Hello I am a new member. I love many types of cars but I am mainly into Z cars. I have a 1971 240z with a vg30et engine making somewhere in the neighborhood of 300+ hp at the moment. My question is, because I don't have a working welder at the moment, would brazing be strong enough to hold the spider gears solid ? the braze is rated at 65,000 psi tensile strength.

If you truly get the gears clean before starting it should do fine. Having said that, buy a limited slip diff. I can say from experience that solid rear ends suck for anything other than donuts/drag racing.

Solid rears do suck like ansonivan said. Many off-roaders have welded up the spider gears with some success. But many have broken the differential and axles after welding it up, especially if they drive on the street. I would get a limited slip diff as well, better in the long run.

Unless it's a rallycross car. Then it's totally OK. Is it a rallycross car?

I saw guys braze up a motorcycle frame. Had no idea it was that strong of a process. Cool.

+1 a locked rear end sucks for anything but drift, drag & offroad (this includes street driving where it will wreck axle bearings, U-joints and more while eating your tires alive).

If you're not doing one of those three, get some kind of LSD instead. Worm gear type if you just want to keep the silly-spinning down with no maintenance difficulties, or clutch-type if that's not good enough.

Can you really clean all the gear oil out of the diff in car or out to apply the necessary heat to braze the spiders? That's gotta be a lotta heat.

I'd be thinkin' stick weld here even after thorough cleaning/ prep. More forgiving IMO.

... or like they've said, LSD

Many road race cars have run welded rear ends quite successfully, hell many VW racers weld up their R&P in their trans axels. It is said to be the cheapest way to put power to the ground through both driven wheels. Does it have disadvantages, yes it does. BUT when you have a lot of power and can't get the tires to hook up then there is no cheaper way.

You have to change your driving style to make best use of it. You need to have the car pointed where you want to go when you press the GO pedal or have enough power to break both wheels loose and power slide the rear around a turn!

A quick Google says the 240Z has an R180 rear end and a later R200 with limited slip is a direct swap.

You won't like welded up gears when you have to move it around the yard.

http://www.zhome.com/ZCMnL/tech/R200.htm

I ran welded spiders way back in the early '80's on a dirt track car, it used about 10-12" of stagger to get around the corners. Broke the welded spider assy once and went straight into the wall. By the time i got it fixed about 2 weeks later, the car had a spool in it.

Don't weld the spiders together or you'll break stuff.

Weld up the root of two teeth 180 degrees apart from each other on each spider.

This will allow a little bit of slack so things can still move around a bit and still let you dismantle the gears when everything goes sideways on you.

Shawn

VGS30

New Reader

9/20/13 3:15 a.m.

Unfortunately I do not have the funds for a LSD at the moment, my future plans are for a wrx LSD, which should be around $800 with the adapters. The spiders are pretty much junk at this point and I would only run a solid axle so I can keep tuning until I can afford a LSD. I will continue to try and find someone with a welder but if I can't I will try brazing.

We had a welded rear in the Z we raced and it caused the L shaped brackets in the rear that hold the suspension and the dif in place to keep braking.

This required that we make up custom brackets. (that will cost you some serious $$$$ since you don't have a welder) After that it was fine. For the track it was fine. The drivers loved it. I hated it as the crew chief moving the car around sucked.

I would get the proper dif in place first then keep tuning as it will probably cost you more in broken parts in the long run.

I don't so much weld anything together, as fill in the teeth so the gears have nowhere to go.

wspohn

Reader

9/20/13 1:56 p.m.

GameboyRMH wrote:

+1 a locked rear end sucks for anything but drift, drag & offroad

No,, it is actually quite useful in road racing. Once you get rolling you have a very controllable car. The only time it sucks is pushing it around in the pits and when it rains.

ncjay

HalfDork

9/20/13 4:59 p.m.

I tried welding spider gears in a Chevy 10 bolt rear back when I was dirt track racing. First time was unsuccesful. Did you know that welding takes all the heat treat out of a gear? I would probably never attempt to braze anything inside a diff, but it could work. My experience taught me to just do it the right way, either a limited slip or a spool.

https://www.google.com/search?q=welded+spider+gears&rls=com.microsoft:en-us:IE-SearchBox&tbm=isch&tbo=u&source=univ&sa=X&ei=RcQ8UqOcJvW-4APih4CYDw&ved=0CCsQsAQ&biw=1152&bih=721&dpr=1

jimbbski wrote:

Many road race cars have run welded rear ends quite successfully, hell many VW racers weld up their R&P in their trans axels. It is said to be the cheapest way to put power to the ground through both driven wheels. Does it have disadvantages, yes it does. BUT when you have a lot of power and can't get the tires to hook up then there is no cheaper way.

You have to change your driving style to make best use of it. You need to have the car pointed where you want to go when you press the GO pedal or have enough power to break both wheels loose and power slide the rear around a turn!

I just reread this,

Weld the R&P. Don't think it will travel very far.

I remember seeing a picture somewhere that some one actually did it.

Wally

MegaDork

9/20/13 7:50 p.m.

We ran many asphalt circle track cars with welded rears without much trouble. The only one that would complain was my Mom, Dad welded up the rear in his spectator drag Monte and one winter when her Fairmont puked yet another tranny she had to use it to take us to school in the morning. Nothing spices up the car pool like trying to get all the kids to school in the snow with a Big Block and a locked rear.

VGS30

New Reader

9/21/13 12:54 a.m.

dean1484 said:

We had a welded rear in the Z we raced and it caused the L shaped brackets in the rear that hold the suspension and the dif in place to keep braking

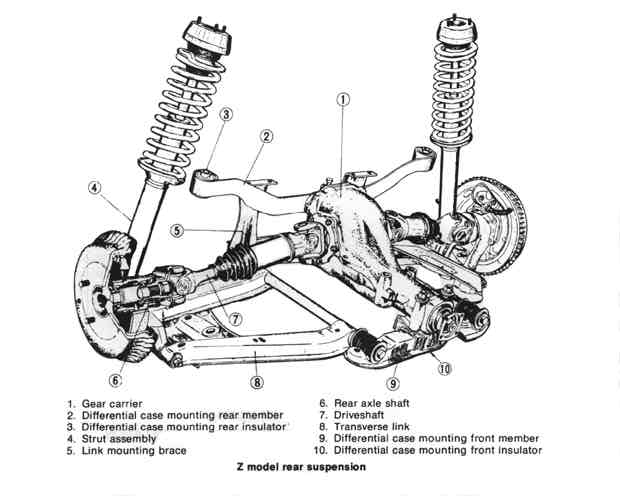

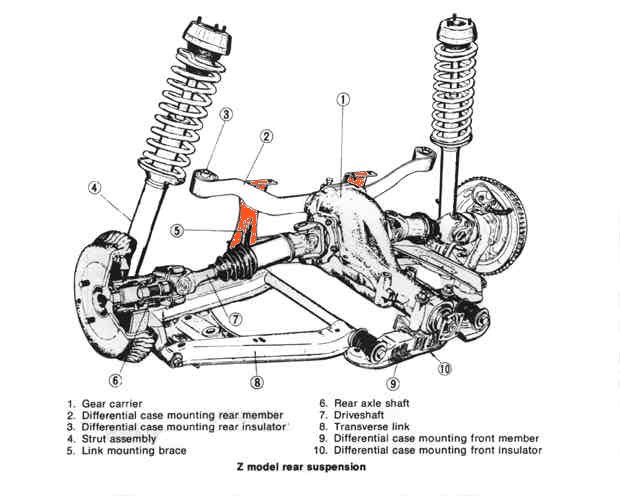

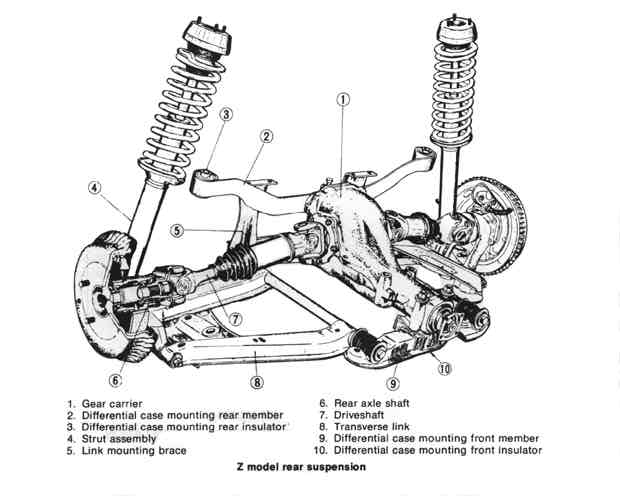

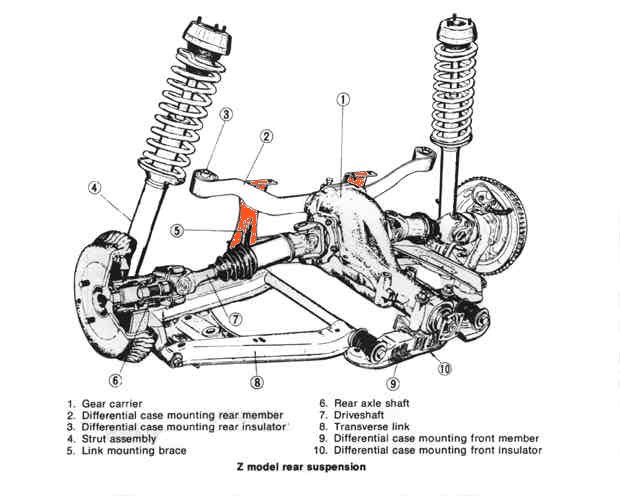

I am not sure what L shaped brackets you are referring to, the 240z diff is mounted to the mustache bar in the rear and to a diff mount in the front which is C shaped.

VGS30

New Reader

9/21/13 3:01 p.m.

well I just brazed it, I got a good braze on it both sides. I did all four corners. I just need to pickup a new gasket and some gear oil and then I am putting it in.

Confused. Brazed "IT". Braze both sides. all four corners. ?

The pieces in red are what I am talking about from the side they look like an L

I'm a big fan of a mechanical locker IE: Tru-trac, Spartan, Detroit, Grizzly heck I even like the centrifical force G80 locker....

I've run a true Posi and it sucks...

A mechanical locker is plenty rowdy on the street with 450+ hp especially Grizzly and Detroit but at least you can actually turn without power sliding.

I think you will regret the welded spiders. I also think if you have the money to throw down big numbers... You better make a plan and save some money to apply it.