I don't think they paid for that ECU, but the budget has definitely increased since the early days. They're not solving many problems with checkbook engineering, though, just able to spend a little more to make it really special. Those brakes and wheels weren't a cheap date though.

I think they're got better return from Binky's high profile in the form of increased willingness of shops to pitch in to help. Like those 3D printed arches.

The clutch peddle solution was rad. I think I watched the articulation 5 or 6 times.

Keith Tanner said:

NOHOME said:

Anyone else not surprised the flexi-alternator drive went kablooee? There is a lot ridding on that and not any easy alternatives.

Alternatives: drive the alternator off a halfshaft and electric AC :)

I'm surprised at the failure mode, I'd never considered the flywheel effect of an alternator. I should have. I learned. It may have failed with simple free revving and not on the road.

I also need to pause the video in a couple of places and take a closer look at what's going on with that clutch pedal. I'm assuming a way to allow for more throw, as anything that decreases throw is going to increase pedal pressure unless there's black magic.

You may be amazed at the slapping noises a belt can make when one of those overrunning clutches locks up. I've seen alternator inertia pull a belt tensioner to its stop a couple times per revolution! Knock-knock-knock-knock. In hindsight the flexishaft could not handle reverse loads, but hindsight is where a lot of engineering revisions get made.

I need to go back and look at the clutch again, but I am thinking that it is a linearizer. It may work quickly at the beginning of the stroke when spring pressure is lighter, then gain mechanical advantage.

11GTCS

Dork

12/19/21 9:44 a.m.

Anyone else notice the bolt spinning itself out of the alternator bracket while watching the engine run the first time once they had put the radiator, etc. on? I’m continually amazed at their solutions to tight packaging problems.

Yes, saw that. I'm sure they did too. Hope there aren't other inaccessible bolts that weren't tightened properly.

I was particularily impressed with their home-made swedging device.

I'm also not a fan of the flex drive, especially in the "S" configuration. A gentle arc with the shafts not parallel seems better to me. But I have no real world experience with this application.

"In the end, we're only 18 months behind where we thought we'd be 3 years ago."

This hit a bit too close to home.

Front end accessory inertia is a very really thing. Keith can probably relate every time he turns his Cummins off. The quintessential Cummins belt pulley screech is caused by the hugemonhous fan wanting to keep spinning after the engine says no.

In reply to maschinenbau :

Can't say I've ever noticed, but maybe mine's a bit newer and they fixed it. You know what I'm going to be doing next time I'm under the hood, of course...

I haven't analyzed it closely enough, but I've been nursing the idea that the crazy clutch linkage is high-motion/low leverage early in travel (to take care of as much travel as possible early, when the total spring force is lower), transitioning to low-motion/high-leverage as the total spring force rises. I wonder if it feels funky. Well, first, I wonder whether I'm on the right track...

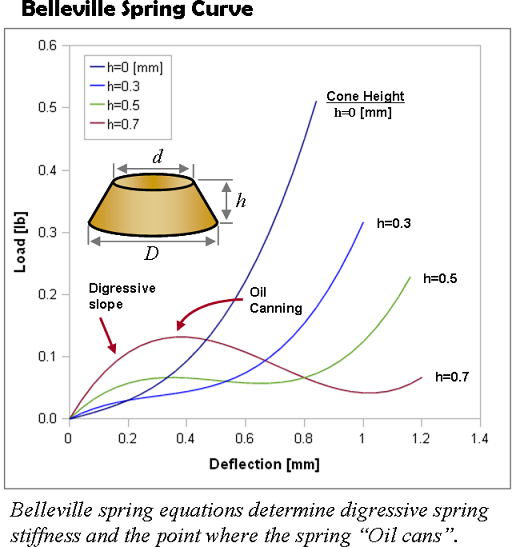

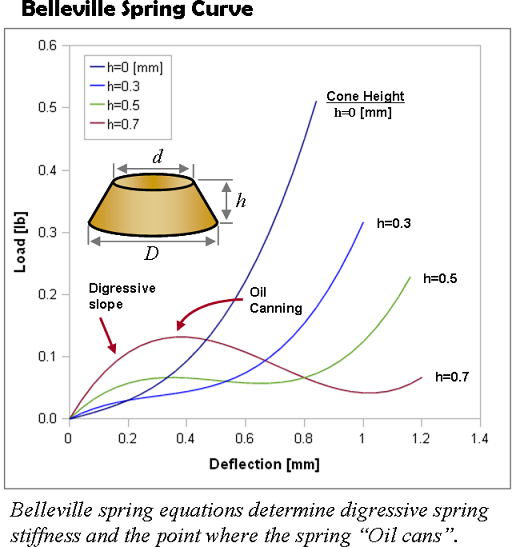

And clutches aren't entirely linear in spring force, are they? Which may have something to do with the big box of failed mechanisms. Take my description above and then try to map it to a spring that starts at one rate, grows slowly in force, then actually adds *rate*, then just when your mechanism is moving into max leverage, the diaphragm spring starts falling off in rate again... Or some variation on that theme.

(Not sure Belleville springs are representative of a diaphragm as used in a clutch, but...)

In reply to Jesse Ransom :

After watching it again, it is definitely high motion early in travel. The linkage bar pulls on the cam from an acute angle at first: high motion/low mechanical advantage. As the travel comes up, it becomes closer to a right angle: lower motion/higher mechanical advantage.

I have a feeling that they stuffed it up a little bit and it's actually stiffer toward the beginning of pedal travel than at the end. Notice that when they test the "shopping trolley", the STI, and the BinkyPedal V1.1, they give a slow deliberate push up to a max reading on the digital scale. On the final pedal assembly, they give a fast stomp before the scale can register a max reading.

I still believe it's all bollocks.  STI clutches are absurdly stiff and not a very good bar to clear. There are cars with twice the torque output with lighter clutches. I'd be pulling it back apart and shopping for a twin disk arrangement. That much clutch effort is going to require pulling it apart soon anyway, after it cracks the fork or the pivot.

STI clutches are absurdly stiff and not a very good bar to clear. There are cars with twice the torque output with lighter clutches. I'd be pulling it back apart and shopping for a twin disk arrangement. That much clutch effort is going to require pulling it apart soon anyway, after it cracks the fork or the pivot.

One other thing I realize is that they do not have an over-center spring on the pedal, like most cars have. The spring is mounted in such a way that you are pushing against it, then it goes over center at the midway point (not just a clever name) and starts assisting your effort on the pedal. Diaphragm clutches feel more linear this way.

I would not be surprised to see a twin clutch in there eventually - an ACT puck clutch with high pedal pressure will not be fun to drive. But iirc this episode was filmed under some time pressure so they did what they had to do.

I think it was intended to be a rally car way back in the beginning, but the plan changed when Nick realized just how much work was going to go into it. Then it turned into a show/street car.

I hadn't watched ANY Binky until December 20 . . . I'm all caught up now! I guess that's the value of being told to isolate. I avoided it for a while because I assumed it was going to be some bastardized chop up with fiberglass flip fronts, and some sort of tube frame. I didn't expect them to rebuild the entire car to match the Toyota suspension pick up points.

The paint is exquisite -- and I was pleased they went with the Old English White and with black roof. I was unsure about the checkered flag motif when they were marking it off. I was wrong. Very wrong. I also didn't think the side stripe was a good aesthetic choice. I was wrong. Very wrong.

My nieghbour a few streets over always has interesting things in his rdrievway -- he seems to buy and sell old and odd stuff. Right now he has a late '70s Leyland Mini shell sitting on a trailer. I've watched the show -- it's like I have a how to manual, right?

We were a Mini family -- here's the only photo I have of my dad's (lateapexer) Cooper S. That godawful thing in the car is a child seat . . . somehow I survived.

There was a lap belt running through the open metal tubing and a strap to hold you in. I can't imagine any of us would have survived anything serious.