In an effort to get my stinky catch can out of my engine bay.. I'm gonna plumb up an evacuation line to the exhaust.

Summit sells the venturi that's welded into the exhaust pipe.

Whos running one? On a turbo car?

The kits look like they only connect to the valve cover. What about the crank case vent? Block it up...?

Just T them up, or run them to separate venturis?

What if at redline the exhaust became positive in back pressure? Could only one vent be plumbed to the venturi and the other be vented to atmo with a check valve that would only vent under positive crank case pressures?

I have a straight through cherry bomb and straight through magnaflow mufflers with 3" system.

Any advice?

Vigo

UltimaDork

1/9/19 9:13 p.m.

All i know about it is from doing some experimentation of my own with no 'kit', and from that I learned that the angles are critical and that the exhaust wont 'pull a vacuum' unless the velocity is pretty high, so only at higher loads. I dont know if a 3" exhaust would ever have a higher pressure (post turbine) than the crankcase will under full boost, so that may not be an issue.

I was thinking that too.. But just in case it would be good to have some sort of relief when it absolutely matters most?

Some of the kits come with a bung that's cut with the required installation angle.

So what kind of inhg did you see?

I'll be plumbing in post 02 sensor.

What about using a crankcase scavenge pump and running the output of that to the exhaust? Or do you have a reason for not running a more conventional setup that has the engine burn the gases to get rid of the smell?

Gimp

SuperDork

1/10/19 8:42 a.m.

We were talking about this in another thread. They work best on open exhausts - if you have a muffler you won't pull as much vacuum.

Also, if you plan on running SCCA autocross, don't do it. They aren't allowed in any class, best I can tell, for safety reasons.

Vigo

UltimaDork

1/10/19 10:10 a.m.

Or do you have a reason for not running a more conventional setup that has the engine burn the gases to get rid of the smell?

Broadly speaking, bigger ring gaps means less cracked ringlands but more blowby. Since oil fumes lower 'effective fuel octane' in the cylinder, people who are running a lot of boost tend not to want to recirculate them back into the intake. Plus, you have to introduce them pre-turbo which means you get oil coating the inside of your intercooler lowering its efficiency and being almost impossible to completely clean.

In reply to Vigo :

It's also possible to have the gases drawn into the manifold when under vacuum to cut the smell at idle, etc. and then just dump them overboard when in boost.

In reply to rslifkin :

A vacuum pump is the way to go but thats $$$s.

My current setup has the stinky vapors blowing right at the firewall that there are holes in for steering column and wiring looms etc.. I have no other space for the catch can.

Running 27 psi atm and its pretty annoying.

I have a turbo a super charger and 2 intercoolers so routing the vent to inlet side isn't ideal

If I install it and check its pulling vac its a win? Just need to figure out a failsafe setup.

In reply to Gimp :

I have straight through mufflers., should work?

Gimp

SuperDork

1/10/19 11:03 a.m.

Craigorypeck said:

In reply to Gimp :

I have straight through mufflers., should work?

Honestly, I'm not smart enough to know. I think it will work, but maybe not as well.

The exhaust evac system works mainly at WOT and higher rpms. You see them on drag cars mostly as they run at WOT/high rpms, usually on open headered vehicles. Exhaust systems tend to diminish the effectiveness. How much? I guess it depends on the system.

An alternative vacuum pump is to find the 92-97 LT1 Camaro/Firebird/Corvette engine and use the electric air pump off of it. No belt drive needed and you can run it off a simple switch.

In reply to 81cpcamaro

I see those smaller vacuum pumps and they all seem to be used for brake boosters. I don't think they will scavenge enough at red line to clear the crank. They'd probably block vapors from escaping imo. They seem to be a set capacity and don't ramp up with revs.. I'm already pwming too much stuff! A belt driven system is a no go. And a proper 12v evav pump pulls a lot of amps and its pricey.

Gonna try this and see...

02Pilot

SuperDork

1/10/19 11:48 a.m.

If you mount the venturi in the exhaust stream you can hook up a slack-tube manometer to measure the vacuum at various engine speeds. Then you'll know if you need to supplement with a pump.

How about a real pcv system?

02Pilot said:

If you mount the venturi in the exhaust stream you can hook up a slack-tube manometer to measure the vacuum at various engine speeds. Then you'll know if you need to supplement with a pump.

Thats the plan I'm.going with.

Matt

New Reader

1/10/19 12:38 p.m.

2 things kept me from running a vac-u-pan system on my road race cars. 1) the temp on the collector would require more than a heater hose (which is what they run on the drag car systems). and 2) they work really well, so well they have been known to pull the oil out of the engine. 1/4 mile at a time its not an issue, but after 20 laps i don't want to find out whats left in the engine the hard way or get flagged for smoke coming out of the car after the vapour filter/canister is full...

Craigorypeck said:

I have a turbo a super charger and 2 intercoolers so routing the vent to inlet side isn't ideal

Where can I see this car, do you have a build thread?

I'm thinking the only really good way to do this is with a vacuum pump, and the next best way would be a VTA catch can setup, which is also a smelly setup and doesn't evacuate the crankcase well...

Do you have any pictures of your current catch can setup? Also with a VTA catch can you can always run the vent hose down below the car to keep the stink from coming into the cab.

GameboyRMH said:

Craigorypeck said:

I have a turbo a super charger and 2 intercoolers so routing the vent to inlet side isn't ideal

Where can I see this car, do you have a build thread?

I'm thinking the only really good way to do this is with a vacuum pump, and the next best way would be a VTA catch can setup, which is also a smelly setup and doesn't evacuate the crankcase well...

Running a vta can now... It's difficult to even get at cause i have so little room.

Build thread here but i think all my pics have died...

https://grassrootsmotorsports.com/forum/build-projects-and-project-cars/twincharged-capri/134911/page1/

Matt said:

2 things kept me from running a vac-u-pan system on my road race cars. 1) the temp on the collector would require more than a heater hose (which is what they run on the drag car systems). and 2) they work really well, so well they have been known to pull the oil out of the engine. 1/4 mile at a time its not an issue, but after 20 laps i don't want to find out whats left in the engine the hard way or get flagged for smoke coming out of the car after the vapour filter/canister is full...

If your crank case vented to the exhaust and your cam cover to atmo. The air would be pulled through the engine without creating a vacuum. Would that be ideal?

I use a hybrid pcv/electric crankcase vacuum system for the Shop Mule RX-7.

Here's a link to it's evac system webpage... http://grannys.tripod.com/evac.html

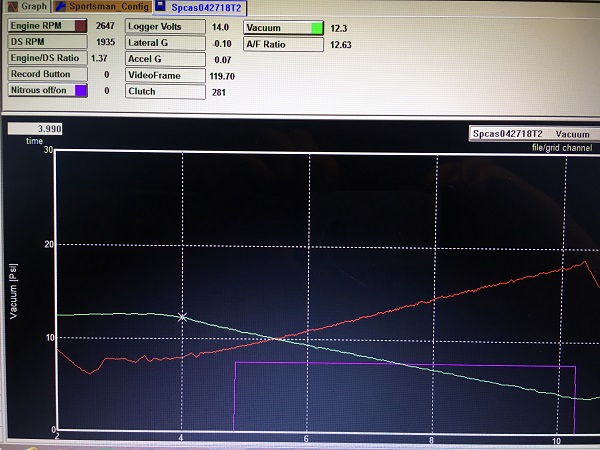

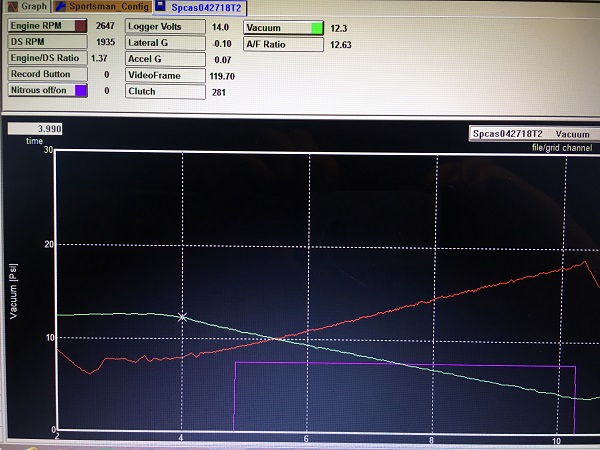

The above data/graph is from a NA WOT 3rd gear pull (2650-6000rpm / 43-99mph) using only the pcv valve shown on the webpage as it's crankcase vacuum source (electric vacuum pump was not switched on for this pull).

Yellow trace is crankcase vacuum

Red trace is engine rpm

Blue trace is the WOT switch for the nitrous (nitrous system was dis-armed)

When I started rolling into the throttle at the 4 sec mark, crankcase vacuum was 12.3"Hg. By the end of the 6+ second pull, the crankcase still had 3.9"Hg of vacuum left. As you can see, there's no reason to activate the electric vac pump unless the nitrous is flowing.

This is a well sealed flat top 355" sbc street engine w/ gapless rings. Well over 800hp on 91oct pump gas when spraying, spins past 9k.

Grant

Vigo

UltimaDork

1/10/19 6:59 p.m.

^That's a lot of information on your webpage! Top notch setup!!

I'm really curious what you had to do to seal the engine for 16" crankcase vacuum, and how/if you measured ring drag on your ring setup.

Just incredible that you can go from 1qt/250miles to negligible with this setup...

Vigo said:

^That's a lot of information on your webpage! Top notch setup!!

I'm really curious what you had to do to seal the engine for 16" crankcase vacuum, and how/if you measured ring drag on your ring setup.

Just incredible that you can go from 1qt/250miles to negligible with this setup...

For external sealing, the dipstick hole was plugged and a sight tube was installed on the side of the pan. The main seals were reversed, and it's got one pc silicone pan gasket and valve cover gaskets that have the metal core and bolt hole sleeves that limit the amount of gasket crush. The biggest pain to seal is the "china wall" between the top of the block and intake manifold. It's easy to find/fix leaks with the engine off, just turn on the electric vac pump and use a stethoscope near the suspected leak areas. I then use the vac pump to clean the leaks, dry the leaks, and then to pull sealer into the leaks.

The engine on the webpage used an $800 Total Seal "Advantage" low tension gapless top ring / Napier 2nd package that was designed for SS Class cars, it used ring groove spacers with lateral gas ports. They reduce ring tension to the ragged minimum for those cars. Torque plate bore/hone. Assembled short block rotating torque was 13.3 ftlbs.

Grant