Dusterbd13 wrote: I'll be working with a map system. So if im understanding this, map should be a pretty stable value across the board, directly related to manifold vacuum. Higher vacuum, less fuel. Lower vacuum, more fuel. And as long as I can find a tune that is roughly the same cam and displacement, it will be close enough to run. Then tune map and fuel for air/fuel ratio desired at idle, cruise, and wfo in that order. Am I understanding this correctly? How do I figure out the map calibration if I can't find a similar setup? Say im starting with a stock tuned port vette tune, an engine that made maybe 200 horse at the wheels. Im going to change it to feed a 425 horse 370 small block. Obviously more volume and fuel per firing cycle, and obviously different vacuum values everywhere. At that point, do I just leave the map table alone and work on fuel?

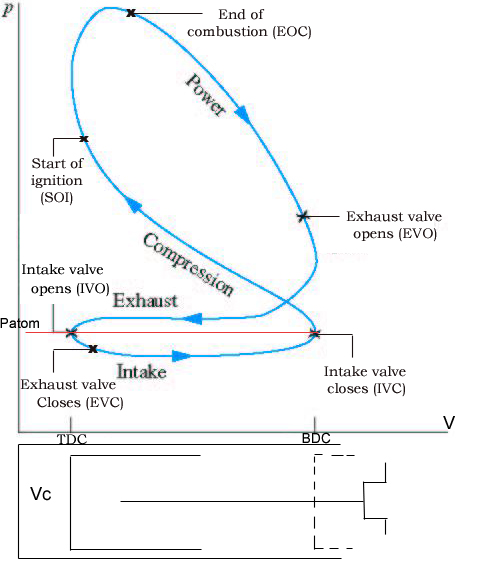

So that more relates to more and less relates to less- change your thinking to pressure instead of vacuum. Less manifold pressure = less fuel, more=more. The math is a little easier to deal with. Besides, the pV=mRT formula uses absolute pressure and temperature, not relative. Manifold vacuum and Fahrenheit are both relative scales.

As for the base engine set up.. you have a 6.0 v8 engine that you think you can make 425hp. Which is just like a 3.0l I4 engine that theoretically can make 212 hp. I could go deep into that, but if you can find an engine that has a similar specific output, with the similar cam timing and number of valves- you can have a good starting map correction table.

That's one major elegance of the MS system. The voleff correction table is dimensionless. All it cares about is basic breathing- valve timing, number of valves, and rough valve area/displacement. If you could find a decent 2V 2.0l 4 cyl that has similar cam timing, take it's table and start there.

The rest of the engine dimensions, you tell the system what they are- and it should do the mass calculation all for you.

That also goes for the fuel injection- send those out, have them get flowed, and stick to that data.

Unless you are getting some really odd voleff numbers (say a lot of it over 1.0), it's easier to stick with one part you are reasonably sure about- and I'll suggest leaving the injectors alone. Change the air tables/functions/calculations.

Going back to the air estimation- that also can be modeled- which is why I asked about a free simulator that can give a decent estimate of flow when one puts in the data. So you can run some simulations and use that data to fill in the tables.

Do you have access to the code GM runs?