IamFODI

New Reader

9/30/23 2:38 p.m.

Been reading up on the Control Blade rear suspension in a lot of Fords and Mazdas pre-2014 or so (e.g. our family's own 2012 Mazda5). One thing I've seen mentioned in multiple places – though not everywhere – is that the blade itself is meant to flex so that other joints in the suspension can move as intended. E.g.: https://www.edmunds.com/car-reviews/track-tests/2010-mazdaspeed3-suspension-walkaround.html

[quote]The control blade (blue) is a trailing arm that locates the wheel in the fore-aft direction. The trick here is its very thin cross-section that allows it to flex a little so it won't interfere with the smooth operation three lateral locating links.[/quote]

Fair enough. Makes sense of the fact that it's a blade rather than, say, a boxed design like a lot of front LCAs.

But the forward bushing also has a bunch of compliance, right? Given that, how relevant is the compliance of the Control Blade? Like, if something needs to give in that part of the suspension, won't it be the forward bushing rather than the blade itself? What's the blade's own compliance really adding?

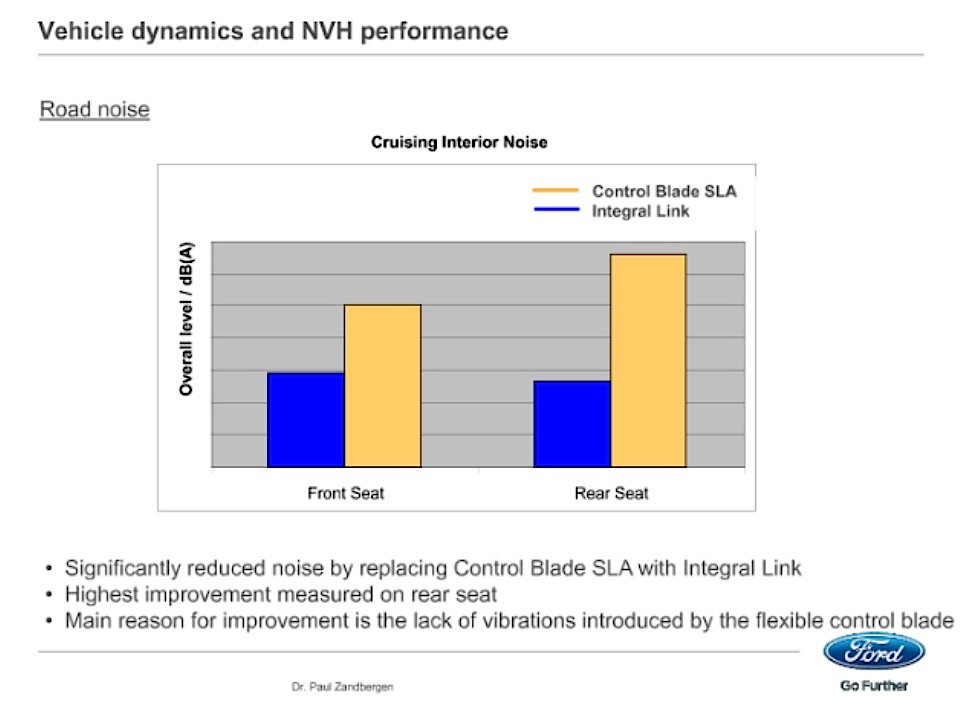

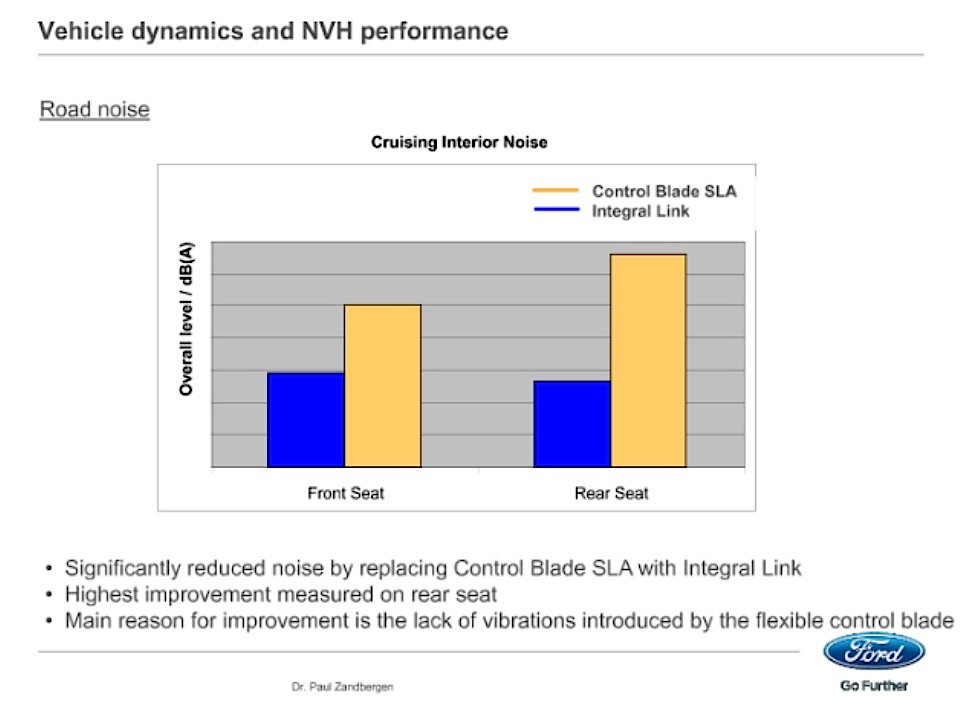

Been thinking about this because I came across some presentation slides from when Ford eventually replaced Control Blade with a design based on an integral link. They cited the flex as a weakness of the design because it generates its own vibrations:

Ignoring practicality for a moment, if one were to make the Control Blade a bunch more rigid while keeping the stock forward bushing, how much (and what) would be lost? Would it just toe in less under compression, or might things start binding up?

Curious to hear any thoughts on this!

I'd like to believe that if they intended to have it flex, they wouldn't have put bushings in it.

I will tell you this: when those bushing do get worn out, it makes the handling spooky as berk.

It does sound like there's some redundancy between the control blade flex and the forward bushing compliance, it looks like if the forward bushing were a spherical bearing with a lot of freedom to rotate, there would be no need for control blade flex at all. It's hard to guess at how much compliance the bushing provides, it may not be as much as you think, cylindrical bushings have been found to give far too little compliance for triangulated 4-link live-axle suspensions for example.

Yes, it has to flex.

An amazing number of suspensions are reliant on the metal parts being flexible in certain axes. Much to the consternation of people who box in their control arms.

In reply to Pete. (l33t FS) :

Since most springs are made of steel, I'm going to say that almost every suspension relies on flexing metal :)

In reply to Keith Tanner :

...now I want to take a steel Corvette transverse leaf spring and figure out how to stick ball joints on each side and mount it securely enough to the chassis to act as a "living hinge" type control arm.

In reply to Pete. (l33t FS) :

That sounds...interesting. It was probably done by Colin Chapman at some point. Didn't he use a sway bar as an upper control arm on the Seven?

In reply to Keith Tanner :

The AC Ace used transverse leaf springs as upper control arms, front and rear. So did, apparently, 260 and 289 Cobras.

Chrysler used the torsion bars as tension rods on the Volare and related cars. Ford used stabilizer bars as tension rods on strut cars from the 80s all the way back to the original strut car in 1950, and for some reason or another this was copied by Mazda and Saturn, although at least Saturn put strategic bends in the bar so the tension forces act on the bushings perpendicularly, so they don't get scary under braking the way old Fords would.

So it's certainly not a new idea

dps214

SuperDork

9/30/23 9:30 p.m.

I don't have any specific knowledge but from looking at the images, it looks like the compliance is to allow for toe change. If the link was rigid that would require the bushing to move along its mount axis which isn't really how those bushings are designed to work.

And the AC ace was a copy of John Cooper's formula cars which started as scavenged pre-war Fiat 500 parts. BMW and Studebaker used transverse springs for control arms prior to WW2 also.

Do control blades get installed in areas so narrow that making them more rigid requires more space than available?

matthewmcl said:

Do control blades get installed in areas so narrow that making them more rigid requires more space than available?

It's a trailing arm suspension with toe and camber links and a fancy name. The camber and toe links control lateral positioning, the "blade" part controls longitudinal and rotational positioning.

Lots and lots of people use it. Honda in particular has been using it since forever, although they initially made the arm rigid and put a toe link on the OTHER side of the main bushing ('88 Civic), which necessarily had to have a ton of compliance since the bushing had to move a lot laterally, and also gyrate, but mostly stay still longitudinally. But it's what has been under their SUVs since forever in this simplified form. Having the toe links closer to the wheel allows the blade to NOT have to be rigid, and thus lighter. The only real loads it sees are braking loads.

GM uses it too, and I am pretty sure Chrysler does as well. Actually, I KNOW Chrysler does, because half the cars they made in the past 20 years were based on an old Mitsubishi design and IT used that setup. And VW uses it.... it's a really simple, lightweight, low NVH, durable way to have an IRS.

If they made it more rigid, it would require replacing the blade with two links, which adds weight, cost, complexity, and NVH.

In reply to Pete. (l33t FS) :

I guess I was just wondering about boxing the arm in and/or making it more rigid. I definitely see the appeal to the design. I plan on building something similar for my Rabbit, eventually. Having lateral links behind the axle line and a front link riding the body line should leave a lot of space in the rear seat area for "stuff."

Actually, along that line, a flexible blade allows the arm to be bent by toe control links, as that suspension approach does nasty things to toe at longer travels. I am looking at having something like a more rigid blade hold a knuckle, myself, but that is not the penny pinching approach.

IamFODI

New Reader

10/1/23 8:43 a.m.

dps214 said:

I don't have any specific knowledge but from looking at the images, it looks like the compliance is to allow for toe change. If the link was rigid that would require the bushing to move along its mount axis which isn't really how those bushings are designed to work.

Now that makes sense! Thanks!

2018 Escape with 57k miles. Twist arm bushing completely separated from arm. Nice.

IamFODI said:

dps214 said:

I don't have any specific knowledge but from looking at the images, it looks like the compliance is to allow for toe change. If the link was rigid that would require the bushing to move along its mount axis which isn't really how those bushings are designed to work.

Now that makes sense! Thanks!

To click another piece of the puzzle into place, for stable and secure handling, the generally accepted suspension geometry toes-in in compression, for roll understeer (negative feedback loop when the car leans in a corner). The geometry also toes-in in droop, to make a light rear more stable in braking.

Aha! Suddenly that goofy Honda Civic toe link makes sense!

This desired trait is easiest to achieve with normal length camber control links and a short toe link. If the toe link is close to the axle, it can be attached to the subframe where NVH can get lost into the subframe bushings. But this means that the chassis end of the trailing arm ("blade") has to be compliant on axis. Or the trailing arm needs to be bushed at both ends. Or, the simple route, it needs to be a little flexible in that direction. A flexible arm is actually the better route here, because the bushing does not have to be engineered to move a lot on axis.

That pic that Angry posted is pretty unusual, and I would be looking for bent links or other damage. Axially speaking, that bushing sort of floats there because suspension loads don't push it that hard.