Taiden

HalfDork

6/12/11 4:47 p.m.

I have a sandblasting cabinet that I made about a year ago. It works extremely well for the first minute, and then clogs up due to water vapor. At first I was so enamored with the idea of not using sandpaper that I would stick it out. I have no idea how I managed to do two wheels and a motorcycle subframe in this thing.

I need to figure out how to stop condensation from making it out the tip. Even on the driest days it's still absolutely painful to use. I've tried leaving the drain cracked and while that helped, it didn't help enough.

I'm about to sandblast all my suspension bits in the coming weeks so I need to find a good solution to this issue. Hopefully one that is less than $50.

Currently I'm using one of the 110v craftsman 25 gal compressors with a single rubber hose (probably 50' long).

Any ideas would be much appreciated.

Info: http://www.about-air-compressors.com/air-water-separator-for-compressor.html

Prices are anywhere from $10 to around $40

I bought three of the large vapor separators at LowesDepot for around $25 each. I don't recall the brand but there's a camel on the sticker. Each has a filter and a separator bowl. There's one at the compressor and one at the inlet for each reel, then a small one at the outlet for my small blast cabinet. So far so good.

seperators are your friends

Taiden

HalfDork

6/12/11 5:56 p.m.

Curmudgeon wrote:

I bought three of the large vapor separators at LowesDepot for around $25 each. I don't recall the brand but there's a camel on the sticker. Each has a filter and a separator bowl. There's one at the compressor and one at the inlet for each reel, then a small one at the outlet for my small blast cabinet. So far so good.

You talking about this jobbie?

http://www.homedepot.com/Tools-Hardware-Air-Compressors-Tools-Accessories-Air-Tool-Accessories-Hoses/h_d1/N-5yc1vZbb3n/R-100040942/h_d2/ProductDisplay?langId=-1&storeId=10051&catalogId=10053#BVRRWidgetID

m4ff3w

SuperDork

6/12/11 6:19 p.m.

What about plumbing an oil cooler (or a/c evaporator) between the compressor outlet and the tank inlet? That seems like it would help alot to me.

probably cost more and do less than a dedicated moisture seperator

This is better

http://www.homedepot.com/webapp/wcs/stores/servlet/ProductDisplay?storeId=10051&productId=100671465&langId=-1&catalogId=10053&MERCH=REC--product-3--100040942--100671465--N&locStoreNum=2510

Ian F

SuperDork

6/12/11 7:55 p.m.

Taiden wrote:

You talking about this jobbie?

http://www.homedepot.com/Tools-Hardware-Air-Compressors-Tools-Accessories-Air-Tool-Accessories-Hoses/h_d1/N-5yc1vZbb3n/R-100040942/h_d2/ProductDisplay?langId=-1&storeId=10051&catalogId=10053#BVRRWidgetID

That works on condensed water... won't help much for water vapor. The condenser idea in front of a separator would help.

Taiden

HalfDork

6/12/11 8:08 p.m.

have any of you had luck with removing water with a method like this?

I believe the water trap can just be a sack of desiccant pellets or just a toilet paper roll

Taiden wrote:

Curmudgeon wrote:

I bought three of the large vapor separators at LowesDepot for around $25 each. I don't recall the brand but there's a camel on the sticker. Each has a filter and a separator bowl. There's one at the compressor and one at the inlet for each reel, then a small one at the outlet for my small blast cabinet. So far so good.

You talking about this jobbie?

http://www.homedepot.com/Tools-Hardware-Air-Compressors-Tools-Accessories-Air-Tool-Accessories-Hoses/h_d1/N-5yc1vZbb3n/R-100040942/h_d2/ProductDisplay?langId=-1&storeId=10051&catalogId=10053#BVRRWidgetID

Very similar. The trick is to use more than one.

Yeah, more than one. I have one at the compressor, then after about 50' of line, another one, then more line to the tool. Works pretty well, but still not perfect. For super dry apps, like painting, etc., I sometimes add ice water around the first separator.

ww

SuperDork

6/12/11 10:21 p.m.

m4ff3w wrote:

What about plumbing an oil cooler (or a/c evaporator) between the compressor outlet and the tank inlet? That seems like it would help alot to me.

Damn! I just tossed out an old A/C condensor!

Well, looks like I'll be digging up another one. That's a great idea for plumbing in front of my water trap after the compressor outlet.

I would even go so far as to put 2 of them in my distribution system.

Need to figure out a way to connect them to the lines though... Need some way to do it that will hold 125-150 psi without bursting...

to ww:

tubing flare connector to NPT

or compression ftg. will hold 150 psi

ww

SuperDork

6/13/11 1:45 a.m.

THIS is why all the cool people hang out at GRM! ;)

re: condensor

keep the coil ID size consistent w/ the compressor tank outlet pipe, filter/ separator, regulator and hose ID

Ian F

SuperDork

6/13/11 7:35 a.m.

ww wrote:

m4ff3w wrote:

What about plumbing an oil cooler (or a/c evaporator) between the compressor outlet and the tank inlet? That seems like it would help alot to me.

Damn! I just tossed out an old A/C condensor!

Well, looks like I'll be digging up another one. That's a great idea for plumbing in front of my water trap after the compressor outlet.

If you have high ambient humidity and/or your pulling a decent amount of CFM, wire a fan to pull air through the condenser as well. The basic idea is too cool the air quickly which will make the water vapor fall out of suspension, which can then be collected by the separator/filter. Make sure you install the parts so water will drain to the bottom - in at the top, out at the bottom. This should dry the air adequately for sand blasting. For painting, I'd probably add a cheap disposable dessicant filter at the gun.

Some of the links suggested also include an oiler - something you don't want before your sand blaster or paint gun.

Taiden

HalfDork

6/13/11 7:44 a.m.

How could one clean out that weird green AC goop from a condenser? Is that stuff inert? I'd be tempted to just fill it with dish detergent water and then blow it out with my air compressor.

I have a spare evaporator from a cabriolet, it's pretty small and thick (that's what she...  ) that I might be able to use.

) that I might be able to use.

crimson

New Reader

6/13/11 8:51 a.m.

change to copper pipe the rubber air lines really create water vapor.

or an engine oil cooler, this one comes w/ 1/2" npt inlet/ outlet installed so no need for compression or flare fittings. Need to change to a 120V fan tho.

http://www.flex-a-lite.com/auto/html/hd-oil-coolers.html

Taiden

HalfDork

6/13/11 2:53 p.m.

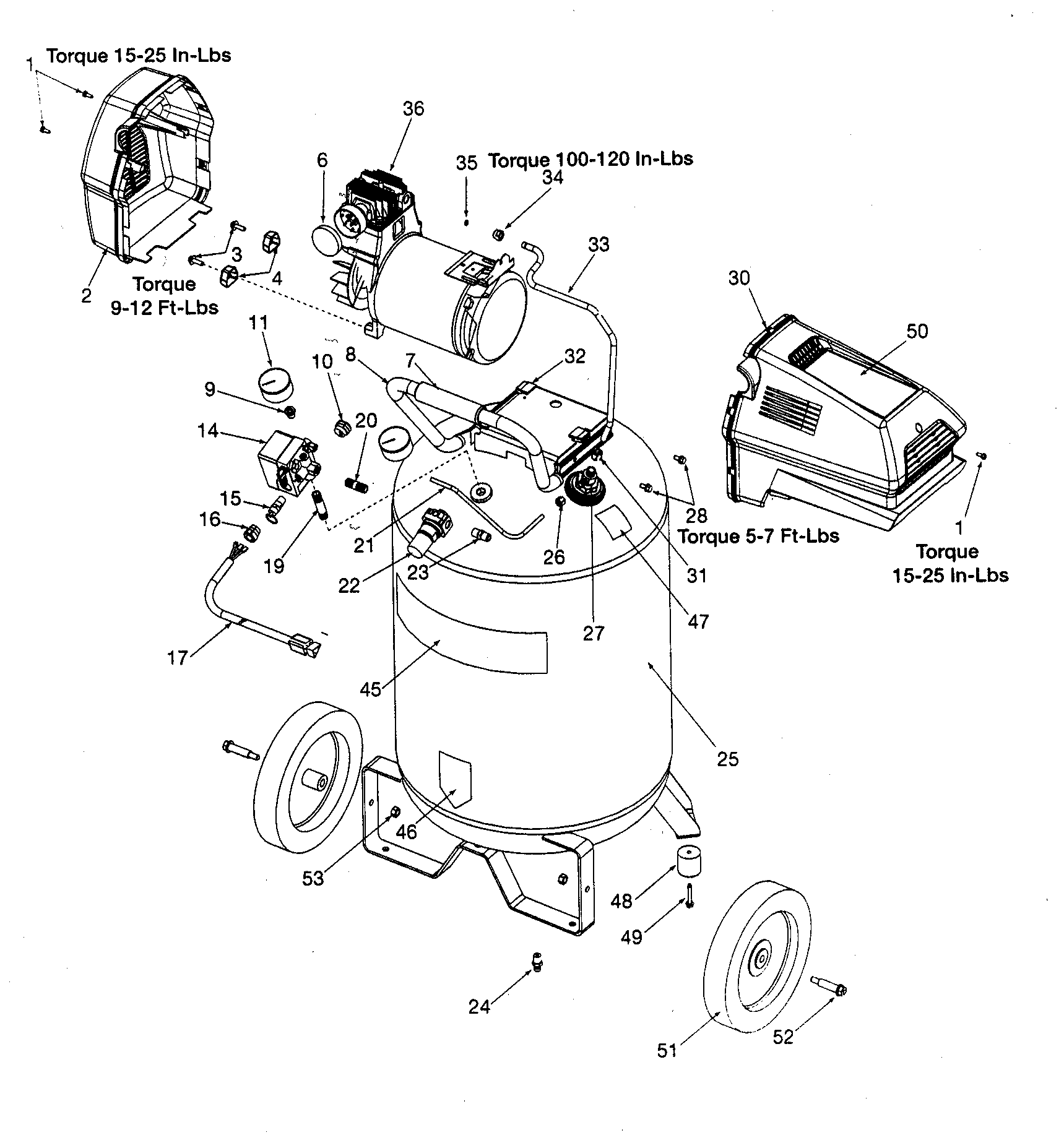

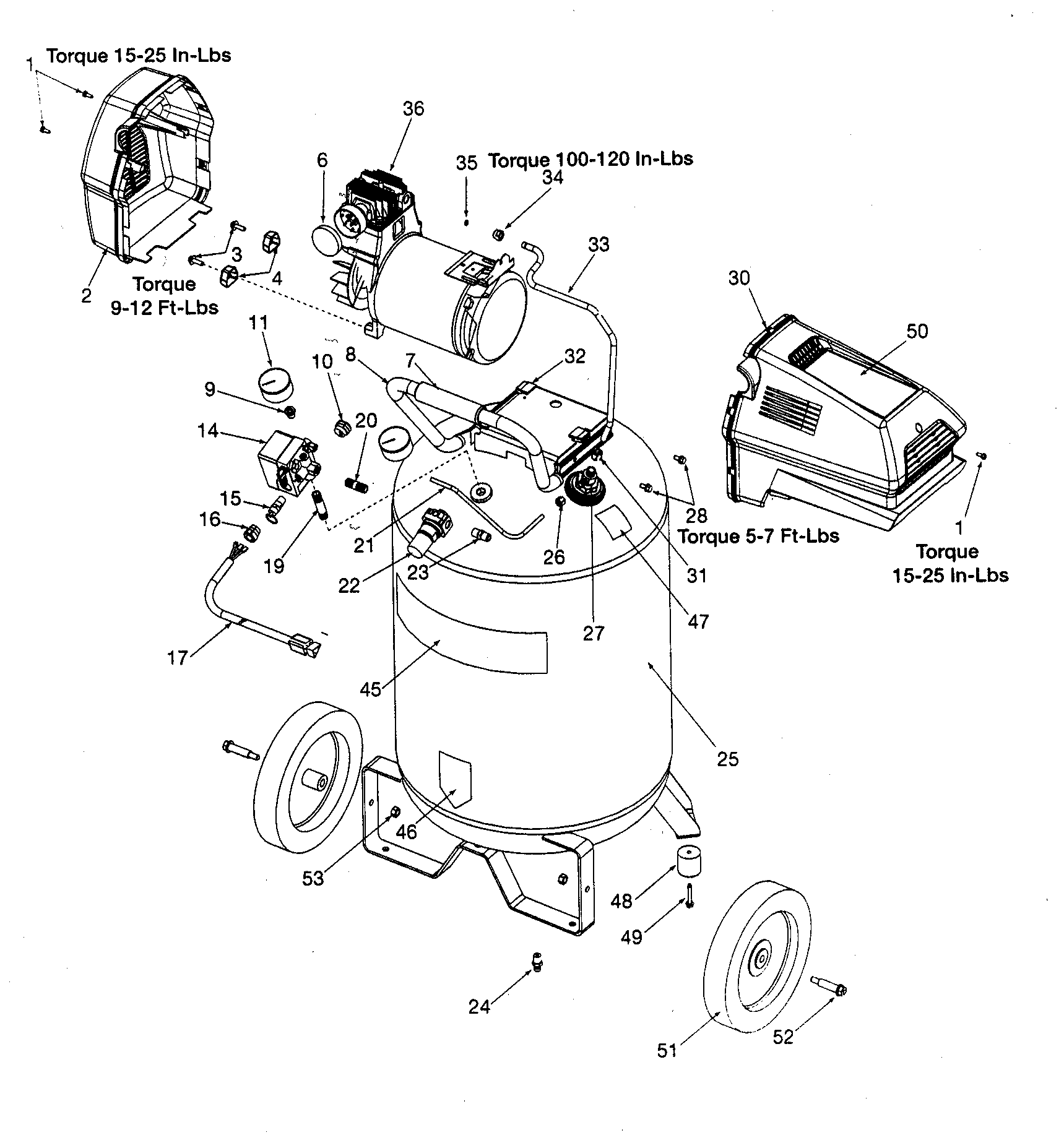

fasted58... I think that's what I'm going to go for. But I'm running into an interesting problem.

The line that goes between the compressor and the tank on my Craftsman compressor use some fittings I cannot identify. They aren't NPT for sure.

Any tips for identifying these fittings?

Taiden

HalfDork

6/13/11 2:55 p.m.

talking about fitting 34 & 31

In reply to Taiden:

You really shouldn't need a cooler between the compressor and tank. The only real benefit of a cooler on the discharge of a compressor would be between the low and high side of a two-stage compressor (referred to as intercooler). The intercooler cools the air from the low side discharge making it more dense going into the high side intake, so more efficient.

In the case of that Craftsman compressor (and most home shop types) the tank will help cool the discharge air somewhat and condense moisture to be removed at the tank drain. The tank will also collect condensate while not in use while just sitting in the shop so the best bet is installing a cooler after the tank discharge valve, then the filter/ separator. Not all filters are separators so watch what you buy. If you have air piping in the shop a drip leg w/ valve on the bottom of the tee would help too.

Taiden

HalfDork

6/13/11 4:07 p.m.

The reasons I had run into for putting the cooler before the tank was to increase the holding capacity of the tank (by making the charge more dense), and to allow the water to come out of its vapor state as it was entering the tank, collecting at the bottom to be expelled by a cracked drain valve.

I ran into this design here:

http://www.dune-buggy.com/webs/Off-Road_Buggies/todd_kirkwood/compressor.html

I bought one of THESE. awhile back, when they were on sale. I don't have the compressor I want as of yet, but had the same model at a shop I worked for, it worked great. Every year or so you'd have to replace the pellets, and everyday drain the compressors.