I’ve browsed the forums for a little over a year now and decided it was about time to make an account and maybe add a little to the community.

My name is Adam Doyle. I’m 26, from Red Oak, TX and for the last three months, my dad and I have been building a mid-engine, tube chassis street/autocross/track car from an 07 Chevrolet Cobalt LS donor car. We’ve thought about making a car like this for years and things finally lined up for us to do it this summer.

As a little bit more of an introduction, I work at the family business that my dad started about 10 years ago. We are a CNC machine shop that specializes in making aircraft fittings. Our hobbies have ranged from RC cars, planes and helis to circle track racing. We built our dirt track cars ourselves and hope to use that experience with this project.

We started with a few goals:

-

Small budget

-

Keep it light: This will allow us to have good performance without needing to break our first goal with costly engine upgrades.

-

Use up the donor: Reusing as much as possible will save money and we get some neat features like automatic headlights, ambient temperature, fuel mileage, etc.

-

Make a fun car

We call our car the Goblin because the name Cobalt comes from the german Kobold that equates to Goblin. Here is a picture of the model we've drawn in Solidworks. Don't mind the magic holding on the spoilers and rear tires.

Updated website: The interactive model linked below still exists, but for more up to date information, check out our main site: DF Kit Car

I’ve also put together a little website where you can spin around the 3D model of the car here: Goblin Info. It is a work in progress and might not work on all devices, but on most you should be able to spin the model around by clicking and dragging (or touching and dragging on touch devices).

My first few posts will be to catch y’all up to where we are at the moment. After that I’ll try to update often.

May 2 - The Donor

We started out by buying a donor car via copart.com. We would have prefered a 2009 or 2010 Cobalt (LAP Ecotec engine for a little bit more horsepower with variable valve timing, tire pressure monitoring system and newer car overall). Due to availability and keeping the cost low, we went with a 2007 Cobalt LS sedan with 129k miles.

This Cobalt had been wrecked in the front (as are most potential donors) but from a visual inspection, the damage didn’t seem to go beyond the radiator. One big plus was that this car cranked up and could still move under its own power.

We drove to Fort Worth, picked up the donor, took it to our shop and immediately got to work stripping pieces from the nose to assess the damage further. We were happy to see that the subframe, which we planned to use on the Goblin, was still straight.

May 9 - Removing the powertrain and subframe

The next weekend we got the engine, transmission and suspension out as one unit connected to the subframe. We took measurements of the subframe to design our frame on Solidworks. Essentially, we are doing what Pontiac did with the Fiero. The subframe, powertrain and front suspension are being translated to the rear and our tube chassis will attach to the stock mounting locations of the subframe.

June 4 - Stripping the donor. Starting on the frame

Our spare time was split between house restorations, rebuilding a Baja Bug and working on the Goblin. In our limited time, we did finish stripping the donor car down to an empty shell.

After stripping the donor, we got to work designing the car on Solidworks. We started by drawing the subframe and building the model from there. We designed the chassis around the stock Cobalt seats and kept the wheelbase to around 95 inches. During the designing process, we kept in mind that anything we drew, we’d have to bend up ourselves. So to make things easier, each tube of the frame is bent on a single plane.

After laying out the frame on the computer, we used the model to make a template the same shape as the lowest rails of the frame. This template was use to weld together a jig to hold the tubing square and aligned to our model while the frame was welded together. Using this jig, we quickly got the basic frame welded. In the following picture you can see the jig under the frame.

We then moved up, building the rest of the front of the frame. Jackson, my nephew and our future racecar driver, got a kick out of sitting in the car.

June 18 - Front suspension

We designed the front suspension around inexpensive coilovers we bought from Speedway Motors. This won’t be the last time we design and build the front suspension, so we did a little work to get a reasonable roll center but to keep things moving forward, we didn’t concentrate too much on optimizing the geometry. That will come at a later date.

June 23 - Rear suspension

So that we could dial in the rear suspension, we used adjustable rods to hold the strut towers in place. In the future, we will replace the rods with welded tubes to make the rear suspension rigid.

The stock springs had the suspension pegged all the way up, so to get down to a reasonable ride height, we cut one coil from each strut. This has the added benefit of increasing the rear spring rate.

We also got the seats installed. They are very easy to deal with since they slip over a square tube in the front and bolt down in the rear. They are very dirty (and keep getting dirtier) so we plan on covering them when we are done.

June 24 - Wiring

There is nothing quite as daunting as the sight of a Cobalt’s worth of wiring strewn across a table (well in this case two pieces of OSB on saw horses).

The task before us was to work our way through the wiring, eliminating systems that we would not be using and figuring out which wires would have to be extended to reach from the fuse block near the engine to the BCM at the front of the car. We took our time trying to make sure that after we extended, routed and connected it all, everything would work as planned.

Also, one of our goals was to make the extensions using only the wire that came with the Cobalt so that we wouldn’t have to buy any extra wire.

June 25 - Fuel tank

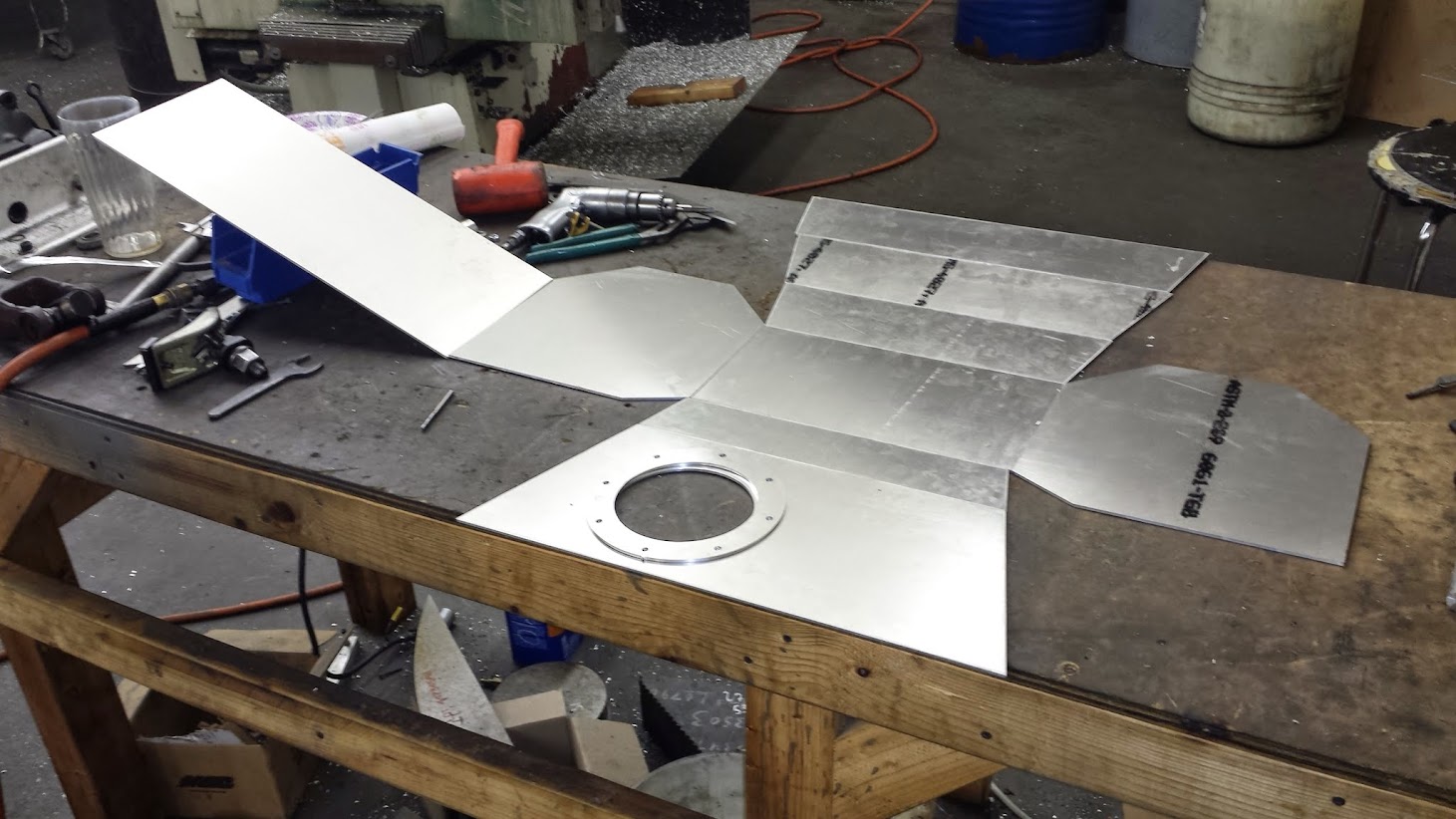

We purchased a 5 gallon plastic tank from Summit Racing but then decided to just fab our own tank. A custom tank would be beneficial for many reasons. First, it would be easy for us to make a tank that accepts the stock Cobalt fuel pump. Second, the tank could be designed to make better use of the space available for a tank. We ended up opting for a custom welded aluminum tank.

We started by drawing a tank on Solidworks that was a nice fit in the space between the front frame tubes. We then laid out each panel of the tank and CNCed them out of .125 inch aluminum.

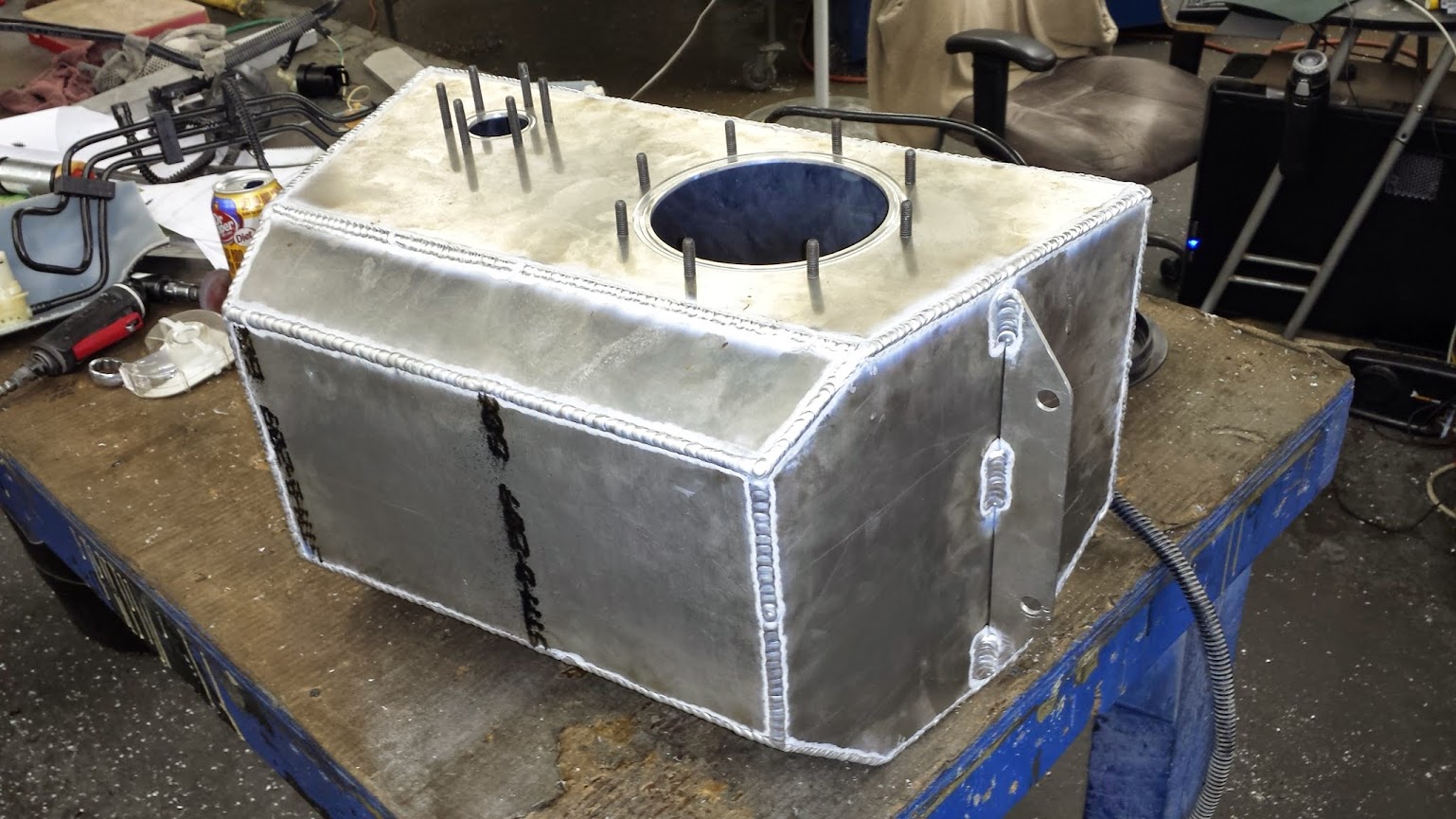

My dad tacked the tank together for a test fit. The tank fit great showing that our frame matched our Solidworks model pretty well.

He then TIG welded all of the seams. The final steps were to add bolts for the Cobalt filler neck and pump to bolt on to and to install the pump tray down inside of the tank.

June 29 - Pedals and steering

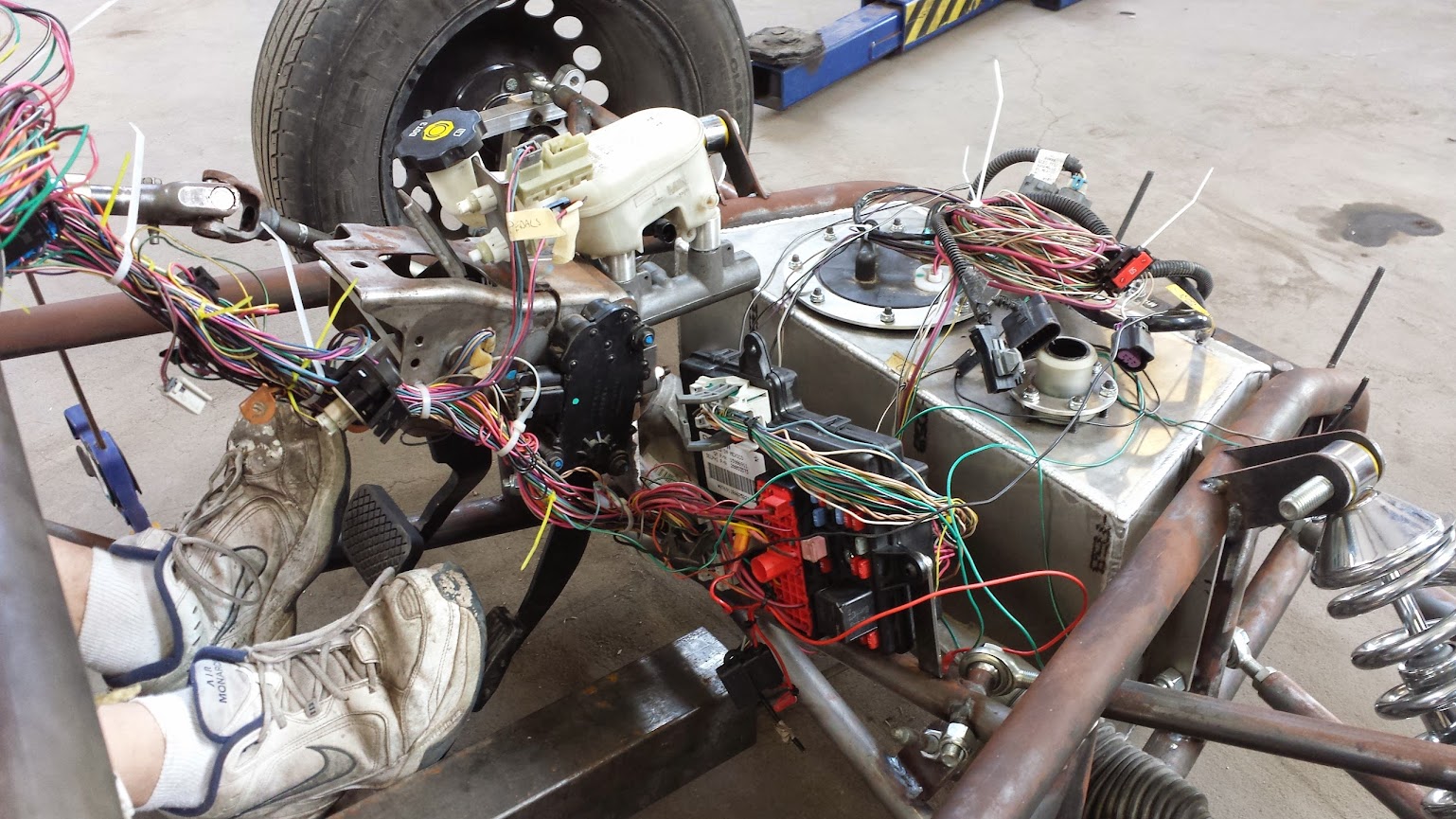

This picture shows how busy the front of the car was getting even before the wiring was run from the rear to the front.

Many things have worked out well from choosing the Cobalt as the donor car. Two of those are the pedals and steering rack.

With the throttle being drive by wire, we don’t have to route a cable from the pedal to the throttle body. Also, with a little creativity, we were able to use the stock master cylinder and brake reservoir.

Eliminating the brake booster required us to shorten the brake push rod. Also, the reservoir had to be turned around backwards or else it would have ended up poking out above the fiberglass nose we’ve drawn up.

Lucky for us, the Cobalt has electric power steering. We’ve eliminated the power assist (won’t need it with a light front end on a track car) and installed the Cobalt rack and pinion. Since the stock system is electric, we didn’t have to deal with deleting hydraulics from the rack.

July 6 - Wiring and gauges

We bravely pushed through the task of figuring out and installing the wiring. A large spinal cord of wires was routed through our tunnel to connect the engine fuse panel to the BCM, front lights and fuel pump. We were able to extend all of our wires using wire from the donor car.

In the following picture you can see how our structural cross brace is used to hold the BCM, pedals, suspension mounts, BCM and eventually will connect to the tunnel.

We had planned all along to use the stock Cobalt gauge panel. This will allow us to use the information panel that gives ambient temperature, fuel range, fuel mileage, coolant temperature, oil life and more. We also think it looks slicker than trying to install individual gauges.

Sorry for such a long post. We are just really excited to let you guys know what we are up to. I'll get the pics and text together for the next post and hopefully by the end of the week have more up.