Here's a project i'm currently working on. Basically, I am building my own bellhousing to adapt a Ford Toploader 4spd transmission to my old school SB Chev V8. I can buy one for around $450, but it's a heavy 1/4" thick steel monster, and I prefer building my own lighter parts if i can. I'm not concerned about it not being "SFI certified", as it's just a fun street car and i have no desire to make it legal for the track.

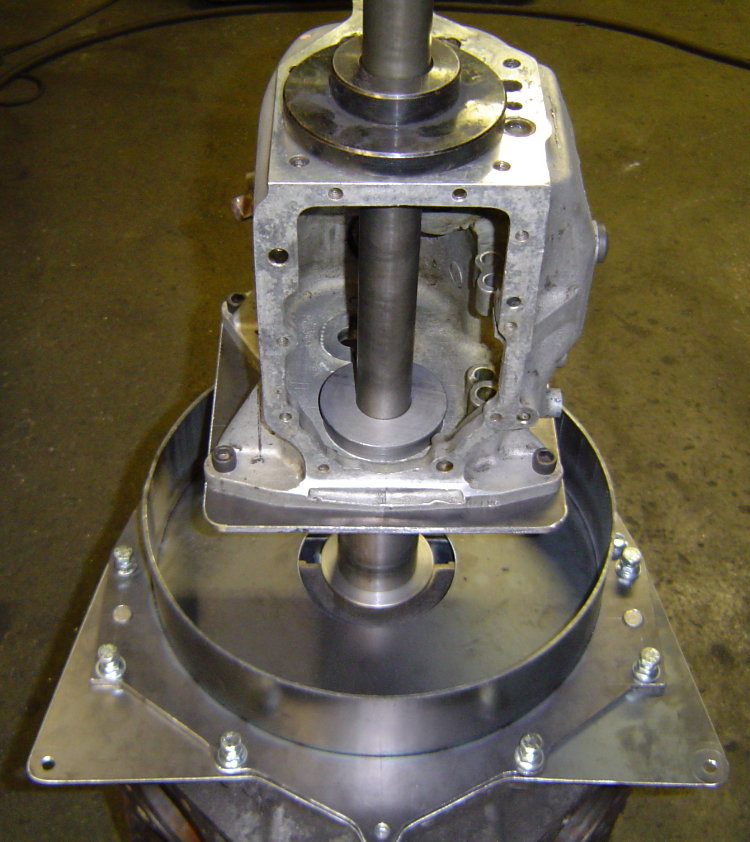

The mock-up began with an old 400 block and an empty transmission case. I am using the alignment bar from my rearend narrowing jig to keep everything straight and true. I spent a couple nights machining some steel pucks to fit in the block's main bearing bores and also the bearing bores in the transmission case. The pucks have an 1.501" hole in the center so that my alignment bar will slide inside everything to keep the engine and transmission bores concentric. I made a ring to center the plate that the transmission will bolt to, and a tube spacer that will set the desired distance between the block and transmission face. I have also made the rear plate that the transmission will bolt to, and have laid out the the flange that will bolt to the block and serve as a pattern for the block plate that will fit behind the flywheel.

Working in my spare time after hours, I expect it will take me a week or two to get it done. The transmission is getting some special work as well, getting faceplated in 2nd, 3rd, and 4th. I'm adapting an aluminum tailhousing from an SROD overdrive trans to replace the Toploader's stock iron piece to shed some weight. Also machined down the Ford throwout collar so that I can use my existing Chevy hyd throwout bearing.

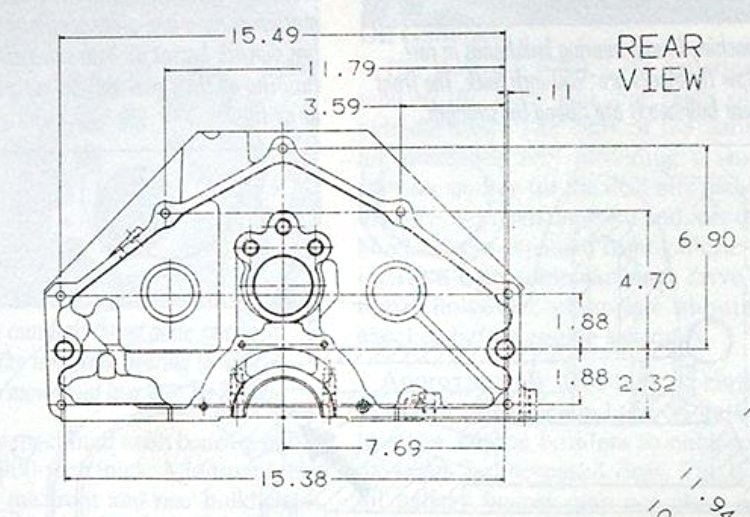

Here's the drawing I used to lay out the block's bolt pattern...

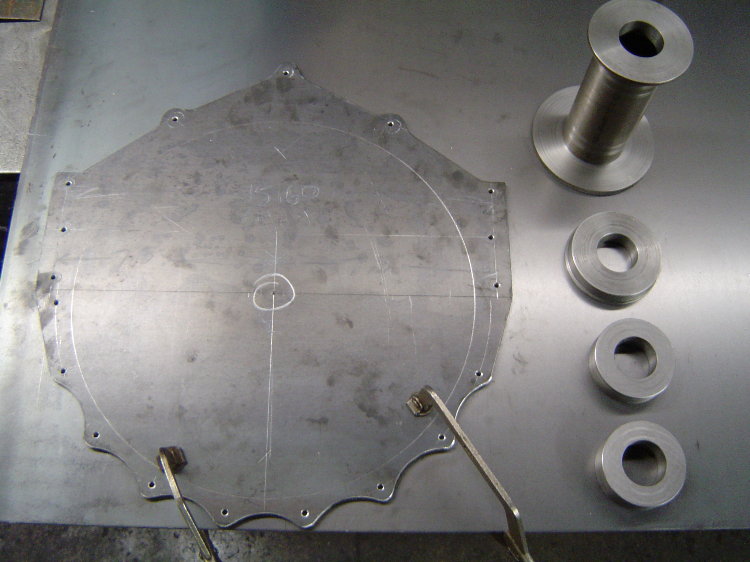

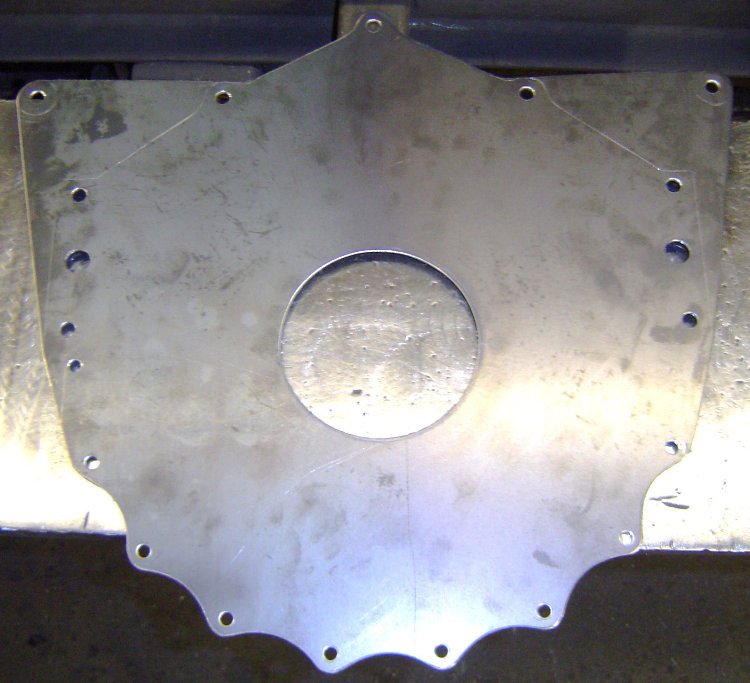

Here's the pattern I made out of 1/4" steel. All the hole locations were laid out, centerpunched, and drilled 3/16" so that the pattern could be transferred to the blank piece of 1/8" that it's laying on, which will be used to make the block protection plate. The steel pucks on the right are the pilot rings and spacer that i mentioned in an earlier post that locate everything in the correct positions for mock-up...

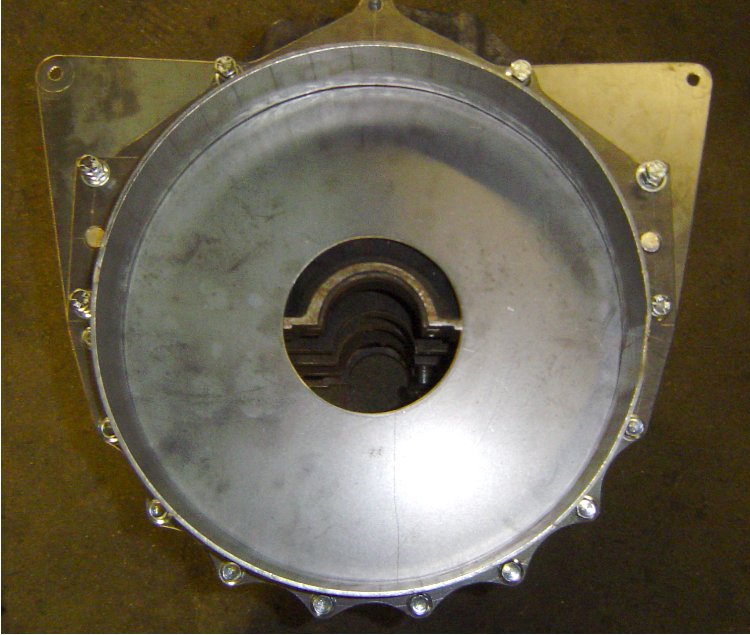

This is the block plate after it was cut out and drilled. The large hole in the center is for the crank's flywheel flange to stick thru, and the 2 larger holes on the sides are for the locating dowels in the block...

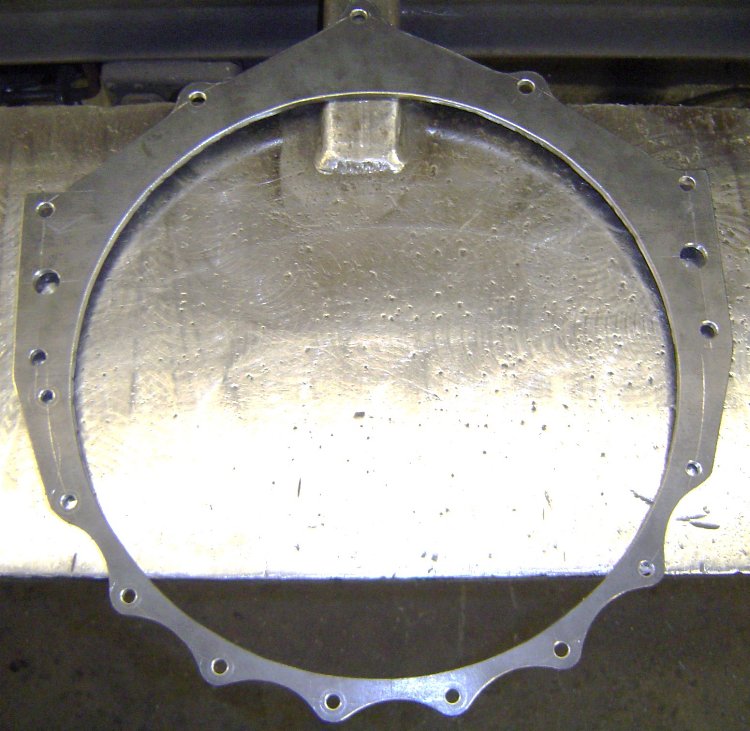

This is the pattern after i drilled it out and cut the center out. It is going to be the forward flange of the bellhousing that bolts to the block, the large hole in the center is necessary to clear the flywheel...

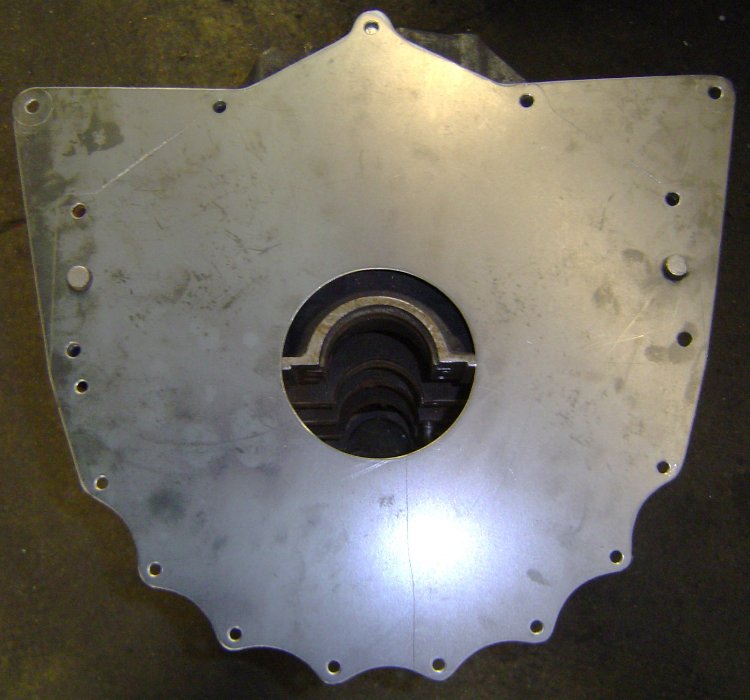

Here's the block plate on a block. The upper "wings" were added as mid-mounting points that will hang the back of the engine from the firewall...

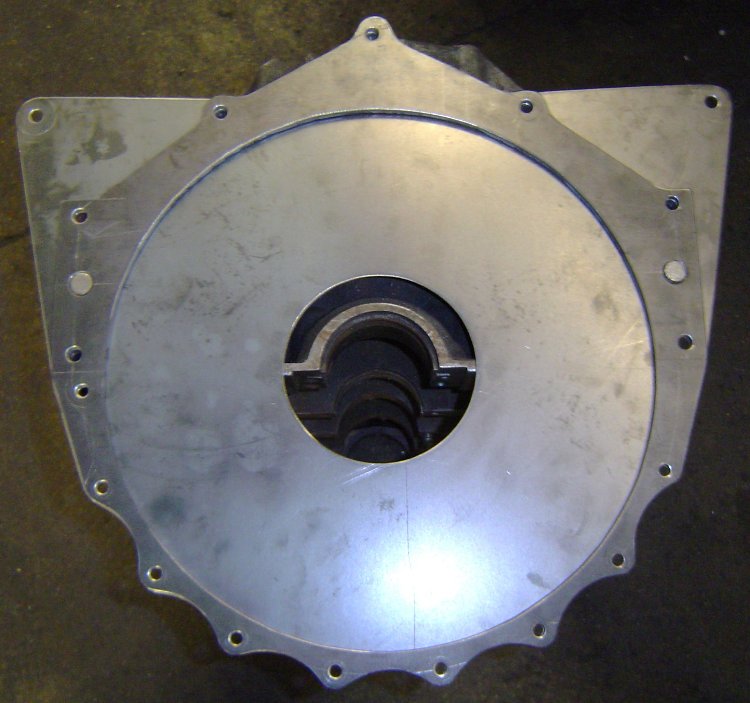

Here's the block plate and flange on a block. The block plate will be sandwiched between the block and bellhousing as shown. I'll soon be creating a hole and pocket for the starter.

The mid-mounts incorporated into the block plate allow me to easily remove the bellhousing/clutch/flywheel from the car without needing to support the engine. Greatly simplifies clutch and transmission maintenance.

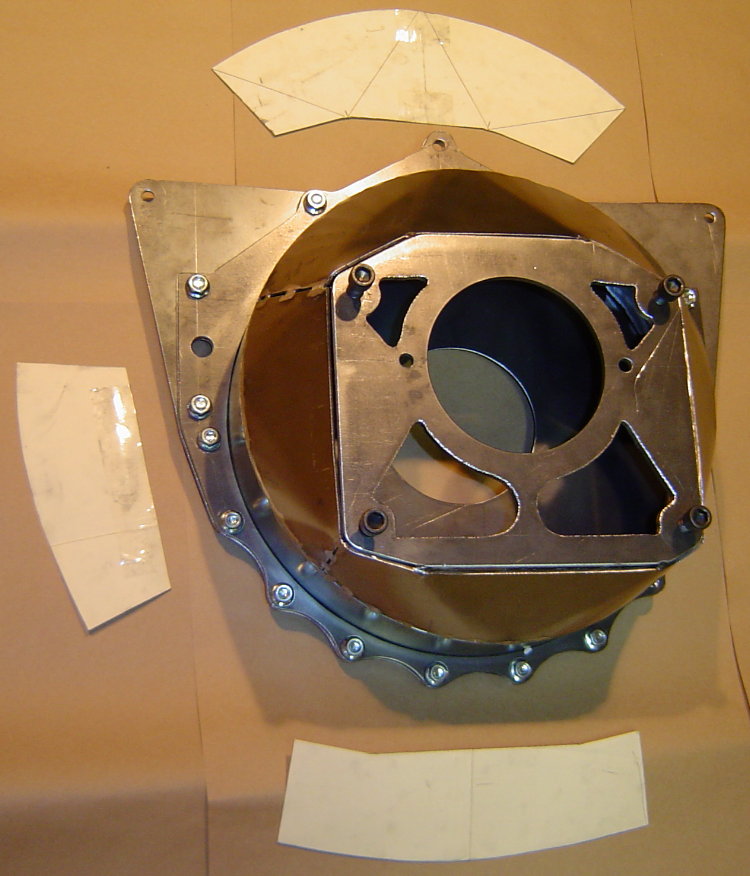

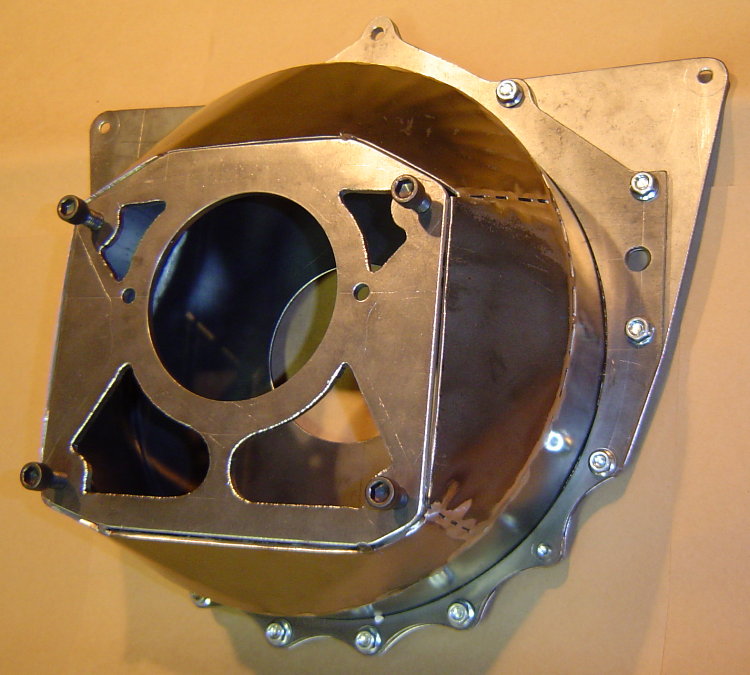

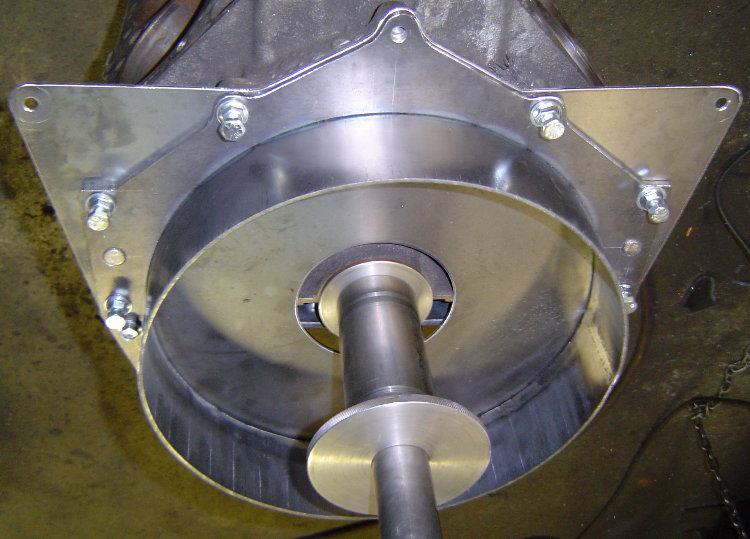

Here I welded the rolled ring to the bell flange, all the holes still line up...

When i made the parts, all the holes were drilled to the same size as the bolts that go thru them. My thinking was that it would keep everything as precision as possible during fab. After i'm done with all the welding, i'll drill them out one size over to allow easier/quicker assembly, maybe 2 sizes over if i decide to powdercoat it.

Here's the alignment bar in place in the block, as well as the spacer that sets the depth between the block and trans case...

Here's the trans case in position located by the pilot rings...

I'll post updates over the next week or so...