Help! My naturally aspirated 1988 FC RX7 has developed a hot idle condition that I cannot seem to solve. It started a month ago and is totally consistent. Once the engine is fully warmed up and the car is driven the idle drops to ~450-500 rpm instead of ~750rpm like it used to. Basically it is barely running and will sometimes stall unless I blip the throttle. Note that if I start the car and let it idle in my driveway it goes through the normal cold high idle cycle (greater than 1,500 rpm) and about 15 minutes later will drop down to the normal hot idle speed of ~750 rpm. However, after I drive off, the first time I put the clutch in the engine will drop to ~450-500 rpm. The engine responds fine to throttle input and pulls as normal. However the hot idle is now way too low. I checked the resistance values for the BAC and AAV air valves. All is fine. I checked the resistance values for the TPS. They resistance values are a bit high at hot idle (i.e. after the thermo wax "sensor" is good and hot and has kicked the throttle shaft off the hot idle cam). The manual says the TPS should read 1K at this condition, but I am getting 1.5K. However, since I have owned the car this is how the TPS has read at hot idle. I even built the two LED test light tool and could never get the TPS set to illuminate "one light at a time" as suggested on the famous aaron cake idle webpage. At this point I am completely stumped. As I mentioned the car runs fine other wise. None of the vacuum hoses came loose, I triple checked (even though a loose hose should raise the idle, right?). I had replaced all of the hoses a couple of years ago so they are all in good shape. I did run a couple of bottles of Techron Fuel System cleaner through the tank this summer. Perhaps I have some debris in the filter restricting flow? I will change the fuel filter but am worried that this is not it. Any other ideas? Temp sensor perhaps? Does anyone know which of the three Temp sensors (rotor housing, back of water pump, radiator) contributes a signal to the idle control logic? Any other thoughts? Thanks in advance. -Ray

Any thoughts from the GRM collective. Many thanks in advance.

Quick clarification question: If you kick down the fast idle early, will the engine eventually idle normal (ie: stalls when cold) but if you drive around for an hour then it idles fine?

Second question: Have you done a compression check while the engine was cold?

It sounds like you've covered all your bases (AAV, Thermowax, TPS, Etc). I think if you had a vacuum leak then the problem would manifest itself no matter what the engine temperature was (when I had a vacuum leak my engine wouldn't idle at all).

To answer your questions (and I'm no expert here, just a previous owner): Temp sensor sounds like a long shot. As whatever the culprit is seems dependent on a static warm up procedure (it's when you kick down the fast idle the problem manifests itself, the temperature sensors don't have much input there, I think). That being said, I'm not sure which of the temperature sensors the computer uses, but I think the one on your radiator is actually a coolant level sensor. From there I would just disconnect one sensor at a time when the engine is warm (and off) and see which one makes the temperature gauge on the dash go "wonkey" (then you know it's the "other sensor" the computer is using).

If you had debris in the fuel filter I think you would see problems under acceleration, not at idle (and vice versa, if you had problems at idle then you're sure as hell going to have problems under acceleration).

Other thoughts: Are you sure the thermowax is good? That was my first "go to".

Crap, I reread your post. Now I read it as "when warm and driving = really low idle". Why not just adjust your idle? (I still would really recommend doing a compression check though). The adjustment is on the top of your throttle body and takes a flat head screwdriver. Loosen the hold nut, I think you tighten the screw, and see what happens. I'd count your turns to make sure you can "undo it" if you don't like the results.

That being said, the fast idle could be overcoming a low compression problem that is manifesting itself when the car is trying to run off it's normal idle circuit.

Good luck.

-Bill

In reply to Hungary Bill:

Thanks Hungary Bill. I had been thinking about adjusting the idle using the "don't touch this screw" on the throttle body. It may be my best bet for now.

I really do need to find someone with the proper equipment to do a compression check to see if I am fighting a loosing battle. I may just have to go to the local Mazda dealer and have them perform the compression check. The car / motor has 156,000 miles on it. It seems to pull strong but you never know.

All you really need is some one to crank the engine and you outside holding the compression valve open on the tool and you will get your 3 readings, expect to do it a few times to get used to it.

Don't mess with the 'don't touch it' screw!!!!  Once it's been changed you are pretty well screwed trying to get it to idle right. The idle adjust screw on top of the TB is your next go to, along with being real sure there's no vacuum leaks. Be sure to check the seals on the primary injectors, if they leak (common) it'll never run right. Also yours should have all the crazy vacuum hoses to the oil injectors, be sure those hoses are all in good shape. Definitely do NOT cap those off, BTW.

Once it's been changed you are pretty well screwed trying to get it to idle right. The idle adjust screw on top of the TB is your next go to, along with being real sure there's no vacuum leaks. Be sure to check the seals on the primary injectors, if they leak (common) it'll never run right. Also yours should have all the crazy vacuum hoses to the oil injectors, be sure those hoses are all in good shape. Definitely do NOT cap those off, BTW.

Also be sure the 6 port valves are closing all the way, if one or both are hanging open at idle weirdness will occur.

In reply to Curmudgeon:

Cumudgeon, thanks for the advice. The "don't touch it screw" is currently un-touched. It still has the factory "glue" on it.

I have already adjusted the idle adjust screw on the top of the throttle body. That enabled me to adjust what I will call the "static hot idle" up from ~750 to 900 rpm. Unfortunately, once I put the car in gear and move it, the first time I hold the clutch in (and or put the clutch in, put in neutral, and release the clutch) the "rolling hot idle" drops back down to ~500rpm. I tried spraying water (from a little spray bottle) around the primary injectors with the engine running and it did not seem to make a difference in the idle.

I will check the 6 port valves next.

I'm not sure if it'll affect your idle, but my GTV6 has a long rubber intake tube running from the MAF to the Throttle body very similar to the RX-7. On the GTV6 it's pretty common for these to get old and crack allowing unmetered air in. Maybe turn off the lights in the garage. Shine a flashlight into your tube, look on the outside for light coming through while bending it a little to exaggerate any cracks that might be there?

I'll admit that I'm kind of reaching here...

Also, I think the injectors that you can see easily (without removing the upper/middle manifold) are the secondary injectors. Is that correct?

Ninja Edit!

It just dawned on me that the problem you are describing coincides with the ECU's change from "open loop" to "closed loop" mode. (again, I may be reaching here) But when your engine has warmed up it transitions to "closedloop" from "open loop" bringing the O2 sensor into the equation.

Could it be possible that a malfunctioning O2 sensor is causing the issue?

Good luck man. I'd really like to know what ends up being the culprit

Yep, the injectors you can see are the secondary injectors.

have you moved your AFM? can you adjust the variable resistor (near the passenger side shock tower) to increase the idle? Sometimes I have had an out of whack VR when i swap engines. A little turn of that resistor can change the idle rpm by a lot if the idle AFR is off.

Have you done any work on the car at all right before this happened?

Most of the items you need to check (thermowax, BAC, etc...) I have not had on my cars for 5 years or so. I will not be any help in diagnosing those.

Not so ninja edit: Ohhhh, I like the o2 sensor idea!

Rob R.

Wvumtnbkr make a good point: When all this is sorted out, I strongly recommend a "rats nest removal" as described on Rotary Resurrection

It really cleans up the engine bay and makes things much easier to diagnose and work on. There are a couple things I'd do different than what's in his writeup (like keep the thermowax, not block off the coolant passages, etc) but that's a thread for another day.

-Bill

Oops...you guys are right, I checked the secondary injectors for leaks. I will see if I can spray the primaries too.

I haven't touched the AFM. The car has a K&N filter with an adapter that bolts directly to the AFM. It was already installed when I bought the car 5 years ago. I didn't think about checking the AFM. Good idea! I'll have to check the service manual to determine what the proper function check is.

I may give the variable resistor a shot if everything else checks out.

The strange think about this is, besides changing the oil and running two tanks with fuel system cleaner I have not done anything to the car this season. I started driving it at the end of March and was enjoying driving it until the beginning of August when the problem started.

Thanks to everyone for the ideas.

The primary injectors are pretty well buried. The easiest way to check them is with carb cleaner, use the straw in the nozzle and stick it under the intake at the front pointing back, give it a snort with the engine idling. If the idle changes at all, you have a vacuum leak somewhere under there. From experience, no one sells the injector seals at AutoZone etc, you'll have to get them from Mazdatrix etc.

The variable resistor is there to set the idle mixture. While it can certainly help with an idle issue, that to me is a last resort, i.e. twiddling it first is a 'band aid' for a vacuum leak or other problem.

cwaters

New Reader

9/20/13 7:09 a.m.

Throttle cable is adjusted correctly? Seems like I had a similar problem once and the cable was either loose or too tight and holding the butterfly open a hair when not needed.

No vacuum leaks?

Isn't there something about the coolant temp sensor at the bottom of the radiator that can make the whole world unhappy if it's not working correctly?

is your AFM mounted in an upright fashion? Meaning, is it in roughly the same position it would be in if it was mounted to the stock air box? I know this can cause problems (I realize you said it has been that way for a while).

Also, the radiator coolant temp sensor does not do all that much. Mine is not connected. (no hole for it in my radiator).

Rob R.

I was able to do a little more troubleshooting this morning. Here is what I found:

1) The air flow meter (AFM) is within all the factory service manual resistance values for the various different pin-outs. Note that the K&N kit keeps the AFM in a normal type position and has a bracket that mounts it to the shock tower and the bracket that holds the variable resistor.

2) In its current setting the variable resistor is within the factory service manual resistance values. Either the adjuster is broken or there is a bunch of hard white adhesive on top to prevent an adjustment from being made.

3) The auxiliary port valves seem to be working. I can reduce the idle speed by pushing the actuation rod in. At idle the rod appears to be as far out as it will go. I tried the "white grease trick" and it looks like the actuator for the auxiliary port valves seem to be working too (i.e. the grease gets wiped off the shaft as the actuator pushes the rod in while driving the car).

I just picked up a can of carb cleaner so I am hoping to do the spray test tomorrow to check for leaks around the primary injectors. I also still need to change the fuel filter.

However, I am starting to think that the problem is really related to temp sensor as I think the water temp gauge is reading too low. I have a dumb question. For the temp sensor in the rotor housing the threaded section acts as the ground, right? The single wire is the signal, right? It has a funny connector and the wire is real thin gauge. I am worried about breaking the wire. Do I just pull the connector straight off or is there some type of trick?

Thanks!

If it is a single wire, then it should be grounded to the housing via the threaded (bonded) portion. It has been about 6-years or so, but I don't remember any special "tricks" to removing the wire. Just grip the connector and pull.

If you have the sensor's "resistance versus temperature value" chart then this would be simple (and a good time) to check. Just put the red lead on the temp sensor wire connector and the black lead to the housing and see what it's resistance is. For giggles you could check it in a pot of boiling water (black lead would go to the threads in that case) to see what it's value is when "hot".

good luck!

-Bill

If you want to take a drive up to my place here in MA I can do a comprehensive compression test on your car. I have developed test equipment specifically for the rotary (I have had many of them and got sick of having a dealer charge me for the test)

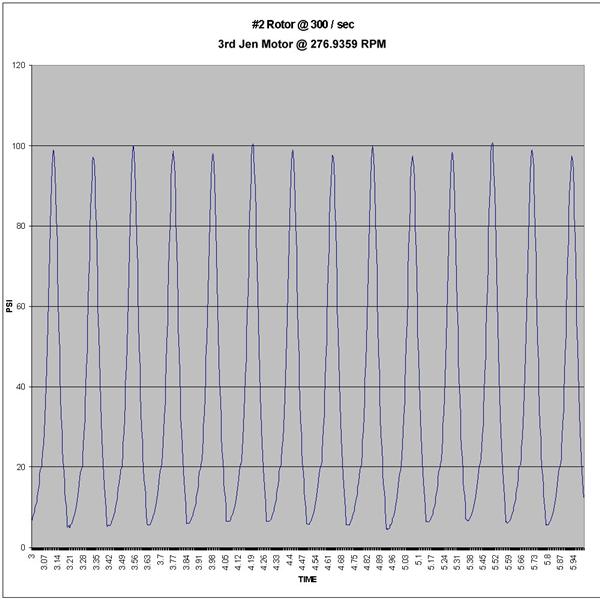

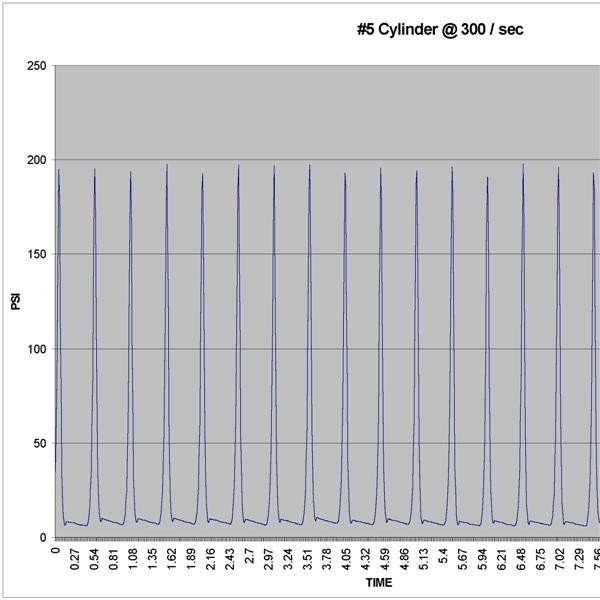

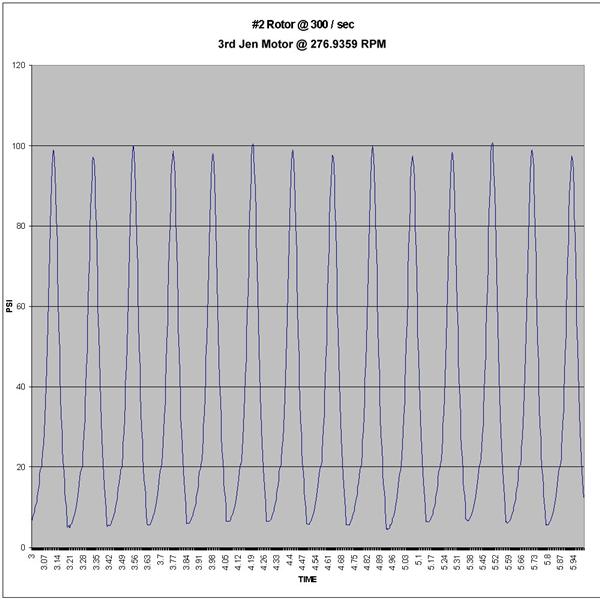

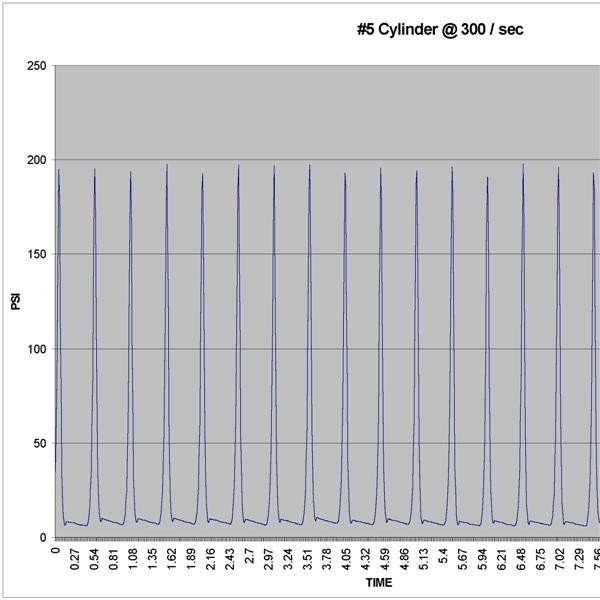

Here is an example of what I get from my testing.

And for those with piston motors I can test those as well. This is what I get.

sweet!

It's like an EKG for our cars!

Hungary Bill wrote:

sweet!  It's like an EKG for our cars!

It's like an EKG for our cars!

Yep. I can tell allot with this tool. I have some fascinating graphs of cars with "issues" It really can give you a really good idea as to the health of your motor. A lot more so than a regular compression test. A subject for another thread for sure. I was trying to market it and sell it but ran out of time and since I was purchasing a house at the same time ran out of $$$ to back it as well. That was 4-5 years back I should probably re visit it now. But I then started the 944 steering shaft rebuilding side business and that has been providing some real good beer money. So this has been on the shelf.

The biggest hurtle was finding a programmer that can write software that can handle the graphing part of it. I tried to teach my self to program but I quickly realized I am better at working / building hardware things. Software programing is an art all in its own. I have come to admire those that can program and do it well. It takes a completely different way of thinking.

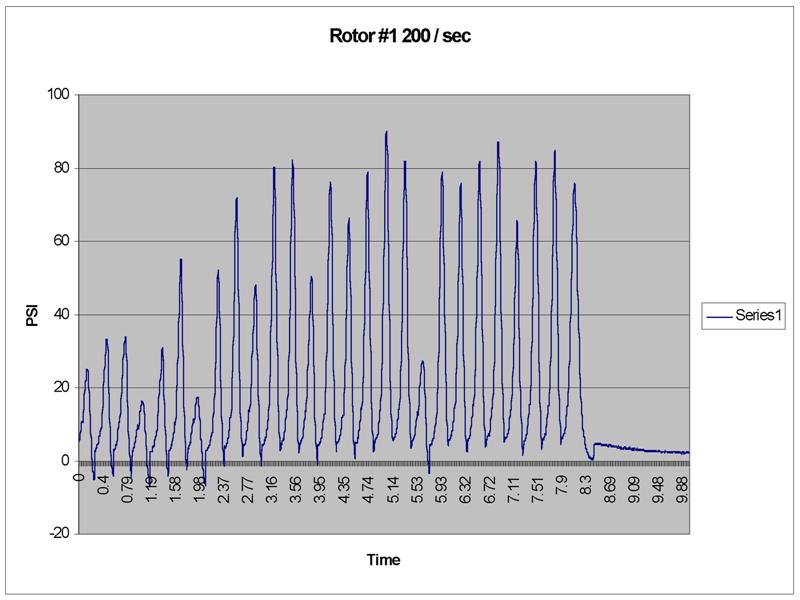

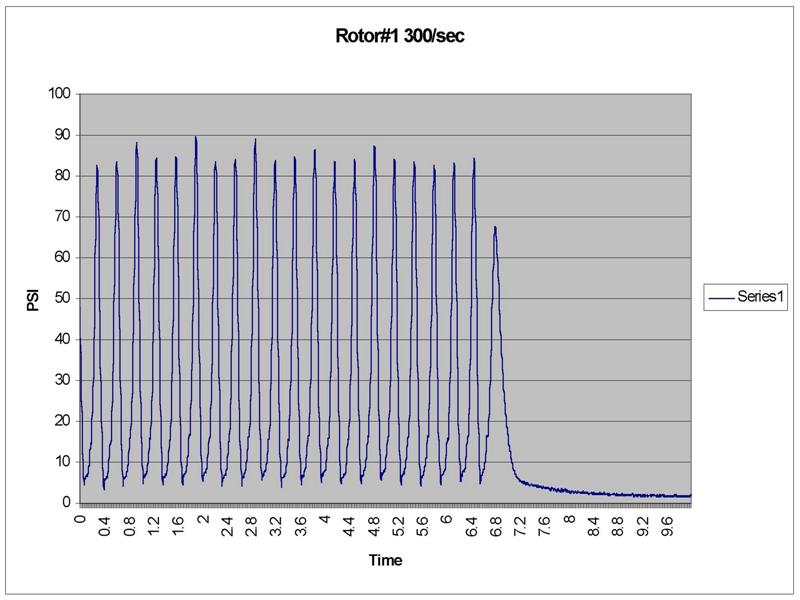

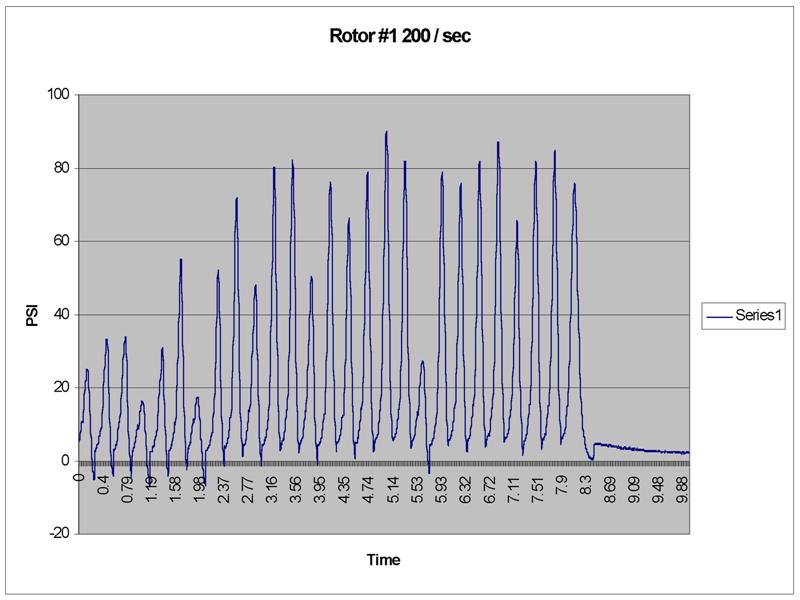

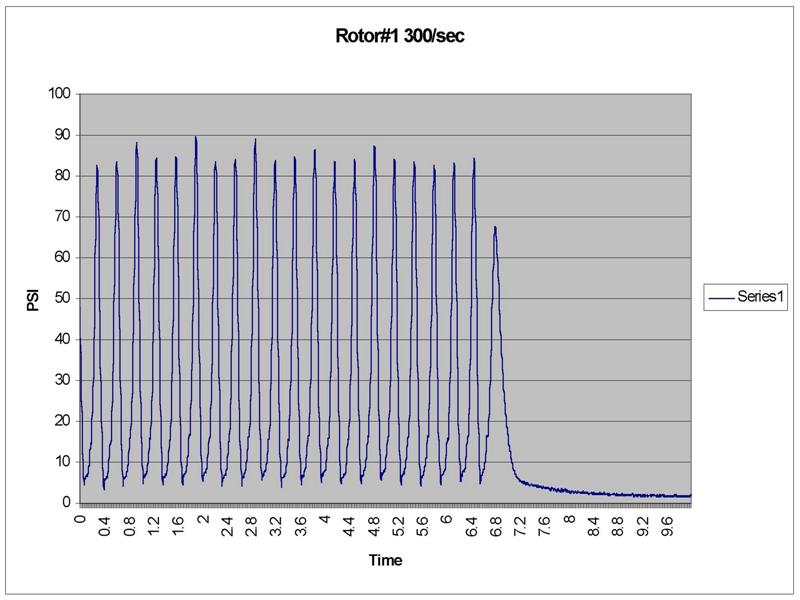

For instance here is a car (my old rx7) with carboned up apex seals

Here it is again after a good ATF treatment.

Got it back to acceptable Compression.

The low temp reading could be the sender, or it could be a bad thermostat. Note: do NOT run a rotary without one! Like a Honda or a 9xx Lotus, no thermostat = overheating.

The coolant sensor for the ECU is in the back of the water pump housing, it has 2 wires. One is 5v reference in, the other is the voltage 'return' to the ECU, not to be confused with a ground. This one, if bad, can definitely cause driveability problems.

The sender for the gauge is the little one back near the oil filter housing, it has one wire and grounds through the threaded body. If this one goes bad, it will only cause the gauge to quit working or read erratically, it won't affect driveability.

The air temp sensor for the ECU is in the intake, it looks a lot like the coolant temp sensor. Those can get carboned up real bad and make them read incorrectly. The flap type AFM has an air temp sensor built into it as well.