I'm on a quest this summer to make my car as vibration free as practically possible. What i would like would be some sort of device that i could use to quantify a vibration so that i could tell if my trial and error methods are making things better or worse. For instance, if i used a hoseclamp to mount a sensor to a lower control arm, I'm thinking it will help me use trial and error to balance an entire tire/wheel/rotor as an assembly. I could quantify the vibration at a certain speeds on a designated section of hiway so that i could tell if small adjustments of weight placement/mass are making things better or worse.

I'm thinking i would also be able to fine tune driveshaft balance as installed with yokes/flanges/etc in place under real world conditions, which might result in a better overall balance job vs a typical balance job done only to the driveshaft.

Maybe some sort of an accelorometer interfaced with a voltmeter might work...does this sound like something that i can put together with $35 bucks worth of stuff from RadioShack?

any <$35 accelerometer won't give you enough instant resolution to be worth a bother. We use a few vibration analyzers here, but all of them run $3-4k.

golfduke wrote:

any <$35 accelerometer won't give you enough instant resolution to be worth a bother. We use a few vibration analyzers here, but all of them run $3-4k.

Cheap!

Mine's $15k without software - dual channel.

For lower priced professional grade stuff that's good, check out CTC in Victor, NY.

Most industrial accelerometers are 100mV/g, but they need to be powered to work. If you're looking at things like balance and alignment, you should check out a velometer instead. It's an accelerometer with extra circuitry to convert the acceleration data to velocity units within the sensor. Just better units for the information you're after.

Most are 1/4-28UNF if you're thinking about making mounting brackets. I much prefer the low profile sensors.

I just use them, so I couldn't tell you what you need to run one to pull an overall level from it. I'm one of those weirdos who looks at squiggly lines all day.

With out frequency knowing the amplitude does little help your guessing in the dark.

The commtest VB8 (4 channel) i work with is close to $30K but you don't need that good of an analyzer.

There are "Reed pen" units avalible cheap.

http://www.mcmaster.com/#vibration-meters/=ls4fgo

bet one could find an old TEC or a CSI 2010 on fle-bay but softwear to use it is no longer suported but most stuff can be done on screen.

Fill out your profile so we know where your located etc.

Do a google search for Briggs and Stratton Vibratach. It's what I used to diagnose NVH (well, the V part) problems at the dealership. It'll tell you (with some math and know-how) if the vib is coming from engine, d-shaft, wheels, etc. I think they are usually $10.

just pack the car full of Dynamat and call it good..

There are also some interesting free apps for smartphones that will let you use their built in accelerometers for this as well.

Not top notch of course, but free.

44Dwarf wrote:

With out frequency knowing the amplitude does little help your guessing in the dark.

Agreed, but it's amazing how many "acceptance" specs out there are overall level in ips.

My thought is if he works with overall velocity and is close enough to the component of interest, he'll be able to make improvements.

He's on his own to determine the cause of the high overall level without knowing the frequency(s), but he'll be able to narrow down the problem geographically and go from there.

I think it's a great idea.

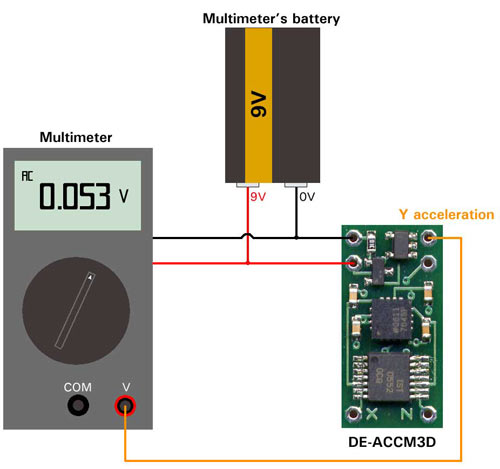

Take one of these (as posted above):

http://www.dimensionengineering.com/products/de-accm3d

And one of these:

http://www.dataq.com/gl/starterkit.htm

Connect DE to Dataq to your laptop.

The DE has 3 axis 500 Hz bandwidth, +-3G range.

The Dataq has 4 channels, and records onto hard drive files, so basically unlimited capacity.

The software lets you play, search, stop, trigger, etc. like a recording oscilloscope.

Drive, record, analyze, adjust.

Repeat as needed.

How we check DIY vibration analysis?

Hello Friends, I want to know how we check personally vibration analysis. What is vibration analysis? How much it is important? Why we use to it. I am concerned. can anyone tell me about DIY vibration analysis?