Dusterbd13 wrote: In reply to egnorant: Won't that overload the two 3/8 bolt that hold the saddle and shaft? Either in shear or tension?

Thought about that as soon as I hit add.

Dusterbd13 wrote: In reply to egnorant: Won't that overload the two 3/8 bolt that hold the saddle and shaft? Either in shear or tension?

Thought about that as soon as I hit add.

Can't you just weld in a Screwjack cup and screw bolt then put a shock where ever it fits then use a rear axel cup at the bottom. looks like early mustang copy look at some upgrades for pony's in the late 60's design

If I have two of each they are yours, I may have a couple of each in the shed. I'll look in the morning. No one even looked at the swap meet,FMV 0.0

On plan b, the s10 bilstien that I have sitting on the bench has been compared to the kybs that came out of the amc. It's a dead shock, but for these purposes....

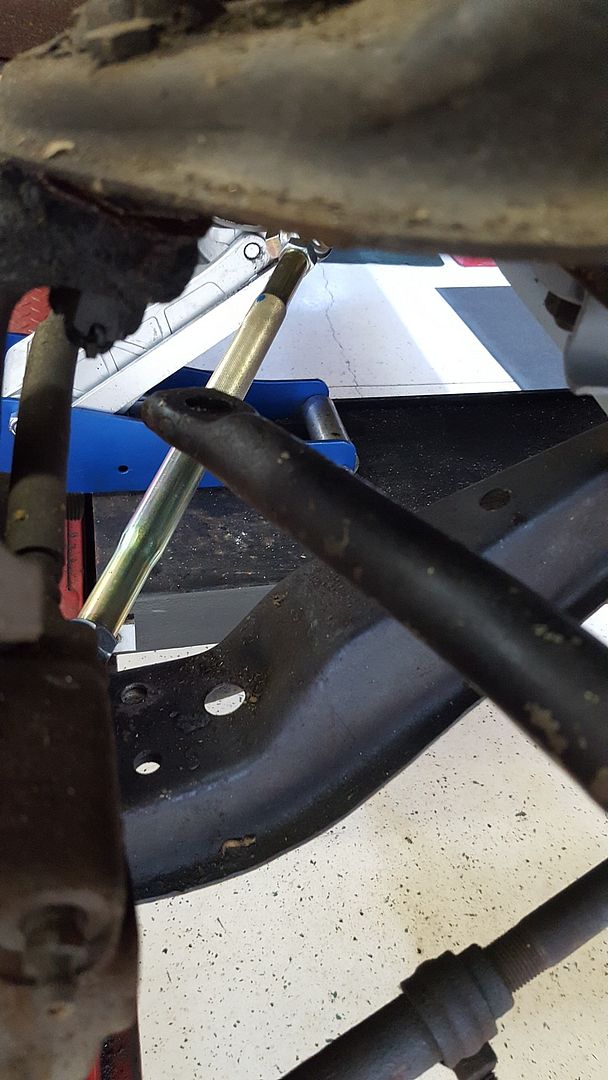

It's actually 1.25 inches shorter compressed in overall length. The threaded section of the shaft is an inch longer than the same section on the amc shock, which if cut and retreated would make it 2.25 shorter overall with a 4 inch ish stroke. The body fits snugly in the coilover sleeve. The crossbar bolt holes are too far apart compared to the amc, so I need to compare it to the spring saddle holes and see what the deal is there. However, the fly in the ointment is that the eye on the shock protrudes under the crossbar about 3/8 to 1/2 inch, meaning that I would have to space it up, losing that much newly found travel and adding stress to the bolt. Alternatively, I could push the bushings and crossbar out, but that would leave me with a bare steel ring that I would then have to adapt somehow to the pin from the factory spring saddle. Might be able to be done with a bearing or bushings get of some sort, but I have no idea how to even research that idea.

Could you just weld in flanges on the control arm to mount the shock at a more appropriate position for range of motion, or am I not over thinking this enough?

I'm going to try to play more with all the different types of shocks I have on hand tonight. As well as take pictures and do a little cad work (the cardboard aided design type)

So, in hand I have 5 inch Circle track springs, really long afco threaded body shocks with coilover springs, s10 front shocks, stock amc parts, mustang front shocks, and an eBay coilover sleeve kit. As well as various lengths of metal. I'm going to try to look at all the options presented in this thread, and take pictures so we can see how they look and if we like them.

So today, I want to keep the brainstorming going to give me every idea and option the hive can come up with to experiment with.

Additionally, I found a 78 amx campaign in trans am by buzz dyer back in the late 70s. He used a threaded body coilover to the factory strut tower, but mounter the lower eyes god knows where and how. The only suspension pictures i have found are worse than my first one in here, showing only the upper.

were a little west of you so still a little dark out, so shower, s t, shave, and i'll go look for stuff, I know i also have some rears the shocks need building and one heim replaced.

you will prob. blow them out. but jags use four so mayhaps 4 electra glide (HD) they don't call them that any mo' I think they are Classics or ultra glide but they are likly expensive

So yeah, im berkeleyed.

Even the shortest shocks are too tall at intended ride heights as the shock body comes through the strut tower.

However i have hope that when I get home and upload pictures of the afco coilover mockups we can figure out something.

Rover P6s had a setup at the front with the shock + spring being horizontally mounted against the A-pillar with a similar rod mechanism to the A-arms transferring the forces to the shock. Maybe that layout would work?

so, in continuation of me making things garder on myself due to knowing there is better options, I present my only real solution other than finding used coils to cut, adapting a s10 bilstein, and dealing with pretty E36 M3ty rates and travel.

what we have here is the hail mary pass. if I go this route, there is NO going back, so it either has to work and work properly, or not be done at all.

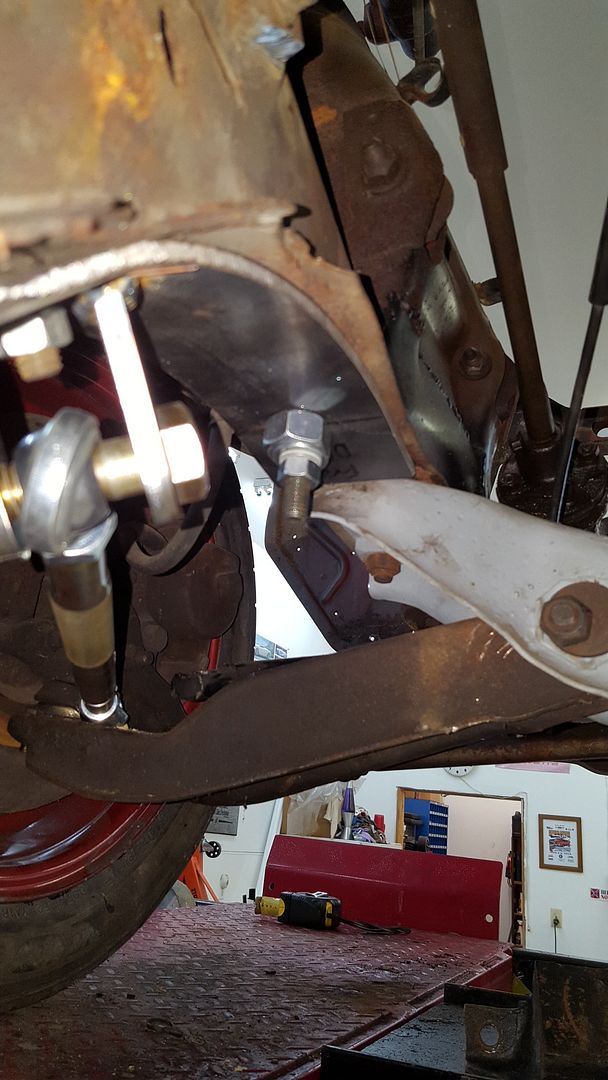

first, this is the suspension as it currently sits. other than coilover, the only things not done are hooking up the sway bar, boxing the control arms, and cutting the inner bushing end (which is bent) from the lower control arm and replacing it with a heim joint while extending the control arm about an inch for more negative camber gain. (unless theres a better way/something I'm missing here)

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_194714_zpsjguxtvyx.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_194708_zpsqbiosmo3.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_194708_zpsqbiosmo3.jpg.html] [/URL]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_194701_zpscdeofydx.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/imagejpeg_3_zpsfbupkiyo.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/imagejpeg_3_zpsfbupkiyo.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_181659_zps1xwwmcor.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_181659_zps1xwwmcor.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_181655_zpsgfmlmkkt.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_181655_zpsgfmlmkkt.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_181643_zps4afu4uw4.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_181643_zps4afu4uw4.jpg.html] [/URL]

[/URL]

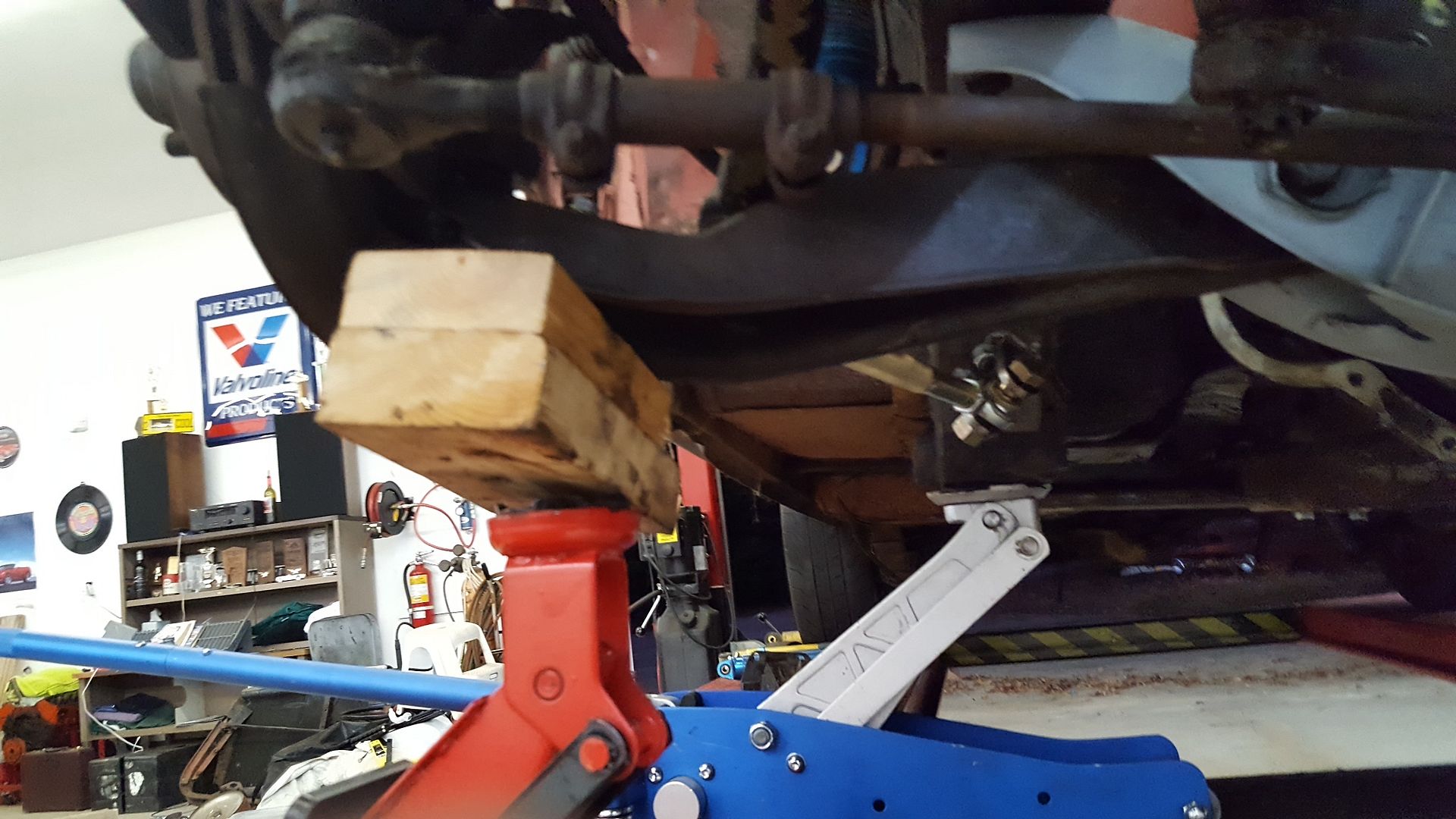

this is an afco threaded body, double heim, circle track shock. it has a total of 7 inches of travel from fully compressed to fully extended. I have removed the factory spring perch and sat the shock in place in these photos, setting the suspension at general ride height based on lower control arm angle. ride height would still need adjusted based upon planned changes and mapping out the camber gain curves after that. this first picture is the control arm angle and tire clearance at current ride height, which again, isn't final. looks to my eye like the outermost end of the control arm will need to come up about 1.5 inches yet, which will set tire and stance right.

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_193232_zpsrfzp2kh7.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_193205_zpsmttkxaxk.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_193205_zpsmttkxaxk.jpg.html] [/URL]

[/URL]

now, there were two general ways I can set this up near as I can tell. if this will even work.

first, I set the shock at the center of travel, and adjusted the spring and perch to be a spacer to hold it there. with this setup, the spring and shock fit through the upper control arm barely resting on a flange in the hole of the upper control arm. upper would need to have the center hole enlarged about .5-1 inch on both sides to allow for movement. the lower end of the shock is out by the balljoint, right wehre the strut rod and sway bar and balljoint all meet. a very busy area in all, but also the thickest steel in the entire lower control arm, as well as the widest area.

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_183558_zpswicpz8az.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_183536_zpsfxfmdljk.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_183536_zpsfxfmdljk.jpg.html] [/URL]

this puts the upper end in the middle of the shock tower, pointed at the cylinder head. this appears to be a single sheet of stamped 14 gauge steel in this area, and I can flex it by hand. no Bueno.

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_183528_zpsrhi4vfvl.jpg.html]

[/URL]

this puts the upper end in the middle of the shock tower, pointed at the cylinder head. this appears to be a single sheet of stamped 14 gauge steel in this area, and I can flex it by hand. no Bueno.

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_183528_zpsrhi4vfvl.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_183531_zpsxdxa4334.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_183531_zpsxdxa4334.jpg.html] [/URL]

[/URL]

so my next thought was to treat it more like a strut. point it straight up and down. to do this, I extended the strut to the extreme end of its travel, moved the coil spring up to the extreme end of travel (its the only coil I have right now. some sort of ebay special..)and moved the lower mount to the middle of the control arm and the upper mount to the middle of the center spring pocket. again, the center of the upper control arm ould need to be cut out. id think that this would bo ok at this point, as it would no longer be supporting the entire weight of the car in its middle. however, the LCA now would be, where it did not before..

there is only about 2 inches of droop travel in these pictures. 5 inches of compression though....

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_184510_zpsbzxog7cn.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_184521_zpsdgbwa6bb.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_184521_zpsdgbwa6bb.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_184525_zpsrjkpzzkd.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_184525_zpsrjkpzzkd.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_184717_zpsyyrceuoq.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_184717_zpsyyrceuoq.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_184720_zpslogsoimx.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_184720_zpslogsoimx.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_184924_zpszpclrtde.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_184924_zpszpclrtde.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_184929_zpscghxxyyn.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/amc/20161028_184929_zpscghxxyyn.jpg.html] [/URL]

[/URL]

so really, these are my options at this point. and I'm well beyond my comfort zone. I know theres things to know about motion ratio, structural integrity, etc, hell, I'm not even sure that it wouldt wind up in some sort of severe bind, as the upper end would be fixed and I'm assuming (and don't know how to check) that the lower point would be moving in some form of arc.

so, theres my brain dump and picture dunp, please, ask questions, offer advice, whatever.

I did find, after much, much research, an AMC spirit that was raced in trans am in 1979. I have blatently stolen the unrestored pictures that follow from adam tarr's photobucket account. it shows the first option I came up with being used, but I'm not certain what all else was changed.

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_3122.jpg.html] [/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_3116.jpg.html]

[/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_3116.jpg.html] [/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_3115.jpg.html]

[/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_3115.jpg.html] [/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_3113.jpg.html]

[/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_3113.jpg.html] [/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_3112.jpg.html]

[/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_3112.jpg.html] [/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_3160.jpg.html]

[/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_3160.jpg.html] [/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_3112.jpg.html]

[/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_3112.jpg.html] [/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_3159.jpg.html]

[/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_3159.jpg.html] [/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_3158.jpg.html]

[/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_3158.jpg.html] [/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_3156.jpg.html]

[/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_3156.jpg.html] [/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_2608.jpg.html]

[/URL]

[URL=http://s180.photobucket.com/user/adtarr/media/Concord/IMG_2608.jpg.html] [/URL]

[/URL]

The other problem is the ridiculous bump steer and camber change, that suspension needs a taller spindle....

I can deal with bump steer, and the extended lca and tall upper ball joint should help cambed gain.

At some point its still a challenge car.

I just figured out that the trans am car has different spindles and the upper control arms have been turned upside down. Appears the innder pivot has been lowered as well.

Hmm....

So, consider this a morning bump for the daytime crowd.

I like 90% of what he has done, I like most of what you are doing, I myself like springs and Shocks Pointing Up And Down not tilted at a 45 deg.angle think more about what you have going and don't hesitate to consider a different Sway bar. it could be easier to move than other components.

But how would I reinforce the lower control arms to deal with the load? Or am i overestimating the forces im dealing with?

Again it loks a lot like early ford mustang,It also dosen't care if its mounted to the top a arm, or from Behind,Your right about forces but most will be on the frame not as much on the arm.

It will snap off the control arm between the ball joint and where the shock is mounted.

The outer arm needs to be boxed at least 2/3 the length and the boxing wrap around the ball joint mounting area.

I think you will have another issue in that the OEM ball joint is not made to support the weight of the car and it will rip the ball out of it.

Change to a screw in lower ball joint and weld a sleeve into the control arm to hold it. Speedway AFCO or others can supply the joint and sleeve.

A tall upper joint will help with bump steer and stupid camber events but you will be very close to it's limit in range of movement. Making an upper arm and moving the inner mounts will give a better result. That will also provide more room for a coil-over.

In reply to bentwrench:

So, would a 1x1 square tube, 1/8 wall, welded to the inside of the control arm from inner pivot to ball joint plate like a spine inside the channel be of help? In addition to boxing it.

All the screw in ball joints appear to be mopar upper ball joints. Is this correct?

forget the tubing just box it. if the rules allow boxing the a arm they shouldn't have a problem with tubular a arms, although a friend once fabbed a set of GM arms over tubulars.

You'll need to log in to post.