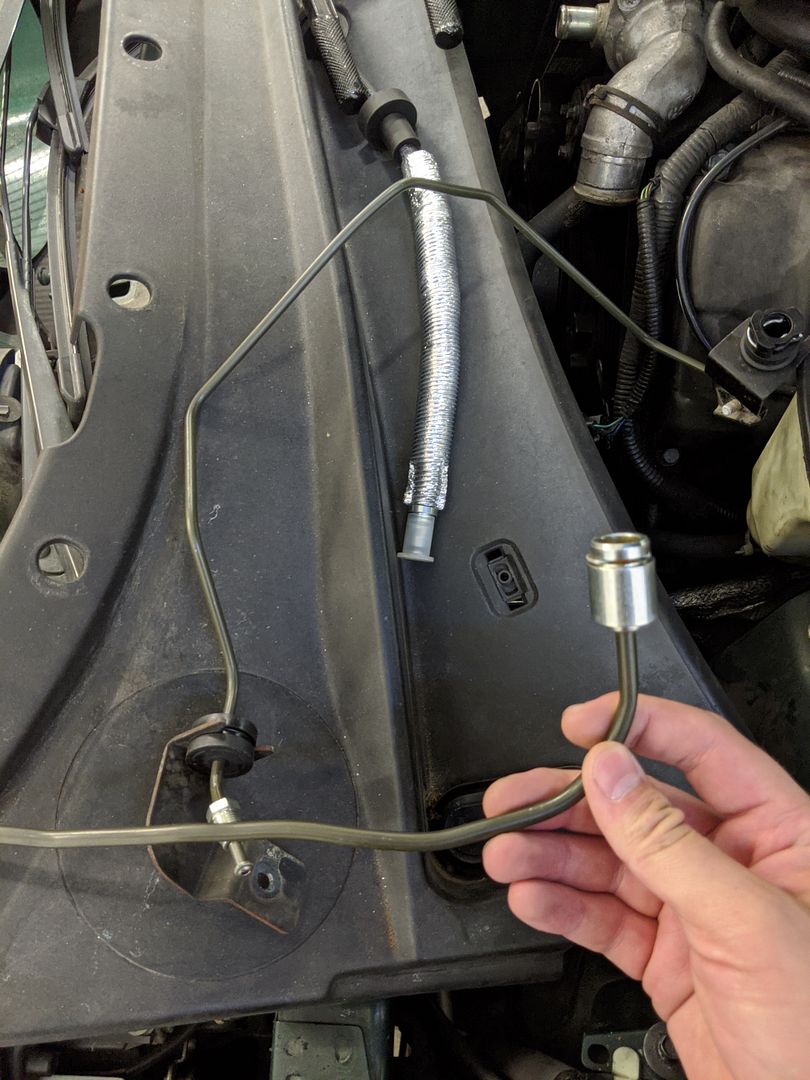

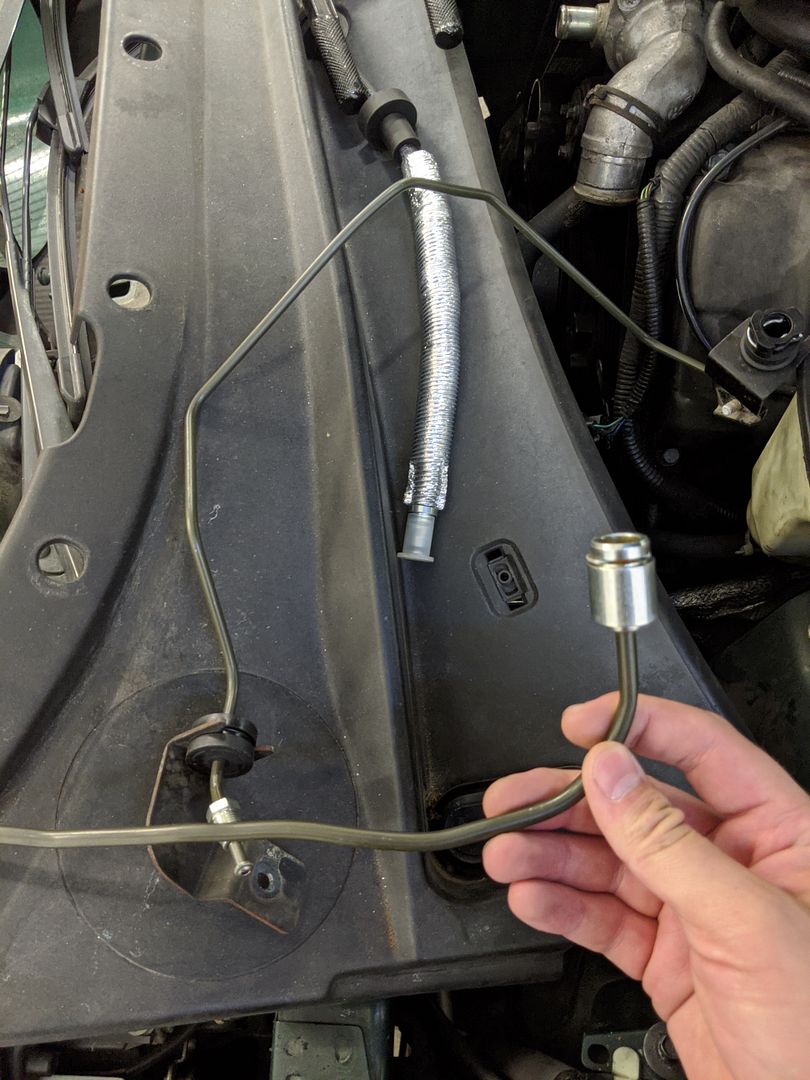

This weekend was kind of all over the place. I finished getting the pedal box/clutch master cylinder into the jag. It uses fairly weird quick disconnect style fittings for the lines. I ordered new ones knowing they wouldn't fit perfect but I could cannibalize them for the fittings. It's like the standard disconnects on GM master cylinders, but backwards. The line has the female and the MC has the male fitting. And they're mostly hardline. Which is nice because I cut the last few inches of either side, bent to point in the direction I needed and I'll have a custom line made when the trans is in and I know how long it'll have to be.

I was also pretty confused on how the pedal return spring works on these. It seems to only "spring back" at the top 1" or so of pedal travel. Anything below that must utilize the hydraulic pressure from the clutch?

Whatever. I hope it works. It'll be a pain to pull back out when the car is back on the ground. I'm still waiting on the new slave cylinder that's coming from across the pond. I have a tracking number but no updates as of yet. Ugh. I'm too impatient. When I got that all bolted down I pivoted to welding.

I welded an elbow to the audi90 intercooler in the hopes of getting a straight shot to the turbo outlet. I realize now (After the turbo and everything is all mounted and torqued down) that I should've welded a 90* on the turbo outlet and then I could've just used a long straight silicone coupler/reduzcer to hit the intercooler. I'm not pulling all that apart now though! Luckily, I found a 2" to 2.5" silicone 90* elbow on amazon that will hopefully work. After a few hours hamfisting my way through TIG'ing (which I've done all of two times in my life so far) I moved on to the trans am.

I found a guy who would make me some customer wheel adapters. I have a set of 4 rear audi r8 19x11 wheels I'm trying to fit.

Audi uses 5x112 and the trans am is 5x120.65. No big deal because I've using a pair of 2" bolt on adapters to run the c6 wheels for a decade or more. However, this guy is deadset on making them hub centric, not lug centric. First off, the trans am uses a cast hub. I don't know how you can make a hub centric adapter fit a cast hub perfectly. Secondly, since it uses a pair of tapered bearings, the hub/spindle stick out a large amount from the wheel mounting flange. So much so they project into the center of the r8 wheel. Which oddly enough uses a smaller hub bore than the trans am. So I'm trying to find a local place that will machine out the center of the r8 wheel so I can fit it over the spindle/hub of the trans am. Then I can commit to a hub bore spec to order from the guy. Since, it seems he won't just run with a lugcentric style. Also, it'd convert from factory m12 lug studs, to the audi m14 lug studs.

Random adapter I picked up but the lug holes are too big. I think these are meant for m14 on both sides.

Old trusty. I've been using this guy for over a decade. I know lug studs/adapters can be a consumable I've just been apprehensive about the quality decline in the last few years.

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)

.jpg?width=1920&height=1080&fit=bounds)