Another magazine that rhymes with "Hop Mod" has an article this month on "antique" 4-cylinder engines that might be a source of inspiration on a project like this. I haven't read it yet.

Another magazine that rhymes with "Hop Mod" has an article this month on "antique" 4-cylinder engines that might be a source of inspiration on a project like this. I haven't read it yet.

stroker wrote: Another magazine that rhymes with "Hop Mod" has an article this month on "antique" 4-cylinder engines that might be a source of inspiration on a project like this. I haven't read it yet.

There are no other magazines....

Great project.

Not sure if everyone has seen this, but Northwest Vintage Speedsters looks like a great club.

I have that issue. It's the first good thing I've seen in Hot Rod for a while.

I'd like to get to Speedy Bill's musem one day but I doubt it will happen.

Rajo, one of the companies that made OHV conversions for the model A 4-bangers also made a cylinder head for the Chevy six.

They added a second intake manifold which fit on a 45 degree angle above the original intake ports. A single carburetor went on this second manifold and a twin-carb manfiold bolted on in place of the stock manifold.

The setup was progressive, the engine ran on the single carb until about 50% throttle, then the two carbs on the second manfiold opened.

Weird.

Wayne and Horning both made 12-port cylinder heads for the chevy six but the price of them is insane.

Shawn

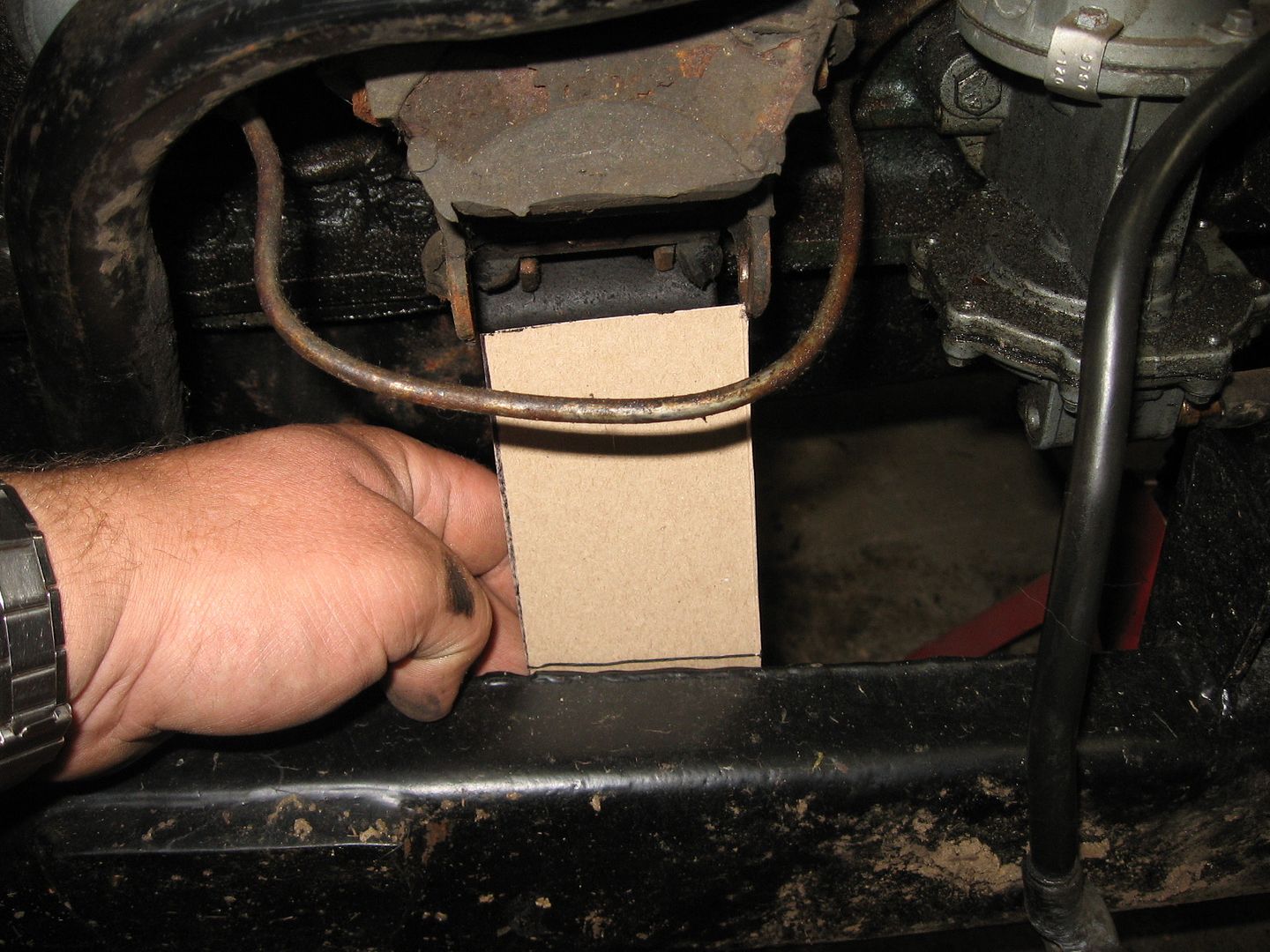

Ok, here's the first step for the engine mount brackets.

I like to use cereal boxes for template cardboard. It's easy to work with.

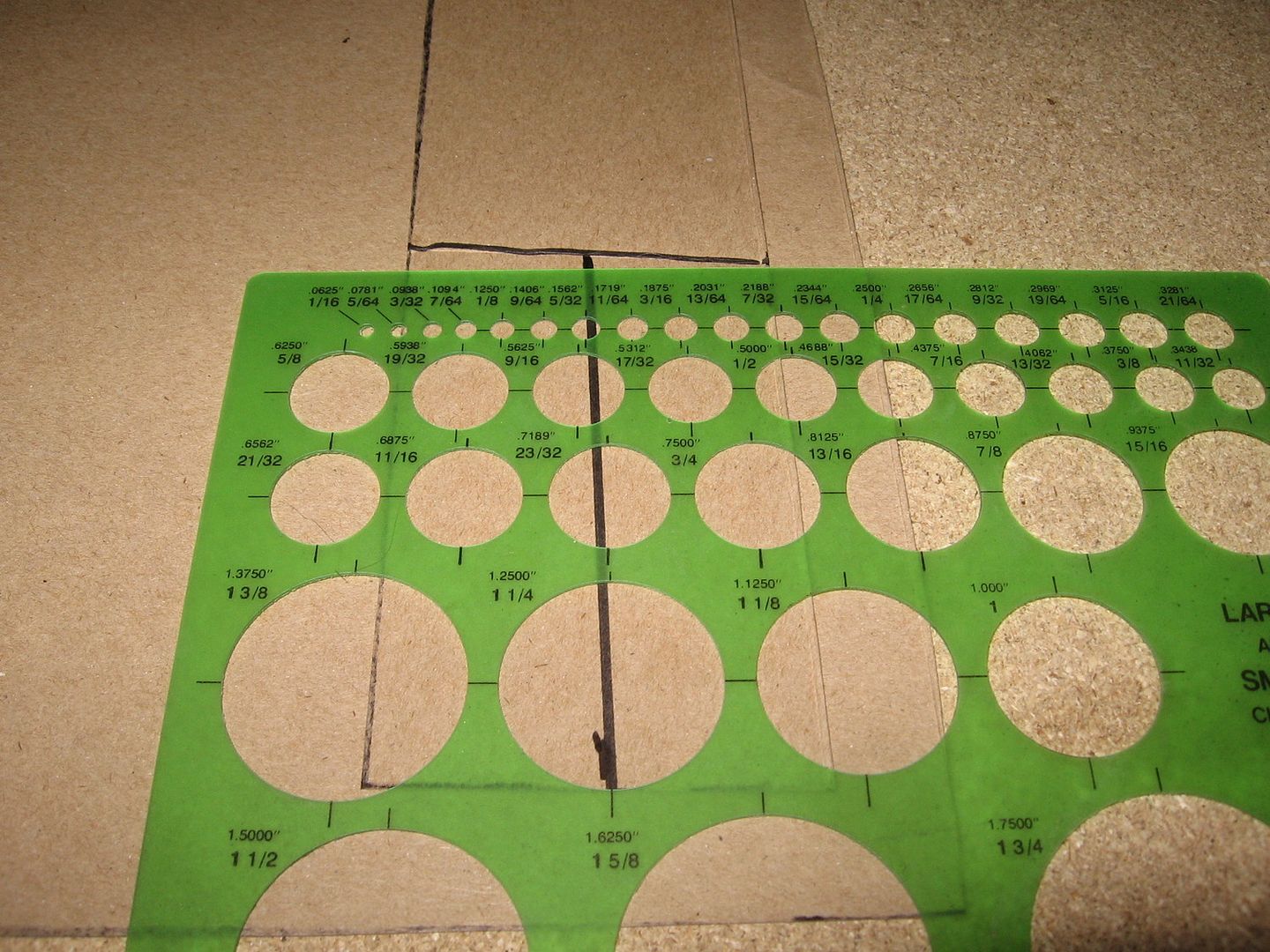

A circle template helps to lay out nice smooth corners:

First, I'm going to cut a piece that will go from the motor mount bolt down to the frame at an angle and then extend to the bottom of the frame on the inside.

These will be bolted down from the top and through the side with threaded rivets, they are bolts with a domed head, from the side they will look like rivets.

Here's the first piece:

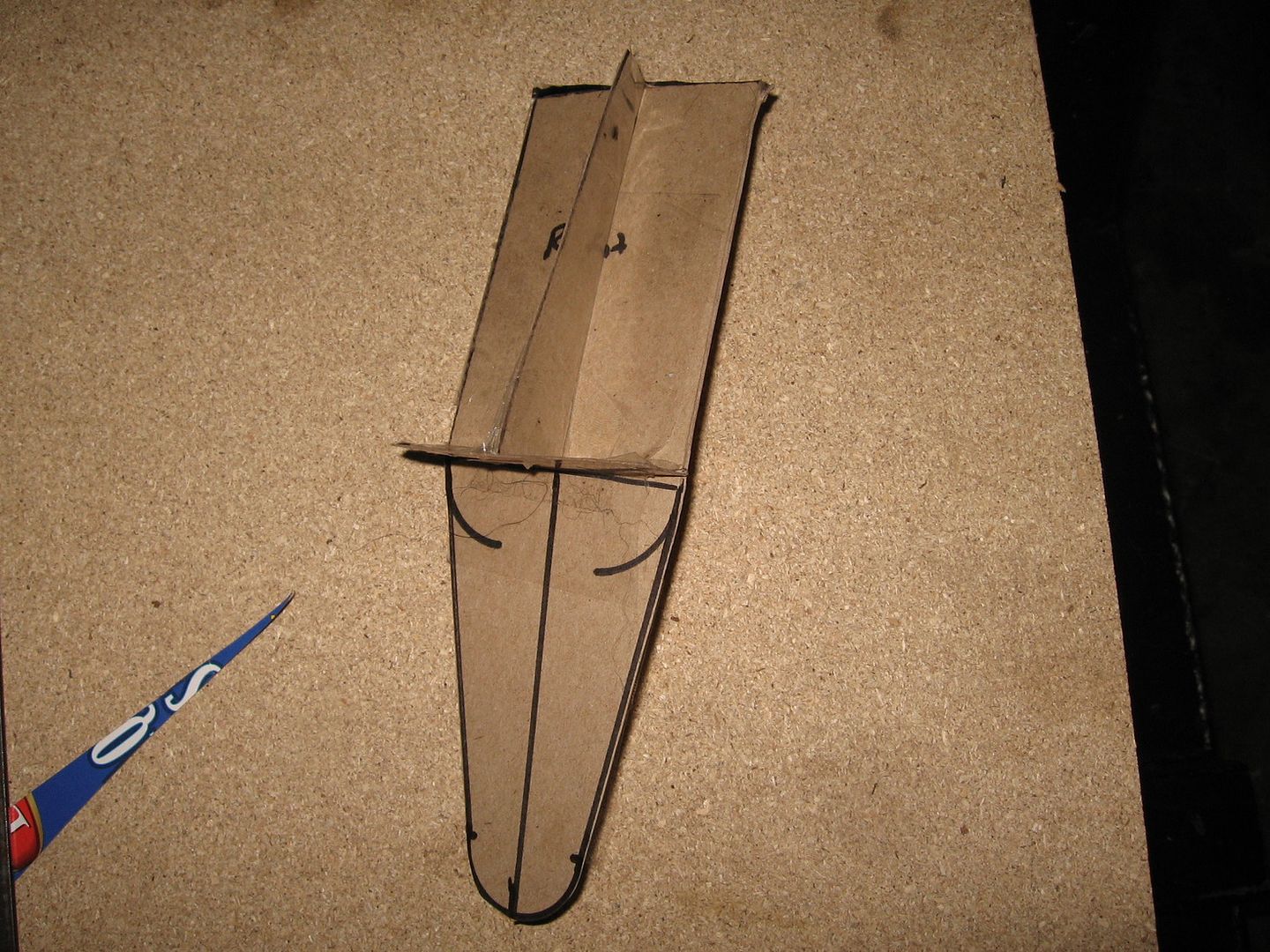

There will be a tube welded to the top of the plate for the mount bolt to pass through, I will add a flat plate which sits on the top of the frame and a gussett on both sides to help take the load.

Here you can see the outer side of the bracket with the gusset and plate taped on. I've tapered and rounded the bracket end to help with the cast look:

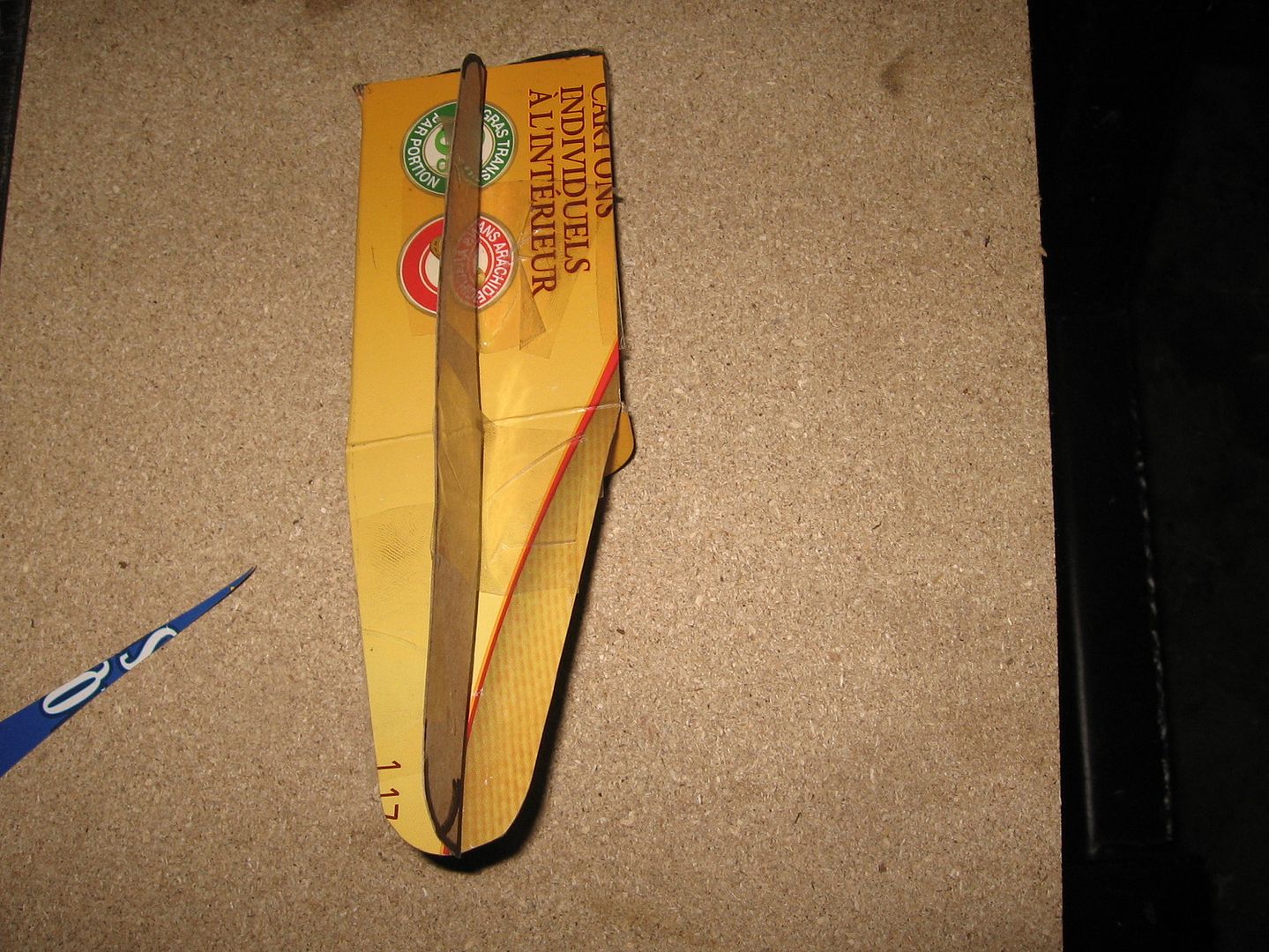

Here is the inner side with the gussett added:

Now that we have a cardboard bracket made and we know it fits, simply cut the tape with a razor blade and you have all the patterns to cut out the plates to build the bracket.

Now I need to make one for the other side.

Here's the wheel and tire package. One of my co-workers decided to go a different route on his '32 Ford so I bought his wheel and tire package.

This is the best thing on GRM right now.

You don't look like you need any help, but I have a couple of old magazine articles (plans actually) from the 30's about building Ford and Chevy Speedsters. Let me know if you'd like a copy.

There is similar build in my future and I am happy to live vicariously thru this build.

Aka...It Awesome!!!

You'll need to log in to post.