I'm getting rolling on Miss Jane, my wife's 196x Austin Mini. SWMBO is willing to let me try and shoehorn in a Honda CBR929 engine. While bike powered Mini's aren't a new idea, the CBR isn't a swap I've found lots of documentation on, so most of the details will be up to me to figure out.

I know there's a whole slew of you who've put motorcycle engines in cars. I don't know if it would be easier to dump info regarding such swaps in this thread (or maybe there is one already...) or if somebody wants to mentor me via PM's, or what... open to suggestions.

Thanks in advance.

You are insane(ly awesome). Im glad that motor went you and that it is going to be put to good use.

I swear I have seen a fireblade (CBR 900 series) motor into a mini before. Ill do some searching.

really mess with poeples minds and run a motor out of a harly....

In reply to ckosacranoid:

That would be silly...

fanfoy

HalfDork

7/6/13 3:41 p.m.

The two big hurdles for a bike engine in a car is the differential spool and the oiling system.

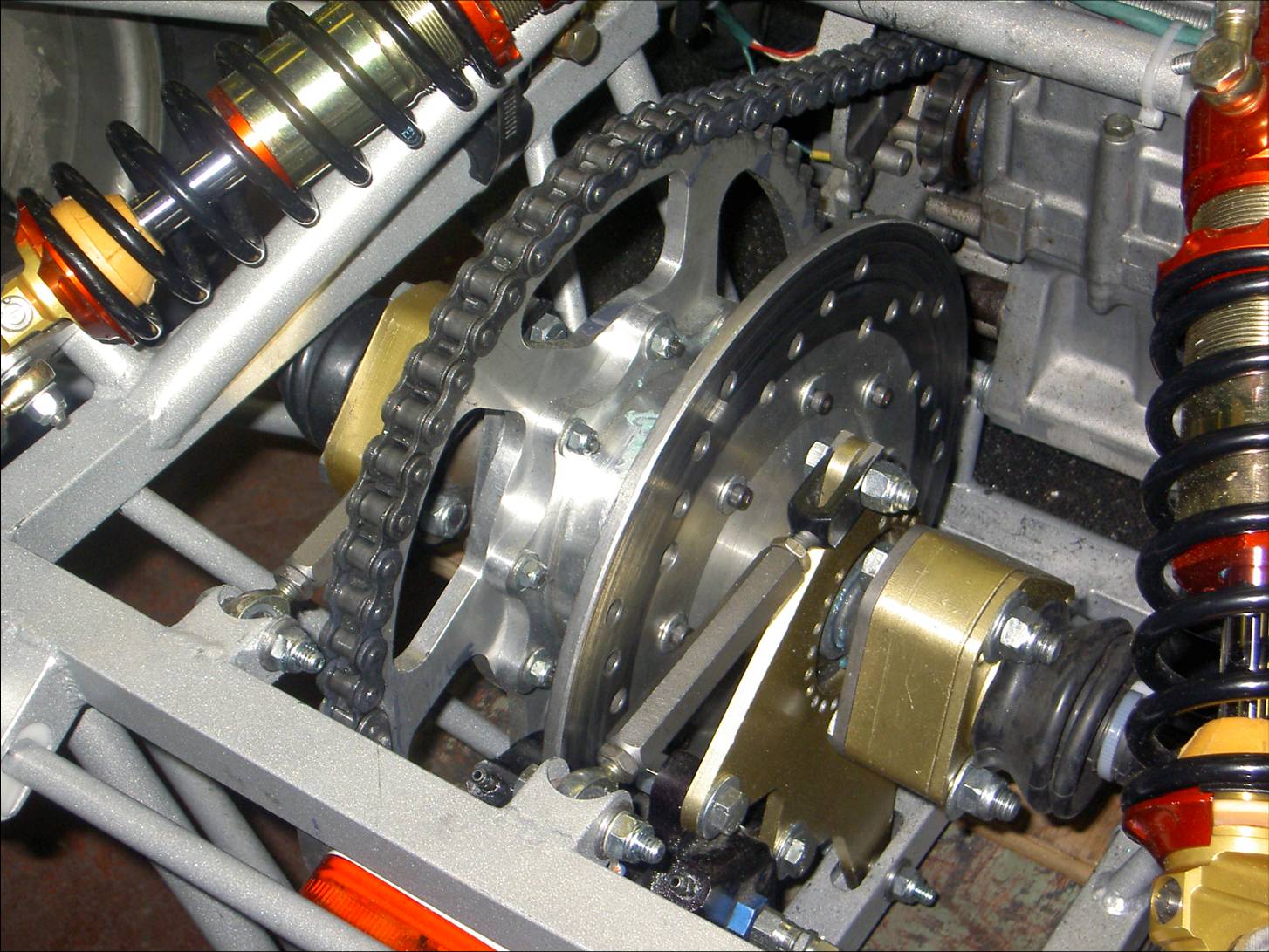

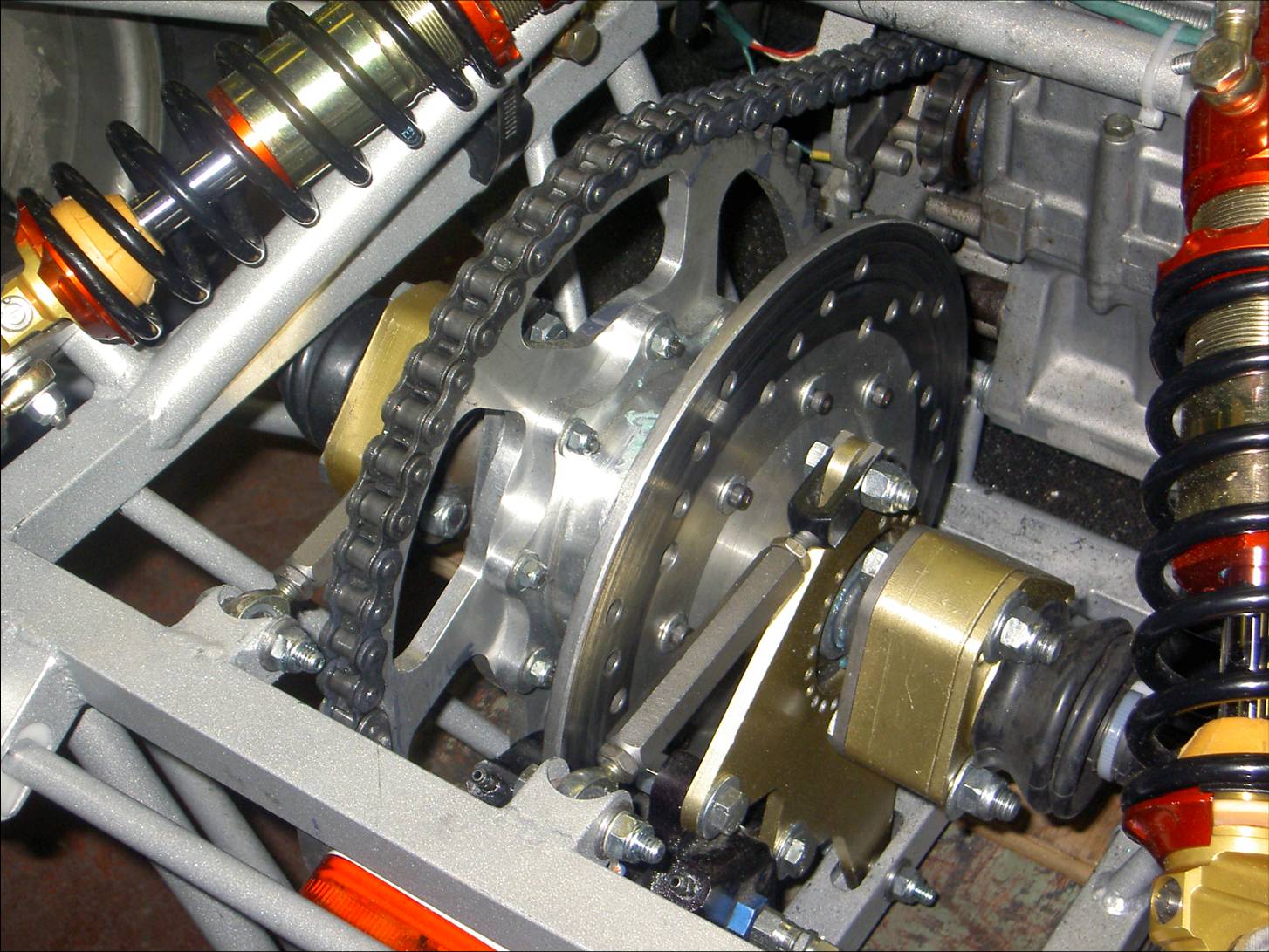

You need to connect the half-shafts to a differential. Then you have to find a way to mount a sprocket to that differential, make a cover for that differential, mount it on some bearing mounts and find a way to make it adjustable so you can put some tension in the chain. Look at FSAE for some ideas, like this:

Then you have to make sure the engine isn't starved of oil when you corner. See project LeGrand to know what happens if you don't. Minimum is a baffle in the sump. I would suggest an Accusump as well. Or you can go all out with a dry-sump system.

For a "heavy" car like a mini, some stronger clutch springs might be a good idea.

The cbr motors have seen lots of in car time with little in the way of oiling issues. Not saying to not take precautions though.

In reply to EvanB:

Nothing official at this time. I want to make sure the CBR starts and runs before I find another home for the 1275 though. I'll keep you informed.

I'd thought about building a pint-sized drag rail around it, but I need that kind of project like I need another hole in my head.

Reverse?

Or is the wife going to pop it in neutral and stick a foot out the door?

I know starter motors have been popular electric reverse, your plans?

I saw a few Honda swaps done on Mini's. All of them have been from a car. The car swap works well.

God only knows how much GRM blew on this piece of E36 M3 that never worked.

http://grassrootsmotorsports.com/project-cars/1959-berkeley-sports/

The engineering of getting a bike clutch and trans to hold up in a car, let alone after you weigh it down with a meatbag or 4, sounds like a nightmare to me. Then there's the diff, backing it up, etc.

Hows a 20 valve Toyota 4AGE and Corolla 5 speed fit in there?

I don't think the 20v+5spd powertrain would fit between the wheels, never mind in the engine bay.

I'm thinking a modern I3 might be a good swap. BEC swaps are another level of difficulty, you should thoroughly explore car-based options first. Maybe a G13B from a Swift?

John seems like the kind of guy that will figure this out with what he's got. Also I have researched bike engines in cars and they do better than you think.

In reply to fanfoy:

I was planning on going with a very non-GRM chain-driven diff. They're out there for just such applications, and start in the neighborhood of $800. Gear and housing are already installed, just have to figure out how to mount it.

Dry sump was on my radar.

In reply to bigdaddylee82:

I am planning on a starter motor for reverse. The car's light and my wife's a boss, but I think she'd get pissy after about the third time she had to push it out of a parking spot.

In reply to Kenny_McCormick:

Gearing will help with that. Its not like I need (or want) this thing to be able to match top speed with a Fireblade, nor expect it to match acceleration with one.

I know there are easier, cheaper, more durable, more documented options out there. I've got this powerplant already though, and might as well try it rather than letting it sit and dropping $$$ on (insert other engine option here) instead. When this project goes tits up, one of you yobbos can buy it from me for next to nothing and turn it into a challenge car. Until then, I'm gonna try to make it work.

I appreciate the group-think. Keep bouncing ideas off me.

First gear on bikes is way long, usually to 60ish. This is what creates a lot of the issues with the clutch, because you have to slip it to get a hard launch or in traffic.

Then the clutches are very small by comparison to a car clutch.

Most I've seen successfully put in a car have gone for as light a weight as possible and an aftermarket high clamping clutch.

I have the diff, brake & sprocket from an FSAE car for such an application. Giubos seem to be your friend in that they help stop the harsh engagements.

I'm pretty sure I know the answer, but I'm asking anyway.

This is a 12 volt bike. Any reason the bike engine wouldn't like a car battery?

ransom

UltraDork

7/7/13 2:24 p.m.

JohnInKansas wrote:

In reply to fanfoy:

I was planning on going with a very non-GRM chain-driven diff. They're out there for just such applications, and start in the neighborhood of $800. Gear and housing are already installed, just have to figure out how to mount it.

Looks like Quaife has been expanding their MC-engined-car line of products. In addition to complete MC-to-diff boxes with reverse, they now have a differential with integral reverse, without the rest of the box... (How the heck...?)

Should be fine, the only issue with a car battery is that a partially discharged car battery can absorb more amps than most motorcycle alternators can produce, which usually fries diodes or the stator. Quick fix is to toss an appropriately rated fuse or self-resetting circuit breaker in the charging circuit.

As to the differential, pick up any irs center section with a removable rear cover (like a Miata one). Remove the rear cover, then take out the guts and discard the gears and pinion assembly. Plug pinion hole, mount motorcycle rear sprocket to carrier assembly, and put guts back in housing. Fab up new rear cover that lets chain come out and covers the chain to catch oil and drain it back to the dif. Oiled chain lasts longer, diff plenty strong, minimal cost and fab work.

I built a chain driven diff for a D/SR back in '89. VW Rabbit open diff, drive flanges, CVs, JFZ inboard brakes. Basically knock the ring gear off, machine a flange to bolt to the ring gear bolt pattern and match the sprocket bolt pattern, flange was extended to allow for a bearing that sat in bearing block. Similar bearing support on other end. Moser cut custom output axles to the VW CV flanges. Machined aluminum cover w/ o-rings sealed the diff. Didn't break the bank but still no reverse.

Piontek built a MC powered kit car that used a toothed inboard brake rotor w/ a starter motor for reverse, IIRC.

It is a MINI. berkeley reverse!

pic doesn't show the details of the chain driven diff but thas all I have now. It can be done. Car is still running in historic.

oldopelguy wrote:

As to the differential, pick up any irs center section with a removable rear cover (like a Miata one). Remove the rear cover, then take out the guts and discard the gears and pinion assembly. Plug pinion hole, mount motorcycle rear sprocket to carrier assembly, and put guts back in housing. Fab up new rear cover that lets chain come out and covers the chain to catch oil and drain it back to the dif. Oiled chain lasts longer, diff plenty strong, minimal cost and fab work.

I love the idea but am unsure of how you are going to do it to a Miata diff. Here is a pic of a couple:

Am I just missing something or are you thinking of a different type of diff? I hope I am missing something because being able to use a Miata diff would make a project I am brainstorming waaay easier.

Yeah, I was thinking about the BMW one piled up next to the Miata one in the shop. Easiest with a sheet metal rear cover.

oldopelguy wrote:

Yeah, I was thinking about the BMW one piled up next to the Miata one in the shop. Easiest with a sheet metal rear cover.

Now I get where I was confused. I was thinking mid engine rwd where the engine sprocket would be on the pinion side. In this case (fwd front engined) the engine sprocket would be on the rear cover side.

pirate

Reader

7/8/13 1:56 p.m.

Unless you are absolutly convinced a bike engine is what you want to do these guys seem to have the answer for high performance Mini's.

http://www.superfastminis.com/GARCIA.htm