to try and limit the variables lets establish the requirements to be meet:

lightweight; just have to be strong enough not to flex with air traveling over and accomplish the remaining tasks.

still swing open like a conventional door, alternative hardware permitted; hinges and handle.

have ability to locate lexan in the up position and down position.

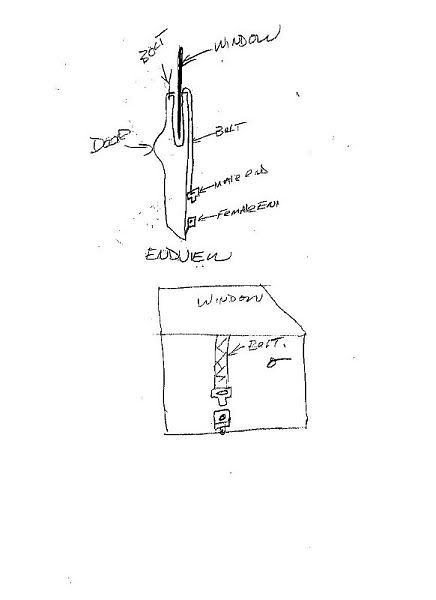

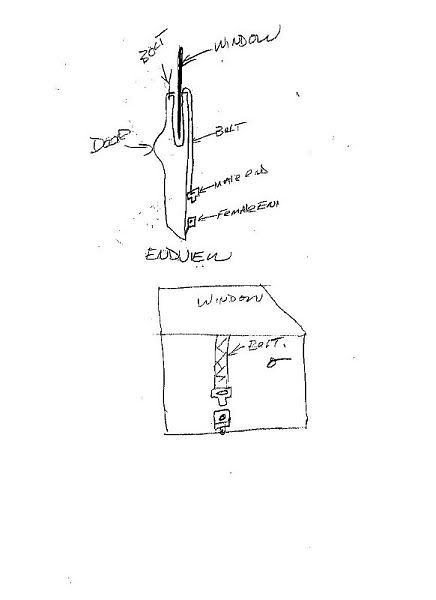

the project in question does not have a window frame; that would make attaching the window in the up position easier, in my opinion. so this leaves one with either making a frame and attaching to the door or making a metal frame the curvature of the natural glass and attaching the lexan to get the appropriate contour. this would then require a channel to allow the window to go up and down within the door.

i was planing on locating an aluminum frame around the top part of the door where the window will be move. this would add some strength and also allow me to weld a tab that i would attach a nylon buckle. this buckle would be routed up over the frame -> below the bottom of window -> back up inside of frame and over the top -> heading back down the edge that would normal mount the door panel. this would allow a means to slide the window up and lock it.

here is a image borrowed from another site to better illustrate this.

are there more efficient ways of accomplishing this function?

how have people accomplished this feat in the past or plan on doing so?

I saw one similar to your design but it used nylon straps riveted to the lexan and velcro to hold the window up. You can always go windowless and make a snap in place cover for when it rains. See that often on race cars.

Have you worked with composites before? If you haven't you are going to want to get plenty of practice. If I was to do that project, I would make the door in two pieces in order to create something for the window to slide into and then get some very good epoxy (not the E36 M3 you get at hardware stores) to put the two parts together. Also I would had some metal plate to mount the door hardware to. Drilled through composites can be very weak.

You could do a vertical split, like on the Factory Five Daytona.

tr8todd wrote: I saw one similar to your design but it used nylon straps riveted to the lexan and velcro to hold the window up...

good idea with the nylon straps; and should be simpler.

i have previously ruled out velcro as i need the window to be more functional with its movements; up and down.

93EXCivic wrote: .

understood, i have worked with composites.

Appleseed wrote: .

would like to keep it one piece if i can.

thank you for the feedback, any more ideas?

take a 2 inch wide nylon strap. on the center line, sink metal eyelets at 2 inch intervals. on teh door, put a metal stud.

this allows adjustment of teh window up and down. this was how hurst did it on the hemi darts.

on the composite door idea....

you running a cage? if you are, and choose to put the doorbars out into the door structure, just make your window tracks route around the cage. that way you can use the cage doorbar for the bottom mount for the indow.

im assuming you want the window for keeoping rain outta the race car, right?

id also suggest some aluminum tubuing inside the door. cross bracing and shell structure. all the fiberglass doors ive ever had flexed like crazy. this should hel[ with that.

Michael